Textile dust collecting device of textile machine for spinning

A technology for dust collection and textile machines, applied in textiles, textiles, papermaking, dryers, etc., can solve problems such as filter blockage, achieve the effects of saving production costs, saving electric energy, and preventing air corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

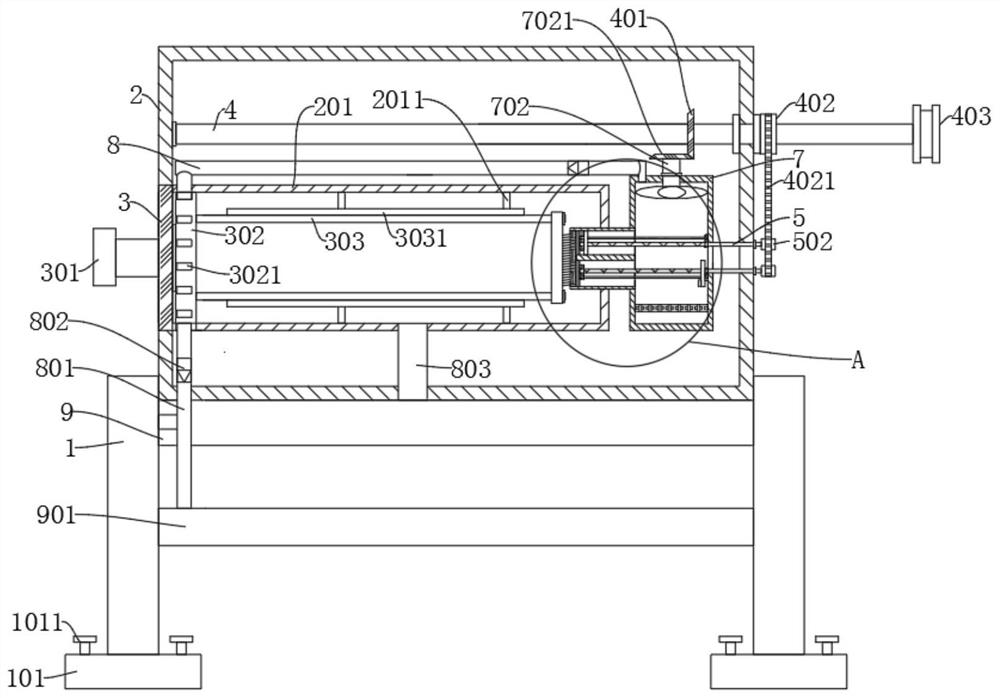

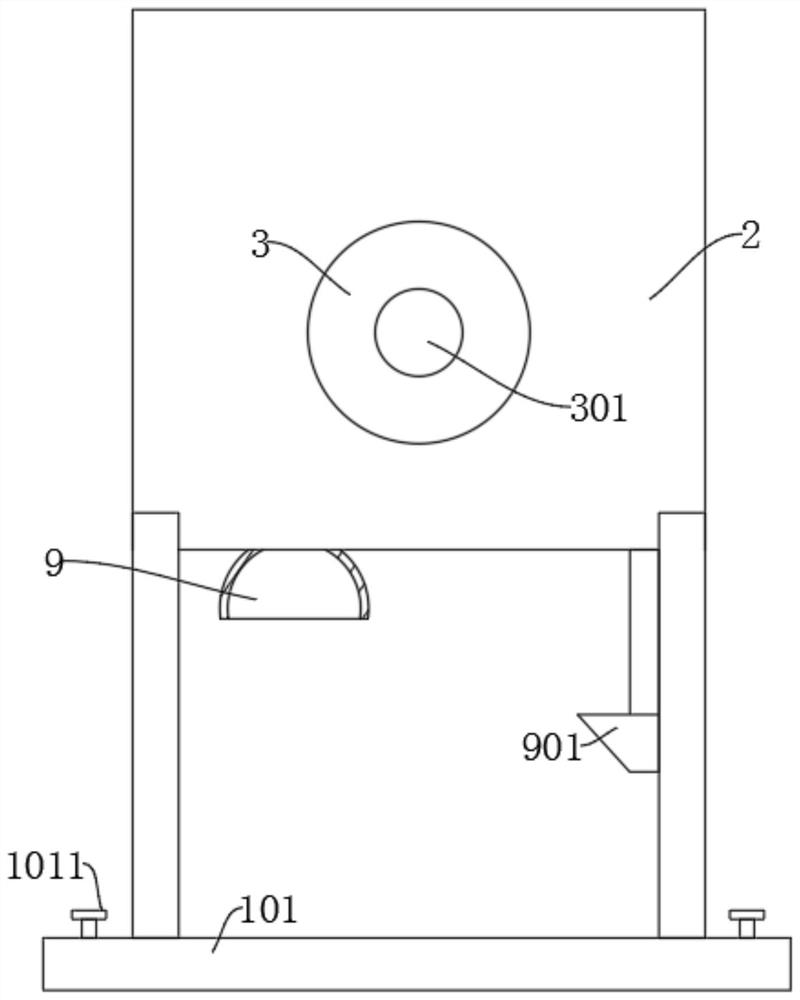

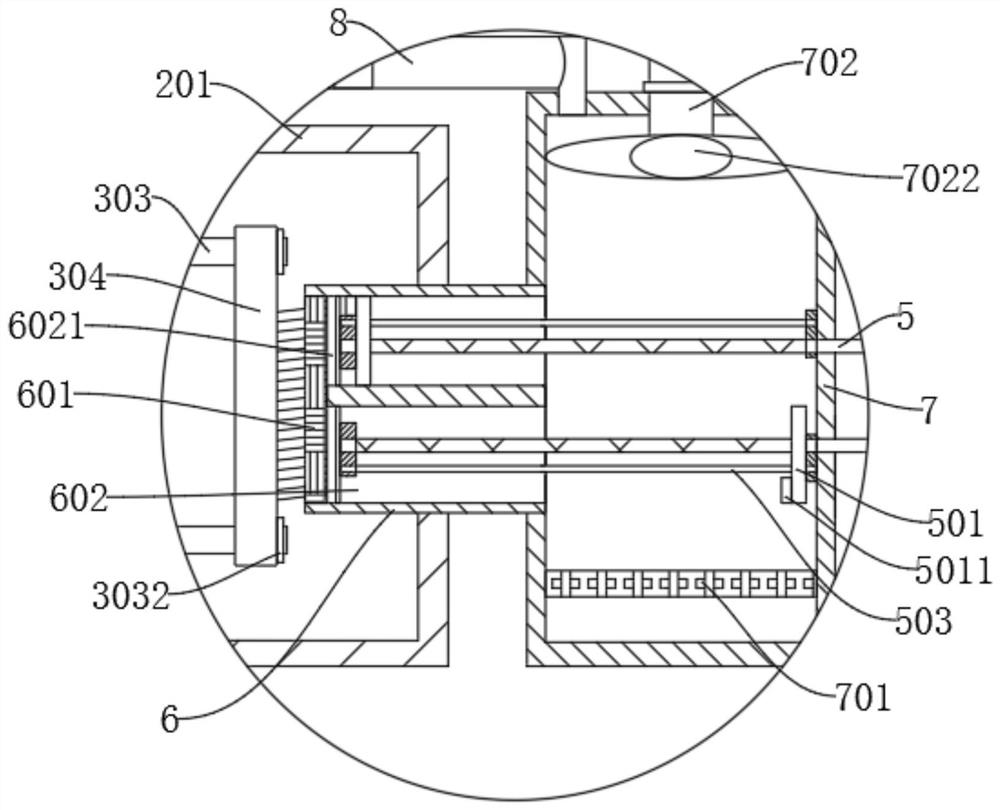

[0029] refer to figure 1 and image 3 , a textile dust collection device for textile machines, comprising a mounting frame 1 and a mounting box 2, the mounting box 2 is fixedly connected to the mounting frame 1, the bottom of the mounting box 2 is fixedly connected with a dust cover 9, and the mounting box 2 is fixed Connected with a storage box 201, the storage box 201 communicates with the dust collection cover 9 through the third air pipe 803, the installation box 2 is fixedly connected with a suction box 7, and the suction box 7 is provided with a suction mechanism, the suction box 7 and the storage box 201 Connected through the filter box 6, the filter box 6 is fixedly connected with a filter screen 601, the filter box 6 is provided with an air inlet hole 602, the air inlet hole 602 is fixedly connected with a mounting plate 6021, and the mounting plate 6021 is rotatably connected with a reciprocating wire Rod 5, the piston plate 501 is threadedly connected to the recipr...

Embodiment 2

[0031] refer to figure 1 and image 3 , is basically the same as Embodiment 1, furthermore, the suction mechanism includes a second gear 7021 and a suction fan 7022, the top of the suction box 7 is rotatably connected to a rotating shaft 702, and the second gear 7021 and the suction fan 7022 are respectively fixedly connected to the rotating shaft The two ends of 702 are fixedly connected with the drive shaft 4 in the installation box 2, and the drive shaft 4 is fixedly connected with the first gear 401, the first sprocket wheel 402 and the connecting wheel 403 from left to right. The first gear 401 Engaging with the second gear 7021, the connecting wheel 403 is rotationally connected with the pulley or sprocket on the spinning machine through the chain 4021 or the belt. When the spinning machine is started, the spinning machine rotates the drive shaft 4 through the connecting wheel 403, The drive shaft 4 rotates the first gear 401 and the first sprocket 402, the first gear 4...

Embodiment 3

[0033] refer to figure 1 and image 3, is basically the same as Embodiment 1, and furthermore, the reciprocating screw rod 5 extends to the outside of the installation box 2 and is fixedly connected with a second sprocket 502, and the second sprocket 502 and the first sprocket 402 are rotatably connected by a chain 4021, and the piston There are two groups of plates 501, two groups of piston plates 501 are symmetrically distributed on two groups of reciprocating screw rods 5, the first sprocket 402 rotates the second sprocket 502 through the chain 4021, and the second sprocket 502 rotates the reciprocating screw rod 5 , so that the piston plate 501 moves back and forth. By providing two sets of piston plates 501, when one set of piston plates 501 enters the air intake hole 602, the other set of piston plates 501 will break away from the air intake hole 602. The wind hole 602 is completely blocked, thereby avoiding causing the dust suction cover 9 to absorb the fluff intermitt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com