Ventilated fermentation equipment

A ventilation fermentation and equipment technology, applied in the direction of biochemical equipment and methods, bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, etc., can solve the problems of bacteria in the air, excessive foam, etc., Achieve the effects of less foam generation, good stirring effect and good oxygen solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

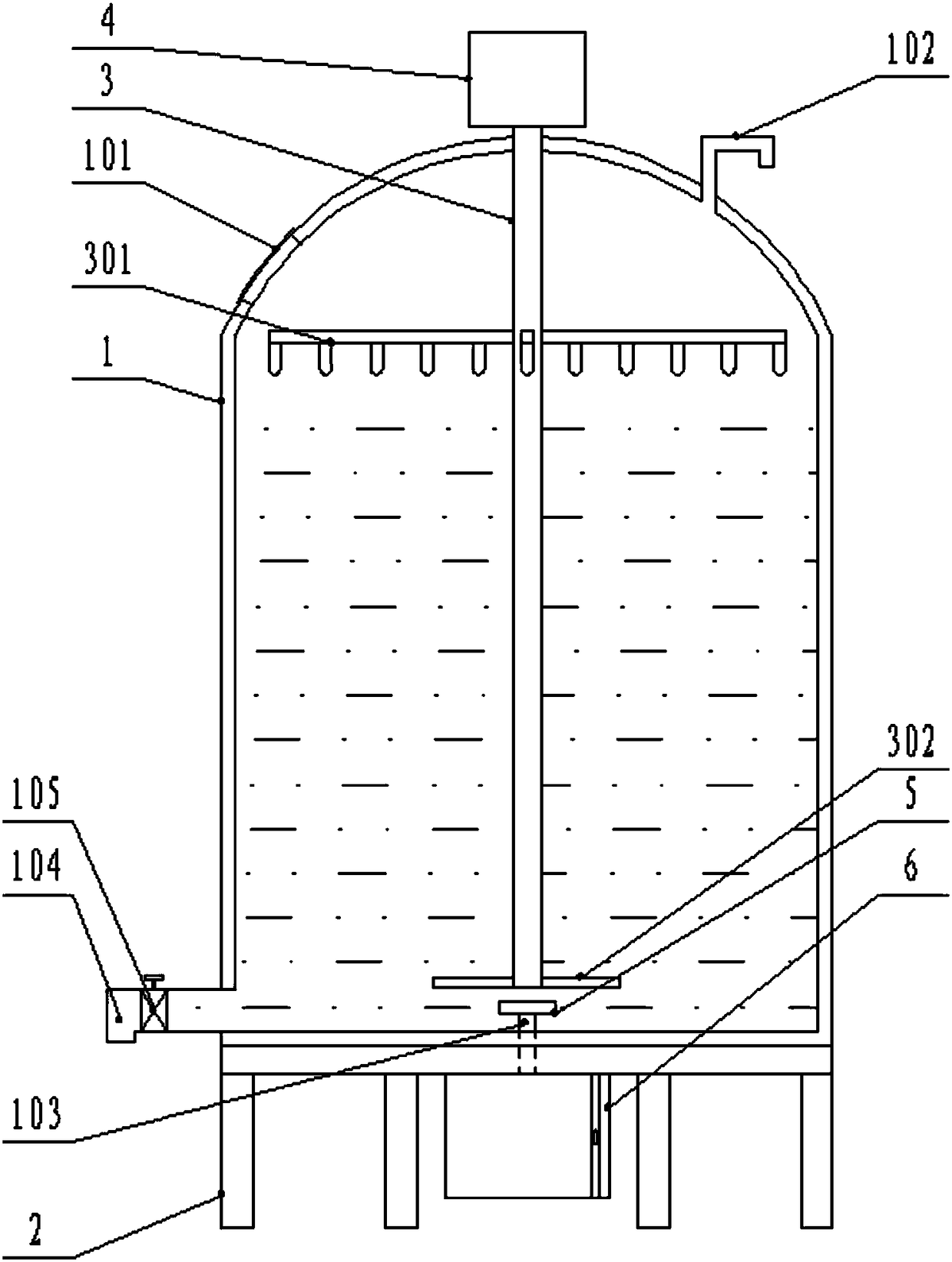

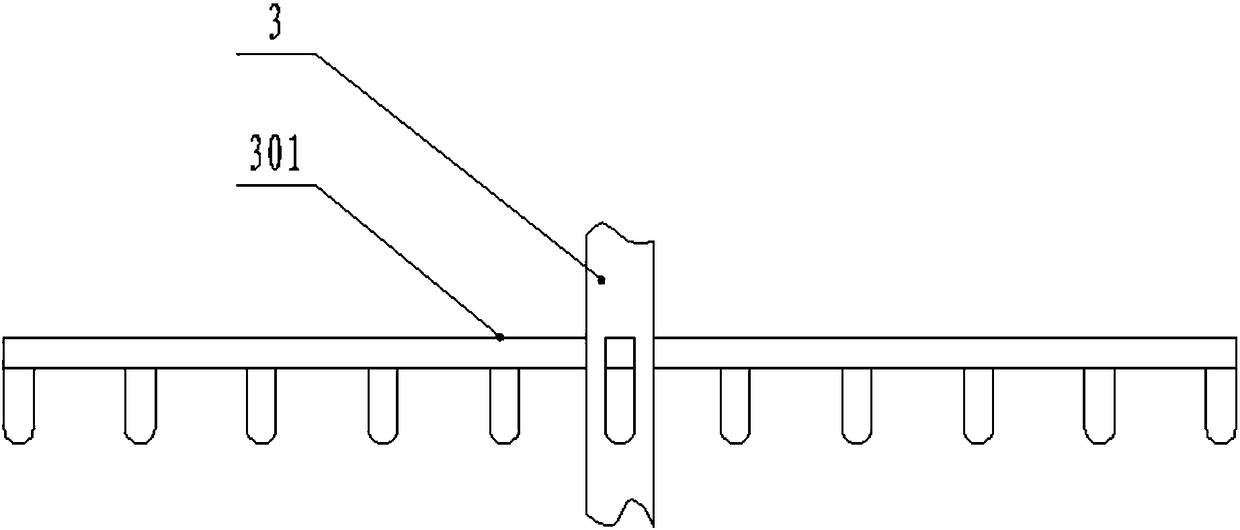

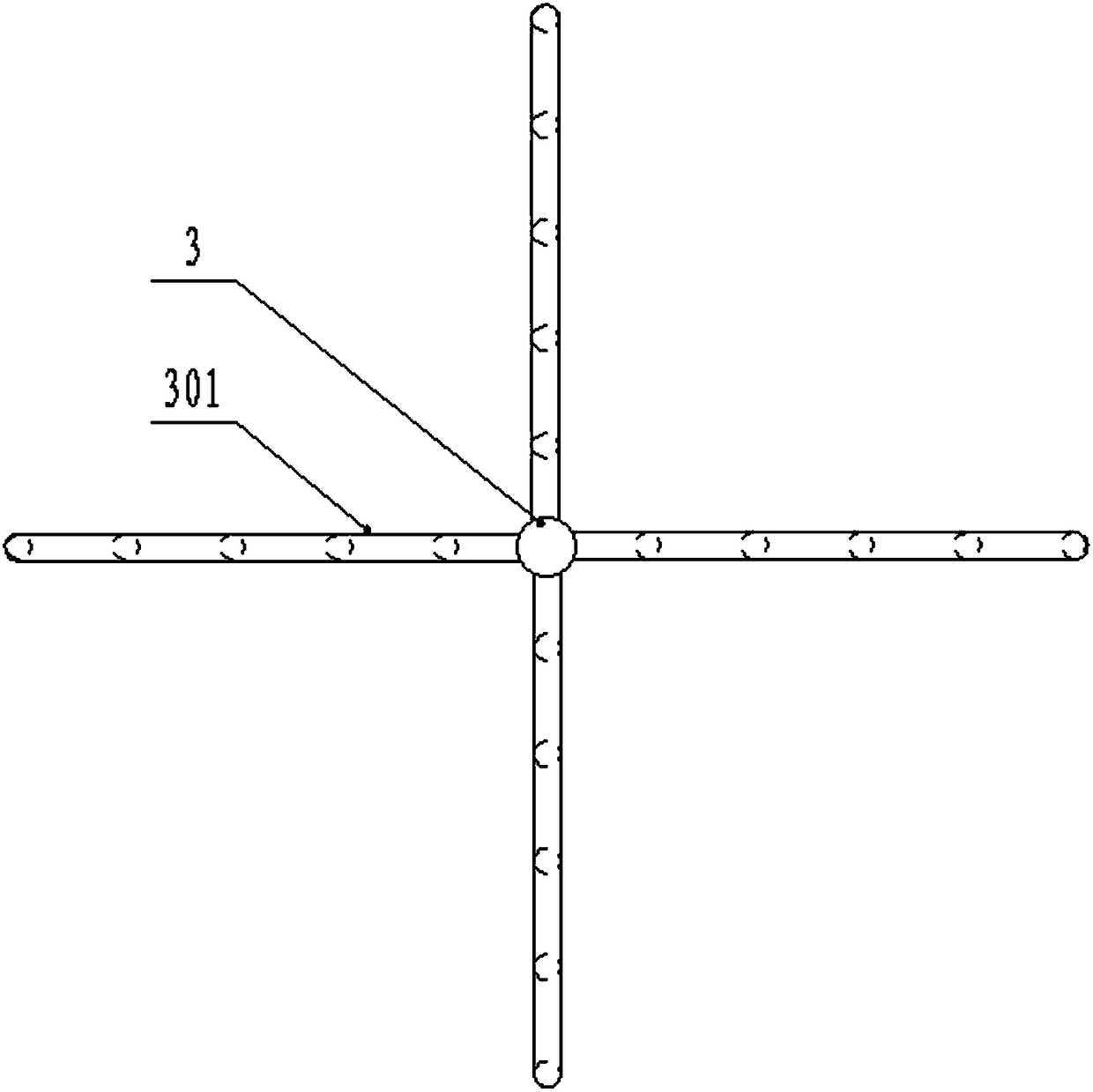

[0033] as attached figure 1 to attach Figure 9 Shown: a ventilation fermentation equipment, including a tank body 1, a feed port 101, a vent 102, an air inlet pipe 103, a discharge pipe 104, a control valve 105, a support 2, a stirring rod 3, a defoaming rake 301, and stirring blades 302, reducer 4, thinning sheet 5, air supply box 6, filter 601, slot 602, isolation plate 603, fan 604, ultraviolet lamp 605, first retention plate 606 and second retention plate 607; tank body 1 is fixed On the top side of the bracket 2; the feeding port 101 is set at the upper left corner of the tank body 1, with a sealing cover; the vent 102 is set at the upper right corner of the tank body 1, communicates with the inside of the tank body 1, and is a bent structure with the opening downward , to prevent external air from entering; the inlet pipe 103 is located at the center of the bottom of the tank body 1, with a one-way valve, which is open from the bottom to the top, otherwise it is closed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com