Water squeezing part, water squeezing device and cleaning equipment for flat mop

A flat-panel mop and component technology, applied in the field of cleaning tools, can solve the problems of low water squeezing efficiency, unclean squeezing, backflow into the mop head, etc., and achieve the effect of compact structure, reasonable design, and improved water squeezing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

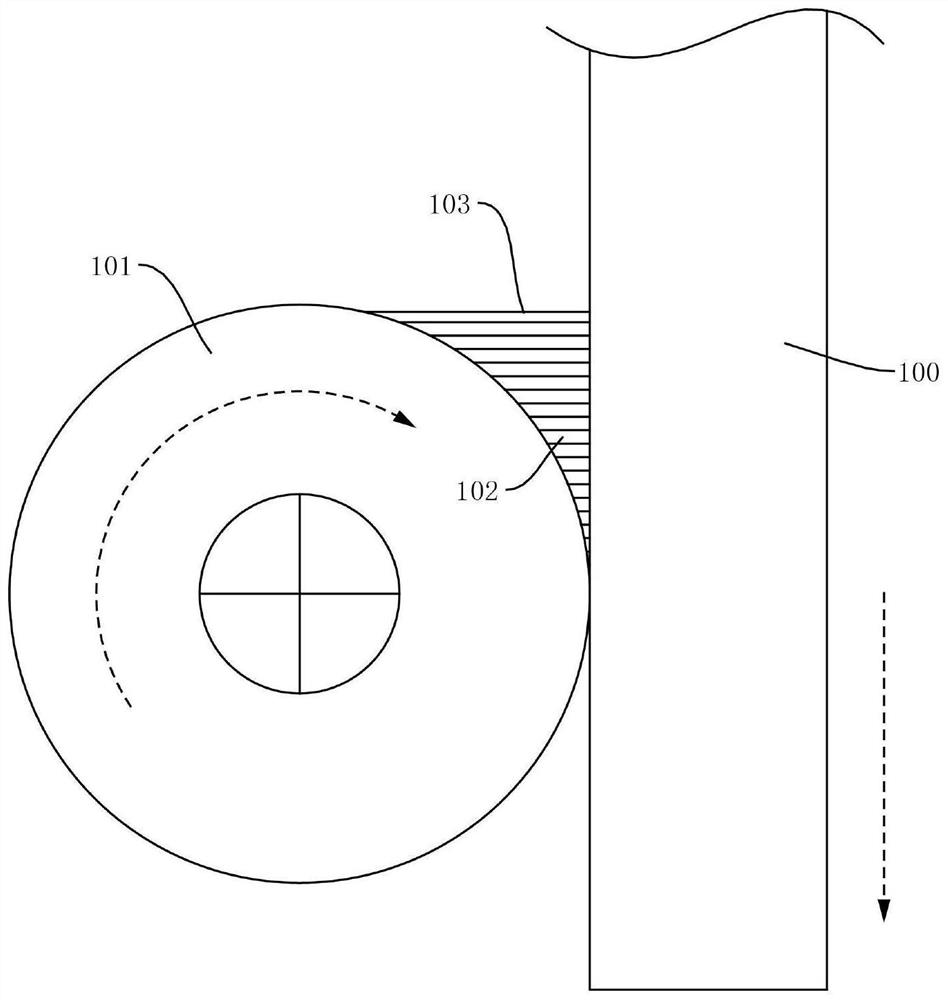

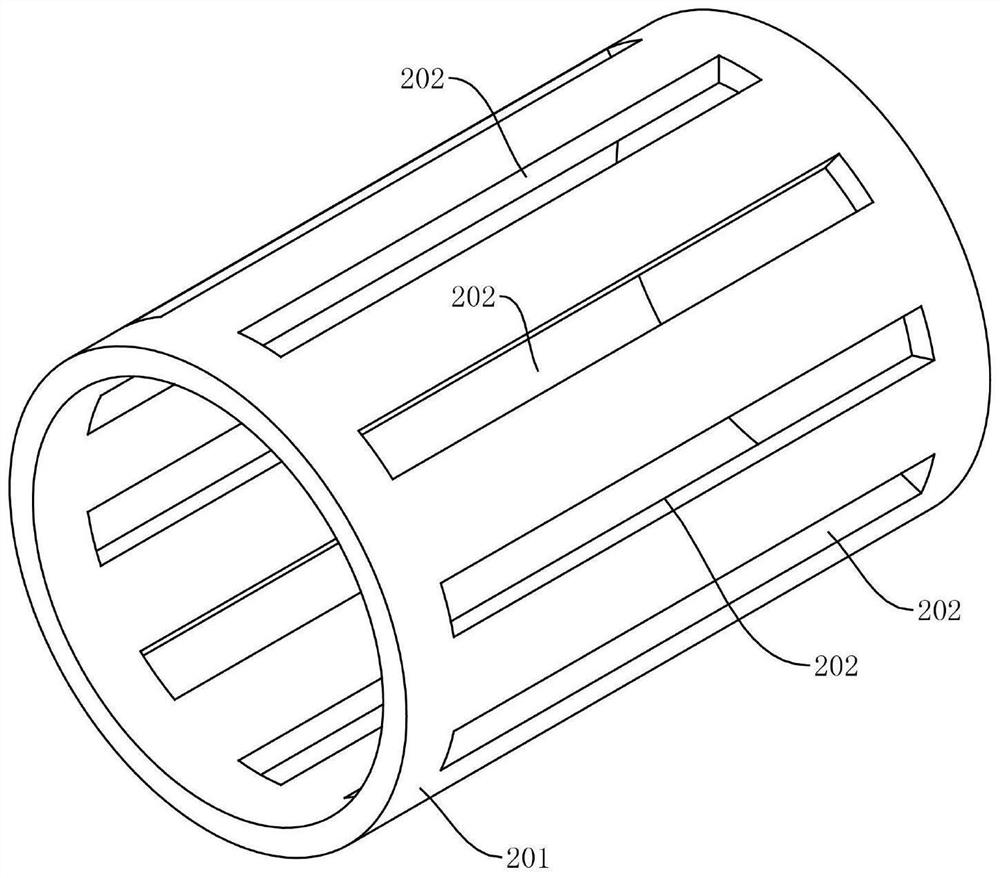

[0054] see Figure 2-Figure 6 , the present embodiment provides a water squeezing part for a flat mop, including a rotating member, and the rotating member includes a water squeezing part 201 for squeezing the mop head 100 and rotating with the movement of the mop head 100, The outer surface of the water squeezing part 201 is configured with several drainage ports 202, such as Figure 2-Figure 6 As shown, the drainage port 202 is used to follow the rotation of the water squeezing part 201, and when it is rotated between the water squeezing part 201 and the mop head 100, the drainage port 202 is used to guide the squeezed water from the drainage port 202 into the squeezing part 202. The squeezed water part 201 prevents the squeezed water from flowing back to the mop head 100, so that the squeezed water part 201 has the functions of squeezing water and guiding water at the same time.

[0055]Specifically, in this embodiment, the rotating member includes a water squeezing part 2...

Embodiment 2

[0072] In order to solve the problem of the installation of the squeeze part 201 and the drainage of internal water, the main difference between this embodiment 2 and the above-mentioned embodiment 1 is that this embodiment provides another structure of the support member 206, specifically, in this embodiment In an example, the supporting member 206 is arranged inside the rotating member, and the end of the supporting member 206 can extend out of the rotating member, such as Figure 7-Figure 9As shown, in order to install the movable support member 206, it is also possible not to extend the rotary member;

[0073] Such as Figure 7-Figure 9 As shown, in this embodiment, the drainage part includes several partitions 209 constructed between the support member 206 and the rotating member, and the partitions 209 are respectively connected to the supporting member 206 and the rotating member, and two adjacent partitions The part 209, the supporting member 206 and the rotating memb...

Embodiment 3

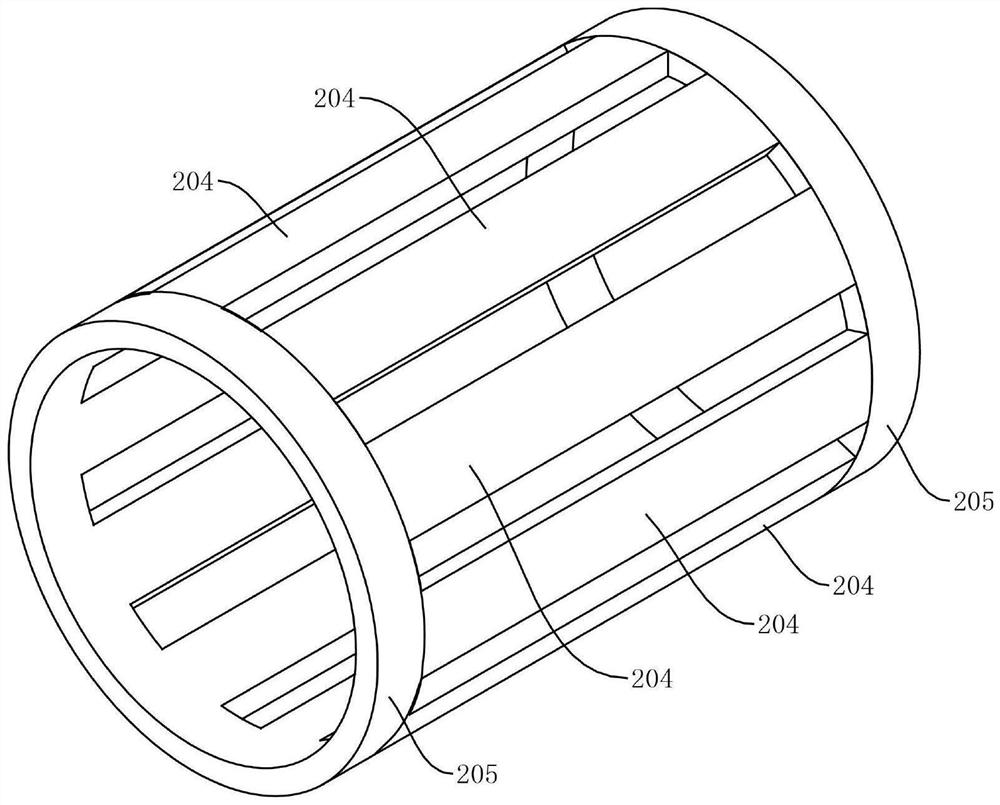

[0077] In order to solve the problem that the mop head 100 is easily deformed to both ends of the water squeezing part 201 during the extrusion process between the mop head 100 and the water squeezing part 201, resulting in low water squeezing efficiency, the third embodiment and the above embodiment 1 or implementation The main difference of Example 2 is that, in the water squeezing member 200 provided in this embodiment, the rotating member also includes a constraining portion 212 configured at the end of the water squeezing part 201 along the circumferential direction of the center axis of rotation of the water squeezing part 201, as Figure 10-Figure 16 As shown, the inner surface 213 of the constraining part 212 close to the squeeze part 201 can be a torus or a circular table surface, and the inner surface 213 is used to constrain and squeeze the mop head 100; specifically, in this embodiment, By constructing the restricting part 212 distributed along the circumferential d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com