Welding sealing system and welding sealing process

A technology of welding sealing and process, applied in metal material coating process, process for producing decorative surface effect, decorative art, etc., can solve the problem of high residual water vapor content, achieve a high degree of automation, meet the needs of mass production, Avoid the effects of increased moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

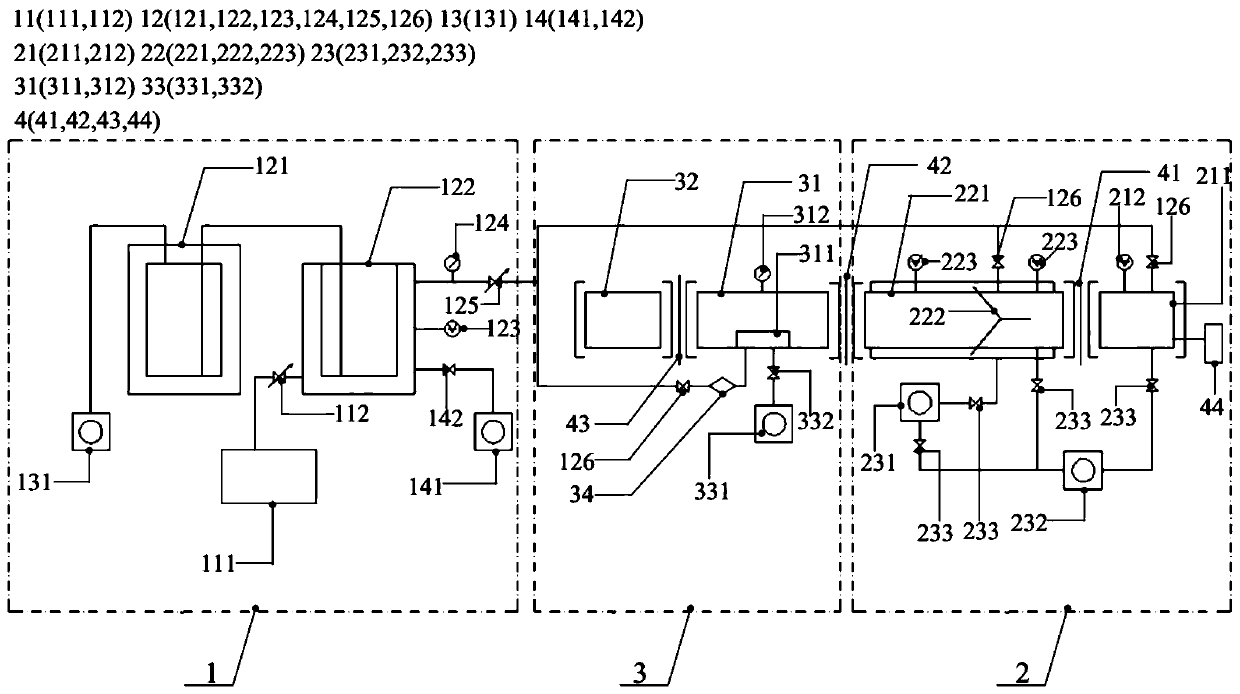

[0074] This embodiment provides a welding sealing system, such as figure 1 As shown, it includes an air filling module 1 , a baking module 2 , a welding module 3 and a transfer module 4 . Wherein, the gas filling module 1 includes a gas supply unit 11 and a condensing unit 12, which are used to provide the baking module 2 and the welding module 3 with process gas in which impurity gases such as water vapor have been removed; the baking module 2 includes a pretreatment unit 21, a baking Unit 22 and the first air extraction unit 23 are used to carry out degassing and baking treatment for the seal to be sealed; the welding module 3 includes a welding unit 31, a discharge unit 32 and a second air extraction unit 33, and the welding module 3 is received by baking The parts to be sealed outputted by the module 2 are welded and sealed under the protection of the process gas atmosphere in the welding module 3 . The transfer module 4 includes a first transfer structure located between...

Embodiment 2

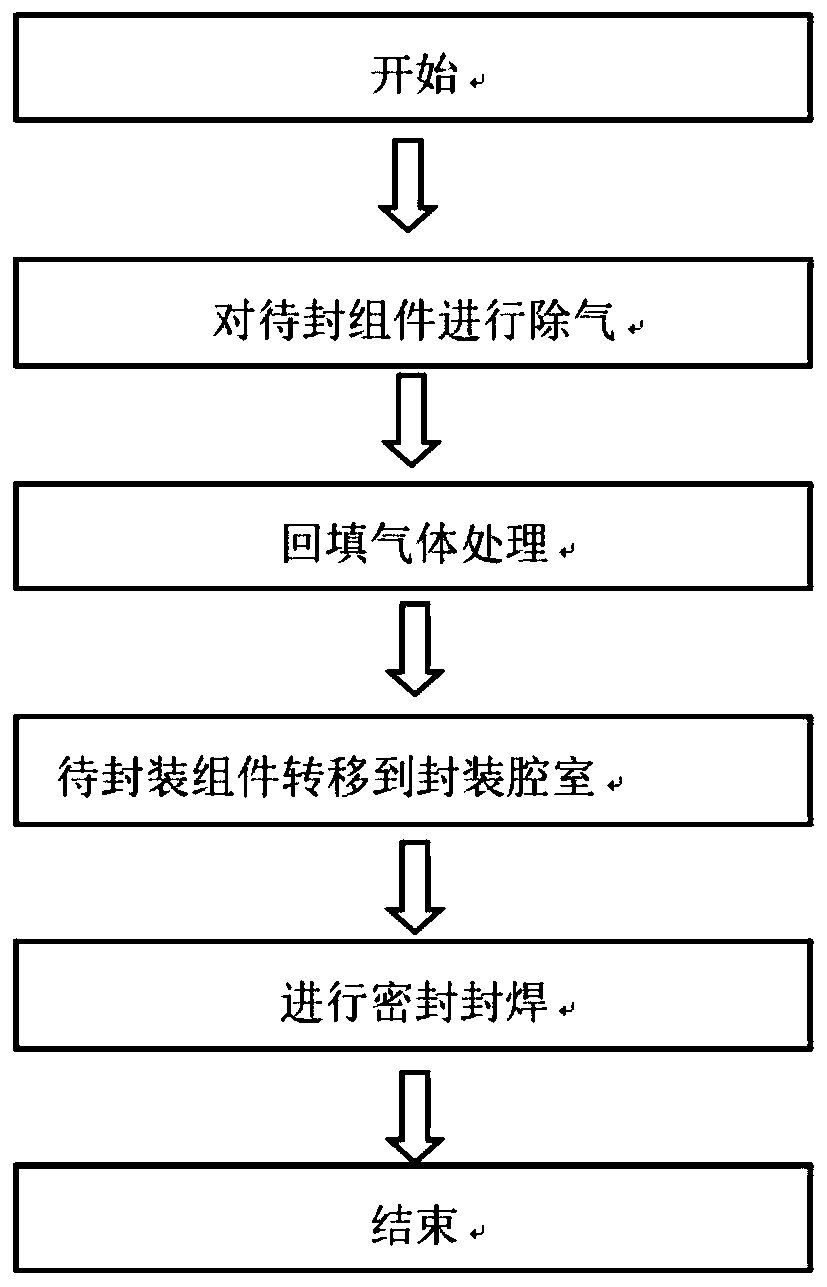

[0087] This embodiment provides a welding and sealing process. The welding and sealing process applies the welding and sealing system in Example 1, which specifically includes the following steps:

[0088] S1, performing gas desorption and baking treatment on the to-be-sealed member in the first reaction zone, and the baking treatment is carried out in a vacuum environment;

[0089] Specifically, in the pretreatment unit 21 located in the first reaction zone, the gas desorption treatment of the parts to be sealed is carried out, and then the parts to be sealed are transferred to the quartz vacuum chamber of the baking unit 22 in the first reaction zone for baking treatment. . During the baking process, the dry pump and the cold pump of the first pumping unit 23 pump air into the quartz vacuum chamber, so that the baked gas is continuously removed, and the vacuum environment of the quartz vacuum chamber is maintained. The temperature of the baking treatment is 140-200°C, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com