Textile ironing device

An ironing device and ironing technology, applied in textiles and papermaking, fabric surface trimming, mechanical cleaning, etc., can solve the problems of strengthening the adsorption of impurities and fabrics, affecting the ironing effect, and inconvenient cleaning, so as to improve the ironing effect , to ensure balance and reduce wrinkles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

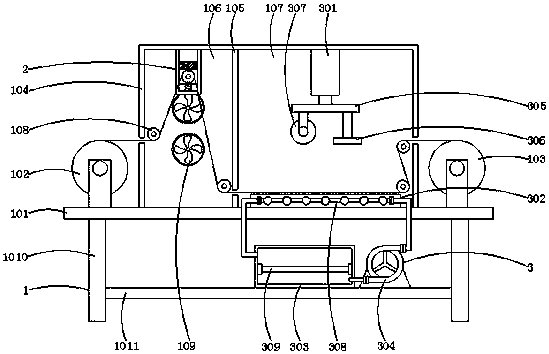

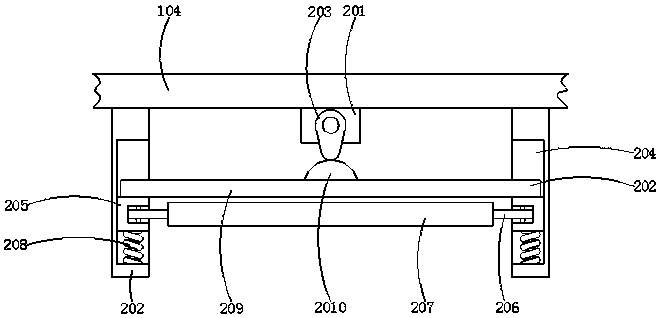

[0021] Such as Figure 1-2 As shown, a textile ironing device includes a base device 1 , a dust removal device 2 and an ironing device 3 , and the base device 1 is provided with the dust removal device 2 and the ironing device 3 .

[0022] Basic device 1 comprises workbench 101, and the top of workbench 101 is fixedly installed with feeding roller 102, receiving roller 103 and operating box 104, and the rear side of feeding roller 102 and receiving roller 103 is all provided with drive motor, and the rear side of operating box 104 The interior is divided into a dust removal chamber 106 and an ironing chamber 107 through a partition 105. Both the interior of the dust removal chamber 106 and the ironing chamber 107 are connected with a cloth guide roller 108 through a rotating shaft. The interior of the dust removal chamber 106 is provided with a suction fan 109. There are two support plates 1010 fixedly installed on the bottom of 101 , and a placement plate 1011 is fixedly inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com