Floating technology for low-grade refractory weathering collophanite section desliming

A low-grade collophosite technology, applied in flotation, solid separation, wet separation, etc., can solve problems such as high content of fine particles, deterioration of the separation environment, and interference in the flotation process, so as to avoid secondary adsorption, The effect of avoiding wastewater treatment discharge and reducing chemical consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

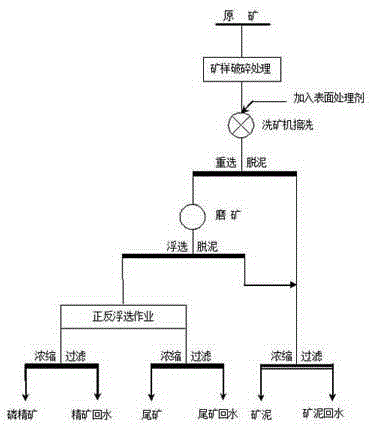

[0028] A sub-stage desliming and flotation process of low-grade refractory weathered collophosite, which is carried out according to the following steps:

[0029] (1) Gravity separation and desliming: first take 1000g of finely crushed phosphate rock sample, pour it into the washing machine, then add 20ml of water glass with a mass volume concentration of 10%, and finally fill the washing machine with water for stirring and scrubbing After 10 minutes, the scrubbed slurry enters the ore shaker for desliming treatment to obtain coarse minerals and fine mud;

[0030] (2) Flotation desliming: Grinding the coarse-grained minerals obtained by the shaking table to obtain a slurry with a mass fraction of -0.074mm accounting for 92.5%, then adding to the flotation machine, adding No. 2 oil 80g / t and stirring for 3 minutes, aerating Scraping to get flotation slime and underflow. (3) Positive and negative flotation: adopting an appropriate reagent system, under the condition of flotatio...

Embodiment 2

[0033] A sub-stage desliming and flotation process of low-grade refractory weathered collophosite, which is carried out according to the following steps:

[0034] (1) Gravity separation and desliming: first take 1000g of finely crushed phosphate rock sample, pour it into the washing machine, then add 25ml of water glass with a mass volume concentration of 10%, and finally fill the washing machine with water for stirring and scrubbing After 15 minutes, the scrubbed slurry enters the ore shaker for desliming treatment to obtain coarse minerals and fine mud;

[0035] (2) Desliming by flotation: Grinding the coarse-grained minerals obtained by the shaking table to obtain a pulp with a mass fraction of -0.074mm accounting for 95%, then adding it to the flotation machine, adding No. 2 oil 100g / t and stirring for 3 minutes, aerating Scraping to get flotation slime and underflow;

[0036] (3) Positive and negative flotation: adopt the appropriate reagent system, under the condition o...

Embodiment 3

[0039] A sub-stage desliming and flotation process of low-grade refractory weathered collophosite, which is carried out according to the following steps:

[0040] (1) Gravity separation and desliming: first take 1000g of finely crushed phosphate rock sample, pour it into the washing machine, then add 22ml of water glass with a mass volume concentration of 10%, and finally fill the washing machine with water for stirring and scrubbing After 12 minutes, the scrubbed slurry enters the ore shaker for desliming treatment to obtain coarse minerals and fine mud;

[0041] (2) Desliming by flotation: Grinding the coarse-grained minerals obtained by the shaking table to obtain a pulp with a mass fraction of -0.074mm accounting for 93.8%, then adding to the flotation machine, adding No. 2 oil 90g / t and stirring for 2.5min, Inflate and scrape bubbles to obtain flotation slime and underflow;

[0042] (3) Positive and negative flotation: adopt the appropriate reagent system, under the cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com