Pneumatic hammer type anode rapping device

A technology of rapping device and pneumatic hammer, which is applied in the direction of electrode cleaning, electrostatic effect separation, solid separation, etc., to achieve the effect of improving the effect of dust removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

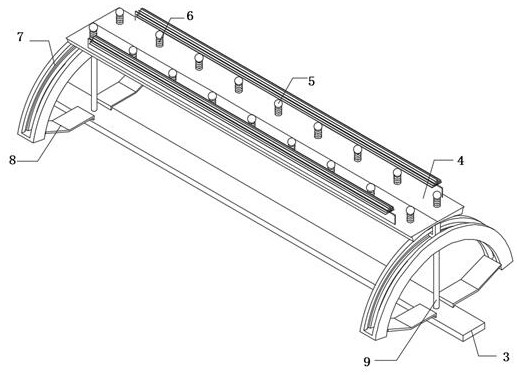

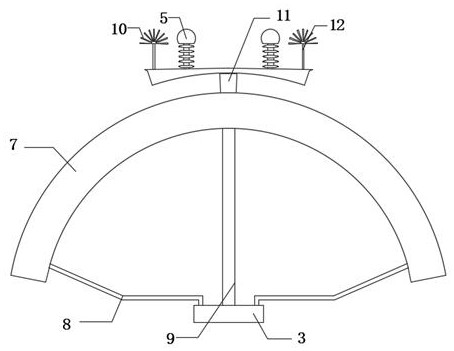

[0021] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

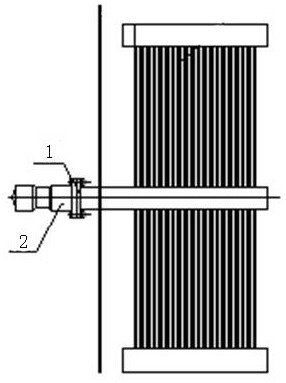

[0022] refer to figure 1 and Figure 4-5 , a pneumatic hammer type anode rapping device, comprising a pneumatic hammer 1 and a rapping anvil 2, the pneumatic rapping hammer 1 is composed of a magnetic piston 101, a base plate 102, a three-way solenoid valve 103 and a return spring 104, and the rapping anvil The outer wall of 2 is provided with an anti-secondary dust assembly, and the anti-secondary dust assembly includes a fixed frame 13, a motor 19 is fixedly connected to one side of the inner wall of the fixed frame 13, and the output shaft of the motor 19 is fixedly connected to a rotating shaft 14 through a coupling. The rotating shaft 14 is connected to the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com