Boost jet nozzle for blockage removal of air pre-heater of heat-engine plant

A technology of air preheater and thermal power plant, which is applied to injection devices, removal of solid residues, liquid injection devices, etc., can solve the problems of insufficient heat exchange efficiency of air preheaters, threatening the safe operation of boilers, and difficult cleaning and construction, etc. Improve the effect of clearing blockage, improve blocking efficiency, and enhance efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

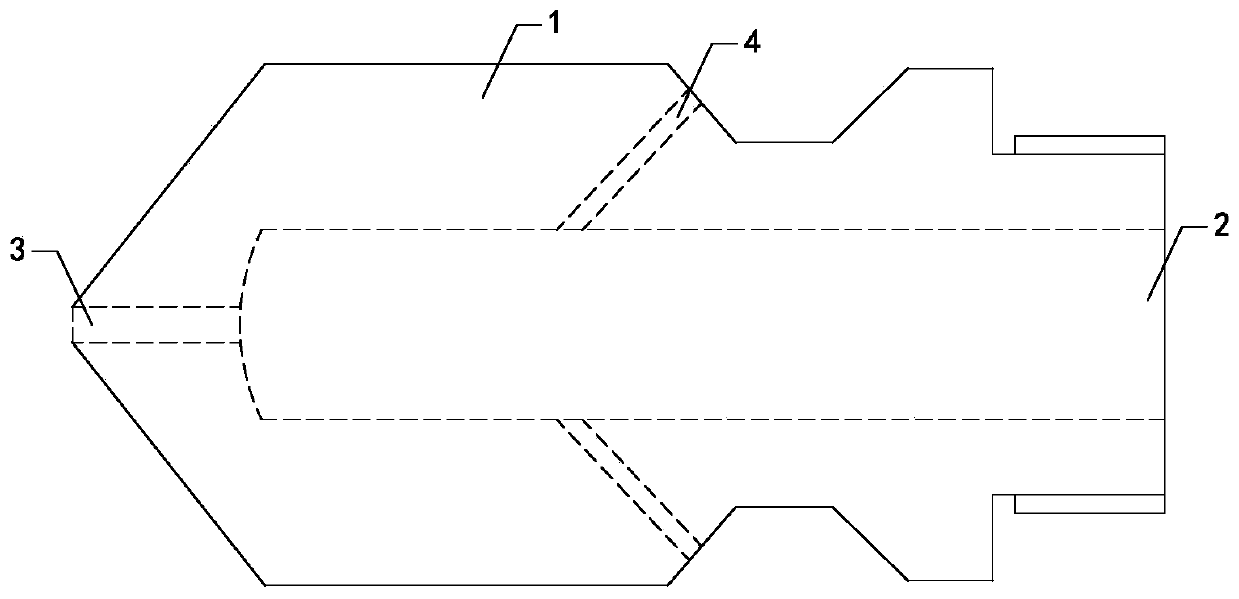

[0011] Such as figure 1 As shown, a thermal power plant air preheater blockage cleaning booster jet nozzle of the present invention includes a nozzle body 1, a groove 2 is provided at the right end of the nozzle body 1, a jet impact nozzle 3 is provided at the left end of the nozzle body 1, and a jet impact nozzle 3 The right end is connected with the left end of the groove 2, and the right side of the side wall of the nozzle body 1 is connected with three groups of booster nozzles 4, and the three groups of three groups of booster nozzles 4 are all connected with the side wall of the groove 2, and the three groups of booster nozzles 4 are connected with the nozzle body. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com