Dust removal device for glass screen

A glass screen and dust technology, applied in the direction of removing smoke and dust, cleaning flexible items, chemical instruments and methods, etc., can solve the problems of affecting the quality and efficiency of loading, poor operating environment, serious dust, etc., to improve the degree of automation, avoid two The effect of secondary adsorption on and improving the dust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

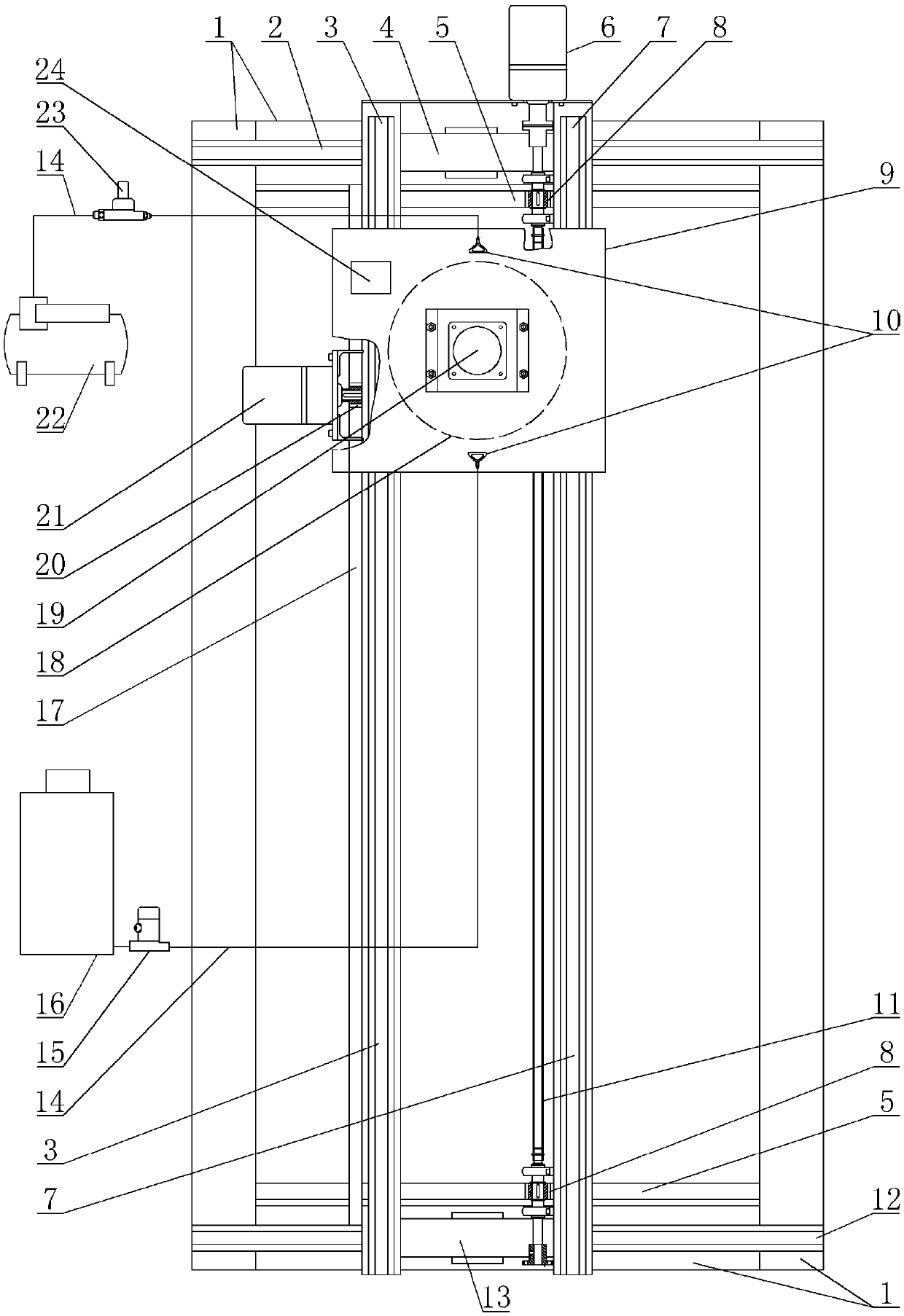

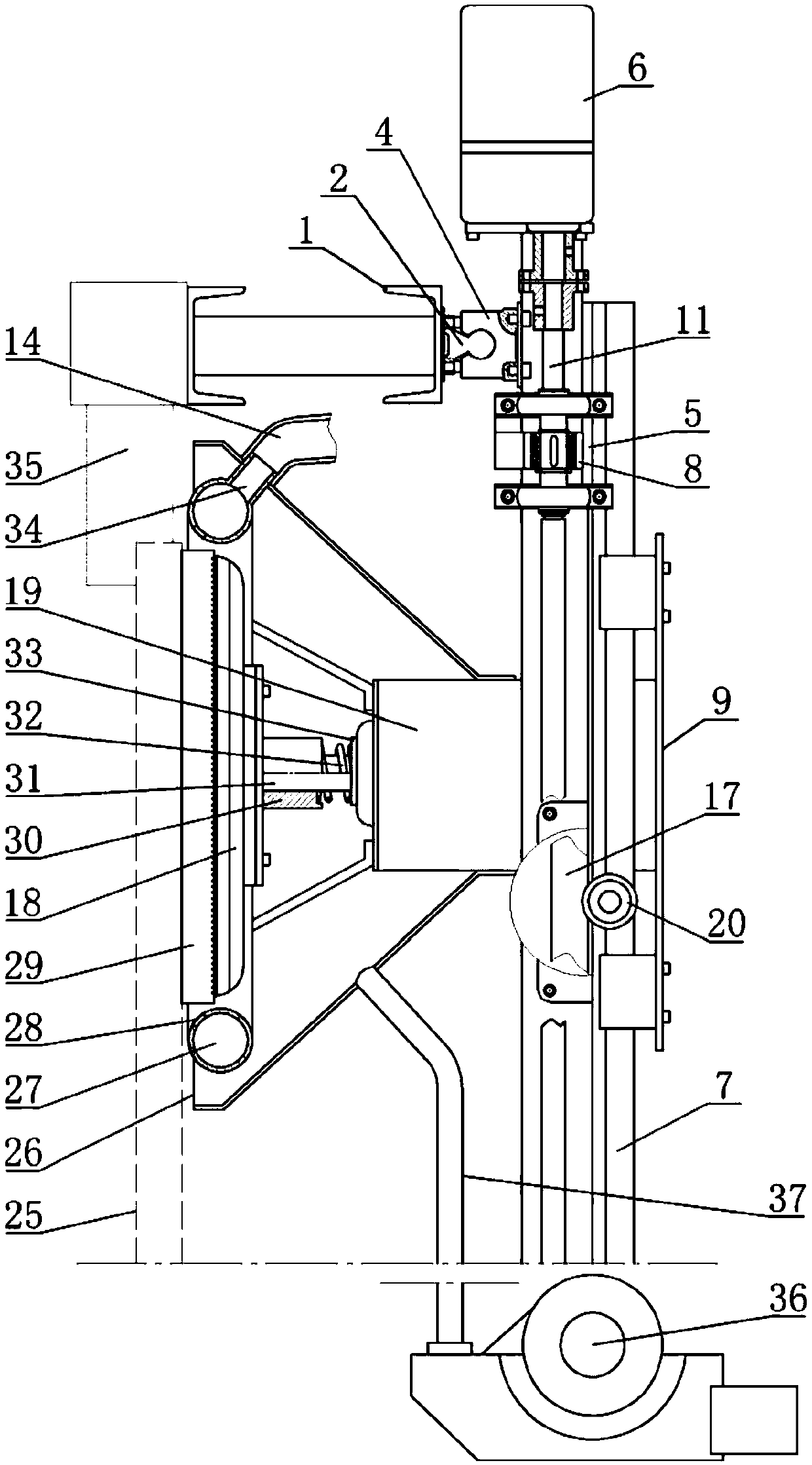

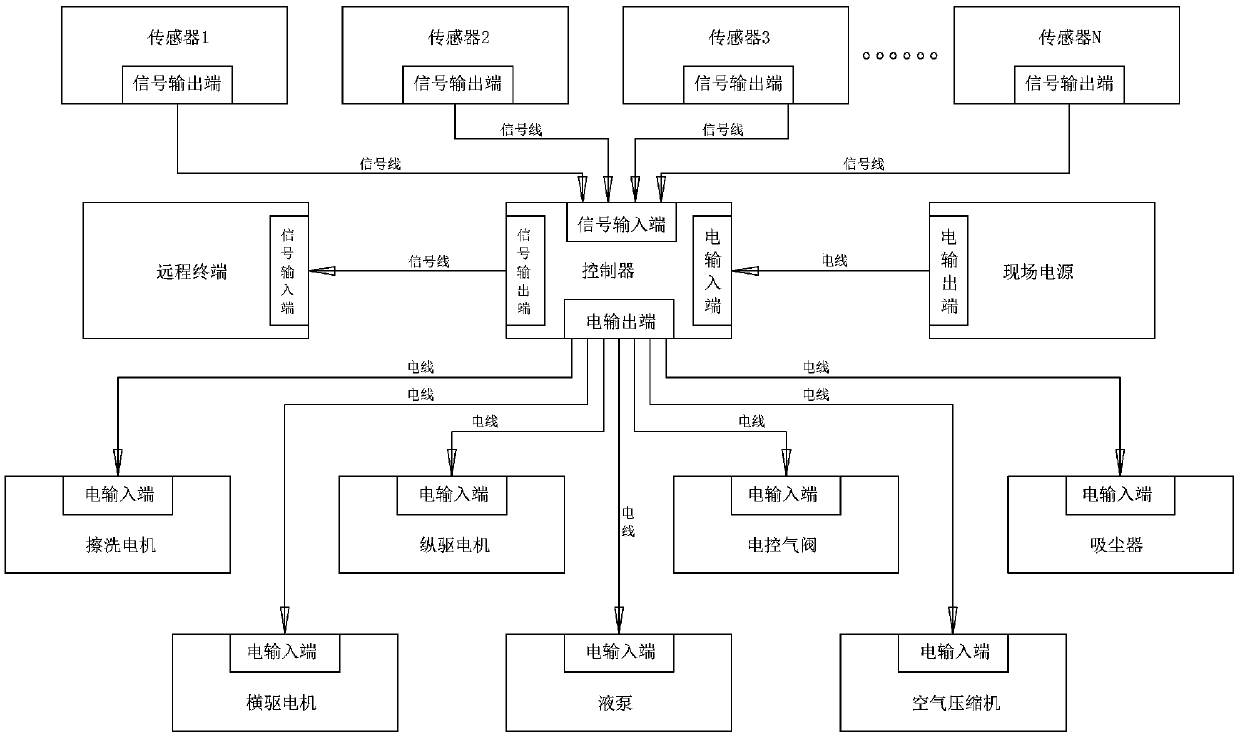

[0015] The glass screen dust removal device has a frame 1, a traveling mechanism, a scrubbing mechanism, and a controller 24; the traveling mechanism has an upper rail 2, a lower rail 12, a horizontal drive motor 6, a horizontal drive rack 5, and a horizontal drive gear 7 , upper slide plate 4, lower slide plate 13, left longitudinal rail 3, right longitudinal rail 7, scrubbing slide plate 9, longitudinal drive motor 21, longitudinal drive rack 17, longitudinal drive gear 20; The connecting and lower cross rails are fixedly connected with the lower end of the frame, the cross drive racks are fixedly connected with the upper and lower cross rails or the frame, the upper and lower cross rails and the cross drive racks are arranged in parallel, the cross drive gears and the motor shaft of the cross drive motor 11 Fixed connection, the horizontal drive gear and the horizontal drive rack are meshed and connected, the body of the horizontal drive motor is fixedly connected with the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com