Patents

Literature

30results about How to "Improve squeeze efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

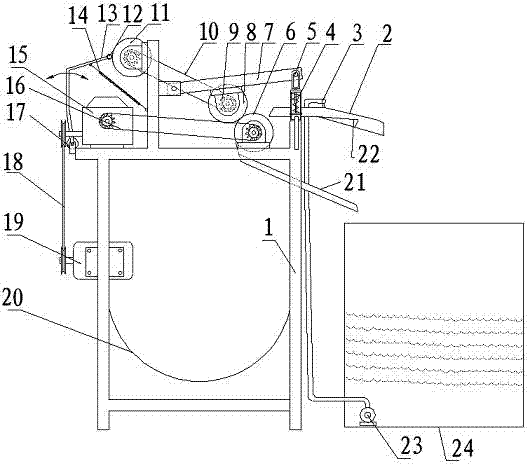

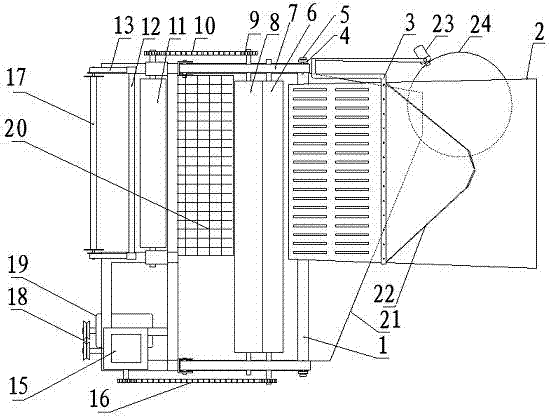

Imitation fur setting process

InactiveCN108385313AImprove uniformityQuality improvementSucessive textile treatmentsTwo or more solvent application treatmentFiberWater resources

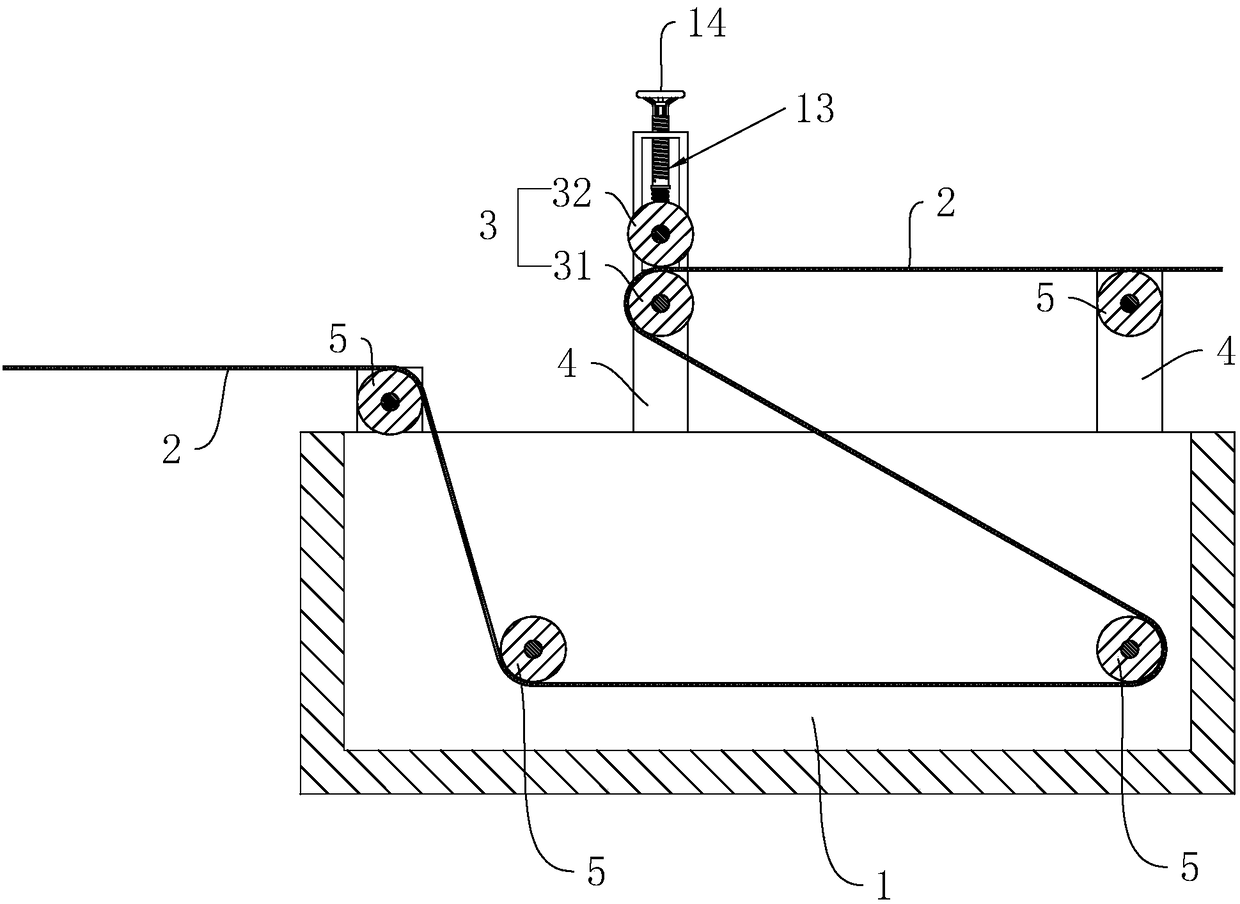

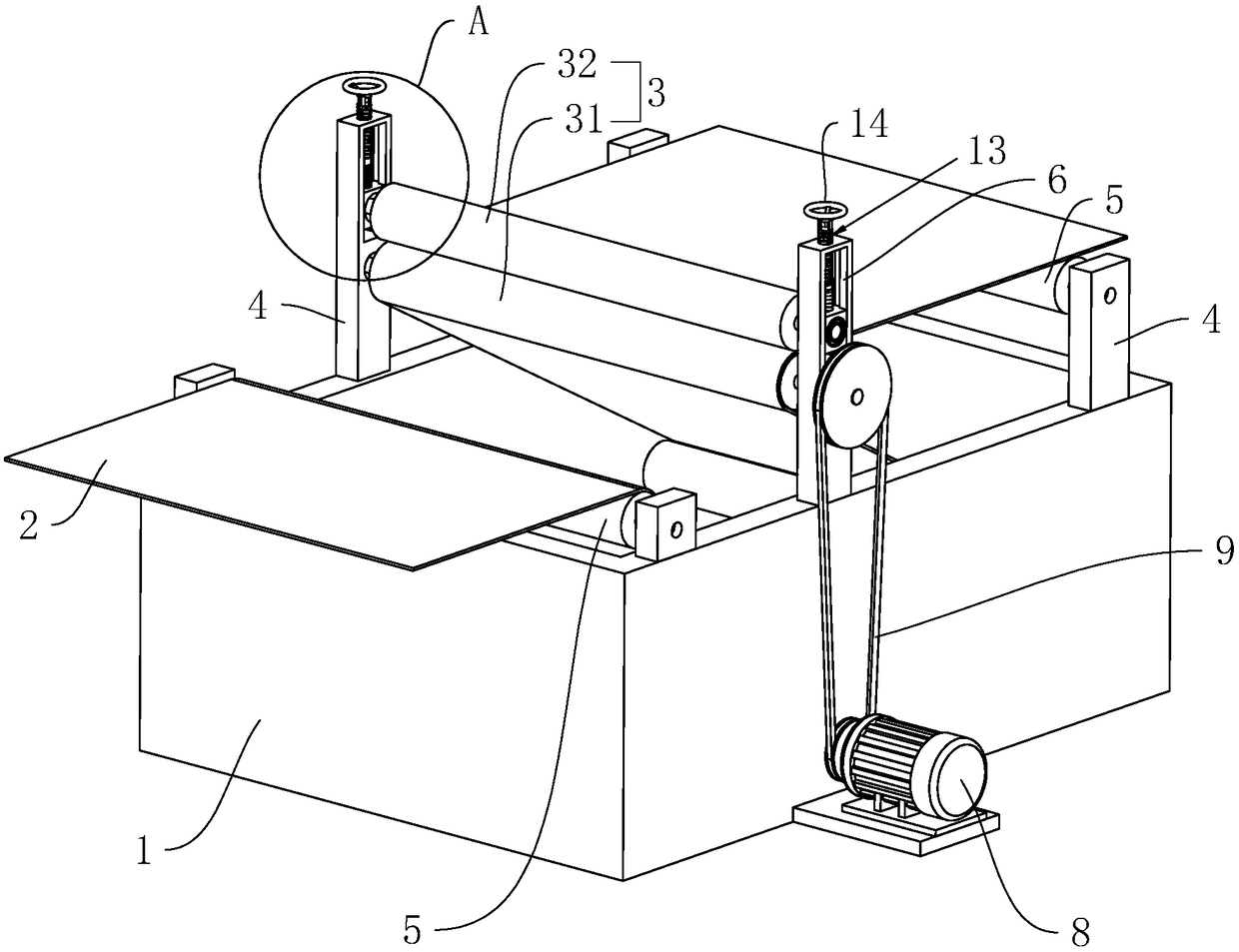

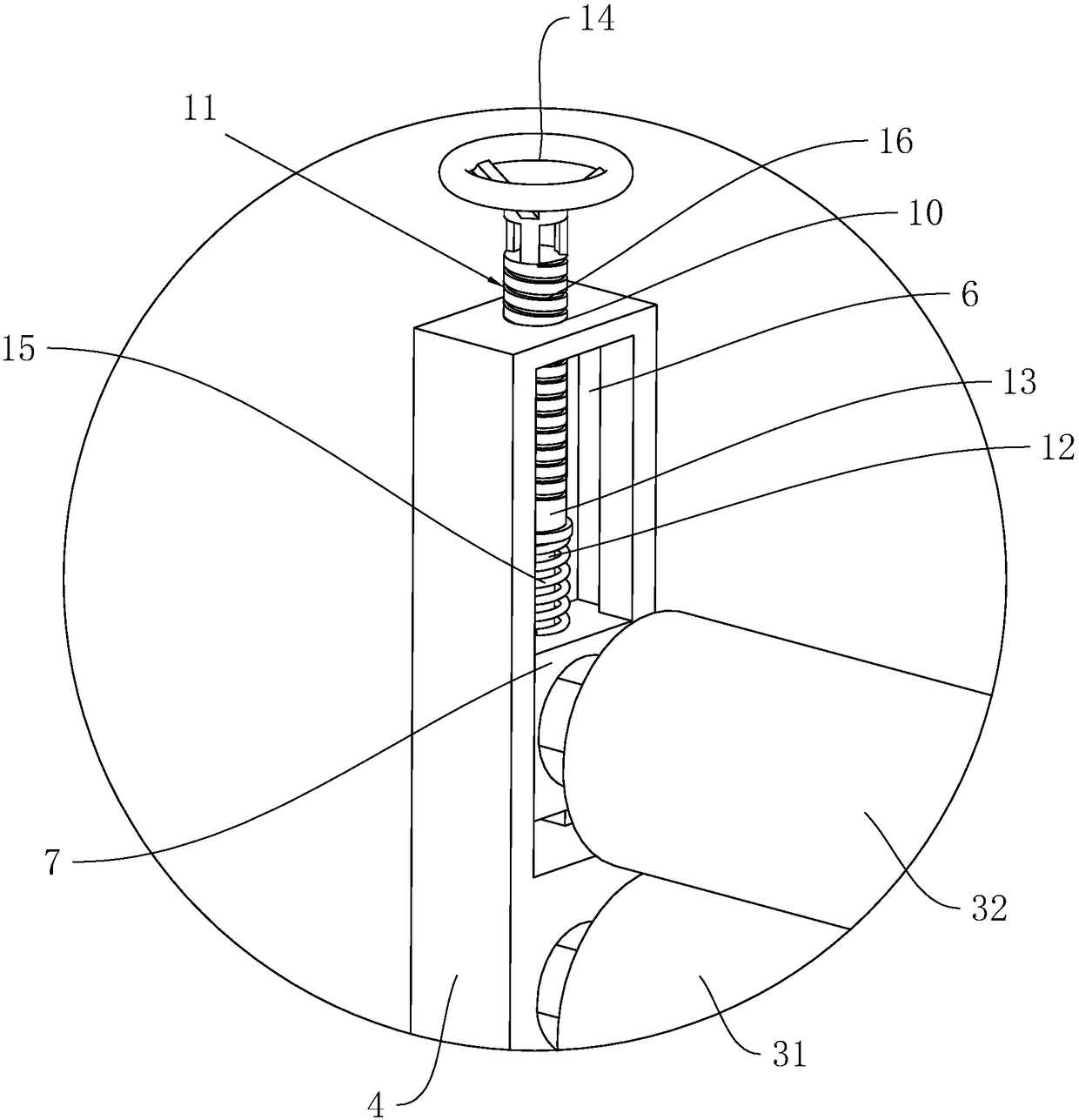

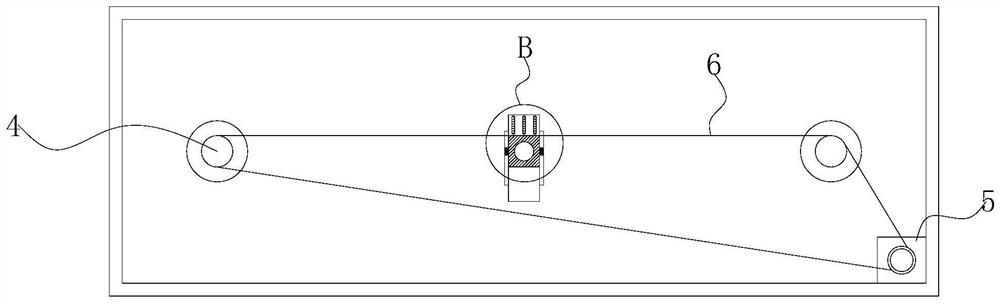

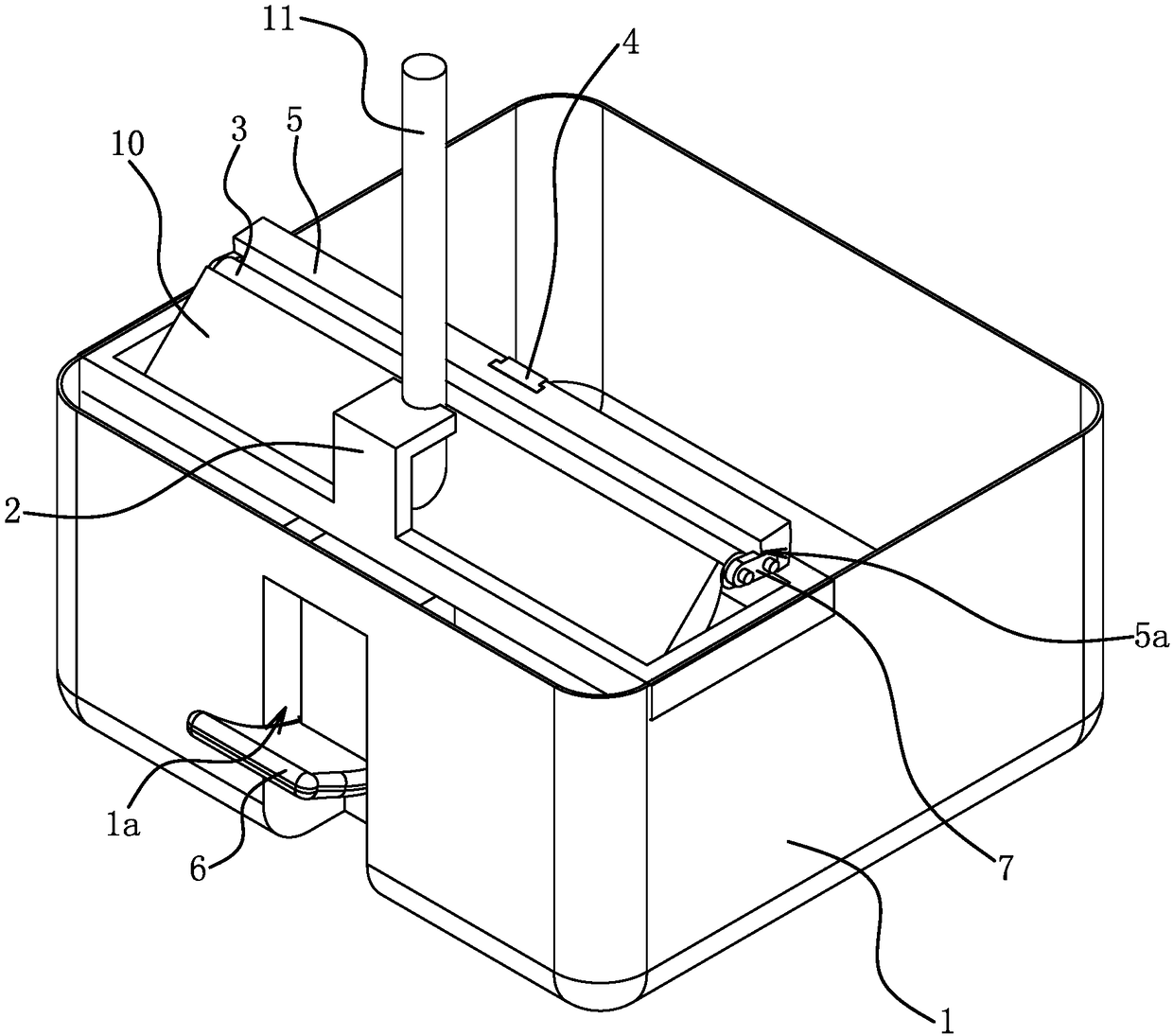

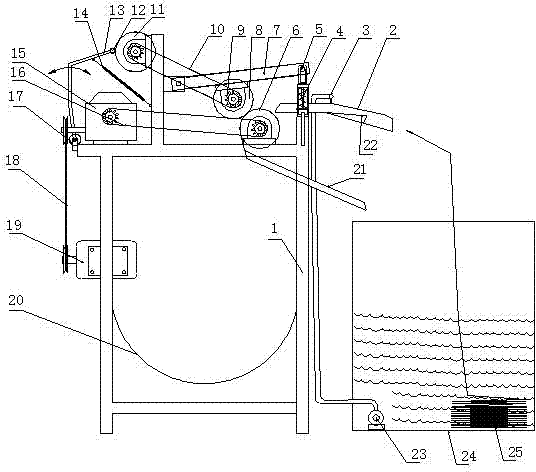

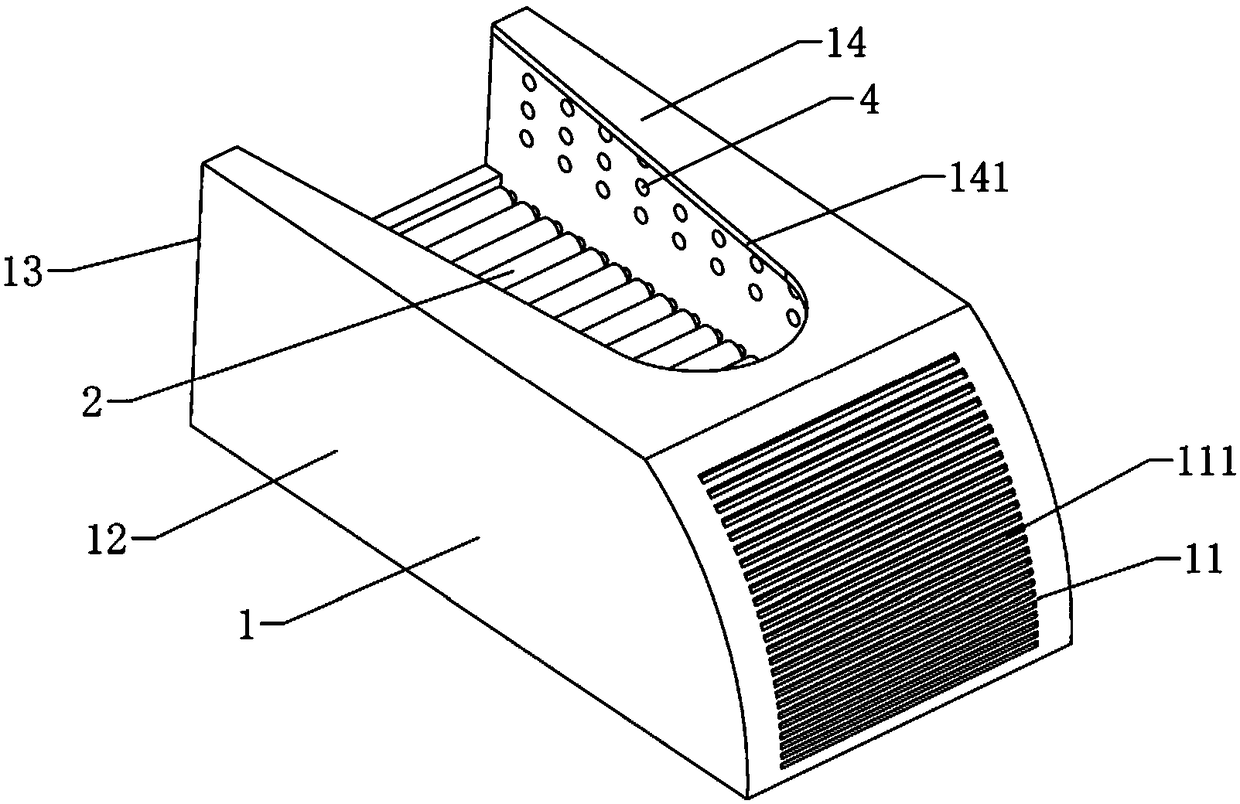

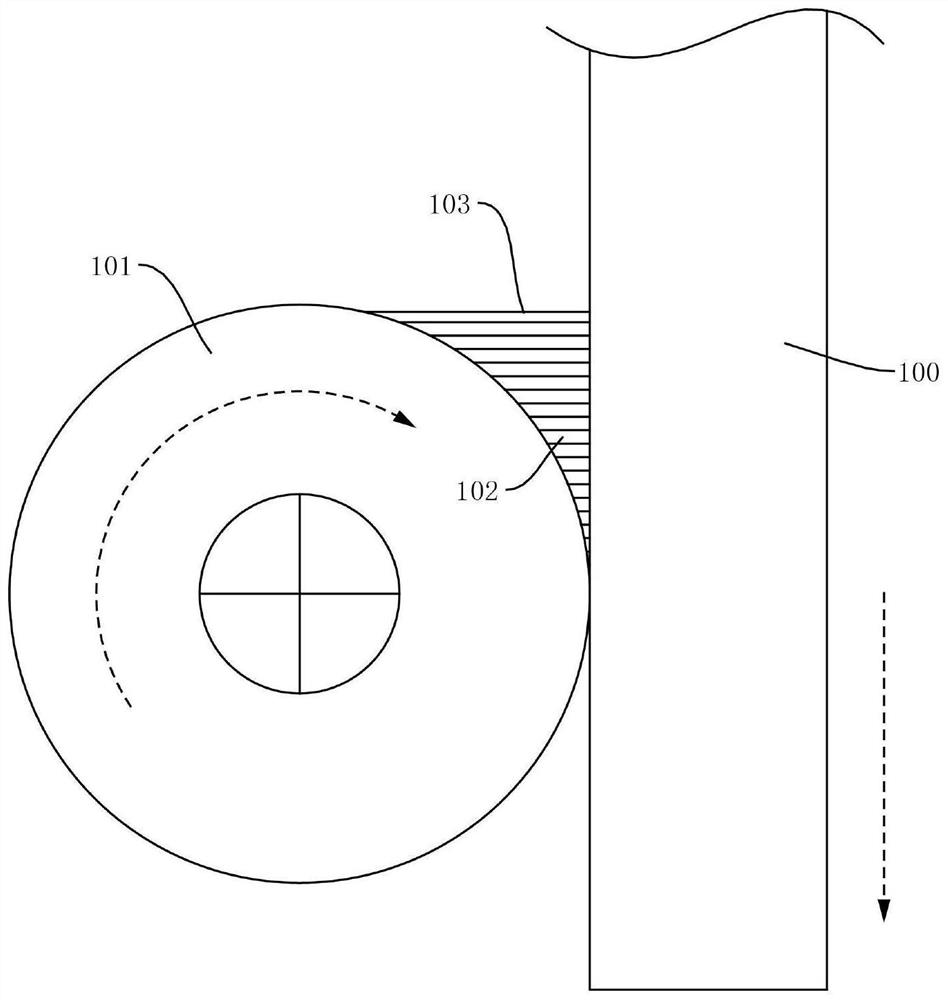

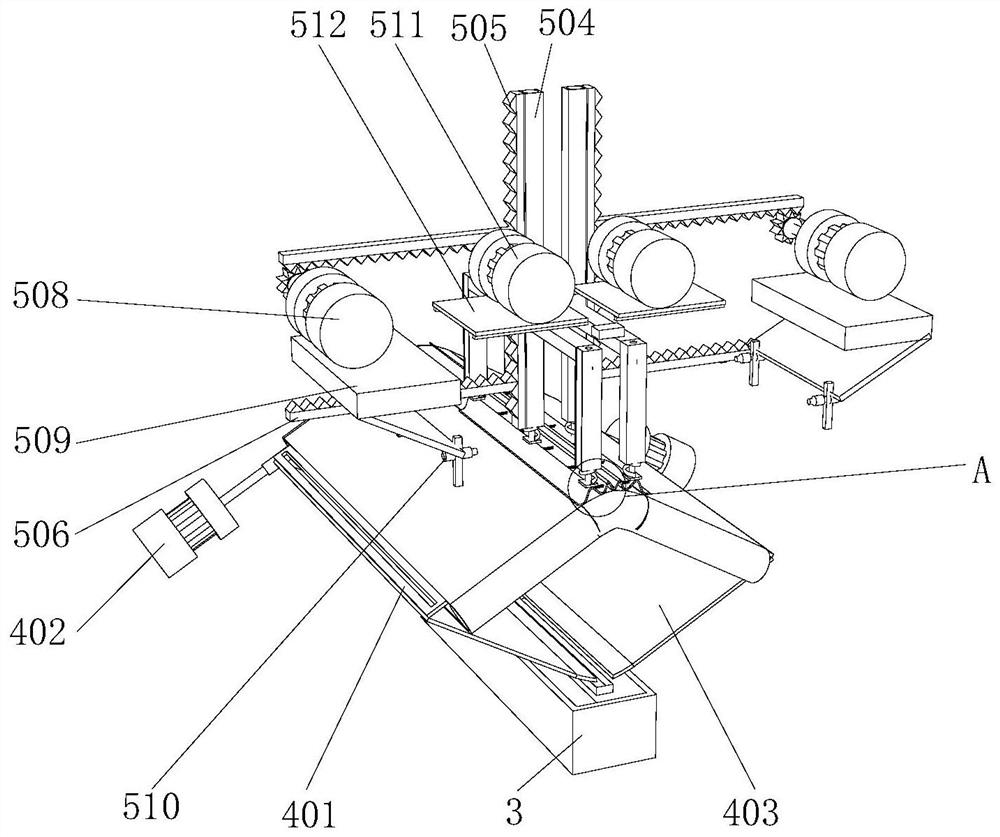

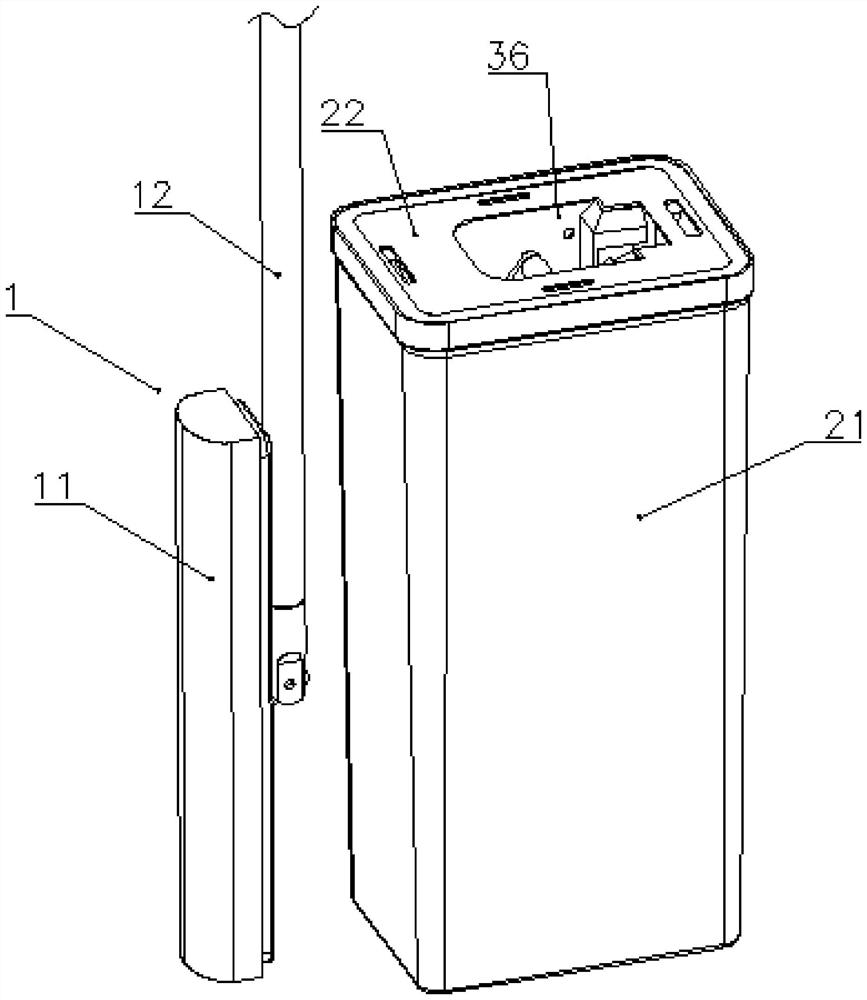

The invention discloses an imitation fur setting process, and belongs to the technical field of imitation fur processing. The imitation fur setting process is technically characterized in that an imitation fur finished product can be obtained by gray cloth unwinding, cleaning, decontaminating-flushing, dehydrating-scutching, first setting, napping, second setting-drying, third setting-drying, cooling-setting and coiling-warehousing. Through a three-setting process, the fiber uniformity among imitation fur surfaces is improved, and the imitation fur finished product is more attractive and better in quality; a water squeezing roller is provided, so that the moisture in imitation fur between a first roller and a second roller can be squeezed out and reflow into a water groove, the water resource is saved, and the comprehensive utilization rate of the water resource in the water groove is increased. Moreover, a driving assembly is provided, and the second roller is further compressed on the first roller, so that the water squeezing efficiency is increased; meanwhile, the imitation fur setting process can be suitable for water squeezing operation of imitation furs of different thicknesses, and has higher efficiency.

Owner:嘉兴市远大纺织印染有限公司

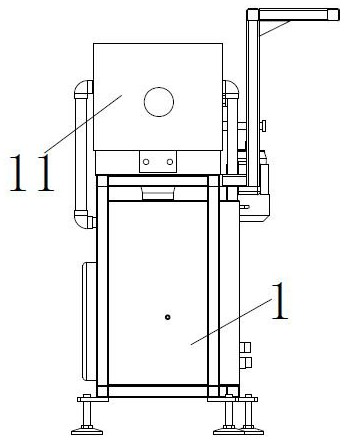

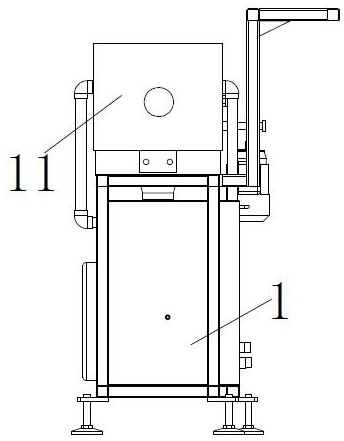

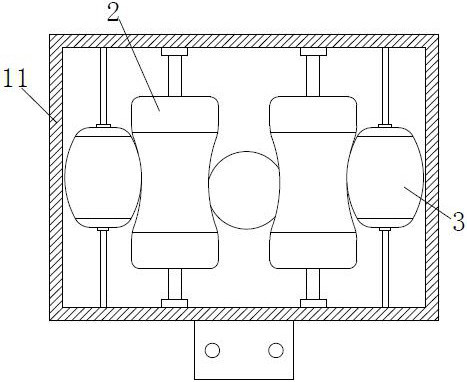

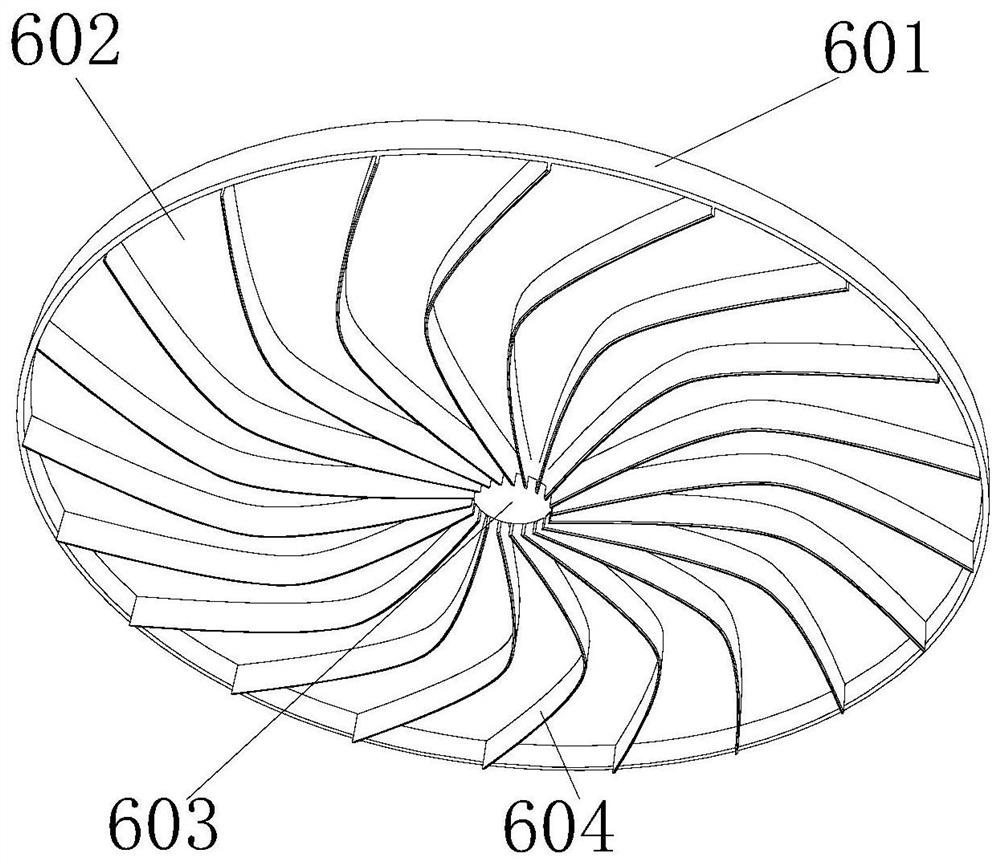

Pushing, pressing and stirring wall-scraping type kitchen garbage squeezing device

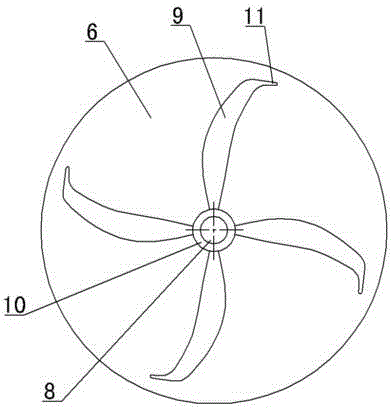

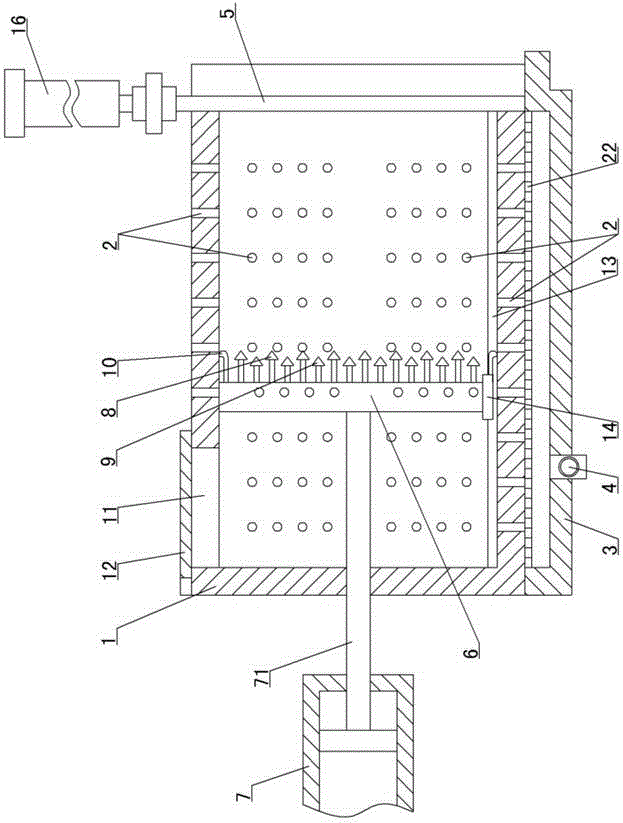

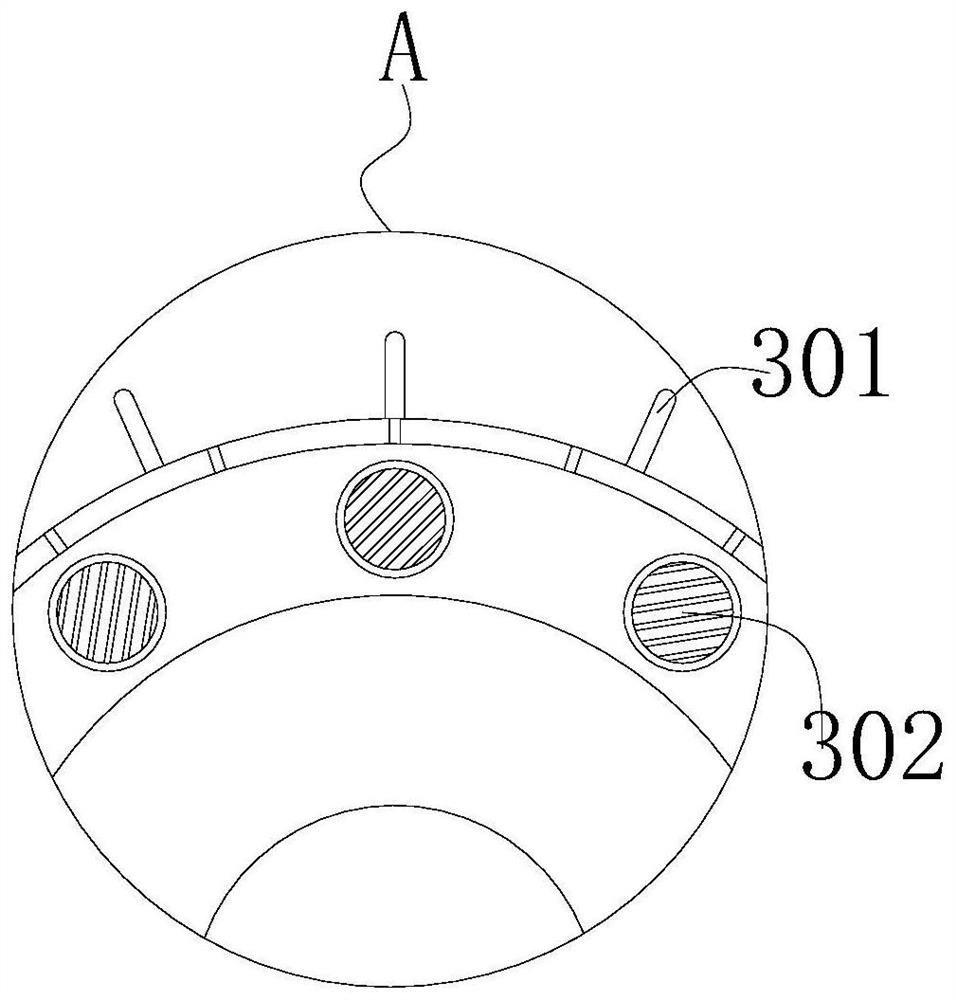

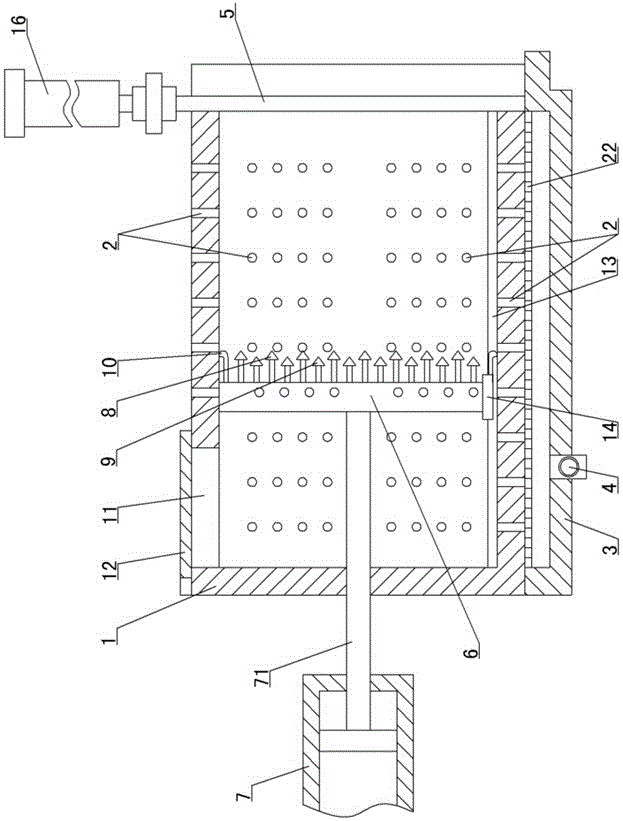

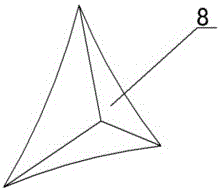

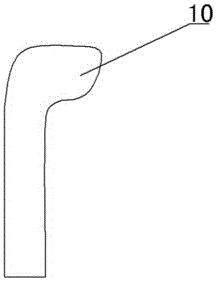

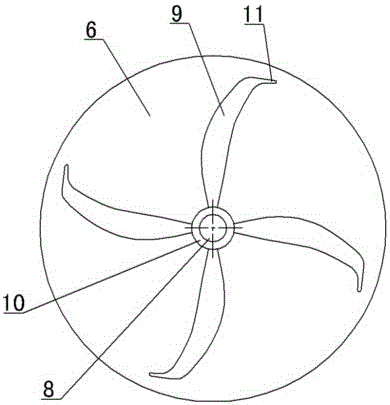

The invention discloses a pushing, pressing and stirring wall-scraping type kitchen garbage squeezing device. The device comprises a round squeezing box body, wherein squeezing holes are uniformly distributed in the surrounding wall of the round squeezing box body; a water-receiving box body is arranged at the bottom of the round squeezing box body; a door plate is arranged at an opening of the round squeezing box body; a round squeezing pressing plate is arranged in the round squeezing box body and is driven by a piston rod of a squeezing hydraulic cylinder to reciprocate in the round squeezing box body; at least two propeller blades are arranged in front of the round squeezing pressing plate; one end of each propeller blade is connected with a self-rotating shaft sleeve; the piston rod penetrates through the round squeezing pressing plate; the self-rotating shaft sleeve is arranged at the front end of the piston rod; a wall-scraping blade edge is formed at the other end of each propeller blade and is in contact with the inner wall surface of the round squeezing box body. The scheme adopts a stirring wall-scraping way to stir, extrude and dehydrate kitchen garbage, so that a squeezing hole is prevented from being blocked, and the squeezing efficiency is improved.

Owner:蚌埠中知知识产权运营有限公司

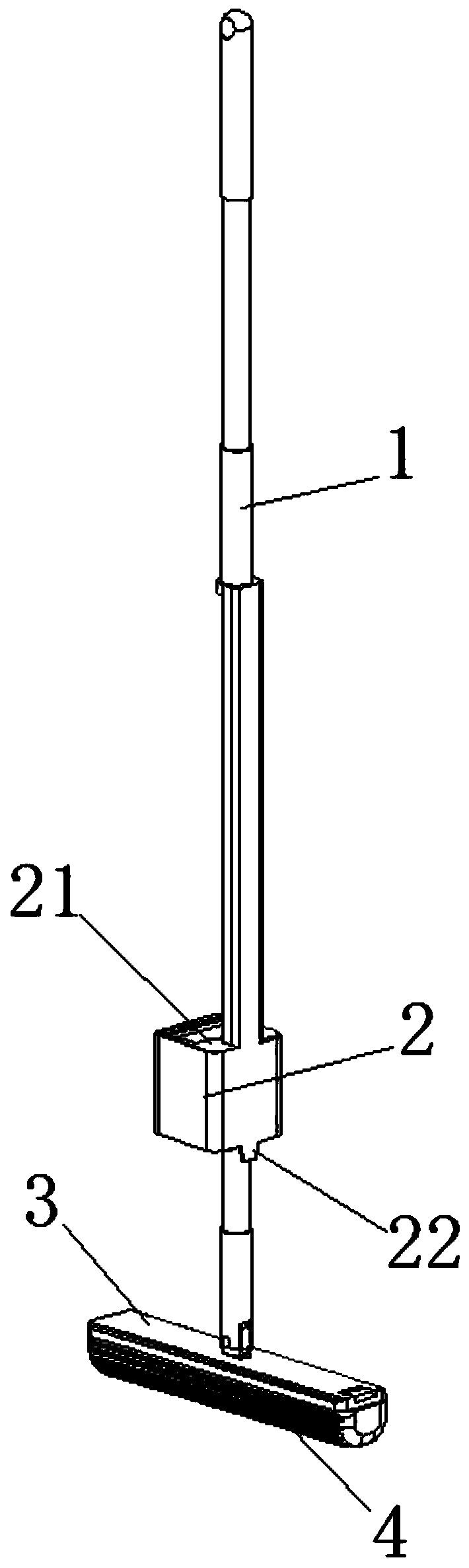

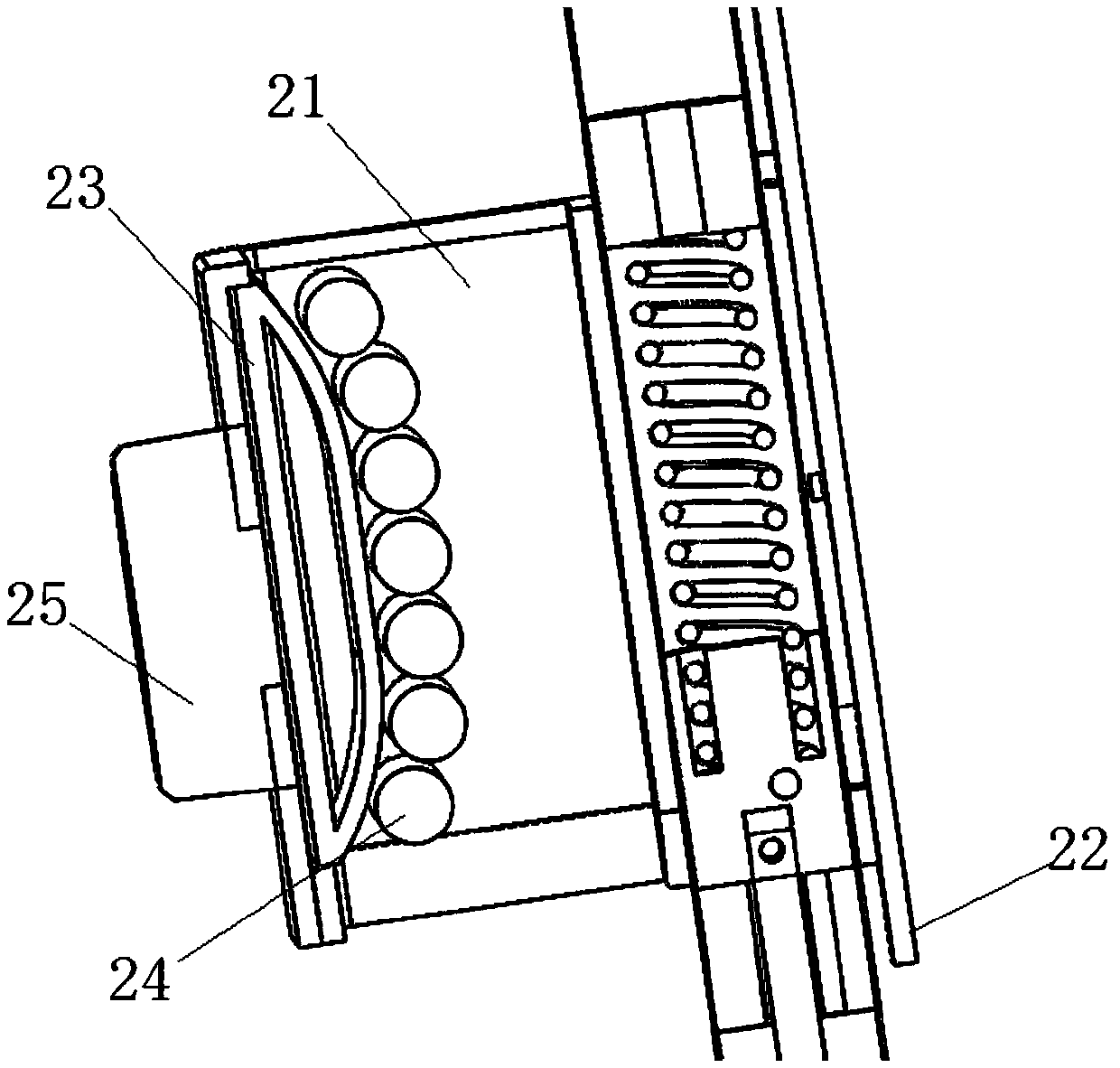

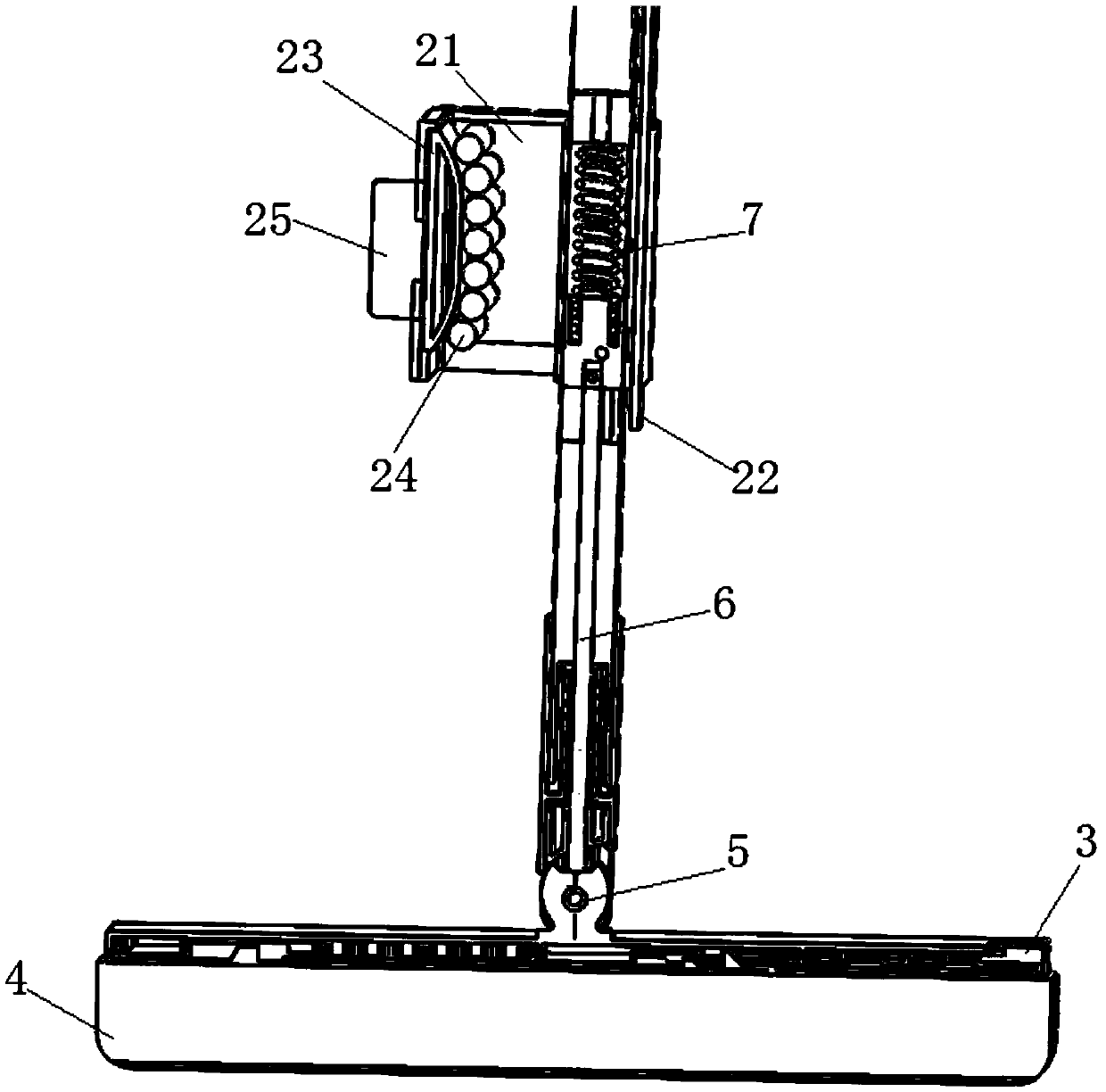

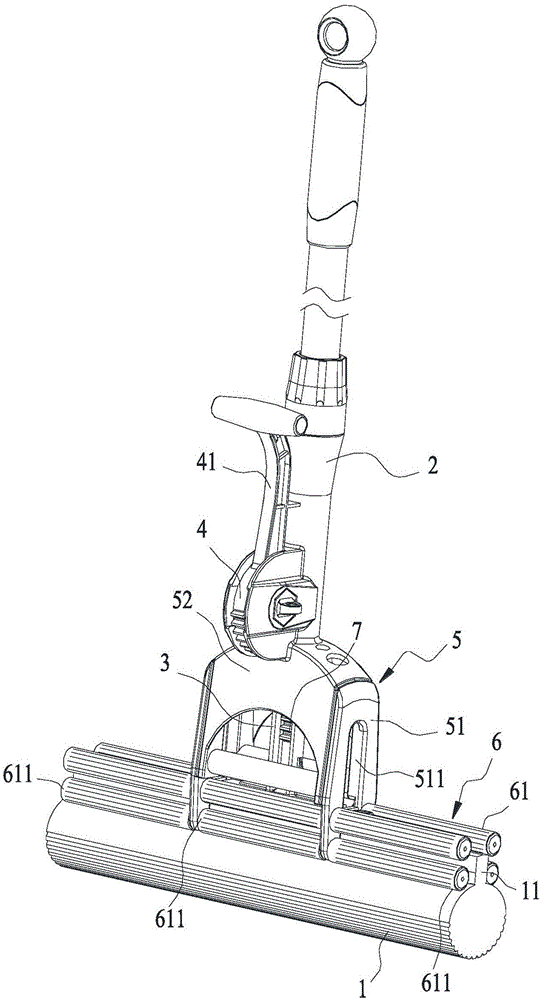

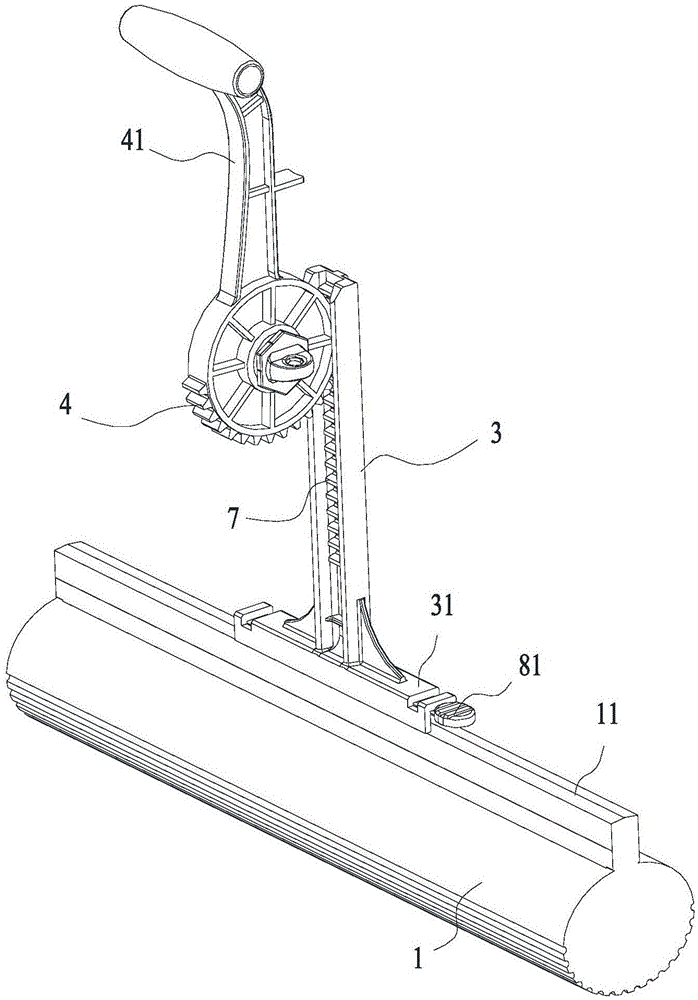

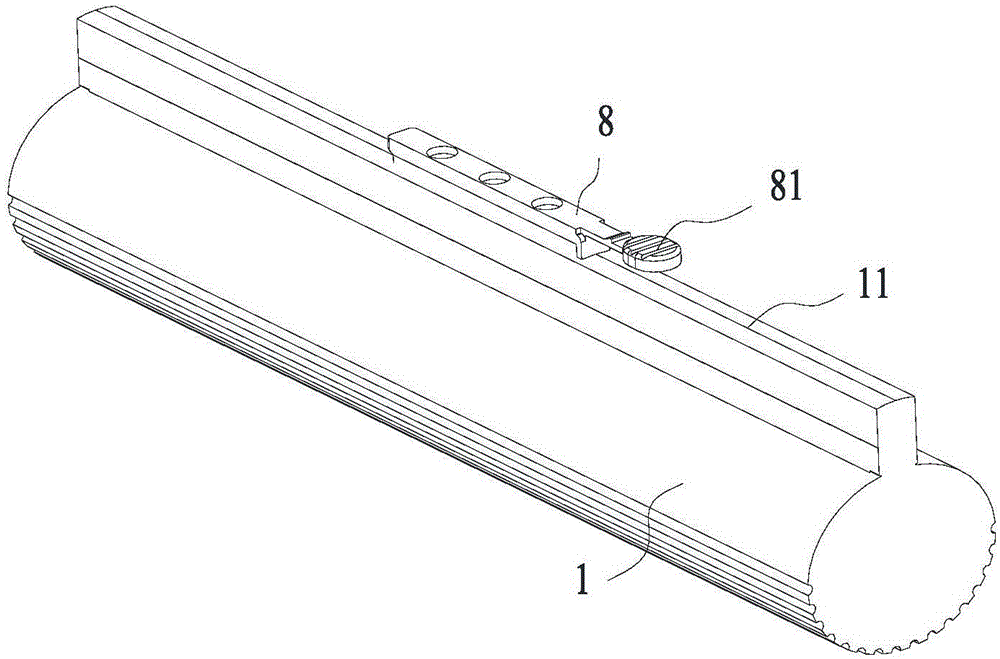

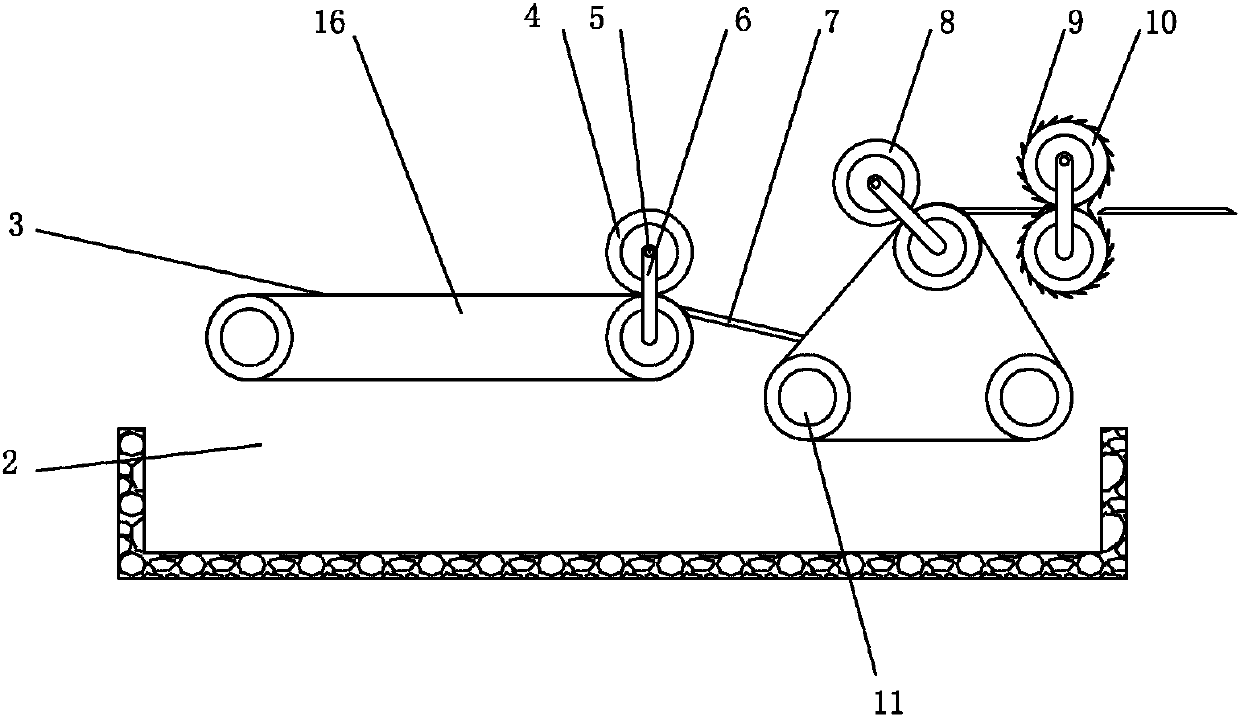

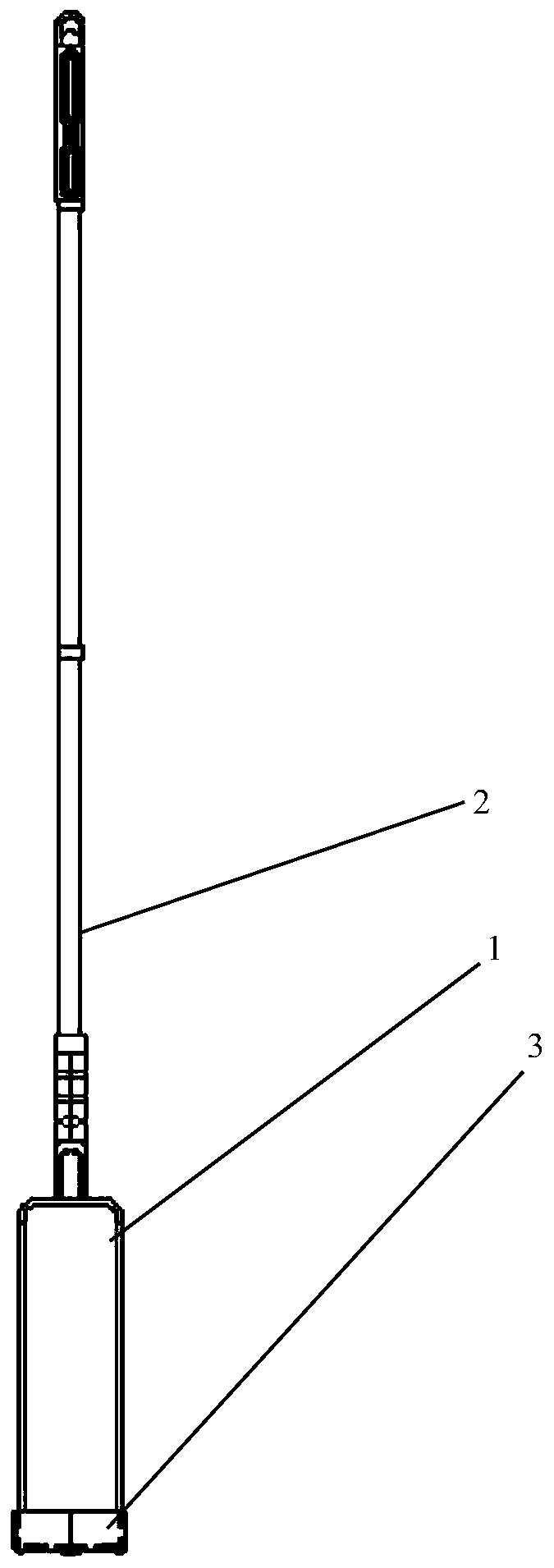

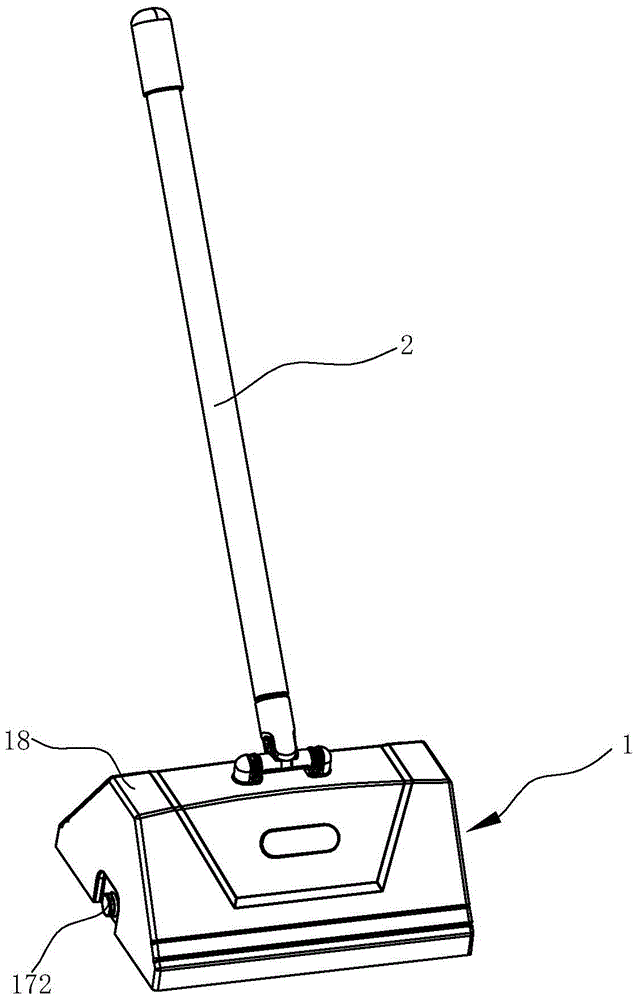

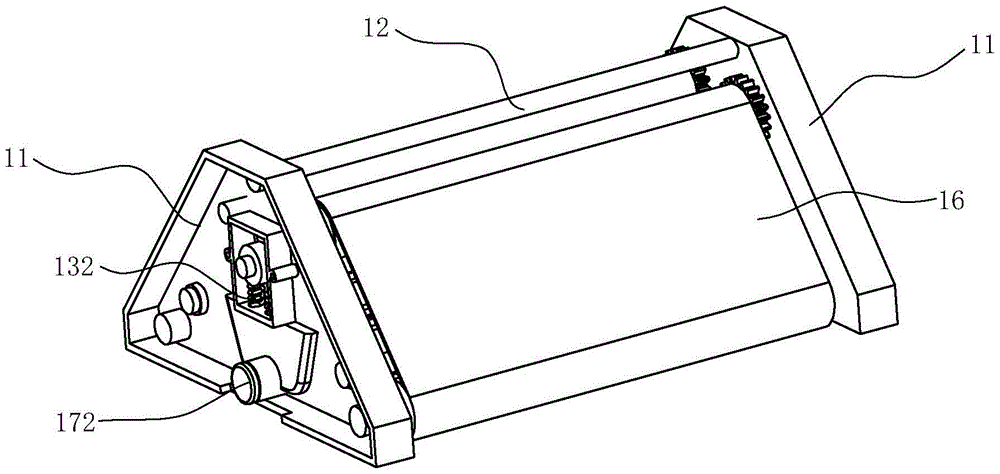

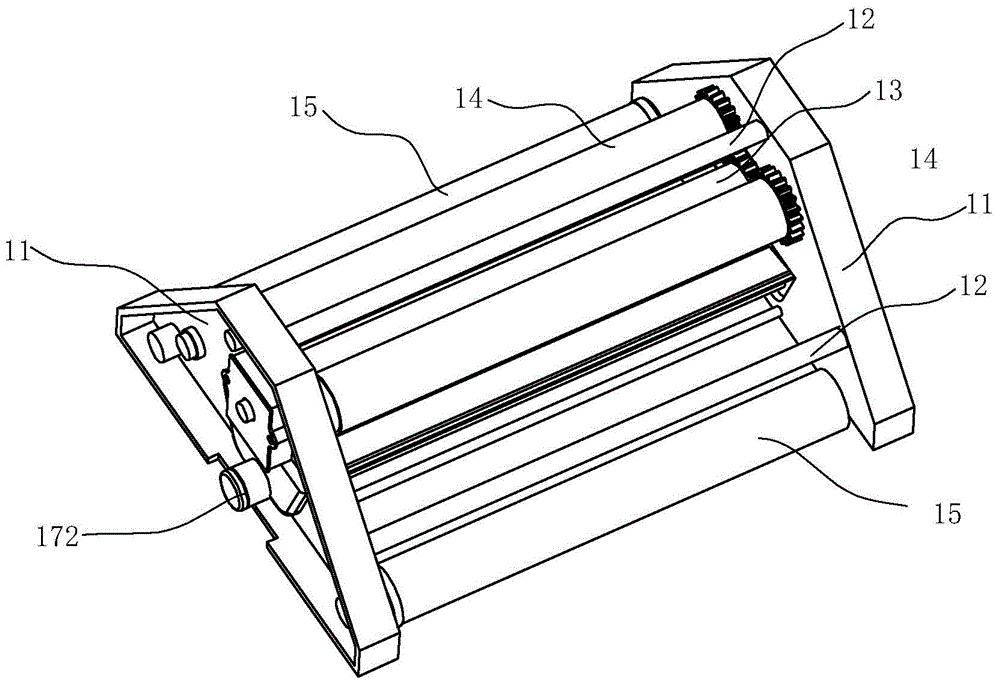

Collodion mop

PendingCN109567694ARealize two-way water squeezeImprove squeeze efficiencyCarpet cleanersFloor cleanersIndustrial engineering

The invention provides a collodion mop. The collodion mop comprises a rod body, a sleeve and a mounting plate; a collodion mop head is arranged on the mounting plate, and the mounting plate is hingedwith the rod body to form an articulated shaft; the sleeve is provided with a first sidewall and a second sidewall in opposite arrangement; a sleeve bracket is arranged on the first sidewall, and thesleeve bracket can be fixed on the first sidewall; an end surface, oriented to a second sidewall, of the sleeve bracket forms a first cavity together with the second sidewall; the sleeve and the rod body is in sliding connection; when an extension direction of the colloidal mop head is parallel to an axial direction of the rod body, the cavity can be sleeved on the collodion mop head, and slide inthe extension direction of the collodion mop head, thereby extruding the collodion mop head in the lifting process; when the sleeve slides to the other end from one end of the collodion mop head andslides to one end from the other end of the colloidal mop head, the wringing can be performed on the collodion mop head, the bidirectional wringing is realized, and the wringing efficiency is improved.

Owner:西安佳品创意设计有限公司

Push-pressing and wall shoveling type water squeezing device for kitchen waste

A push-pressing and wall shoveling type water squeezing device for kitchen waste comprises a water squeezing tank, wherein water squeezing holes are formed uniformly in the peripheral wall of the water squeezing tank, a water receiving tank is arranged at the bottom of the water squeezing tank, a door plate is arranged at the opening part of the water squeezing tank, a water squeezing pressing plate is arranged in the water squeezing tank and reciprocates to squeeze water in the water squeezing tank under driving of a piston of a water squeezing hydraulic cylinder, large shovel cutters and small shovel cutters are uniformly distributed on the front side of the water squeezing pressing plate in a vertically staggered manner, wall scraping shovel blades are arranged on the periphery of the water squeezing pressing plate and contacted with the inner wall surface of the water squeezing tank. The scheme adopts a pushing-shoveling mode to squeeze and dewater the kitchen waste, blockage of the water squeezing holes is prevented, and the water squeezing efficiency is increased.

Owner:TANGSHAN CHENXI MACHINERY MFG

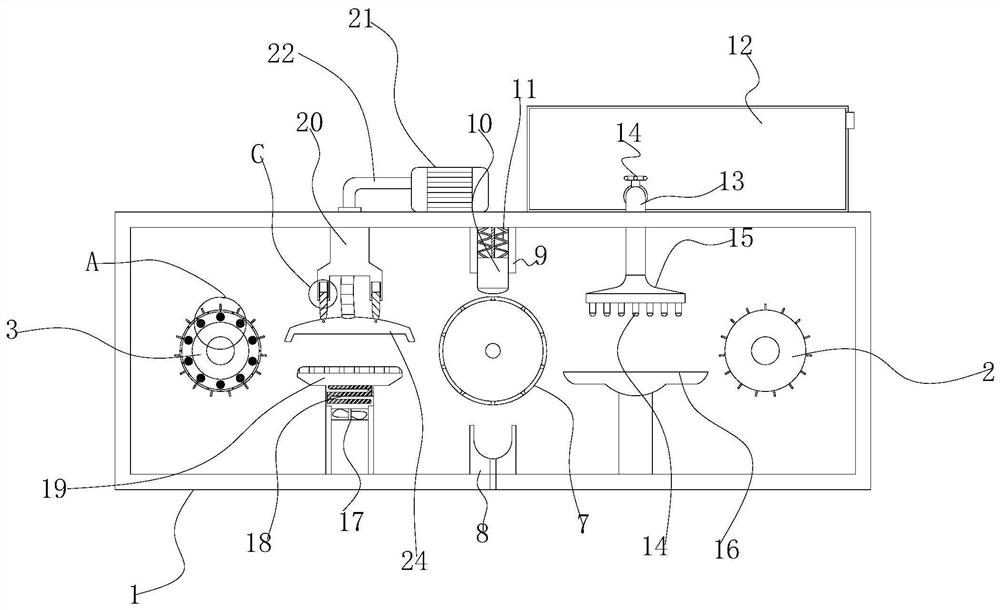

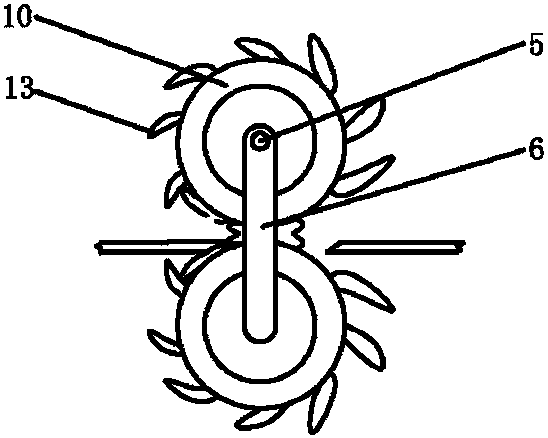

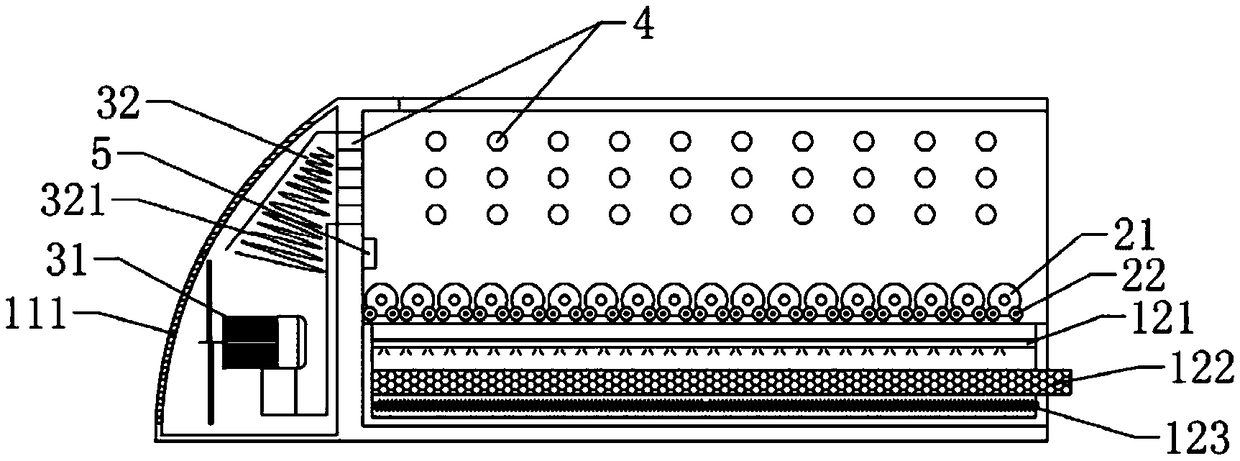

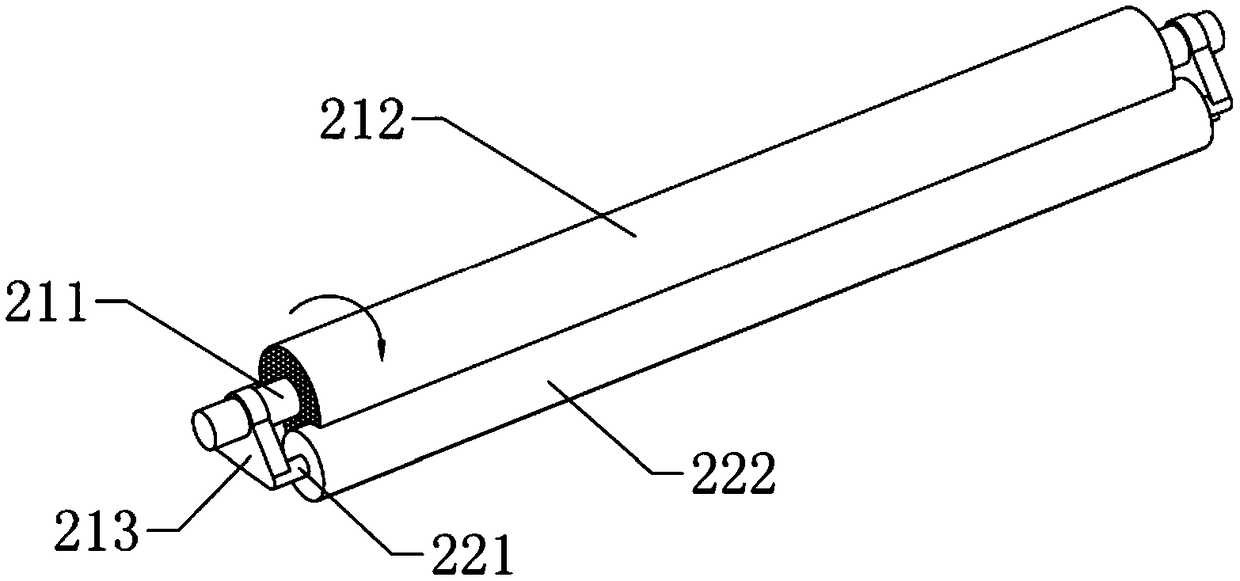

Carding and cleaning device for textile fabric processing

PendingCN112176577AAchieve the effect of combingTo achieve the effect of dryingLiquid/gas/vapor removal by squeezing rollersLiquid/gas/vapor removal by gas jetsHeater RodAir blower

The invention relates to the technical field of textile processing, and discloses a carding and cleaning device for textile fabric processing. The carding and cleaning device comprises a box body, a feeding roller and a discharging roller, comb teeth are fixedly connected to the surfaces of the feeding roller and the discharging roller, and a heating rod is fixedly connected to the interior of thedischarging roller. According to the carding and cleaning device, cloth is guided into the box body through the feeding roller on the right side of the interior of the box body, and water in a watertank is sprayed to the cloth through a spray head, so that the cleaning effect is achieved, then the water in the cloth is squeezed out through squeezing between a water squeezing roller and a limiting column, and then air of an air blower passes through a heater, so that hot air passes through the lower portion of the cloth; and steam generated by heating is pumped out through an exhaust fan, sothat the drying effect is achieved, finally, residual moisture in the cloth is dried through heating of the discharging roller and heating rods in the discharging roller, the carding effect of the cloth is achieved through the carding teeth on the feeding roller and the discharging roller, the cloth is more attractive, and follow-up processing and use are convenient.

Owner:JIANGSU YINGZHULIAN TEXTILE TECH DEV

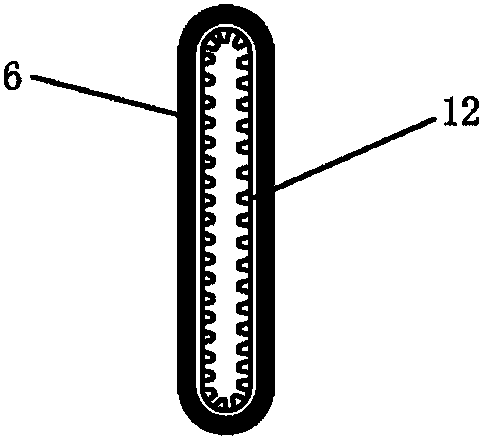

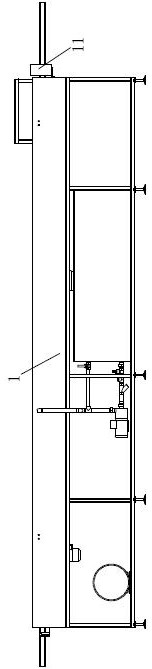

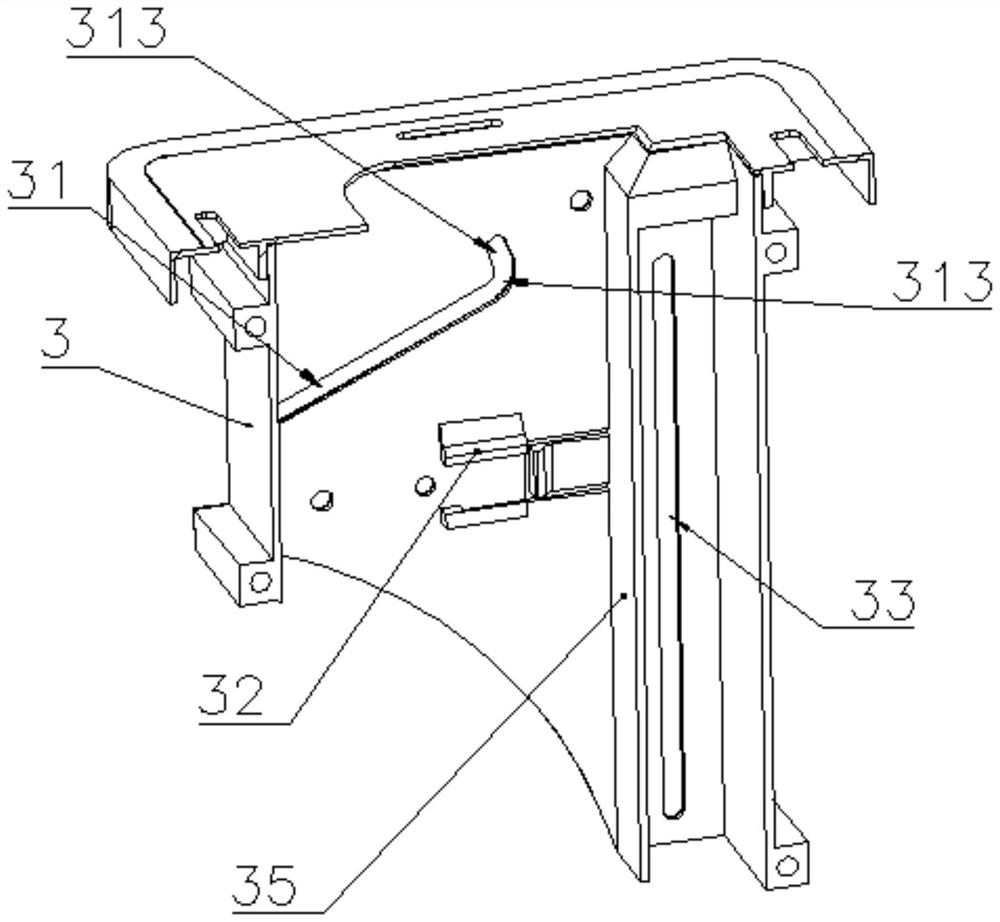

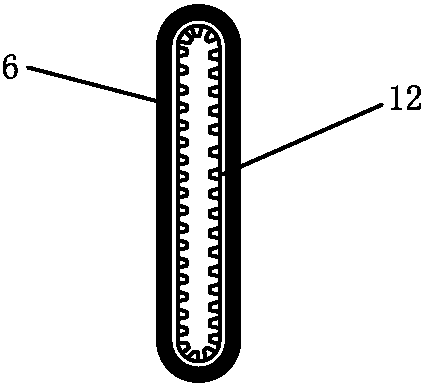

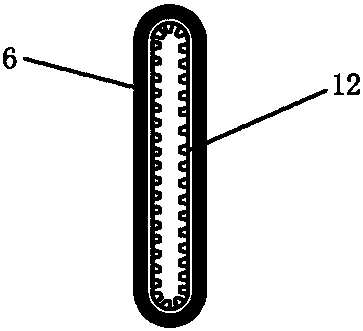

Cleaning machine water squeezing roll

InactiveCN109807149ANovel structural designImprove squeeze efficiencyDrying solid materials without heatCleaning processes and apparatusEngineeringMechanical engineering

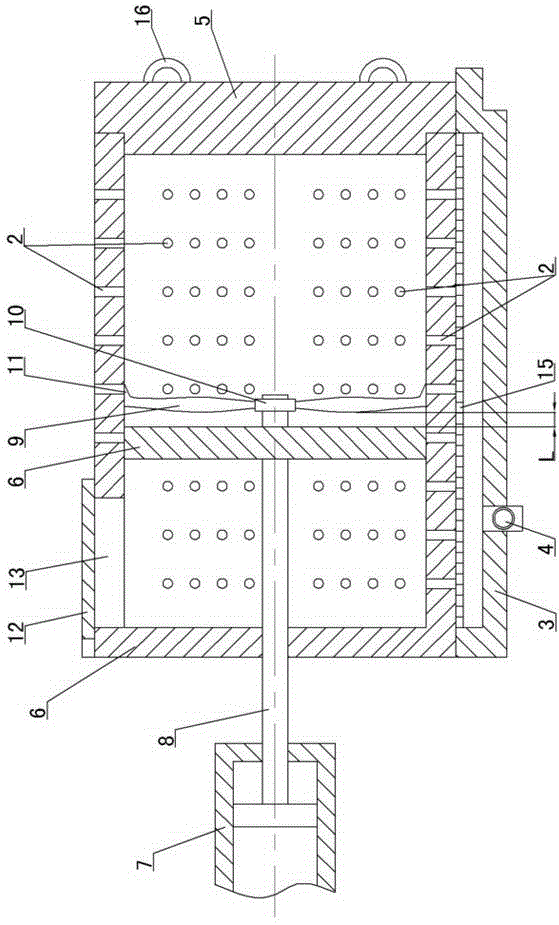

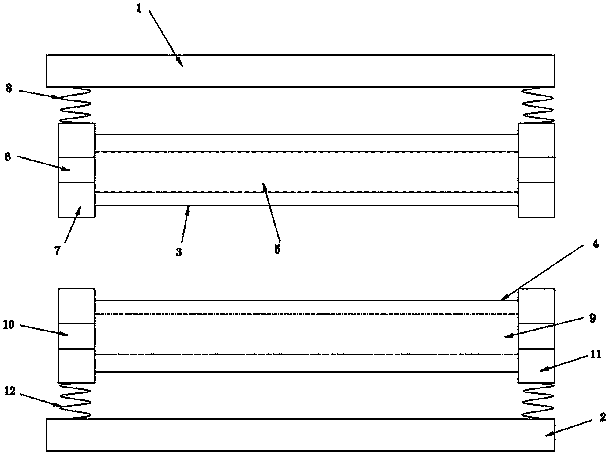

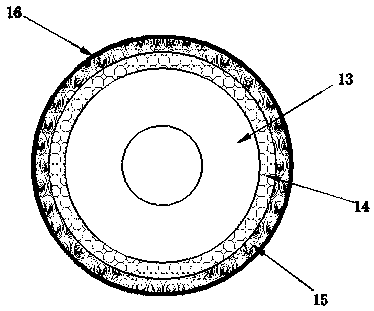

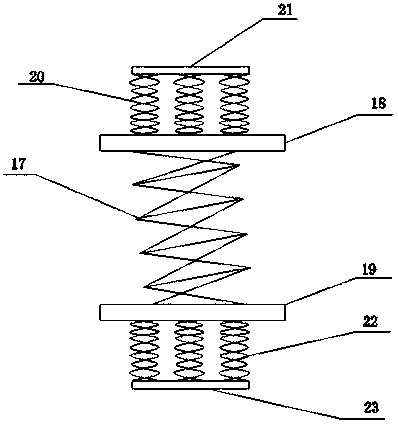

The invention discloses a cleaning machine water squeezing roll. The cleaning machine water squeezing roll comprises an upper bracket, a lower bracket, an upper roll body and a lower roll body; the center of the upper roll body is provided with a first shaft hole, a first rotating shaft is installed in the first shaft hole, first shaft sleeves are installed at the two ends of the first rotating shaft, and first buffering springs are installed between the upper ends of the first shaft sleeves and the inner side of the upper bracket; the lower roll body is arranged under the upper roll body, andthe lower roll body and the upper roll body are symmetrically arranged; and the center of the lower roll body is provided with a second shaft hole, a second rotating shaft is installed in the secondshaft hole, second shaft sleeves are installed at the two ends of the second rotating shaft, and second buffering springs are installed between the upper ends of the second shaft sleeves and the innerside of the lower bracket. The cleaning machine water squeezing roll is novel in structural design, high in water squeezing efficiency, good in effect and suitable for materials with different thicknesses; and in addition, the good buffering performance is achieved, and the service life of the roll bodies can be prolonged.

Owner:江苏振栋精密材料科技有限公司

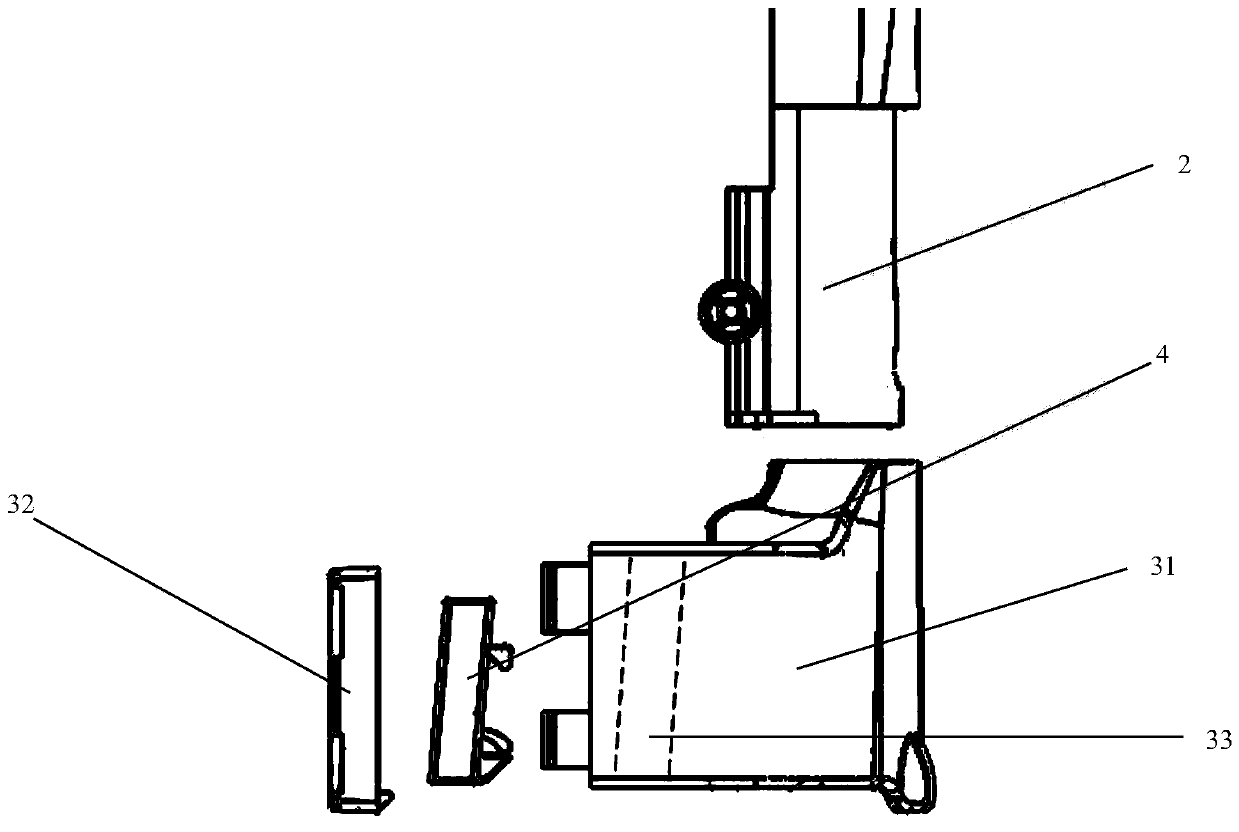

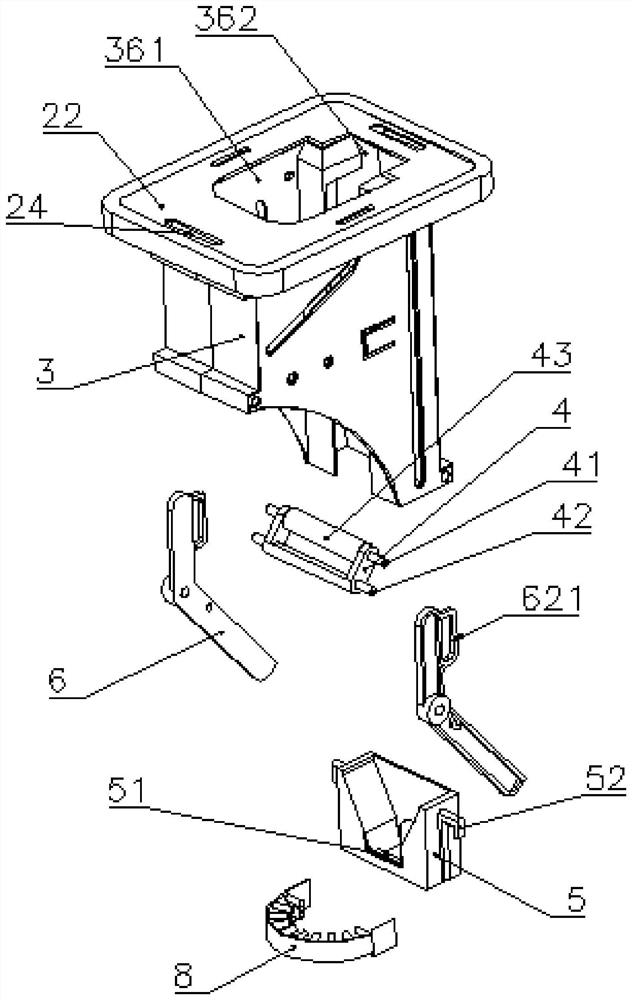

Collodion slab mop cleaning barrel

PendingCN108209784AImprove squeeze efficiencyEasy to operateCarpet cleanersFloor cleanersMechanical engineeringDewatering

The invention provides a collodion slab mop cleaning barrel and belongs to the technical field of living articles. The collodion slab mop cleaning barrel solves the problem that there are no suitabledewatering mechanisms for collodion slab mop working heads at present. The collodion slab cleaning barrel includes a barrel body, a backing part for restraining a collodion slab mop from moving upwards is fixed to the barrel body, and an inner cavity of the barrel body is internally provided with a dewatering roller, an arc guide rail and a sliding base; the arc guide rail is fixedly connected with the barrel body, the sliding base is arranged on the arc slide rail, and the dewatering roller is positioned on the inner side of the arc guide rail and rotatably connected with the sliding base; apedal is also swingingly connected to the barrel body and connected with the sliding base through a transmission mechanism, wherein the transmission mechanism can drive the sliding base to move alongthe arc guide rail when the pedal swings. The collodion slab mop cleaning barrel can achieve dewatering of collodion of the collodion slab mop. The collodion slab mop cleaning barrel can be used for not only cleaning a working head but also dewatering the working head, so that the collodion slab mop cleaning barrel has the advantages that the functions are complete and the structure is compact.

Owner:邱新保

Water-squeezing mop having long service life

The invention discloses a water-squeezing mop having a long service life. The water-squeezing mop comprises a cotton head, a mop rod, a movable rod and a transmission gear, wherein a fixed frame is arranged at the bottom end part of the mop rod; the cotton head is located on the outer side at the bottom end of the fixed frame; clamping water squeezing parts are arranged on the two sides of the fixed frame in a manner of outwards extending; a clamping water squeezing space through which the cotton head penetrates is formed between the clamping water squeezing parts; the movable rod movably penetrates into the mop rod and stretches into the fixed frame; the bottom end part of the movable rod is fixedly connected with the cotton head; a rod body of the movable rod is further provided with a rack which extends along the length direction of the movable rod and the rack is aligned to the clamping water squeezing space; and the transmission gear is pivoted on the mop rod and is engaged with the rack. According to the water-squeezing mop having the long service life, force can be applied on the cotton head in a balanced manner to squeeze water on the basis of guaranteeing the water squeezing efficiency, and the water squeezing operation is easy and convenient.

Owner:郭广玺

Leather wringing device

InactiveCN109722495AIncrease contact areaImprove squeeze efficiencyLeather manufacturingSkins/hides/leather/fur manufacturing apparatusHinge angleWater storage tank

The invention discloses a leather wringing device. The leather wringing device comprises a water storage tank, a first conveying device and third squeezing rollers; the first conveying device is installed above the water storage tank; a fixing bracket is mounted on one side of the upper portion of the water storage tank; the first conveying device and a second conveying device are installed on thewater storage tank through the fixing bracket; a conveyor belt is installed on the outer side of the first conveying device; a first squeezing roller is installed at one end of the first conveying device; fixing rods are arranged on the two sides of one end of the first conveying device; gear hinges are installed in the fixing rods; the second conveying device is installed at one end of a receiving plate; one end of the second conveying device is provided with a second squeezing roller; one side of the second squeezing roller is provided with another receiving plate; one end of the receivingplate is provided with the pair of third squeezing rollers; and one sides of the third squeezing rollers are provided with another receiving plate.

Owner:HUBEI ZHIQUAN PATENT TECH APPL DEV CO LTD

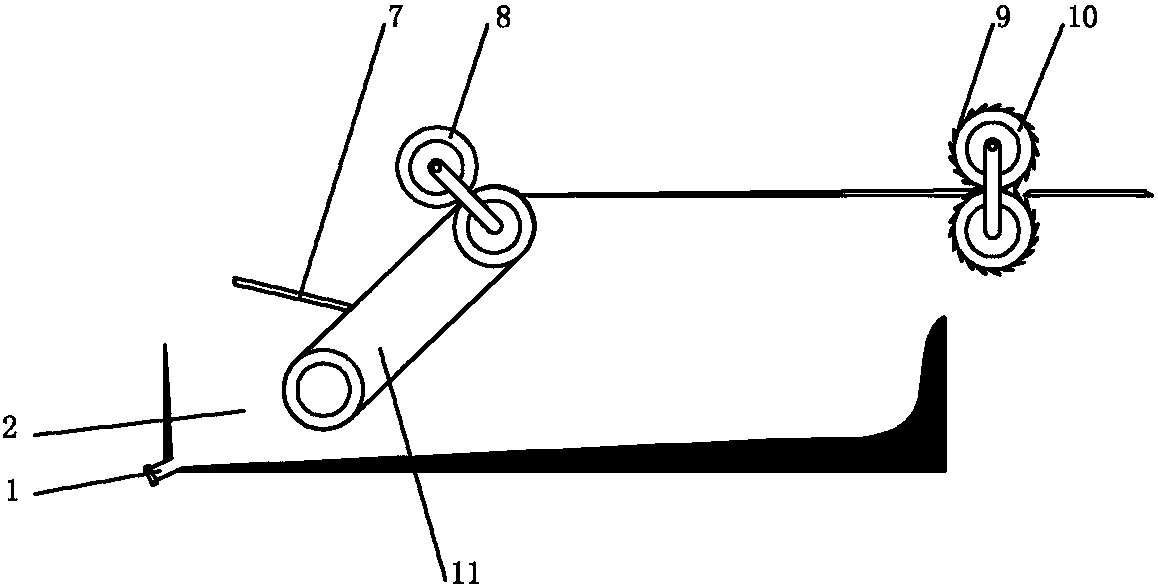

Bean curd cloth dehydrating and coiling machine

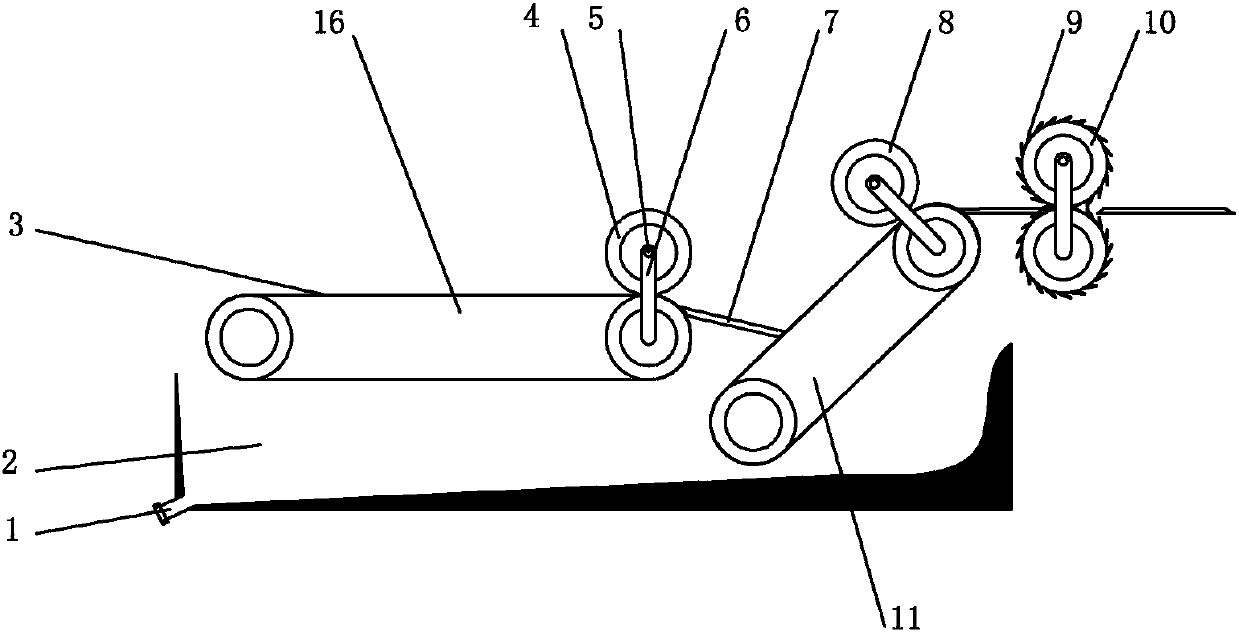

ActiveCN104495448AReduce moisture contentReduce noiseCleaning using liquidsArticle deliveryAgricultural engineeringSprocket

The invention discloses a bean curd cloth dehydrating and coiling machine. The bean curd cloth dehydrating and coiling machine comprises a frame, a lower rubber roller, an upper rubber roller, an upper rubber roller bracket, chain wheels, a chain, a cloth coiling transmission wheel, a bean curd cloth guide roller, a bean curd cloth bracket, a bean curd cloth coiling rod and a pull spring, wherein the upper rubber roller bracket is hinged to the frame; an upper rubber roller revolving shaft is arranged on the upper rubber roller bracket; a lower rubber roller revolving shaft is arranged on the frame below the upper rubber roller; the upper rubber roller and the lower rubber roller can be used for clamping bean curd cloth till the bean curd cloth is in contact with each other; a cloth coiling transmission wheel revolving shaft is arranged on the frame; the chain is arranged on an upper rubber roller revolving shaft chain wheel and a cloth coiling transmission wheel revolving shaft chain wheel; the lower rubber roller is used for driving the upper rubber roller to rotate through friction; the chain is used for driving the cloth coiling transmission wheel to rotate; a bean curd cloth guide roller revolving shaft is arranged on the frame; the bean curd cloth bracket is hinged to the frame; a bean curd cloth coiling rod revolving shaft is arranged on the bean curd cloth bracket; the bean curd cloth coiling rod is in contact with the cloth coiling transmission wheel through the pull spring; the cloth coiling transmission wheel is used for driving the bean curd coiling rod to rotate through friction. The bean curd cloth is wound on the bean curd cloth coiling rod through the upper rubber roller, the lower rubber roller and the bean curd cloth guide roller.

Owner:李威

Pushing and shoveling kitchen garbage squeezing device

A push-pressing and wall shoveling type water squeezing device for kitchen waste comprises a water squeezing tank, wherein water squeezing holes are formed uniformly in the peripheral wall of the water squeezing tank, a water receiving tank is arranged at the bottom of the water squeezing tank, a door plate is arranged at the opening part of the water squeezing tank, a water squeezing pressing plate is arranged in the water squeezing tank and reciprocates to squeeze water in the water squeezing tank under driving of a piston of a water squeezing hydraulic cylinder, large shovel cutters and small shovel cutters are uniformly distributed on the front side of the water squeezing pressing plate in a vertically staggered manner, wall scraping shovel blades are arranged on the periphery of the water squeezing pressing plate and contacted with the inner wall surface of the water squeezing tank. The scheme adopts a pushing-shoveling mode to squeeze and dewater the kitchen waste, blockage of the water squeezing holes is prevented, and the water squeezing efficiency is increased.

Owner:TANGSHAN CHENXI MACHINERY MFG

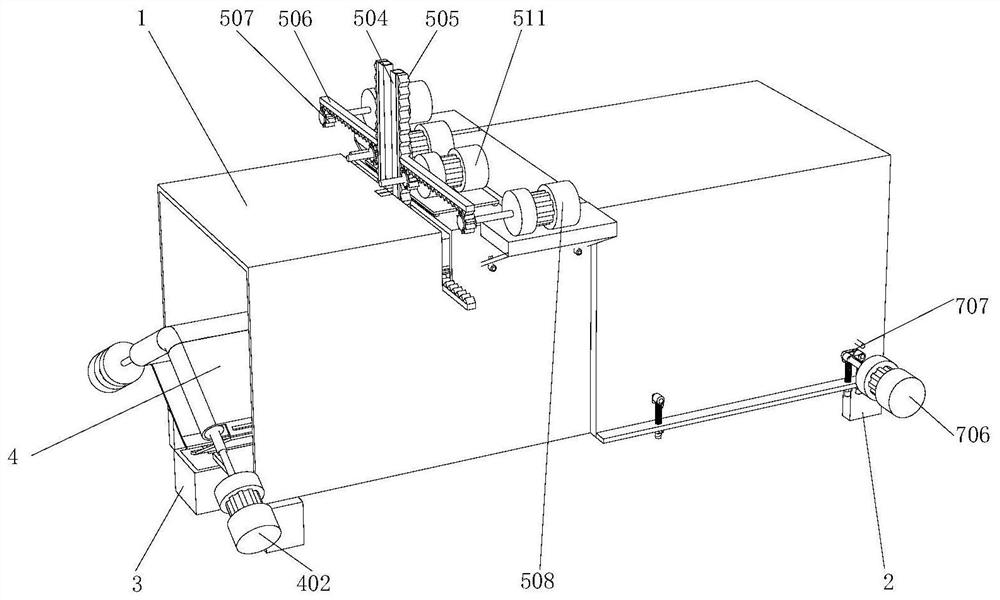

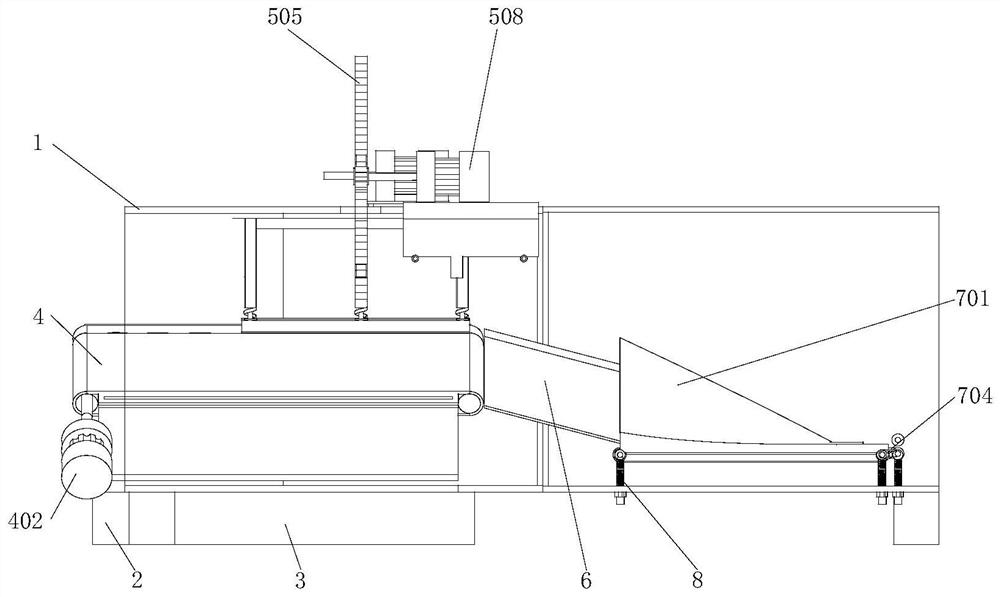

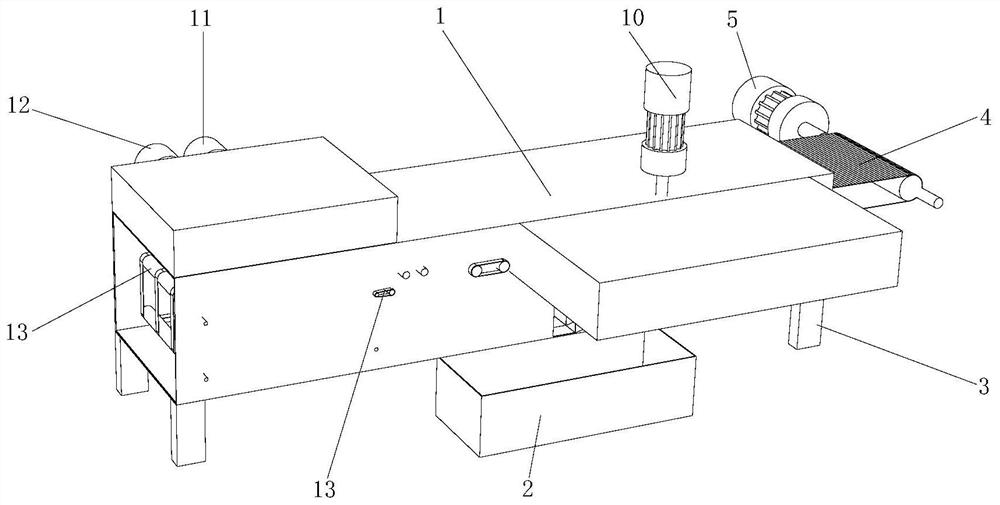

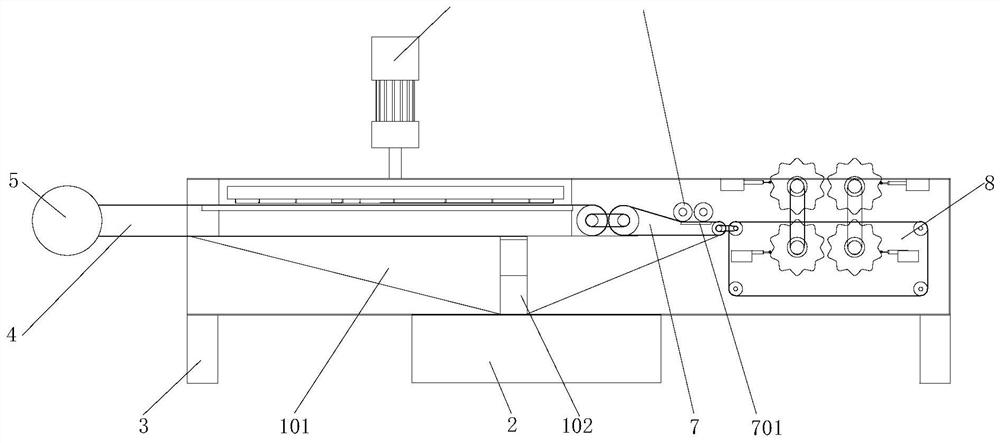

Novel fuel pipe extrusion production equipment

ActiveCN112757604AAvoid damageImprove squeeze efficiencyDrying solid materials without heatTubular articlesFluoroplastReduction drive

The invention belongs to the technical field of fuel pipe production, and particularly relates to novel fuel pipe extrusion production equipment. The novel fuel pipe extrusion production equipment comprises a core material releasing machine, a front traction machine, a composite extruder, a fluoroplastic extruder, an air cooling device, a wrapping extruder, a cooling tank and a rear traction machine, wherein the front traction machine, the composite extruder, the fluoroplastic extruder, the air cooling device, the wrapping extruder, the cooling tank and the rear traction machine are sequentially arranged along a core material conveying path; and the fluoroplastic extruder comprises a machine body, a servo motor installed on the machine body, a speed reducer connected to the output end of the servo motor, a feeding cylinder installed on the machine body, a screw connected to the output end of the speed reducer, a cover body installed on the machine body, an extrusion cylinder penetrating through the cover body, a plurality of heating rings arranged on the extrusion cylinder in a sleeving mode, and an extrusion head connected to an outlet of the extrusion cylinder. A drying box is additionally arranged at the end part of a water tank, so that water stains on the surface of a pipe can be adsorbed when the pipe preliminarily treated by the water tank extends out of the water tank, the pipe with less residual water stains enters a next step, and the problem that an external diameter detector is damaged due to excessive residual water stains is solved.

Owner:GUANGZHOU CHENGXIANG MACHINERY

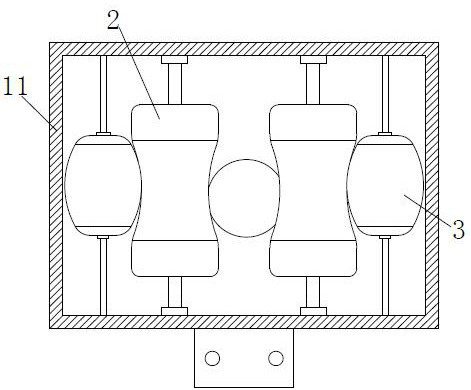

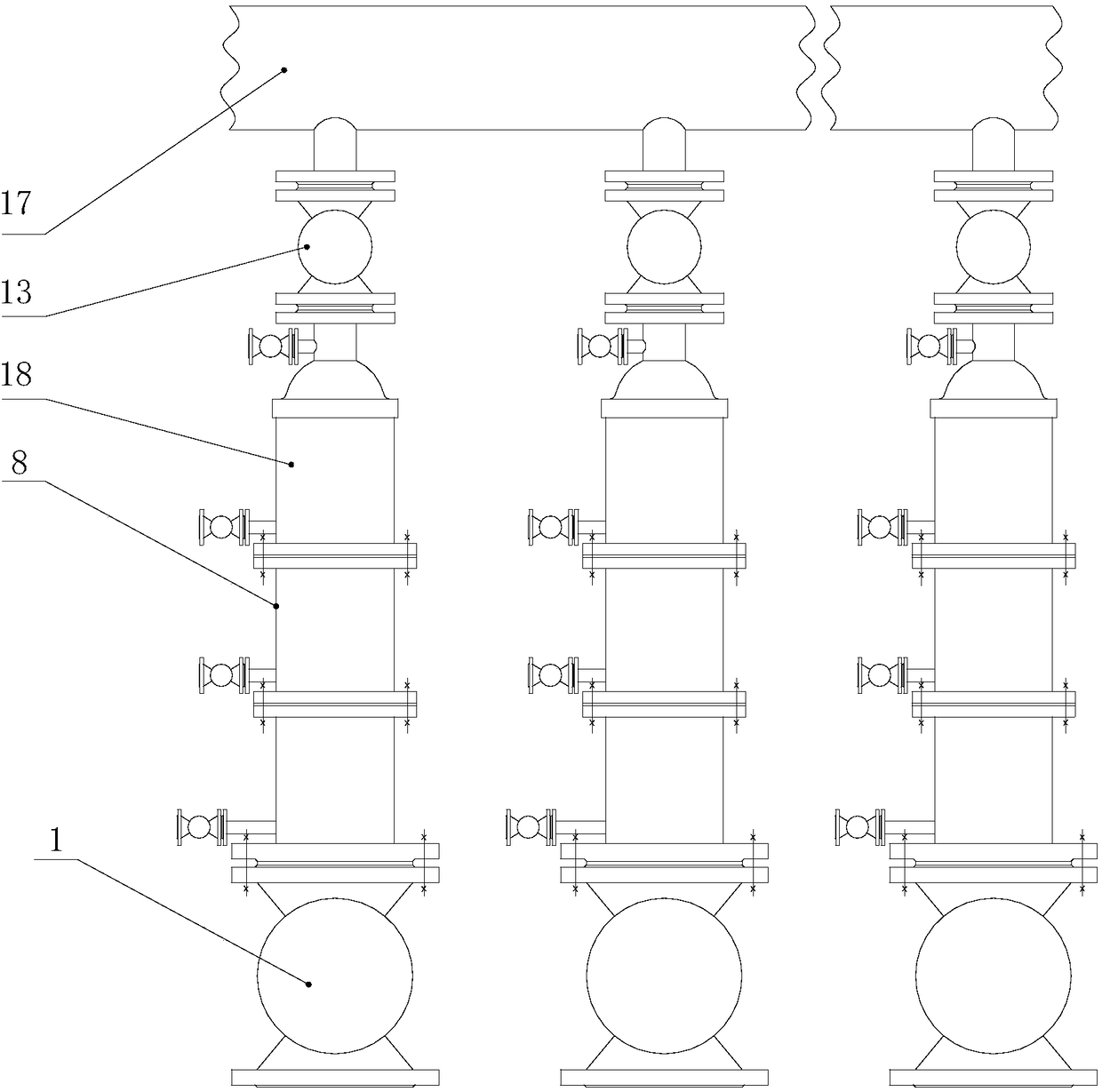

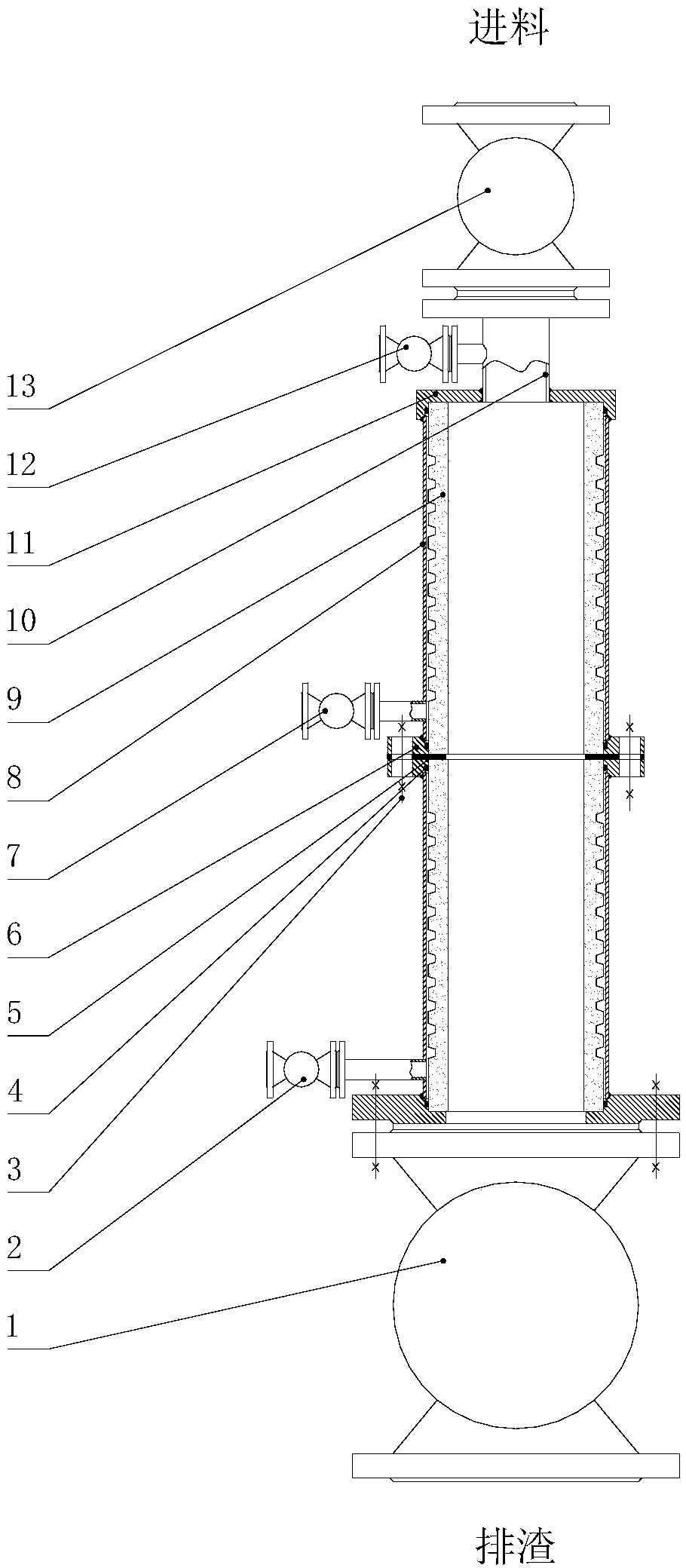

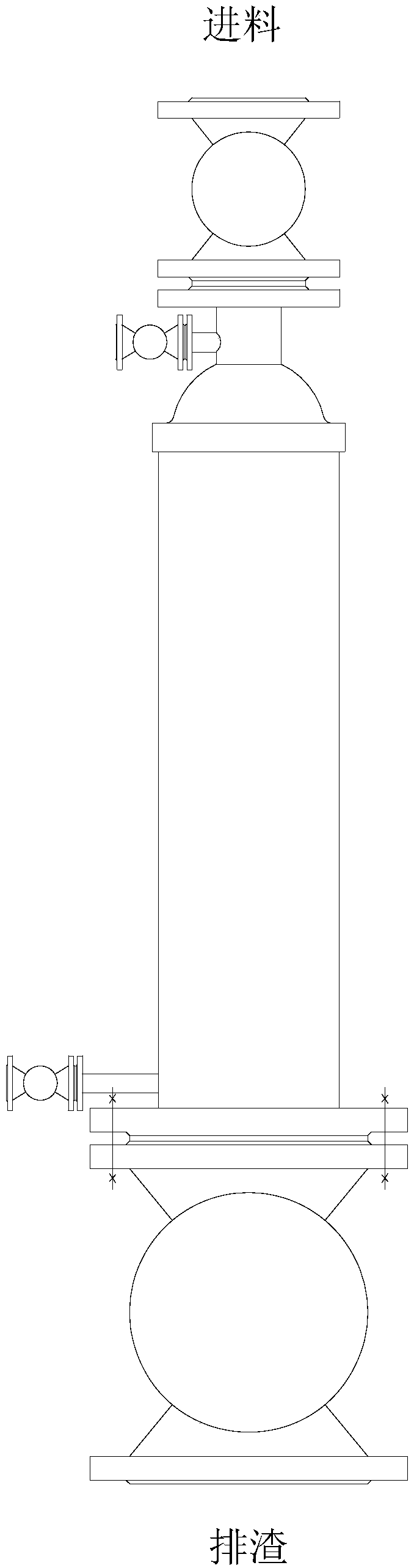

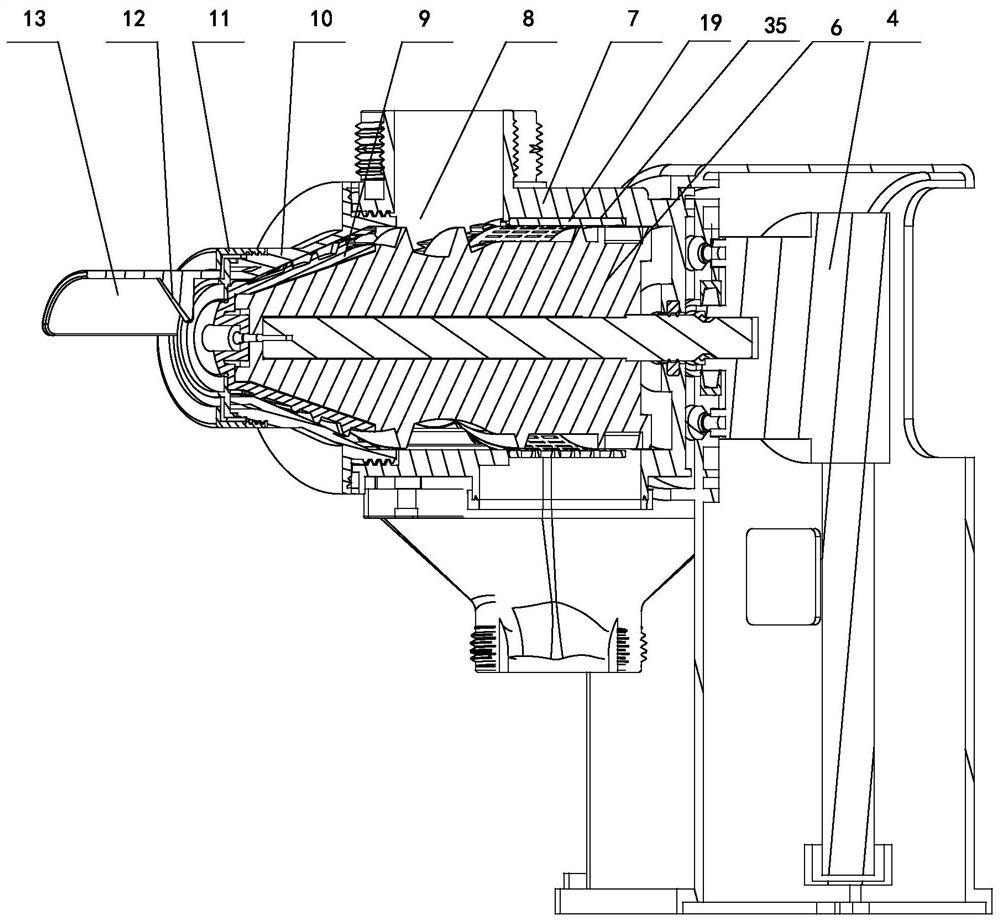

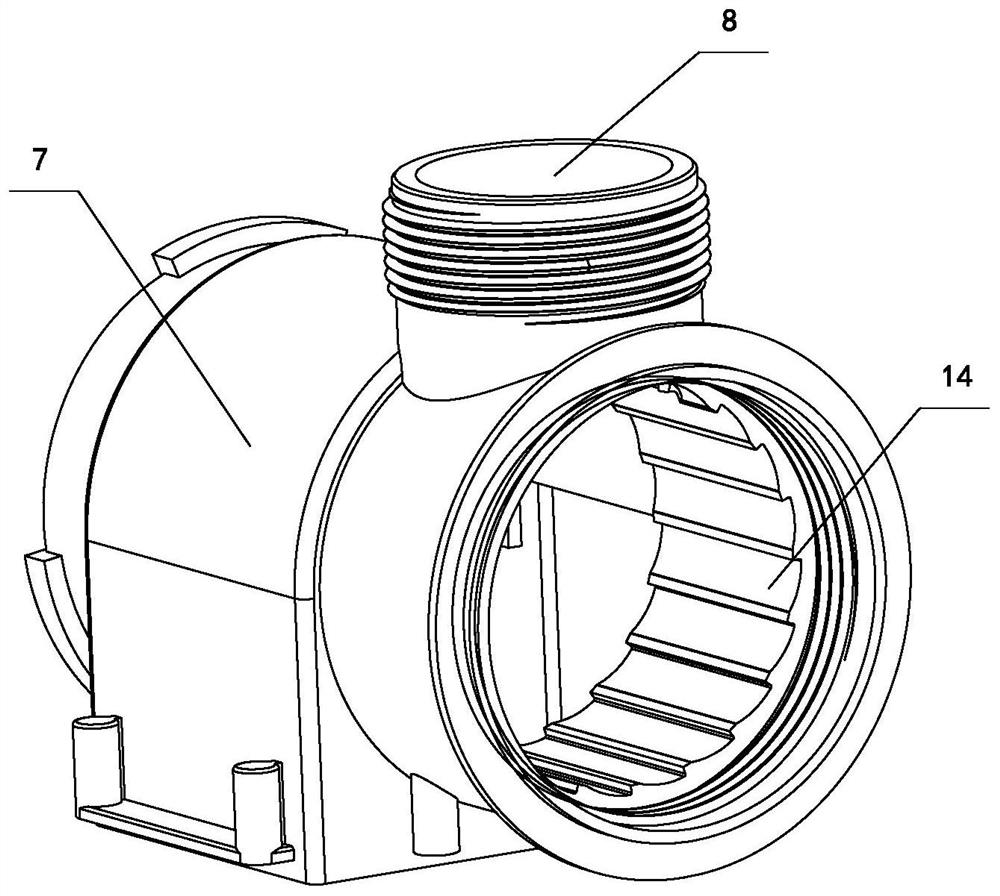

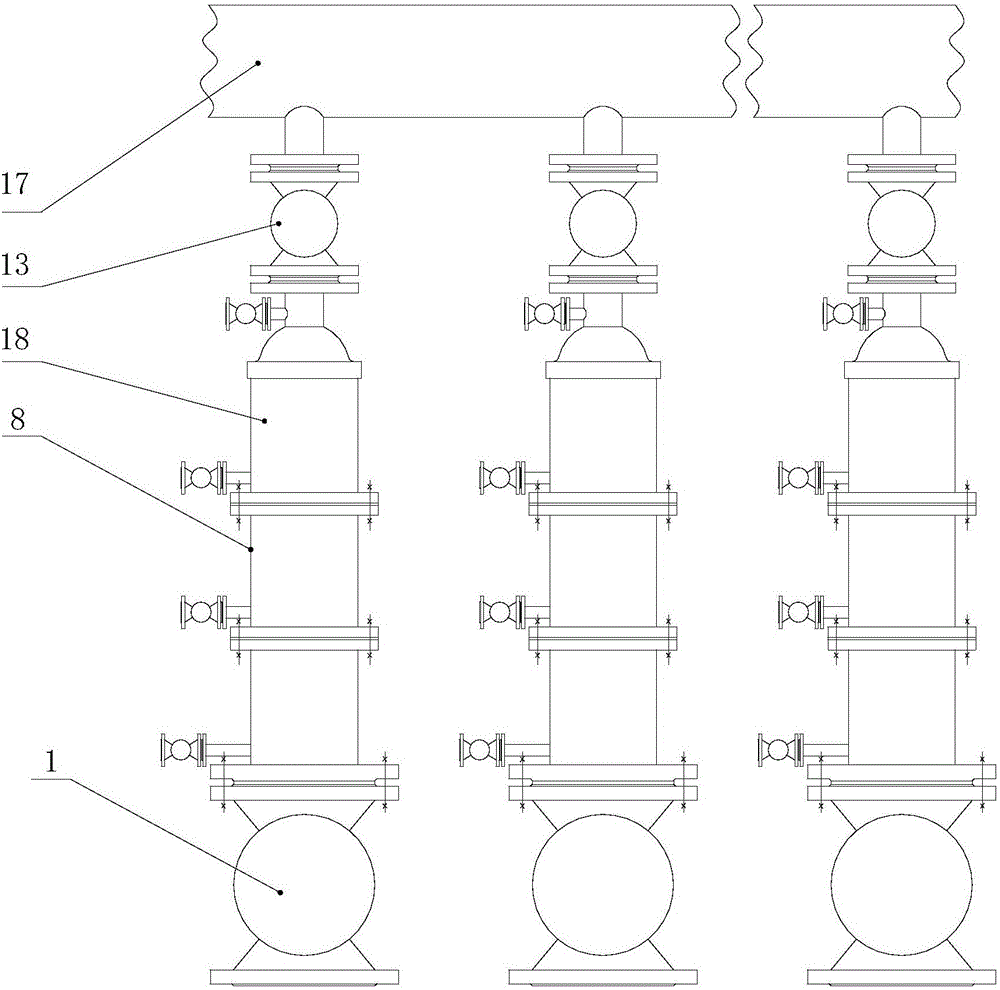

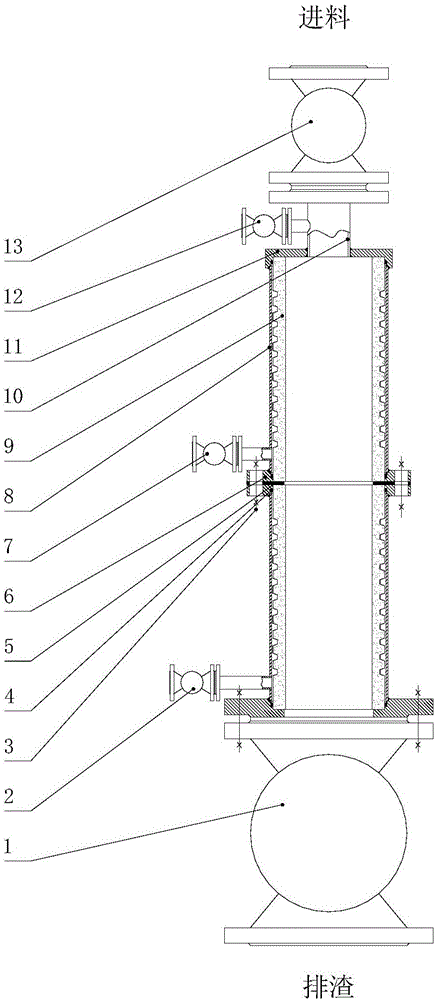

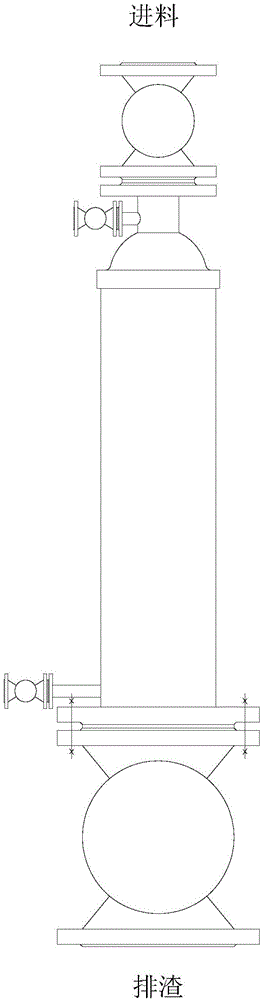

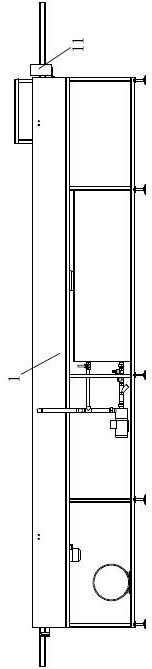

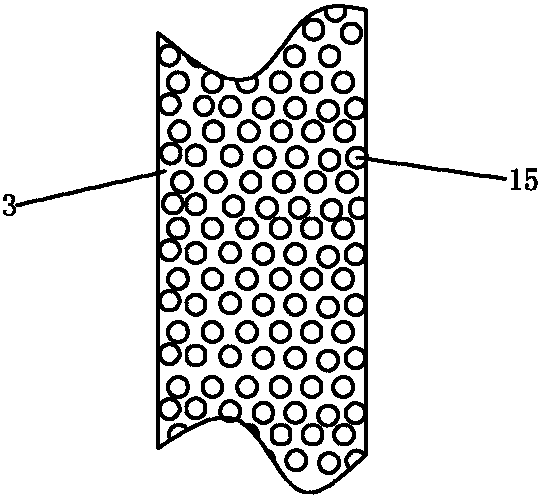

A filter and squeeze drying unit for easy-to-filter materials

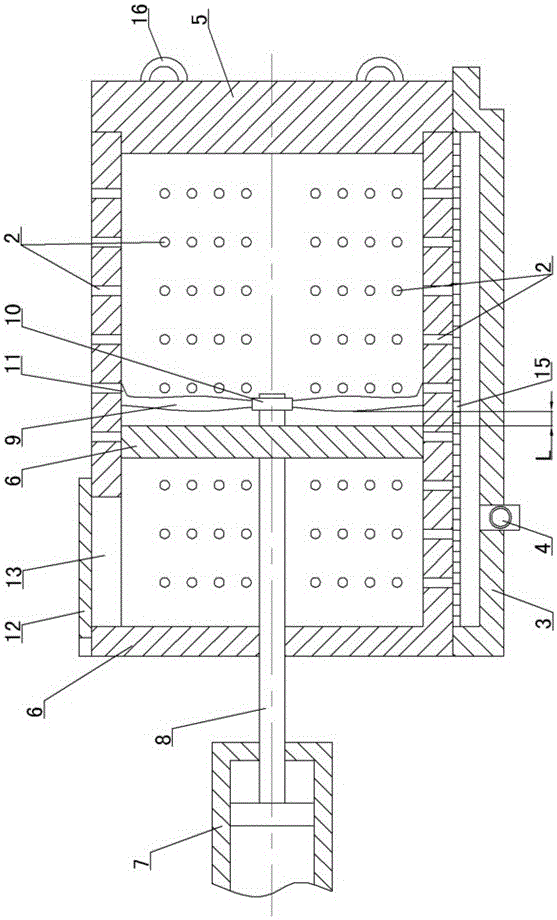

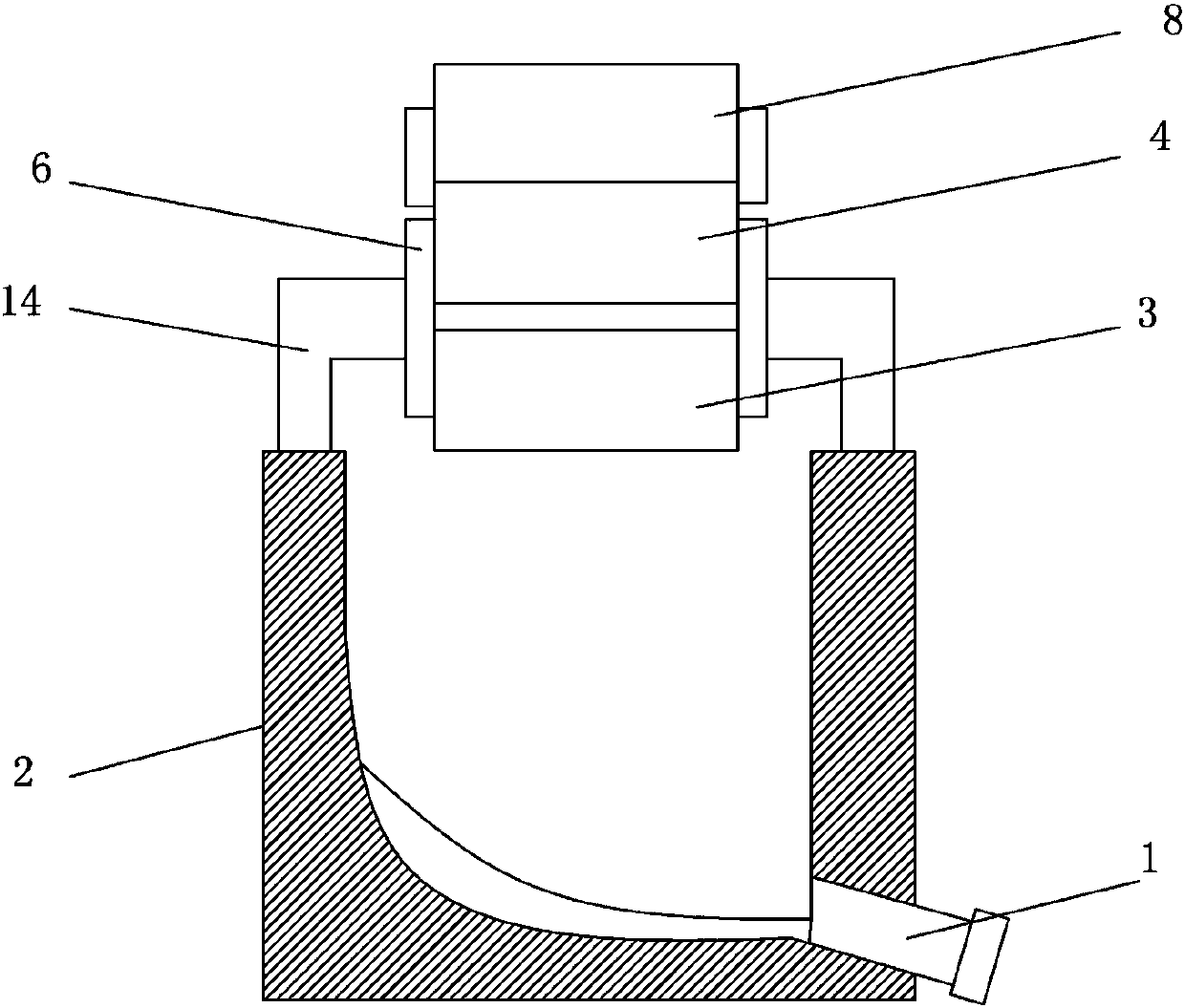

ActiveCN106039803BClose in timePrevent unfavorable running water and other situationsStationary filtering element filtersEngineeringFilter material

The invention discloses a filtering and squeezing unit for filterable materials. The filtering and squeezing unit comprises a distribution pipe (17), which is connected to one or more filtering and squeezing machines (18) through feed valves (13). The filtering and squeezing machine comprises a barrel (8), the upper end of which is connected to the feed valve (13) and the lower end of which is provided with a discharge valve (1). An irregular-shaped filter pipe (9) is arranged inside each barrel (8). A positive blow valve (12) is disposed between the feed valve (13) and the barrel (8). The lower part of the barrel (8) is provided with a back-blow outlet valve (2). According to the invention, multiple materials can be filtered and squeezed at the same time, and the operation is carried out under airtight condition. In addition, filtering effect is good, squeezing efficiency is high, filter cakes can be continuously produced, and the operation can be effectively combined with production activities.

Owner:ZHEJIANG DONGOU FILTERING MASCH MFG CO LTD

Simple shoe dryer for preventing indoor slippery conditions in rainy days

InactiveCN109008894AGuaranteed continuous water absorptionDry fastFootwear cleanersEngineeringUltraviolet germicidal light

The invention relates to the field of articles of daily use, in particular to a simple shoe dryer for preventing indoor slippery conditions in rainy days. The simple shoe dryer comprises a box body and a dewatering roller row; the box body comprises an air feeding part, a water accumulation part, side baffles and a top plate; the air feeding part is arranged at the head of the box body, the wateraccumulation part is arranged below the dewatering roller row, the side baffles surround three sides of the dewatering roller row to form a foot placing area, and the top plate is arranged above the dewatering roller row and connected with the tops of the side baffles; an opening is formed in the top plate and communicated with the foot placing area, the size of the opening is gradually increasedfrom the head of the box body to the tail of the box body, and the water accumulation part is internally provided with an ultraviolet sterilizing lamp tube, drawable antibacterial water-absorbing cotton and an electric heating evaporating pipe from top to bottom in sequence; the dewatering roller row comprises several water-absorbing rotary rollers which are arranged side by side and several water-squeezing press rods arranged below the water-absorbing rotary rollers, and the water-absorbing rotary rollers comprise rotary shafts and water-absorbing material layers.

Owner:朱哲凡 +1

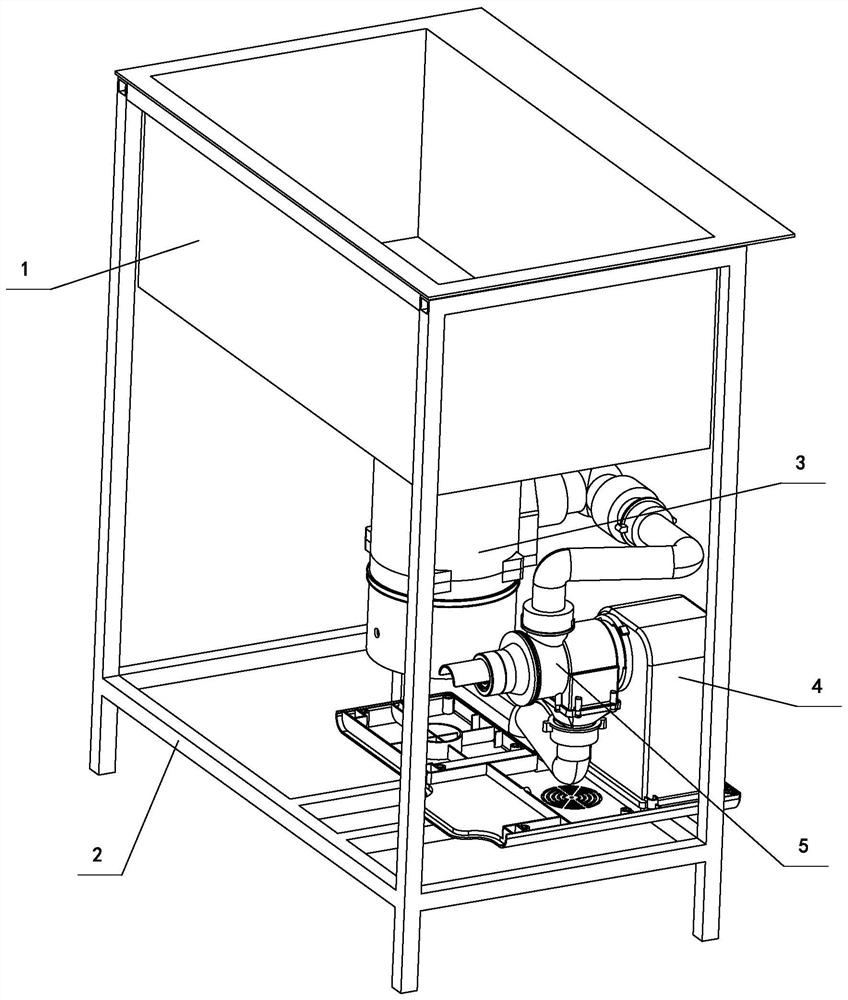

Solid-liquid separation device and kitchen waste disposer with same

PendingCN113665159AWon't clogEasy to handleDomestic plumbingPressesRefuse DisposalsIndustrial engineering

The invention discloses a solid-liquid separation device. The solid-liquid separation device comprises a driving mechanism, a separation cylinder, a screw head cover and a screw; the separation cylinder is provided with a feed end and a liquid discharge port; one end of the screw head cover is connected with one end of the separation cylinder, and the other end of the screw head cover is a solid discharge port; the driving mechanism is connected to the end, away from the screw head cover, of the separation cylinder and is in transmission connection with the screw; the screw is rotationally connected in the separation cylinder, one end of the screw is connected with the driving mechanism, and the other end of the screw is located in the screw head cover; a filtering structure is also arranged in the separation cylinder; and the feed end and the liquid discharge port are staggered. After the above structure is adopted, kitchen garbage cannot block a sewer pipeline, collected garbage is in a solid block shape or strip shape, and therefore garbage is easy to dispose, the situation of liquid seepage is avoided, and garbage is more convenient to dump.

Owner:NINGBO MEIGAO KITCHENWARE CO LTD

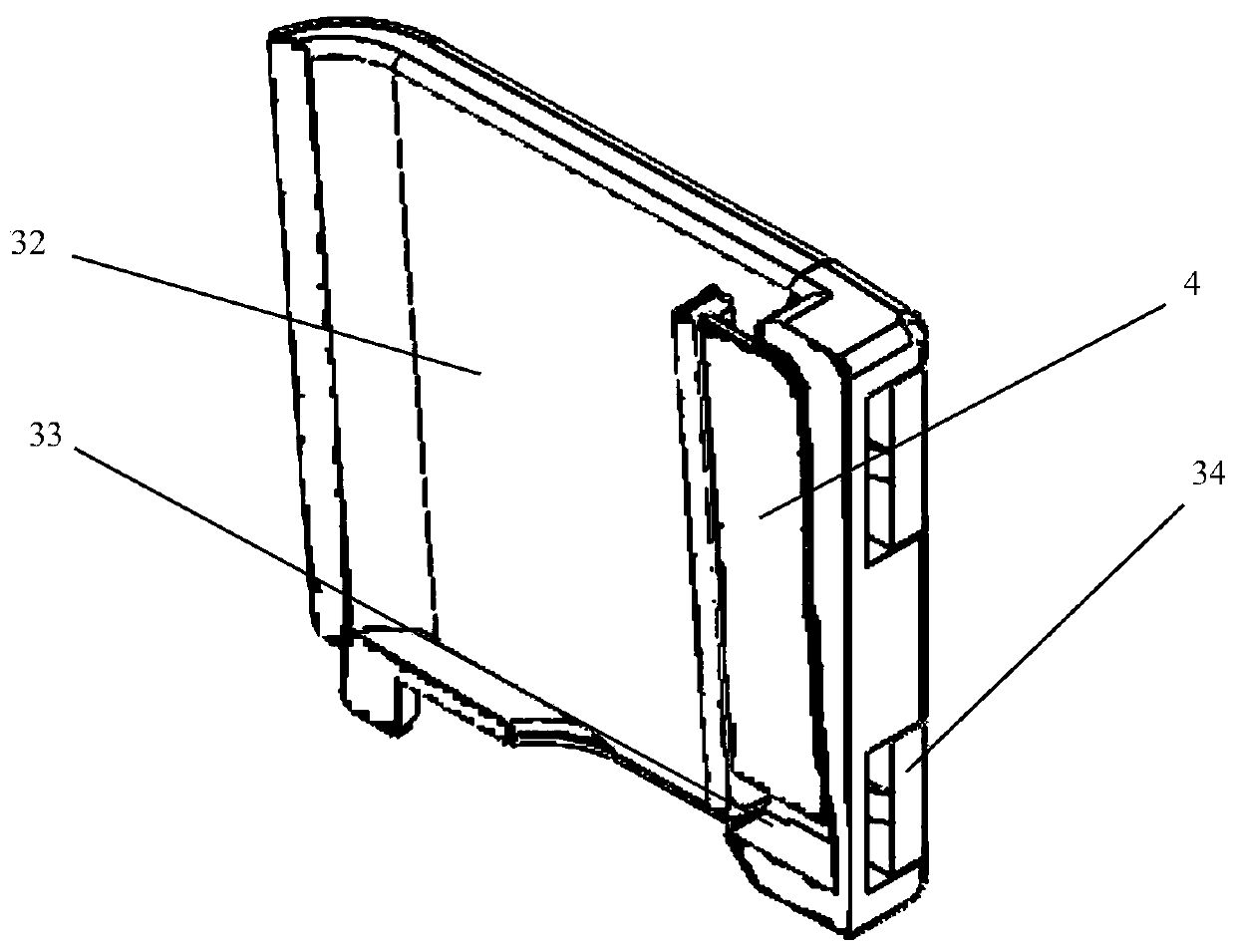

Water squeezing part, water squeezing device and cleaning equipment for flat mop

PendingCN112998613AInhibit refluxAvoid formingCarpet cleanersFloor cleanersEnvironmental engineeringMechanical engineering

Owner:成都美派环保科技有限公司

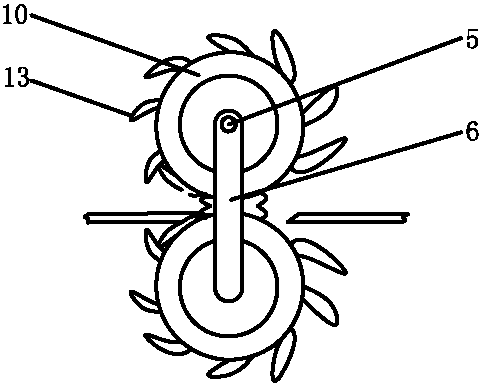

Pushing and agitating wall scraping kitchen waste squeezing device

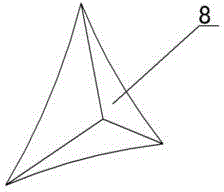

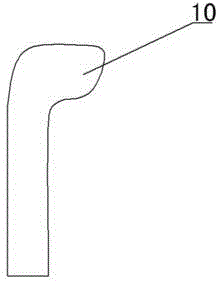

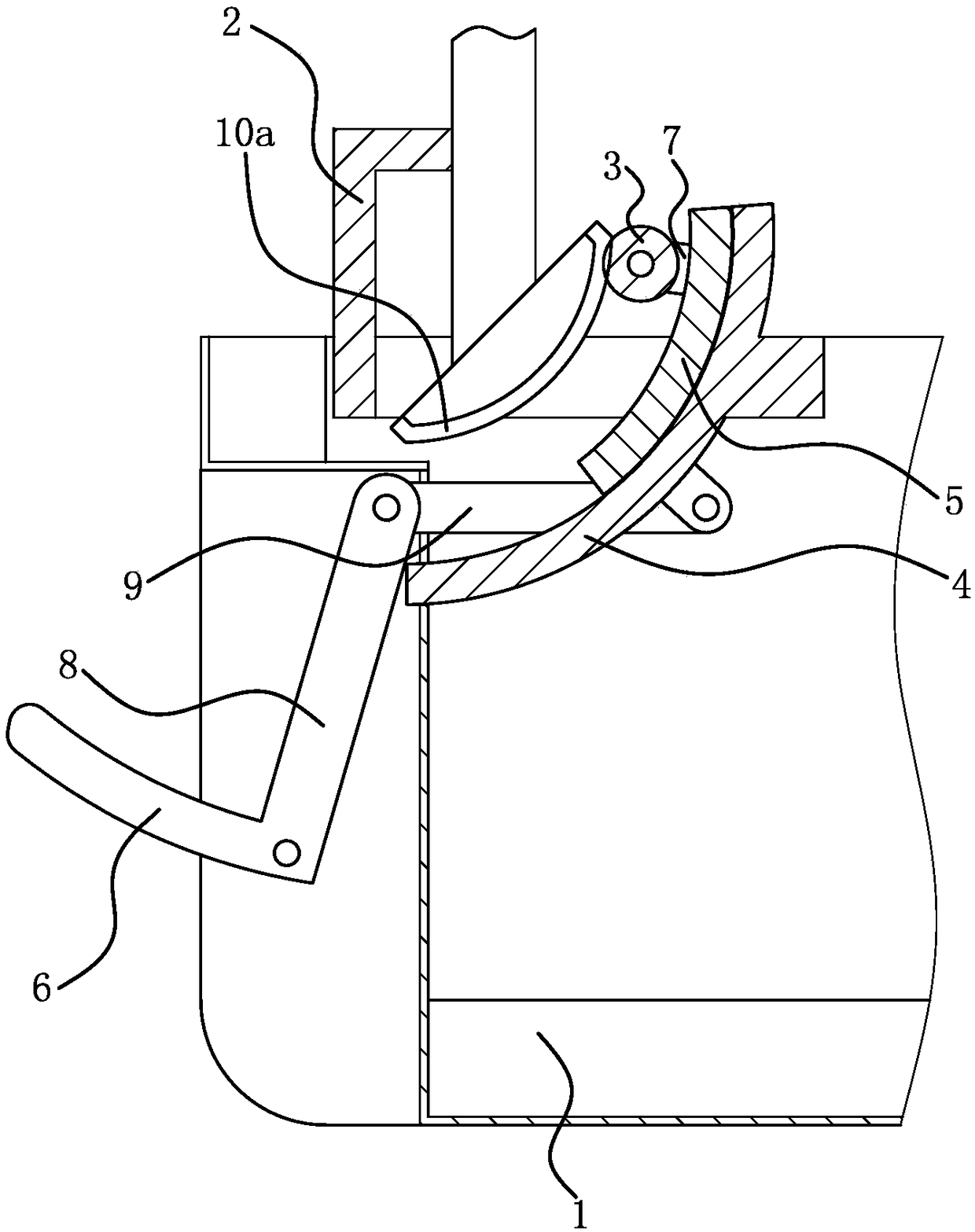

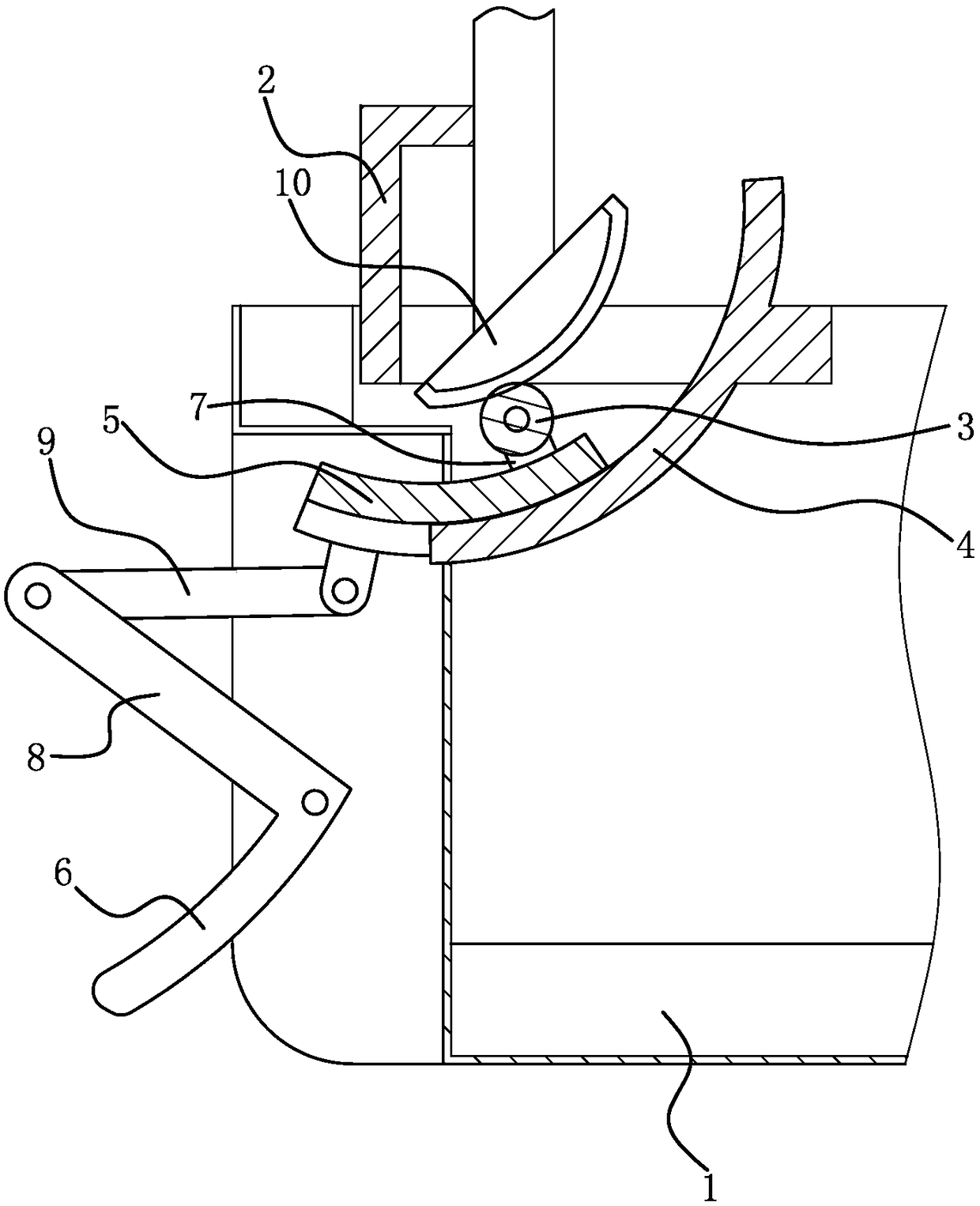

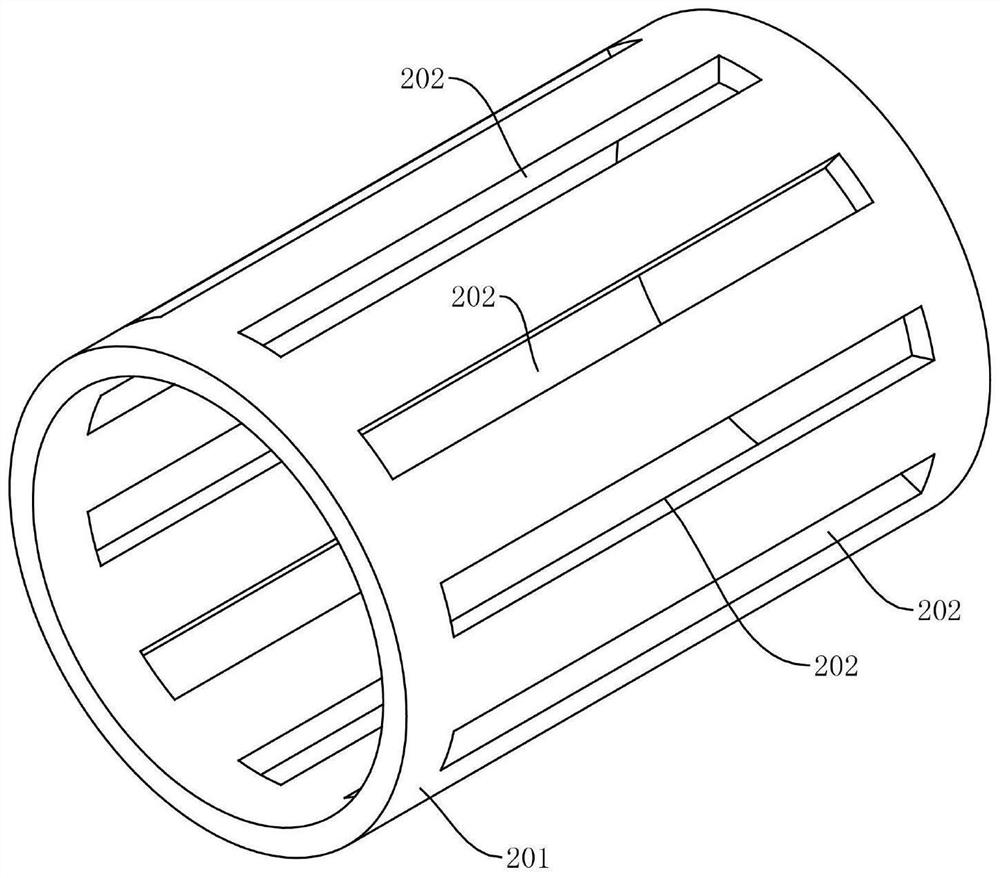

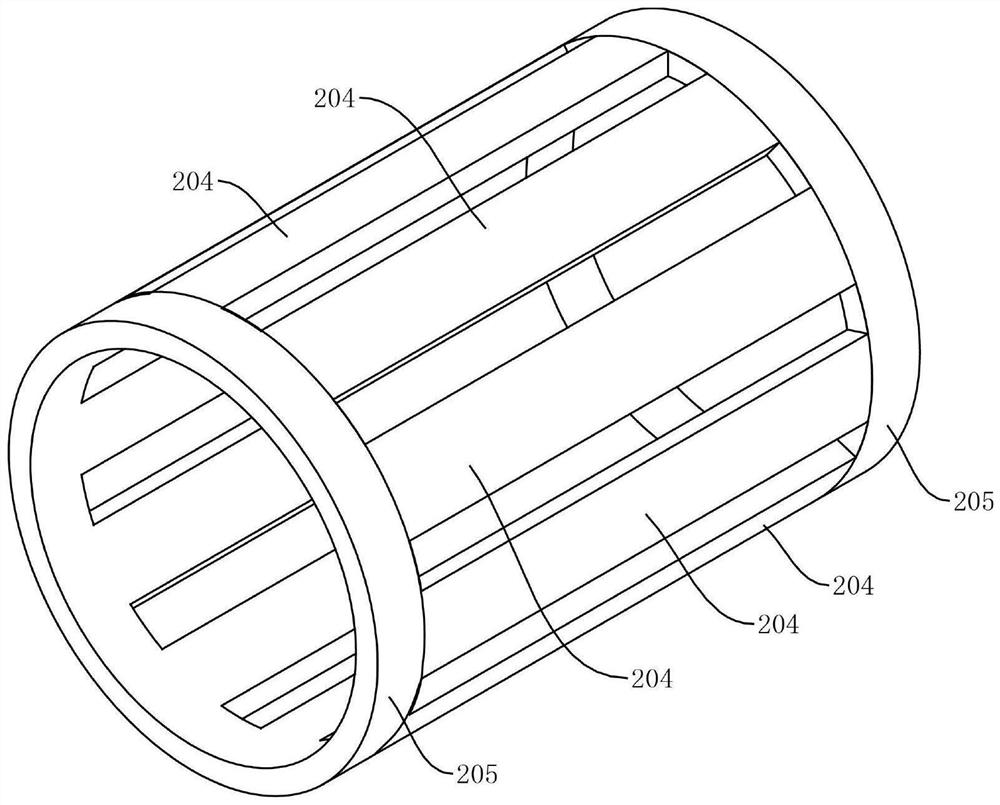

ActiveCN104589686BAvoid cloggingImprove squeeze efficiencyPressesHydraulic cylinderReciprocating motion

The invention discloses a pushing, pressing and stirring wall-scraping type kitchen garbage squeezing device. The device comprises a round squeezing box body, wherein squeezing holes are uniformly distributed in the surrounding wall of the round squeezing box body; a water-receiving box body is arranged at the bottom of the round squeezing box body; a door plate is arranged at an opening of the round squeezing box body; a round squeezing pressing plate is arranged in the round squeezing box body and is driven by a piston rod of a squeezing hydraulic cylinder to reciprocate in the round squeezing box body; at least two propeller blades are arranged in front of the round squeezing pressing plate; one end of each propeller blade is connected with a self-rotating shaft sleeve; the piston rod penetrates through the round squeezing pressing plate; the self-rotating shaft sleeve is arranged at the front end of the piston rod; a wall-scraping blade edge is formed at the other end of each propeller blade and is in contact with the inner wall surface of the round squeezing box body. The scheme adopts a stirring wall-scraping way to stir, extrude and dehydrate kitchen garbage, so that a squeezing hole is prevented from being blocked, and the squeezing efficiency is improved.

Owner:蚌埠中知知识产权运营有限公司

Squeezing device for papermaking

InactiveCN112211026AImprove water squeeze effectImprove water absorptionPress sectionWater savingPapermaking

The invention provides a squeezing device for papermaking, and relates to the technical field of papermaking. The squeezing device for papermaking comprises a shell, a driving motor, a shaft, a hose,a first water squeezing mechanism and second water squeezing mechanisms, and the first water squeezing mechanism is arranged at the bottom end of the shell. Water in a water squeezing device is discharged through the first water squeezing mechanism, the top end of the first water squeezing mechanism is fixedly connected with the top end in the shell, and the shaft penetrates through the central axis of the first water squeezing mechanism and is fixedly connected with the first water squeezing mechanism. A driving motor is arranged on the left side of the first water squeezing mechanism, the output end of the driving motor is fixedly connected with the shaft, the hose is fixedly connected to the bottom end of the right side of the first water saving mechanism, and the second water squeezingmechanisms are arranged on the left side and the right side of the first water saving mechanism and movably connected with the first water squeezing mechanism. The squeezing device solves the problemthat the squeezing efficiency of a squeezing device is affected due to the fact that water can be thrown out and fall on squeezed paper blanks in the rolling process of a rolling shaft after the paper blanks are squeezed through the rolling shaft.

Owner:俞大陆

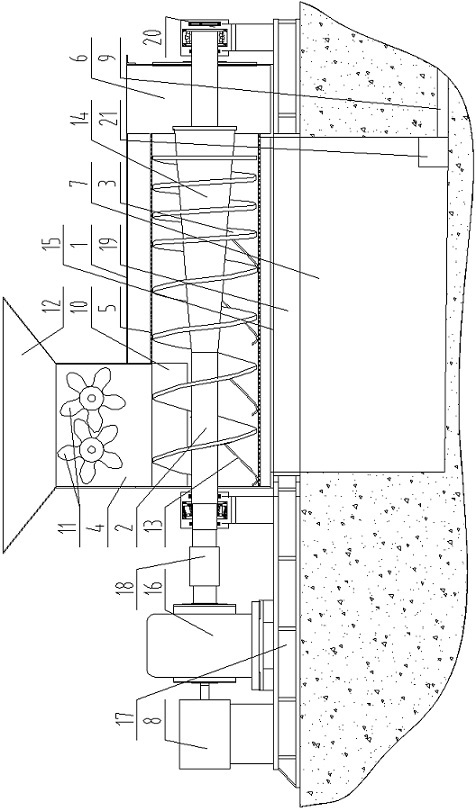

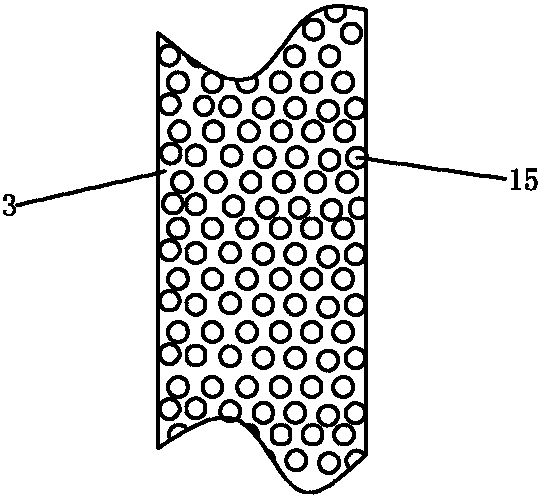

A slag extrusion pipe structure of a sisal mesophyll slag extrusion machine

The invention discloses a slag extruding tube structure of sisal hemp leaf pulp slag-extruding machine. The tube wall of a slag extruding tube is a screen board with multiple water filter holes whichare uniformly distributed; one end of the top of the slag extruding tube is equipped with a notch which defines a charge hole B; a slag extruding roller is coaxially and rotatably connected in the slag extruding tube; the surface of the slag extruding roller is equipped with a slag extruding plate of a spiral structure in an axial direction of the slag extruding roller; the outer diameter of the slag extruding plate is matched with the inner diameter of the slag extruding tube; the slag extruding roller provides drive force through a drive device A, and rotates around the axis of the slag extruding roller; and under rotation action of the slag extruding roller, the slag extruding plate rotates to the other end from one end of the charge hole B. known from the structure, the leaf pulp slag-extruding machine extrudes leaf pulp through action of mechanical extrusion force to extrude juice from leaf pulp, so that recycling amount of sisal hemp juice is increased, and extruded slag furthercan be collected.

Owner:JIANGSU HIMALAYA NATURAL FIBER PROD

Novel flat mop free of hand washing

PendingCN111202476AReduce mechanical damageExtended service lifeCarpet cleanersFloor cleanersEngineeringMechanical engineering

The invention discloses a novel flat mop free of hand washing. The mop comprises a flat mop base plate, a mop rod and a stroking head body. The stroking head body is installed on the mop rod in a sliding mode and provided with a stroking opening for the flat mop base plate to penetrate through to squeeze water. An elastic water squeezing part is arranged on the stroking opening and comprises an elastic water squeezing scraping part extending from the inner wall of the stroking opening to the middle of the stroking opening; a water squeezing gap is formed between the front end of the elastic water squeezing scraping part and the opposite inner side face of the stroking head body, and the elastic water squeezing part is arranged in a water squeezing sliding groove obliquely formed in the stroking opening in a sliding mode. The size of the water squeezing gap is automatically adjusted through the elastic water squeezing part arranged in a sliding mode during water squeezing, and the effects of saving labor during pushing down and improving water squeezing efficiency are achieved; the elastic deformation of the elastic water-squeezing scraping blade forms cleaning and water-squeezing effects on the mop, so the water-squeezing efficiency is high; the flat mop is scientific and reasonable in structural design, can effectively relieve mechanical damage of the flat mop base plate to the elastic water squeezing part, prolongs the service life of the elastic water squeezing part, and has the advantages of being small in water splashing, high in mopping efficiency, good in user experience and the like.

Owner:株洲好媳妇家居用品有限公司

Filtering and squeezing unit for filterable materials

ActiveCN106039803AClose in timePrevent unfavorable running water and other situationsStationary filtering element filtersFilter effectMechanical engineering

The invention discloses a filtering and squeezing unit for filterable materials. The filtering and squeezing unit comprises a distribution pipe (17), which is connected to one or more filtering and squeezing machines (18) through feed valves (13). The filtering and squeezing machine comprises a barrel (8), the upper end of which is connected to the feed valve (13) and the lower end of which is provided with a discharge valve (1). An irregular-shaped filter pipe (9) is arranged inside each barrel (8). A positive blow valve (12) is disposed between the feed valve (13) and the barrel (8). The lower part of the barrel (8) is provided with a back-blow outlet valve (2). According to the invention, multiple materials can be filtered and squeezed at the same time, and the operation is carried out under airtight condition. In addition, filtering effect is good, squeezing efficiency is high, filter cakes can be continuously produced, and the operation can be effectively combined with production activities.

Owner:ZHEJIANG DONGOU FILTERING MASCH MFG CO LTD

New fuel pipe extrusion production equipment

ActiveCN112757604BAvoid damageImprove squeeze efficiencyDrying solid materials without heatTubular articlesFluoroplastReduction drive

The invention belongs to the technical field of fuel pipe production, and specifically relates to a new type of fuel pipe extrusion production equipment, including a core material releasing machine, a front traction machine sequentially arranged along the core material conveying path, a compound extruder, and a fluoroplastic extruder , air cooling device, wrapping extruder, cooling tank and rear tractor, the fluoroplastic extruder includes the body, the servo motor installed on the body, the reducer connected to the output end of the servo motor, and the feeder installed on the body The barrel, the screw connected to the output end of the reducer, the cover installed on the machine body, the extrusion barrel passing through the cover, the multiple heating rings set on the extrusion barrel, the extrusion tube connected to the exit of the extrusion barrel head; by adding a drying box at the end of the water tank, when the pipes that have been initially treated by the water tank extend out of the water tank, the water stains on the surface of the pipes can be adsorbed, so that the pipes with less water stains can enter the next step , to avoid the problem of damage to the outer diameter detector caused by excessive water stains.

Owner:GUANGZHOU CHENGXIANG MACHINERY

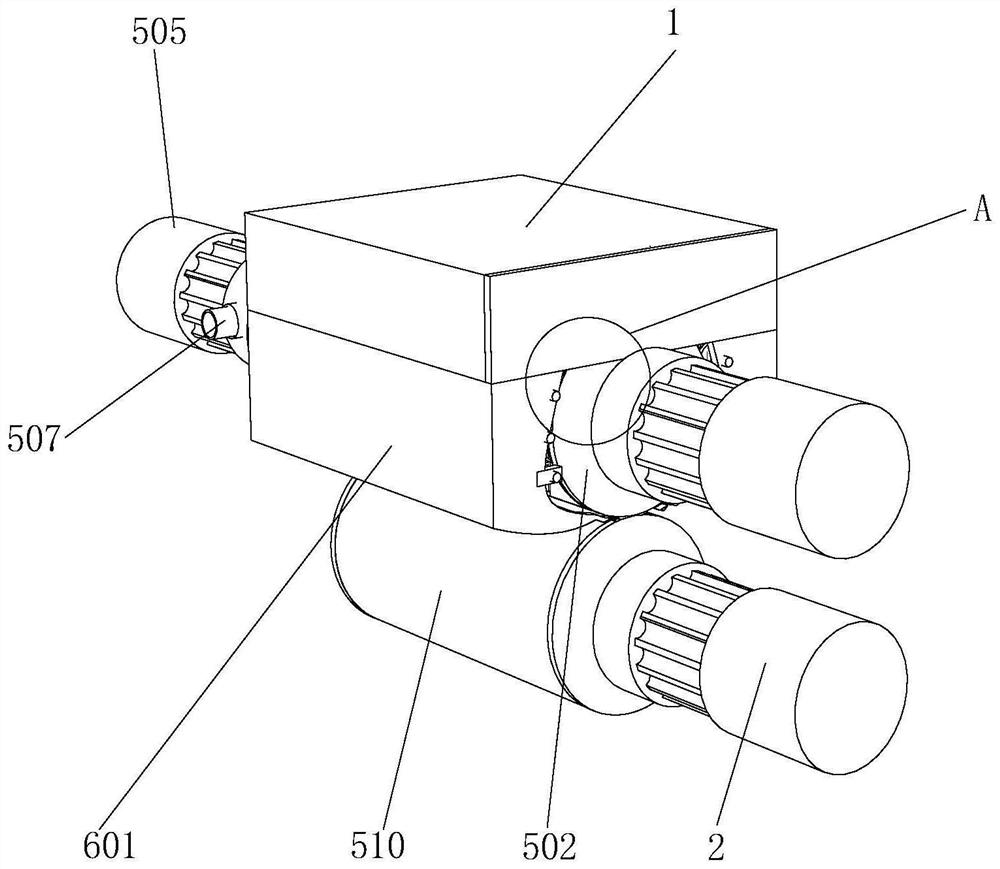

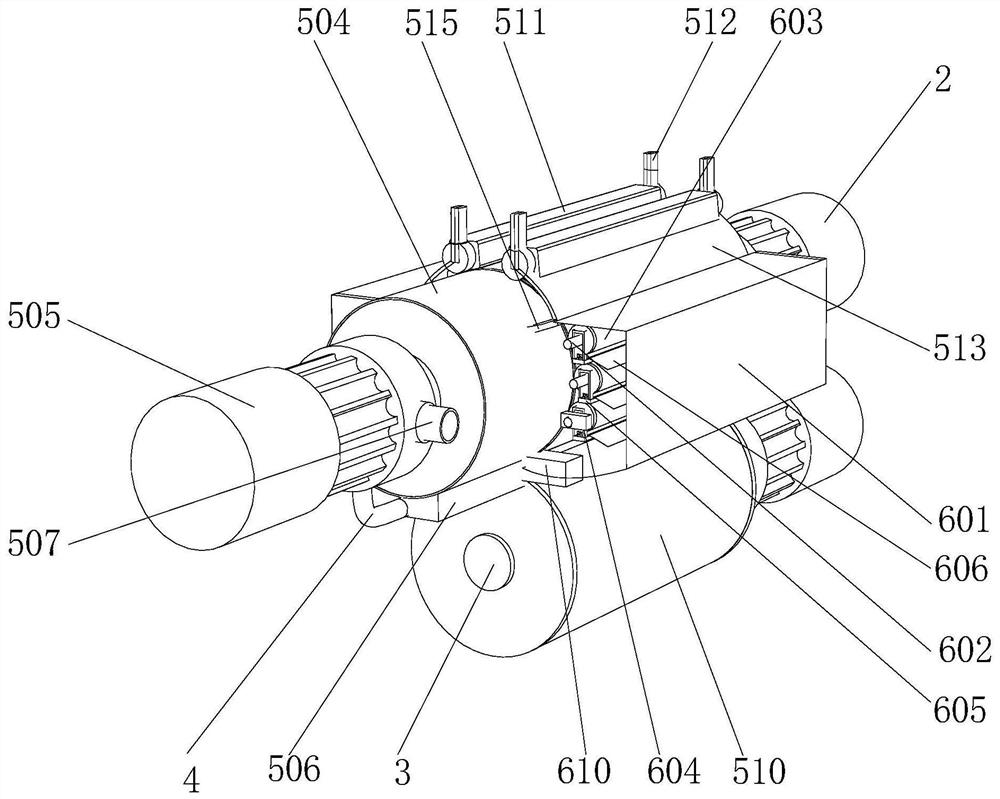

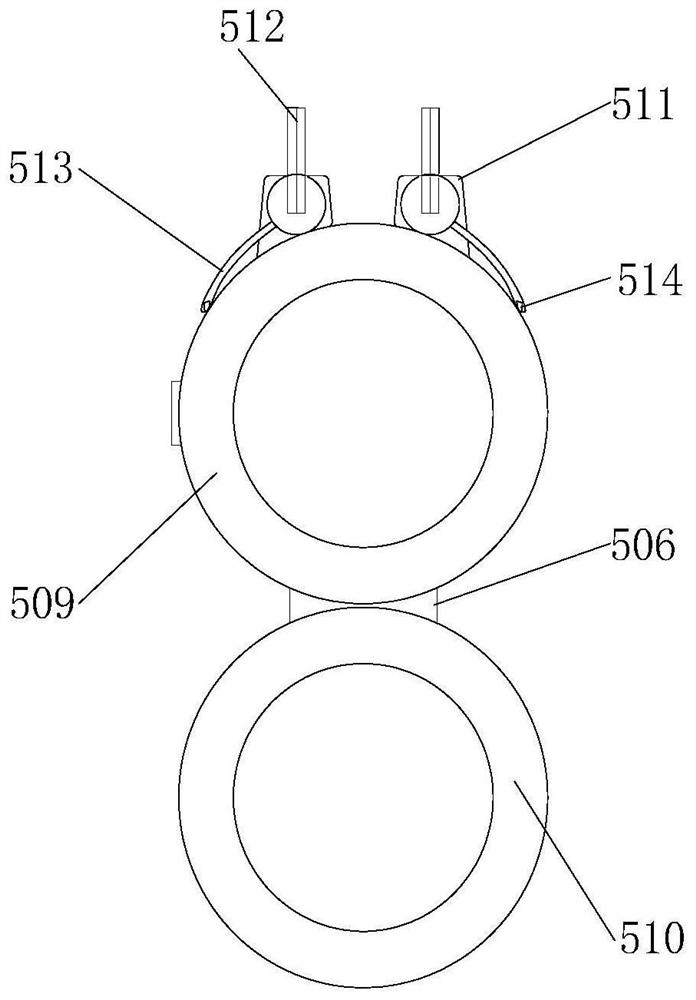

A leather multi-stage squeezing device

ActiveCN112029915BEasy squeezeImprove squeeze efficiencyLeather pressing/rollingSkins/hides/leather/fur manufacturing apparatusStructural engineeringMechanical engineering

The invention provides a leather multi-stage squeezing device, which relates to the technical field of leather processing. The multi-stage water squeezing device for leather includes a casing, a bracket, a water collecting tank, a first transmission device, a water squeezing mechanism, an arc-shaped inclined plate, a flattening mechanism, an adjustment device, a bracket fixedly connected to the bottom of the casing, and a casing. A water collecting tank is arranged between the bottom bracket on the left end, and the water collecting tank is flexibly connected with the casing. The inside of the casing is provided with a first transmission device near the bottom. The left and right sides of the first transmission device are fixedly connected with the inner wall of the casing. The first transmission device There is a water squeezing mechanism on the top, and an arc-shaped sloping plate is installed on the right end of the first transmission device. Both sides of the arc-shaped sloping plate are fixedly connected with the inside of the casing. Adjusting device, the adjusting device slides through the bottom ends of both sides of the casing and is connected with the casing, thereby solving the problems of low water squeezing efficiency during the leather squeezing process and the secondary adsorption of the squeezed water by the leather.

Owner:台州玉釉新材料科技有限公司

A functional non-woven fabric continuous liquid removal device

InactiveCN109722824APrevent backflowAvoid destructionLiquid/gas/vapor removal by suctionLiquid storage tankEngineering

The invention discloses a functional non-woven fabric continuous liquid removal device. The device comprises a liquid storage tank, a first conveying device and third extrusion rollers; the first conveying device is mounted above the liquid storage tank; a liquid outlet is formed in one corner of the liquid storage tank; a fixed bracket is mounted on one side of the upper part of the liquid storage tank; the first conveying device and a second conveying device are mounted on the liquid storage tank through the fixed bracket; a conveying belt is mounted on the outer side of the first conveyingdevice; a first extrusion roller is mounted at one end of the first conveying device; fixing rods are arranged on the two sides of one end of the first conveying device; gear hinges are mounted in thefixing rods; and the second conveying device is installed at one end of the bearing plate; a second extrusion roller is installed at one end of the second conveying device; the bearing plate is arranged on one side of the second extrusion roller; a pair of third extrusion rollers is installed at one end of the bearing plate; and the bearing plate is arranged on one side of the third extrusion rollers.

Owner:HUBEI ZHIQUAN PATENT TECH APPL DEV CO LTD

Water squeezing mechanism

ActiveCN111938530AImprove squeeze efficiencySave spaceCarpet cleanersFloor cleanersStructural engineeringMechanical engineering

The invention discloses a water squeezing mechanism which comprises a squeezing part, a driving part and a linkage part, a mounting base comprises at least two oppositely-arranged wall faces and a vertically-through penetrating opening, and the linkage part is connected with or abuts against the driving part and the squeezing part and is suitable for being in linkage with the driving part and thesqueezing part, so that the driving part and the extruding part are close to each other or far away from each other, and the motion component directions of the driving part and the extruding part in the vertical direction are always opposite; the extruding part and the driving part at least have a first state of being far away from each other and a second state of being close to each other, and inthe second state, the extruding part can extrude and dewater the wiping object placed in the penetrating opening; the water squeezing mechanism further comprises a locking structure enabling the squeezing part to be kept in the second state. The water squeezing mechanism can be switched between two states, the use mode better conforms to habits of consumers, one-time squeezing dehydration is achieved, and the water squeezing mechanism is convenient to use and high in dehydration efficiency.

Owner:永康市清唯工贸有限公司

Functional non-woven fabric liquid removal conveying device

InactiveCN109724369APrevent backflowAvoid destructionDrying solid materials without heatLiquid storage tankNonwoven fabric

The invention discloses a functional non-woven fabric liquid removal conveying device comprising a liquid storage tank, a second conveying device and third pressing rollers. A first conveying device is installed above the liquid storage tank, one corner of the liquid storage tank is provided with a water outlet, a fixing bracket is mounted on one side of the upper portion of the liquid storage tank, the second conveying device is mounted on the liquid storage tank through the fixing bracket, fixing rods are arranged on the two sides of one end of the second conveying device, gear hinges are installed inside the fixing rods, one end of a bearing plate is provided with the second conveying device, one end of the second conveying device is provided with a second pressing roller, one side of the second pressing roller is provided with another bearing plate, one end of the another bearing plate is provided with a pair of third pressing rollers, and one sides of the third pressing rollers are provided with another bearing plate.

Owner:HUBEI ZHIQUAN PATENT TECH APPL DEV CO LTD

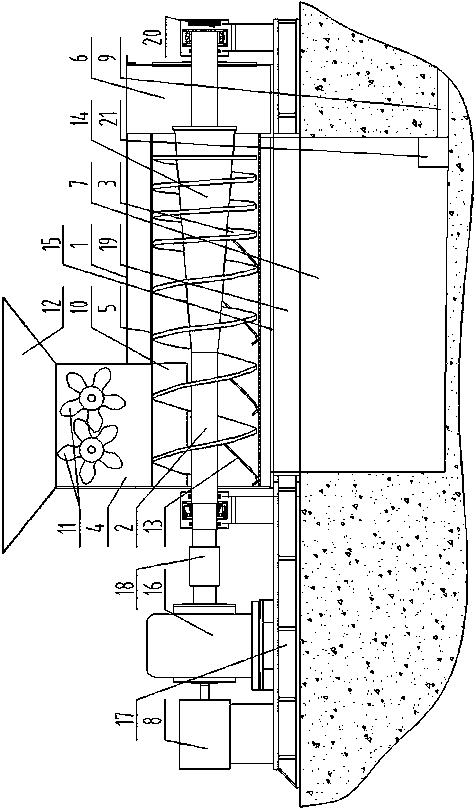

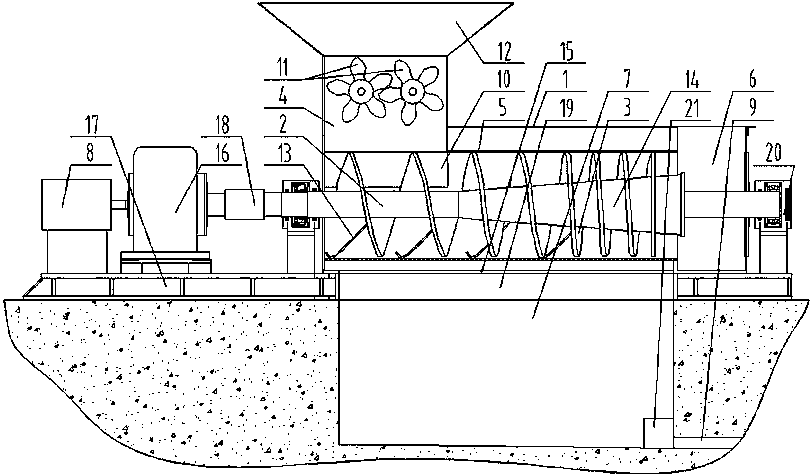

Slag extruding machine of sisal hemp leaf slag-juice separation production line

The invention discloses a slag extruding machine of a sisal hemp leaf slag-juice separation production line. The slag extruding machine is characterized in that a feeding port is formed in one end ofthe top of a water extruding tank, the other end of the top of the water extruding tank is provided with a discharging port, a partition plate located between the feeding port A and the discharging port in the water extruding tank divides the water extruding tank into a water extruding groove and a slag discharging groove, a water extruding pipe is fixedly connected in the water extruding groove,the pipe wall of the water extruding pipe is a mesh plate with a plurality of water filtering holes uniformly distributed, a notch is formed in the position, correspondingly located below the feedingport A, of the top of the water extruding pipe to form a feeding port B, a slag extruding roller is rotationally connected into the water extruding pipe, a water extruding plate of a spiral structureis arranged on the surface of the slag extruding roller in the axial direction of the slag extruding roller, and a liquid discharge port is formed in the position, on one side of the water extruding groove, of the bottom of the water extruding tank. According to the structure, the slag extruding machine of the sisal hemp leaf slag-juice separation production line has the effects that by means of the mechanical extrusion force, leaf pulp is extruded, so that juice in the leaf pulp is extruded as much as possible, then the recovery amount of the sisal juice is improved, and the extruded slag canbe further collected.

Owner:JIANGSU HIMALAYA NATURAL FIBER PROD

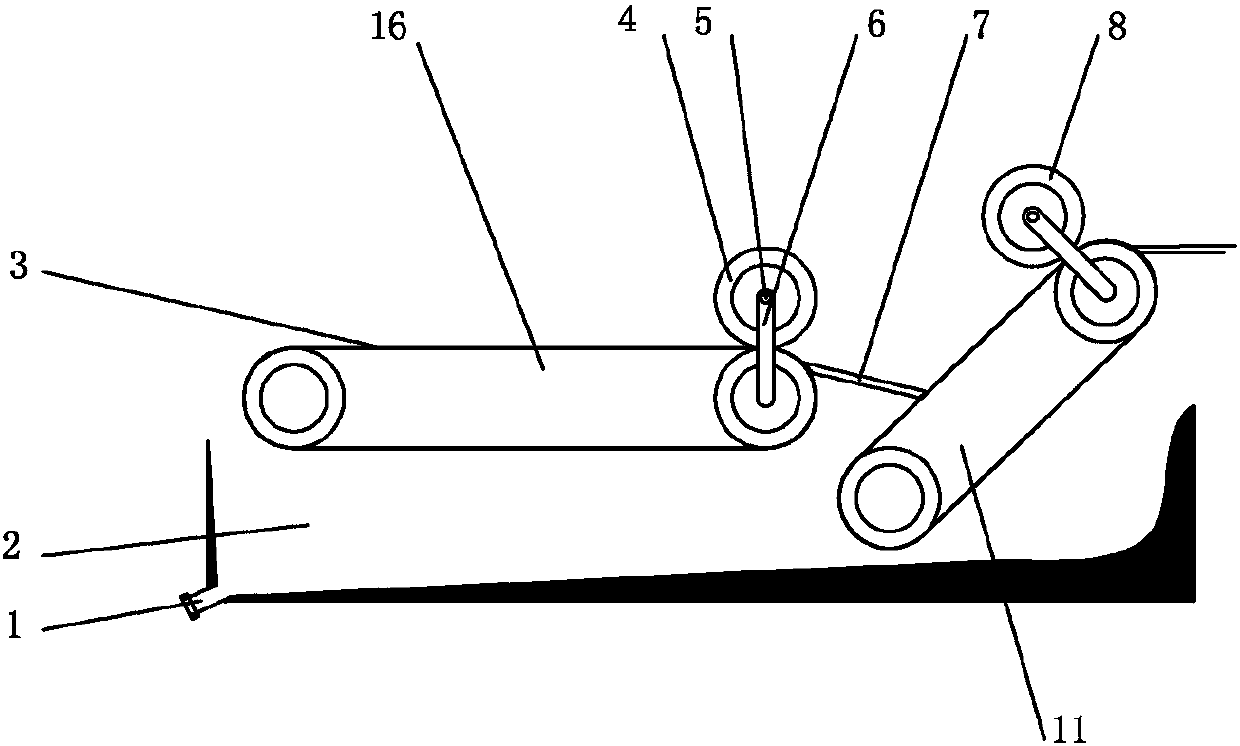

floor cleaner

ActiveCN104594271BEffective squeezeImprove squeeze efficiencyCarpet cleanersFloor cleanersSewageEngineering

A floor cleaner, comprising: a floor cleaning mechanism (1), comprising two frames (11), positions thereof being fixed relative to each other, and a main shaft (13) and rollers (15), each having two ends respectively and rotatably disposed on the two frames (11), a water absorption cloth (16) having two closed ends and being wound on the roller (15), and a water storage compartment (17) disposed below the main shaft (13). The rollers (15) are on a front side and a rear side of the main shaft (13). A lowest free surface of the water absorption cloth (16) is lower than a bottommost part of the frame (11). The floor cleaning mechanism also comprises side shafts (14), each having two ends respectively and rotatably disposed on two sides of the frames (11) and rotating in a direction opposite to a rotation of the main shaft (13). The water absorption cloth (16) is wound on the side shaft (14) and the main shaft (13) in opposite directions, and a portion of the water absorption cloth (16) between the side shaft (14) and the main shaft (13) is squeezed by the side shaft (14) and the main shaft (13). The floor cleaner can prevent a secondary contamination of a floor by dirty water.

Owner:NINGBO ELMAR ELECTRIC MFG CO LTD

A functional non-woven fabric continuous conveying device

InactiveCN109722822APrevent backflowAvoid destructionLiquid/gas/vapor removal by suctionEngineeringNonwoven fabric

The invention discloses a functional non-woven fabric continuous conveying device. The device comprises a first conveying device and a second conveying device; a conveying belt is mounted on the outerside of the first conveying device; a first extrusion roller is mounted at one end of the first conveying device; fixing rods are arranged on the two sides of one end of the first conveying device, gear hinges are installed in the fixing rods, the second conveying device is installed at one end of a bearing plate, a second extrusion roller is installed at one end of the second conveying device, and the bearing plate is arranged on one side of the second extrusion roller.

Owner:HUBEI ZHIQUAN PATENT TECH APPL DEV CO LTD

Leather wringing device

InactiveCN112029916AImprove squeeze efficiencyImprove water squeeze effectSkins/hides/leather/fur manufacturing apparatusLeather dryingElectric machineryDrive motor

The invention provides a leather wringing device, and relates to the technical field of leather processing. The leather wringing device comprises a machine shell, a water collecting tank, a support, afirst transmission device, a first driving motor, a wringing mechanism, a second transmission device, a third transmission device, an adsorption mechanism, a second driving motor, a third driving motor and a fourth driving motor; the water collecting tank is arranged in the middle of the left side of the machine shell; the first transmission device is arranged on the left side in the machine shell; the wringing mechanism is arranged above the first transmission device; the second driving motor is fixedly connected to the top end of the wringing mechanism; the second transmission device is arranged at the right end of the first transmission device; the third transmission device is arranged at the right end of the second transmission device; and adsorption mechanisms are arranged inside andabove the third transmission device. The problems that the wringing efficiency is low due to the secondary water absorption phenomenon of the leather in the wringing process of the leather and the softness of the leather becomes poor due to the fact that the drying time is too long due to residual water on the surface of the leather after wringing are solved.

Owner:高焕梅

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com