Stamping method used for hollow pin copper bar cold heading and forming and capable of achieving quick positioning and forming

A hollow needle and cold pier technology, applied in the field of copper rod cold pier stamping, can solve problems such as slow speed, and achieve the effects of reducing production costs, good product quality, and improving labor conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

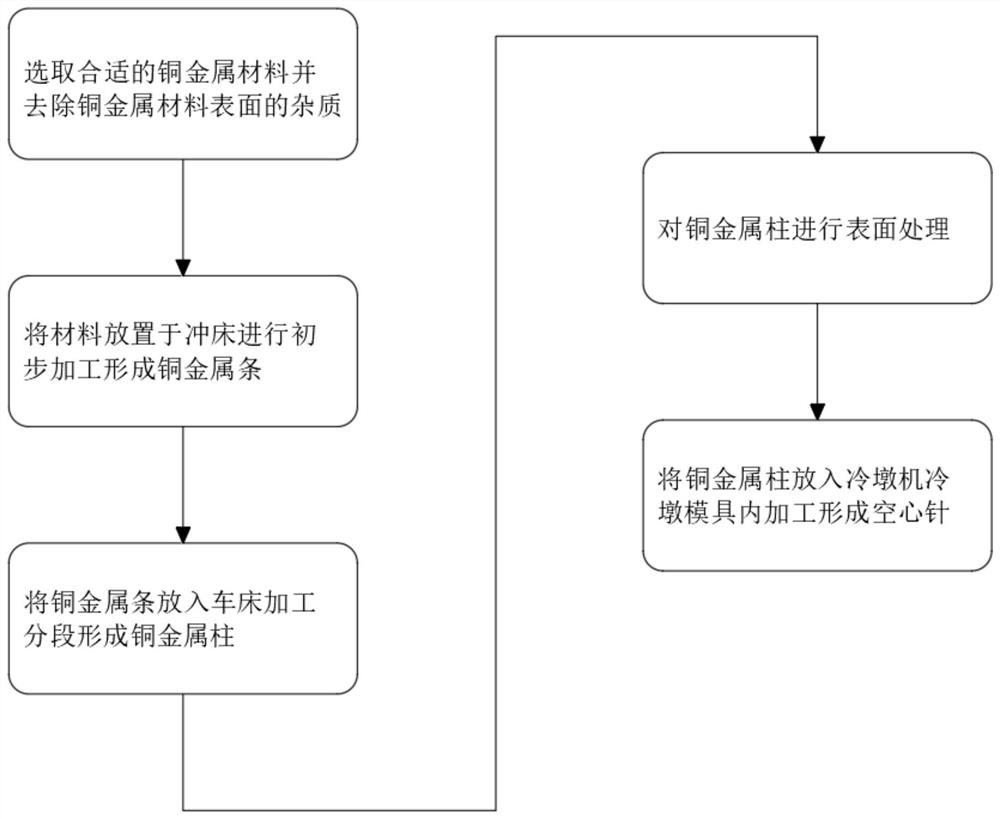

[0033] Embodiment 1 A kind of punching method of the cold pier forming of the hollow needle copper bar of rapid positioning forming, comprising:

[0034] 1. Select materials to remove impurities

[0035] Remove impurities after selecting a copper metal block of appropriate size

[0036] (1), manual wiping and scrubbing;

[0037] (2) Soak the copper metal material into the cleaning agent for heating and cleaning, soak the copper metal material into the trichlorethylene metal surface cleaning agent, use the principle of swelling to improve the solubility of organic pollutants such as oil, and completely remove the metal Surface organic pollutants, etc., the non-ionic surfactant contained in the cleaning agent can reduce the surface tension of the solution, and has a strong penetration ability, can penetrate between the metal surface and various pollutants, and hold up the pollutants , so that it is separated from the surface of the metal material to achieve the purpose of remo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com