Equipment for fermenting mandarin orange, coarse grain, rice flour and fruit enzyme

A technology for fruit enzymes and fermentation equipment, which is applied in biochemical equipment and methods, bioreactor/fermenter combinations, bioreactors/fermenters for specific purposes, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

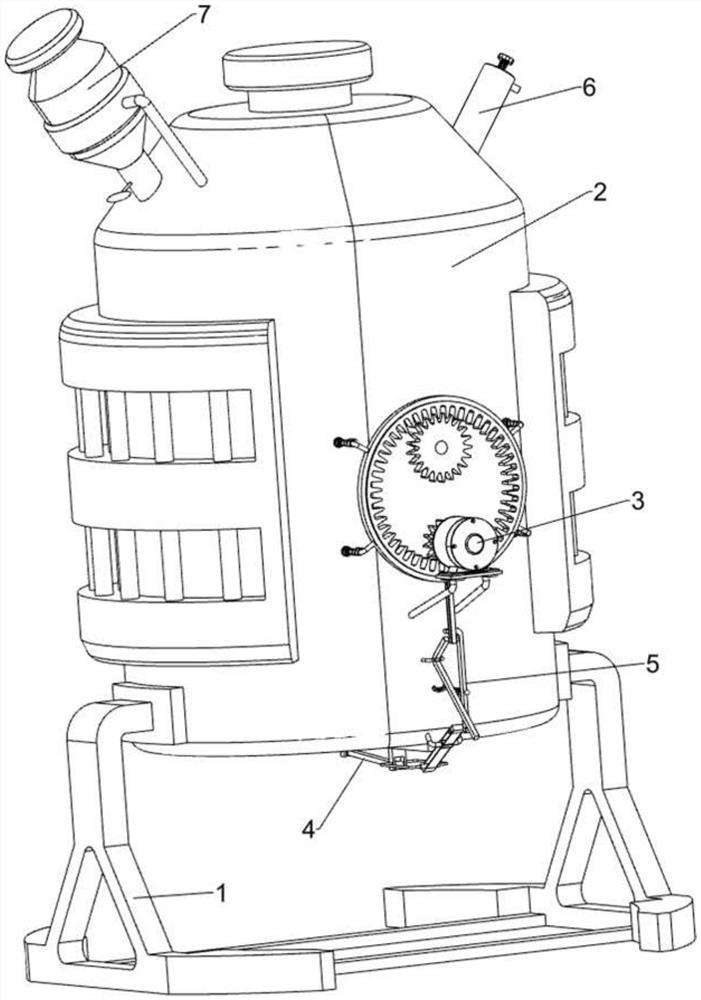

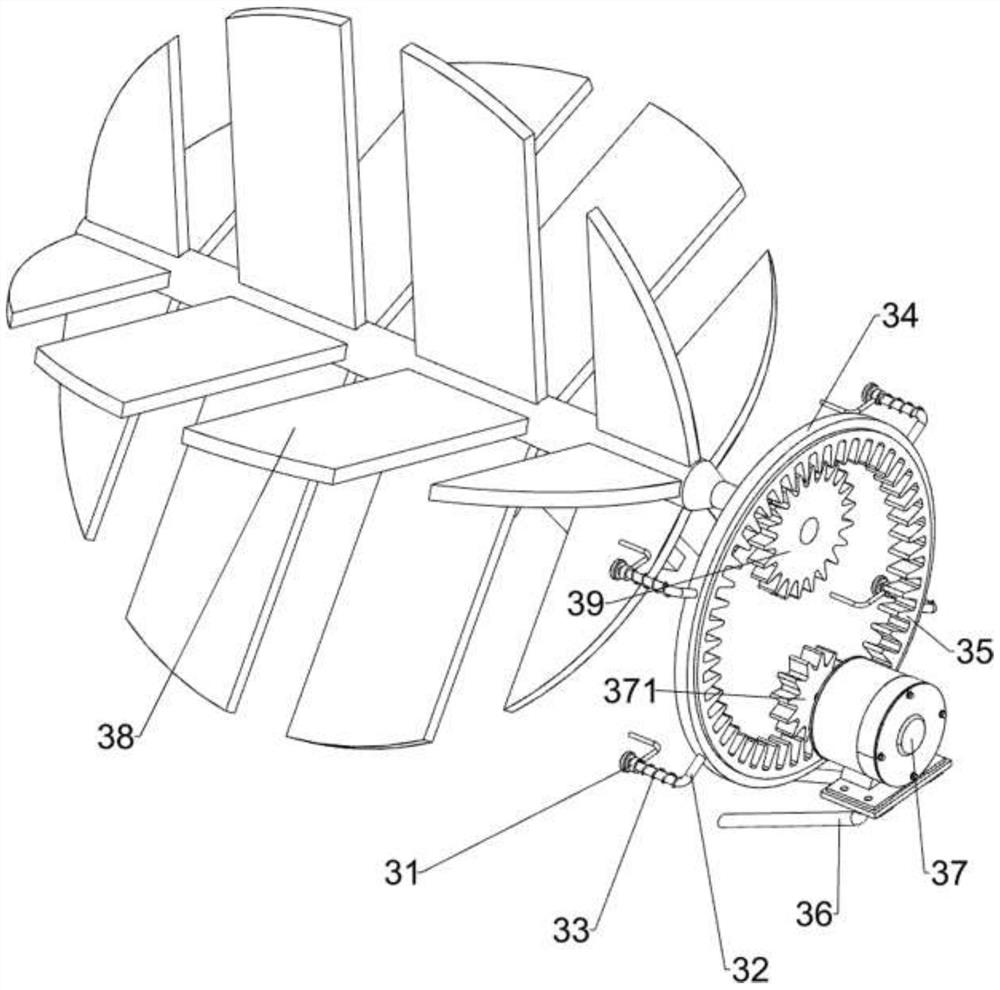

[0025] A kind of tangerine coarse grain rice flour fruit enzyme fermentation equipment, such as figure 1 As shown, it includes an installation base 1, a placement assembly 2, a stirring assembly 3 and a discharge assembly 4. The installation base 1 is provided with a placement assembly 2, and the placement assembly 2 is provided with a stirring assembly 3 for stirring by rotating. The assembly 2 is provided with a discharge assembly 4 for discharging in a rotating manner.

[0026] When fermenting fruit enzymes, the staff puts the raw materials into the placing component 2 for fermentation, and the raw materials can be stirred by the stirring component 3 during fermentation, and the raw materials are discharged through the discharging component 4 after the fermentation is completed.

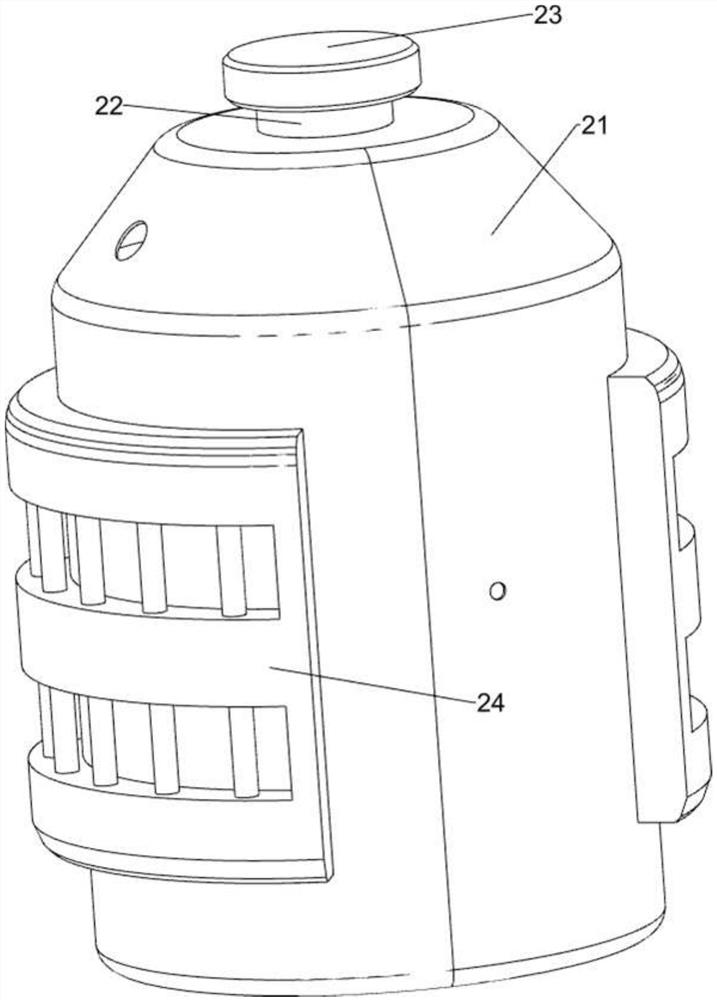

[0027] Such as figure 1 , figure 2 and Figure 4 As shown, the placement assembly 2 includes a fermentation cylinder 21, a feed pipe 22, a cover 23 and a heating ring 24, the installation base...

Embodiment 2

[0034] On the basis of Example 1, such as figure 1 and Figure 5 As shown, a pull assembly 5 is also included, and the pull assembly 5 includes a swing block 51, a second slide block 52, a connecting rod 53, a cross bar 54, an L-shaped plate 55, a third spring 56, a V-shaped plate 57, a fourth Spring 58 and vertical plate 59, the bottom front side of fermentation cylinder 21 is rotated and is provided with swinging block 51, and the inner sliding type of swinging block 51 is provided with second slide block 52, and the rotating type on second slide block 52 is provided with connecting rod 53, connects The rod 53 is connected with the first slide block 42, and the lower part of the front side of the fermenting cylinder 21 is provided with a cross bar 54, and an L-shaped plate 55 is slidably arranged on the cross bar 54, and the L-shaped plate 55 is slidably and rotationally connected with the swing block 51. A third spring 56 is wound around the plate 55 and the cross bar 54, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com