New fuel pipe extrusion production equipment

A technology for production equipment and fuel pipes, which is applied in the field of new fuel pipe extrusion production equipment, can solve problems such as damage to the outer diameter detector, achieve good water absorption and increase the water squeezing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

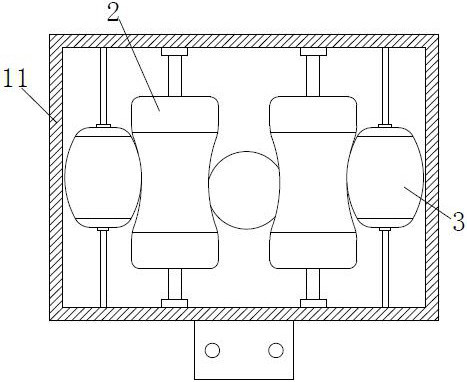

[0032] As an embodiment of the present invention, a No. 1 telescopic rod 21 is fixedly connected between the water-absorbing sponge 2 and the rotating rod; the end of the No. 1 telescopic rod 21 is fixed inside the water-absorbing sponge 2; 21 is covered with a spring 22; one end of the spring 22 is fixedly connected to the side wall of the No. 1 telescopic rod 21, and the other end is fixedly connected to the middle part of the rotating rod; Multiple sets of supporting columns 23; the supporting columns 23 are rotatably connected with a No. 2 telescopic rod 24; one end of the No. 2 telescopic rod 24 is hinged to the middle part of the No. 1 telescopic rod 21, and the other end is fixedly connected to the inner side wall of the water-absorbing sponge 2; While the pipe material squeezes the water-absorbent sponge 2, because the pipe material will contact the middle part of the water-absorbent sponge 2, the No. 1 telescopic rod 21 inside the water-absorbent sponge 2 will be pushe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com