Collodion slab mop cleaning barrel

A technology of flat mop and cleaning bucket, which is applied to cleaning carpets, floors, cleaning equipment, etc. It can solve the problems of large size, inability to clean in small spaces, inconvenient use, etc., and achieves convenient operation, stable and reliable water squeezing effect, and movement stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

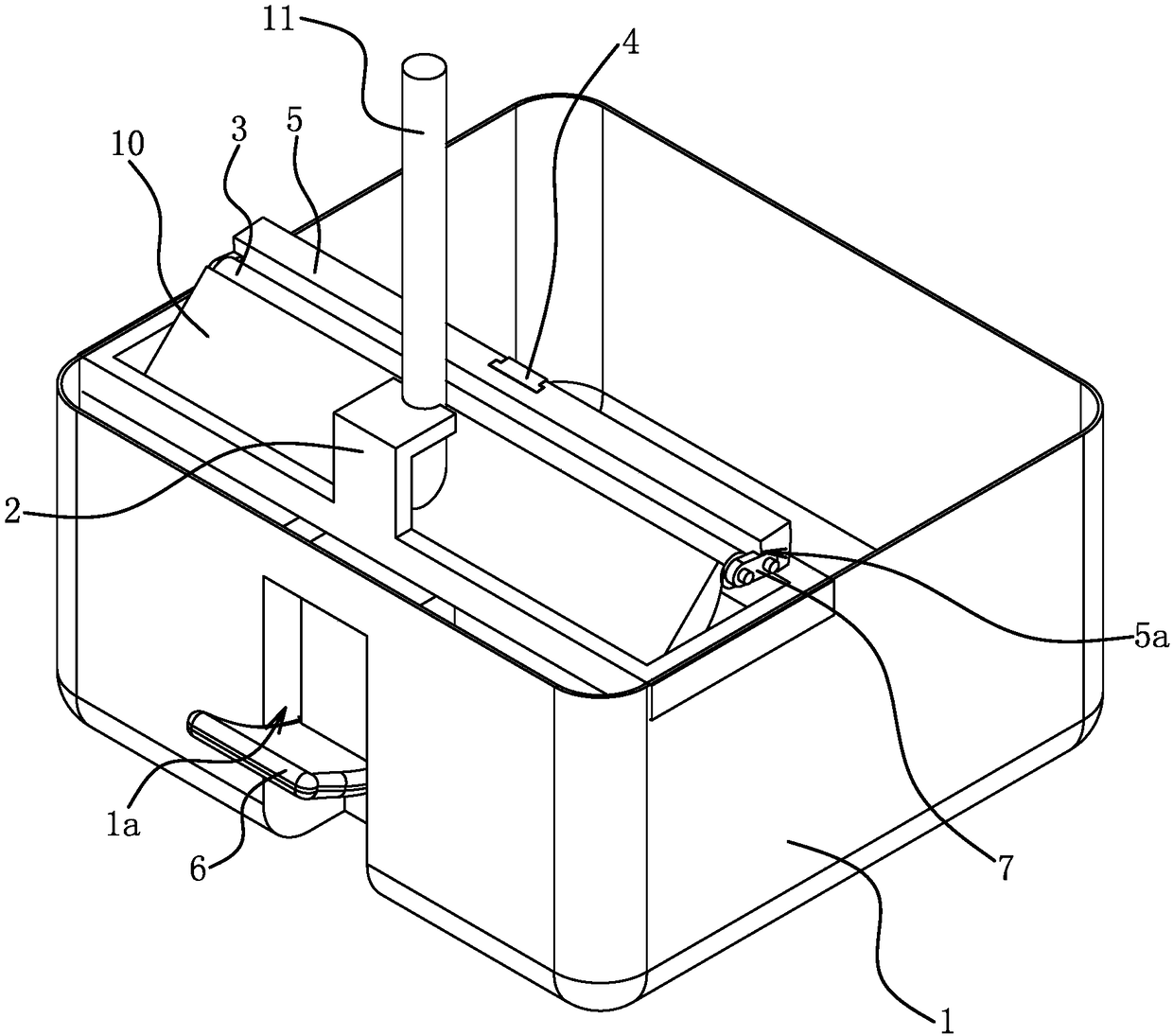

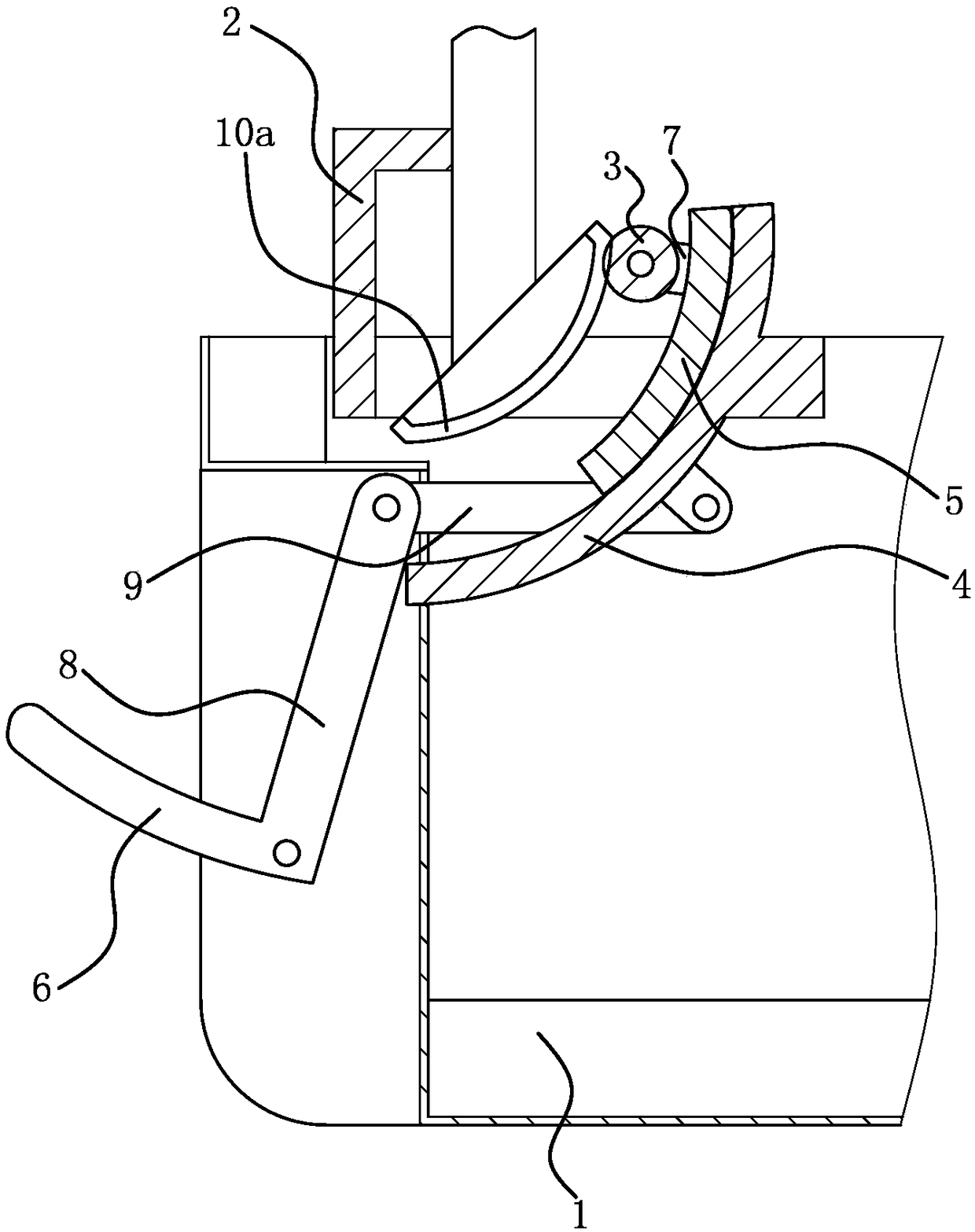

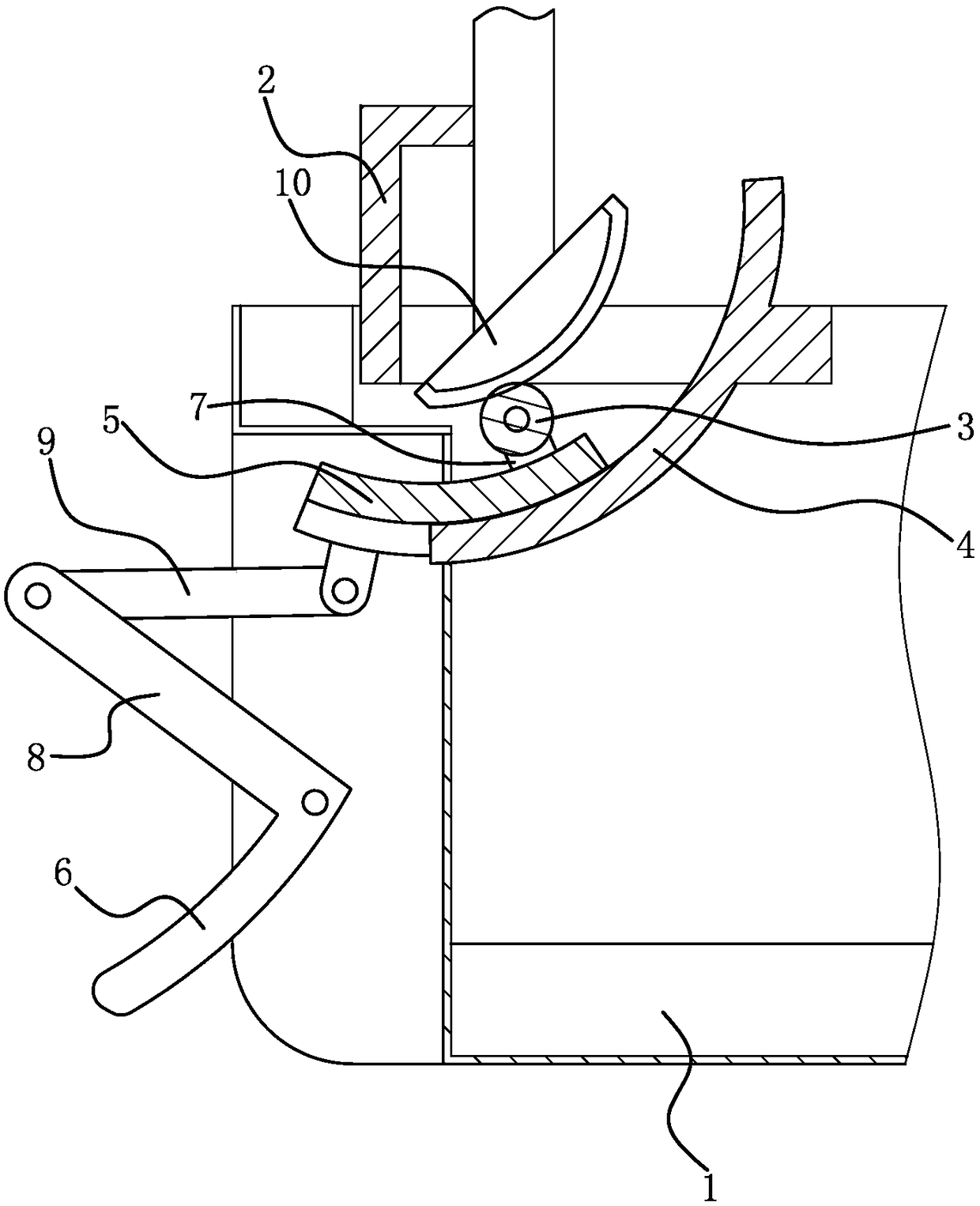

[0018] Such as Figure 1 to Figure 3 As shown, the collodion mop cleaning bucket includes a bucket body 1, a backing 2, a squeezing roller 3, an arc guide rail 4, a sliding seat 5 and a pedal 6.

[0019] The brim of barrel body 1 is fixedly connected with backing 2, and backing 2 is for the working head 10 backside of collodion flat mop or mop handle 11 root parts to lean against, realizes limiting that collodion flat mop moves upwards. By controlling the inclination angle of the abutment surface in the backer 2, the orientation of the working face of the working head 10 can also be controlled; The collodion flat mop leaning against the backer 2 is in the best water-squeezing state.

[0020] The arc guide rail 4 is located in the barrel body 1 and both ends of the arc guide rail 4 are fixedly connected with the barrel body 1, and the concave surface of the arc guide rail 4 faces the backer 2. The position and orientation of the arc guide rail 4 match the working surface of t...

Embodiment 2

[0028] The structure and principle of this embodiment are basically the same as those of Embodiment 1, and the basic similarities will not be described redundantly, only the differences will be described, and the differences lie in the transmission mechanism. The transmission mechanism includes a steel cable and a reversing roller connected in rotation with the barrel body 1. The steel cable passes through the wheel surface of the reversing roller. One end of the steel cable is connected with the sliding seat 5, and the other end of the steel cable is connected with the pedal 6. A return spring is provided between the seat 5 and the barrel body 1, and a second spring may not be arranged between the pedal 6 and the barrel body 1 . When people step on the pedal 6, the pedal 6 swings and pulls the cable, and the cable pulls the slide 5 to move down along the arc guide rail 4; when the pedal 6 is released, the slide 5 is forced to reset under the elastic force of the return spring,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com