A filter and squeeze drying unit for easy-to-filter materials

A squeeze dryer and material technology, which is applied in the field of processing equipment for easy-to-filter materials, can solve the problems of large labor costs, low filter cake density, inconvenient production, etc., and achieve energy saving, high squeezing efficiency, and improved efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

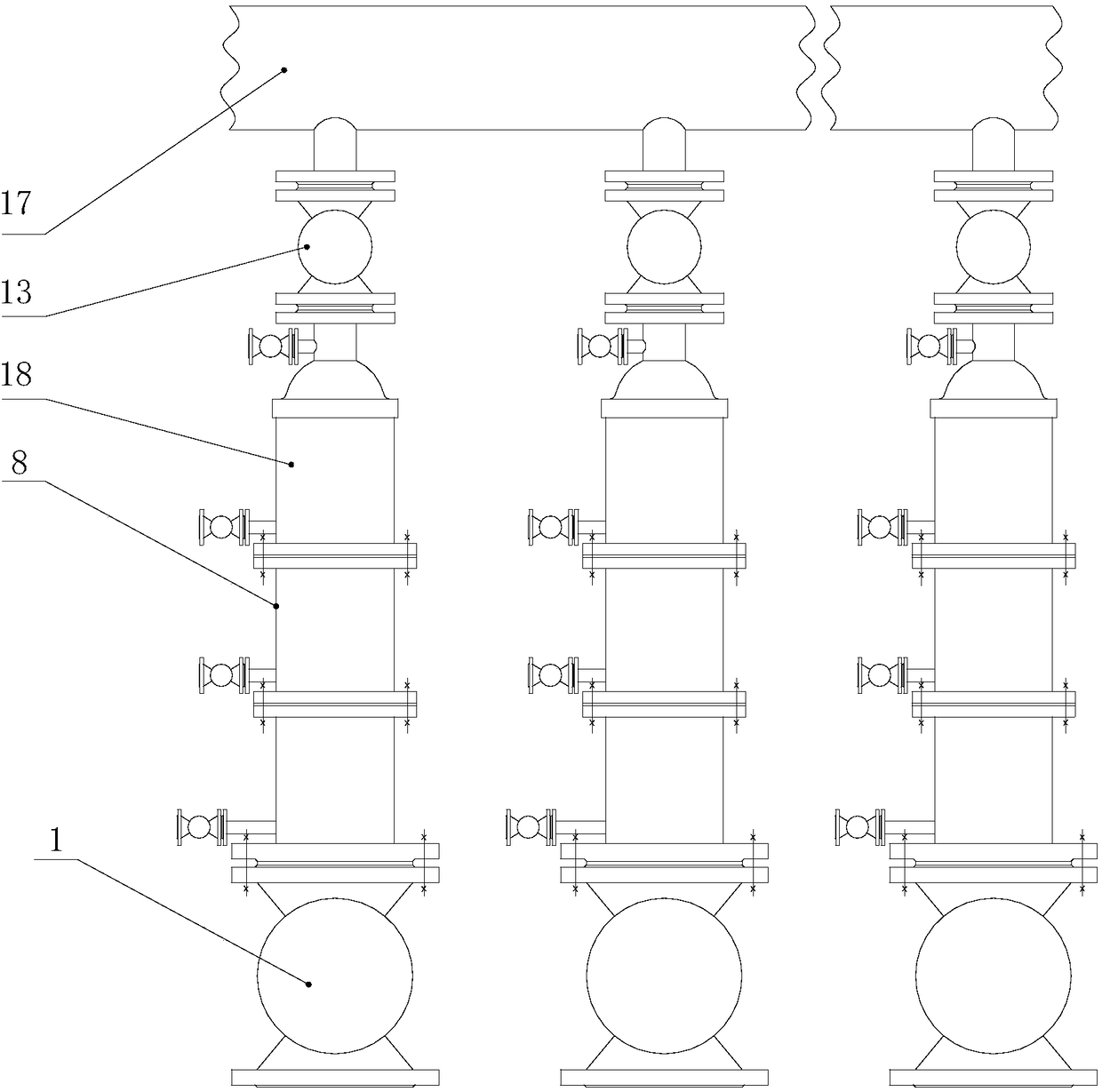

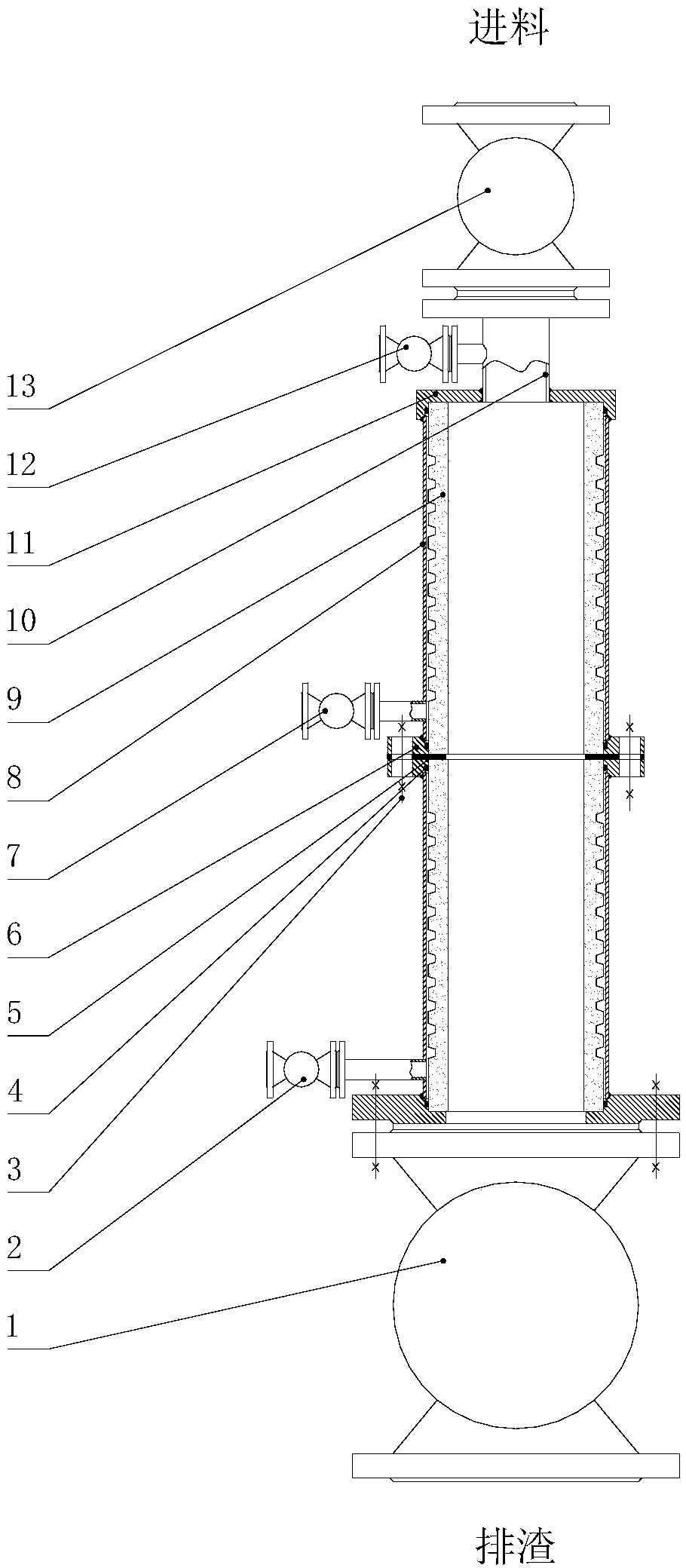

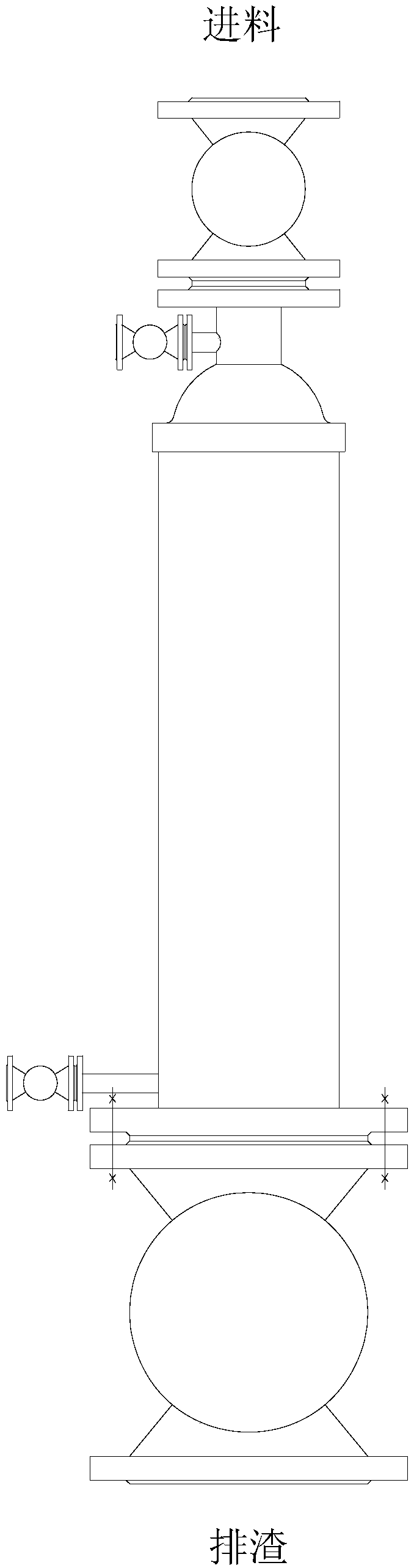

[0030] Example. A filter and squeeze drying unit for easy-to-filter materials, which is composed of figure 1 with 2 As shown, the distribution pipe 17 is included, and the distribution pipe 17 is connected with one or more filter squeezers 18 through the feed valve 13. The filter squeeze dry machine includes a cylinder 8, and the upper end of the cylinder 8 is connected with the feed valve 13. 8. A discharge valve 1 is provided at the lower end of the cylinder body 8. A special-shaped filter tube 9 is provided inside the cylinder body 8. A forward blowing slag discharge valve 12 is provided between the inlet valve 13 and the cylinder body 8. A reverse blowing discharge valve 12 is provided at the bottom of the cylinder body 8. valve 2.

[0031] Such as Figure 4 As shown, the cross-section of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com