Bean curd cloth dehydrating and coiling machine

A cloth rolling machine, tofu technology, applied in the direction of winding strips, sending objects, cleaning methods and utensils, etc., can solve the problems of inconvenient operation, long dehydration time, large power consumption, etc., and achieve simple and convenient operation, extrusion The effect of high water efficiency and low water content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

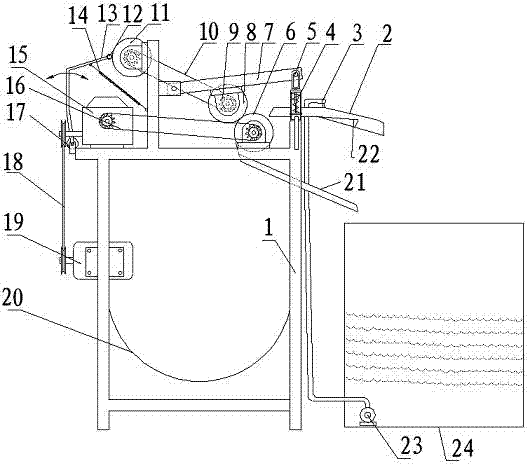

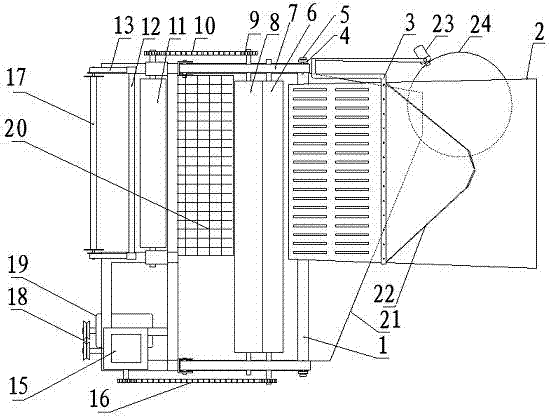

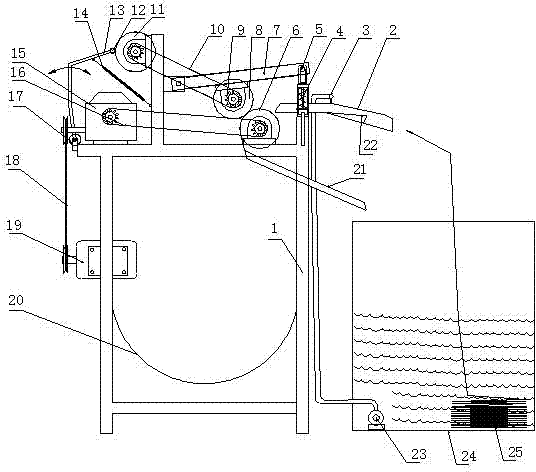

[0016] Examples of the present invention figure 1 , figure 2 , image 3 , Figure 4 As shown, it includes a frame 1, a screen 20, a transmission device, a cloth rolling mechanism, and a cleaning device; the transmission device and the cloth rolling mechanism are installed on the frame 1; the transmission device includes a tensioner 4, a hook 5, and a lower rubber roller 6 , upper rubber roller support 7, upper rubber roller 8, sprocket wheel 9, chain 10, rolling cloth transmission wheel 11, reducer 15, lower roller transmission chain 16, transmission belt 18, motor 19; upper rubber roller support 7 is hingedly installed on On the frame 1; the tensioner 4 is installed between the upper rubber roller bracket 7 and the bracket 1 through the hook 5; the rotating shaft of the upper rubber roller 8 is installed on the upper rubber roller bracket 7, and the sprocket wheel is installed on the upper rubber roller 8 rotating shaft; The rotating shaft of the lower rubber roller 6 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com