Shaking dust removal power transformation cabinet

A technology of substation cabinets and cabinets, applied in the field of substation cabinets, can solve problems such as poor practicability, lack of dust collection and cleaning measures, and lack of protection measures for dust removal and insect prevention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

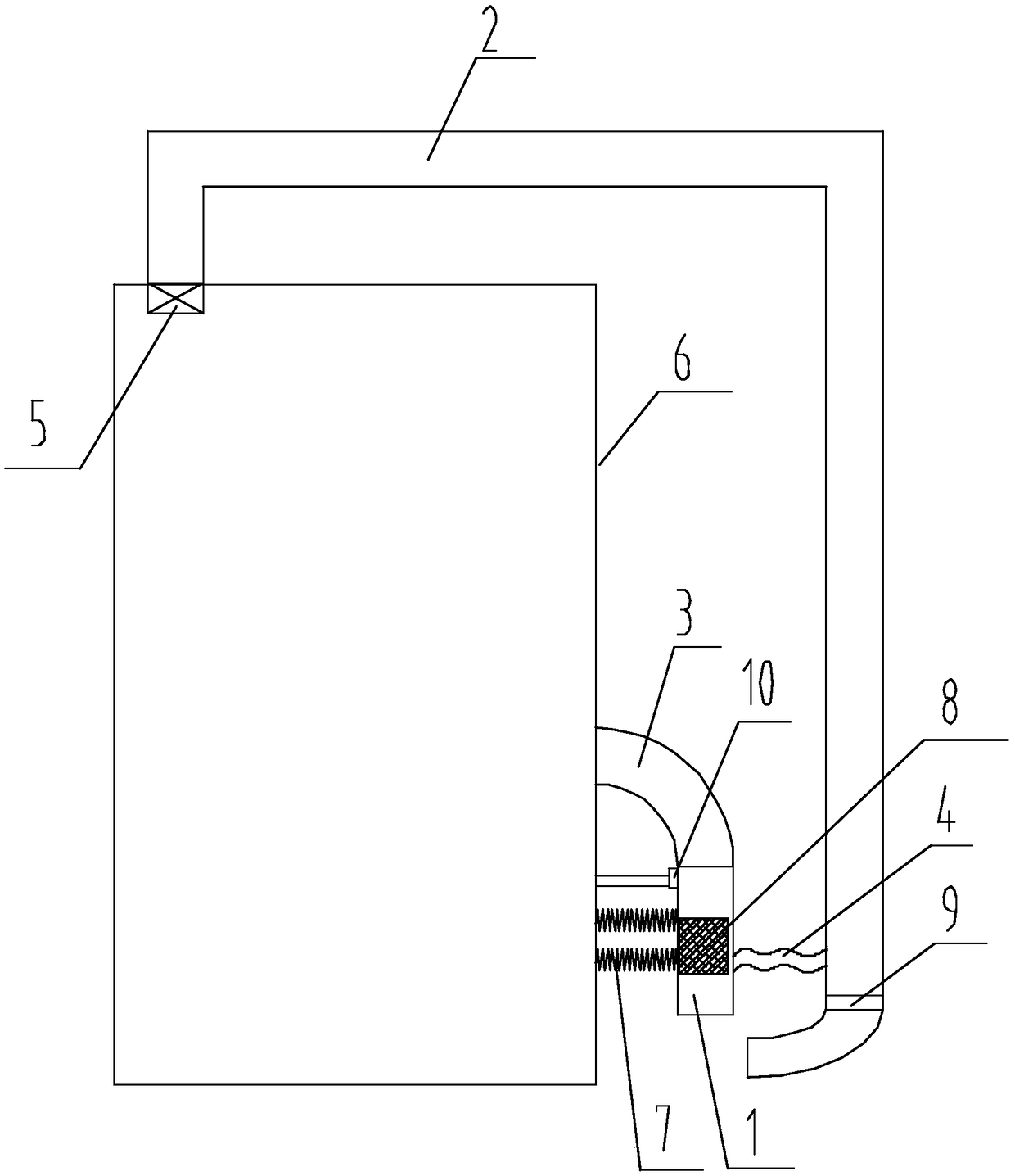

[0022] refer to figure 1 , The present invention proposes a vibrating and dust-removing type transformer cabinet, including: an air inlet pipe 1, an air outlet pipe 2, a first hose 3, a second hose 4, a fan 5 and a cabinet body 6.

[0023] The first hose 3 is installed on the cabinet body 6 and communicates with the air inlet, and the air inlet pipe 1 is installed on the cabinet body 6 through a spring 7 . The first end of the air inlet pipe 1 is connected and communicated with the first hose 3 , and the second end thereof is set lower than the first end. A dust adsorption mechanism 8 is installed in the air inlet pipe 1 . In this way, the air inlet pipe 1 is elastically installed by the spring 7, and is softly connected with the air inlet. When the spring 7 stretches, it can drive the air inlet pipe 1 to vibrate, so that the dust adsorbed by the dust adsorption mechanism 8 is desorbed.

[0024] The air outlet pipe 2 is installed on the cabinet body 6 and communicates with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com