Segmented pulse backflushing air filter core regenerating system and method

A pulse backflushing and air filter technology, applied in the field of air purification, can solve the problems of reducing the efficiency of pulse injection, poor cleaning effect, small specific gravity, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

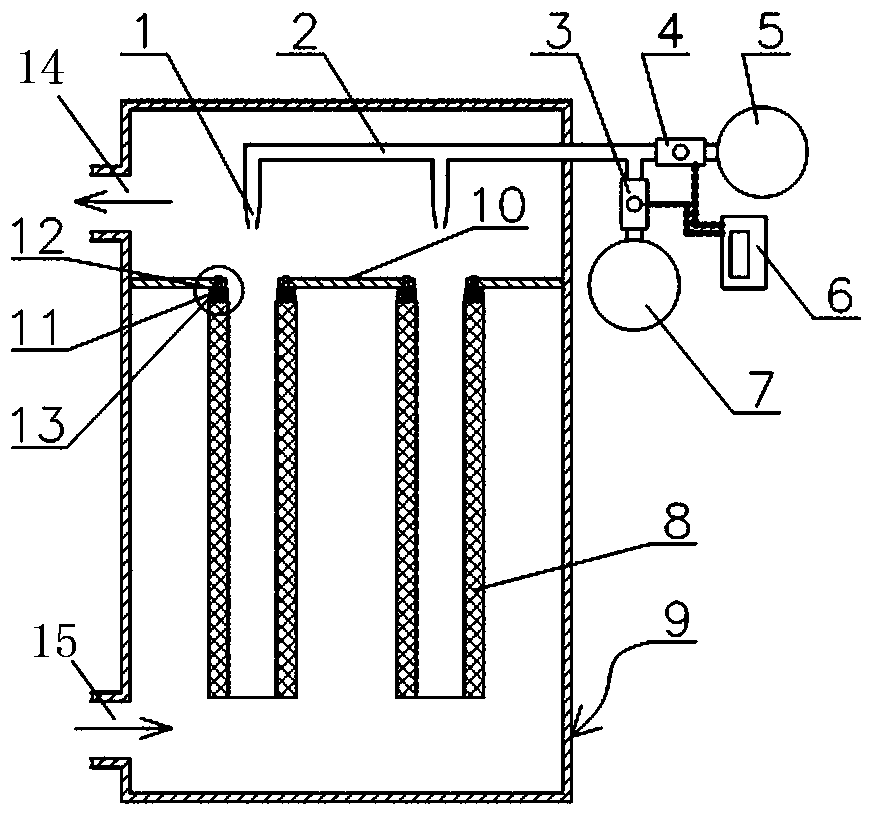

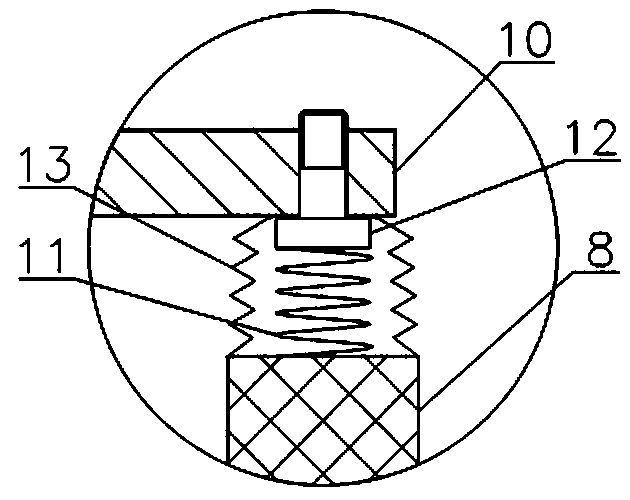

[0026] A segmented pulse back-blowing air filter element regeneration system includes a dust removal box body 9, a filter element 8 installed in the dust removal box body 9, and a pulsating air source arranged on the outside of the dust removal box body 9. An air outlet 14 and an air inlet 5 are respectively provided on the side. The dust removal box 9 is also provided with a partition 10 for fixing the filter element 8. The partition 10 and the dust removal box 9 are in interference fit. 10 is provided with an inner hole, the partition at the lower end of the inner hole is provided with a mechanical cleaning pipe, and the bottom of the mechanical cleaning pipe is sealed to the upper end of the filter element 8; the upper end of the dust removal box 9 is provided with a blowing pipe 2, The blowing pipe 2 is connected with a pulsating air source, and a nozzle 1 is provided at the lower end of the blowing pipe 2 corresponding to the vertical position of the filter element 8, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com