A jet self-priming system with adjustable opening

A self-priming system and adjustable technology, applied in the agricultural field, can solve the problems that restrict the jet self-priming system, such as high efficiency, smooth operation, single structure, rough structure surface, etc., to improve work efficiency, ensure sealing, and speed up self-priming Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below with reference to the drawings and specific embodiments, but the protection scope of the present invention is not limited to this.

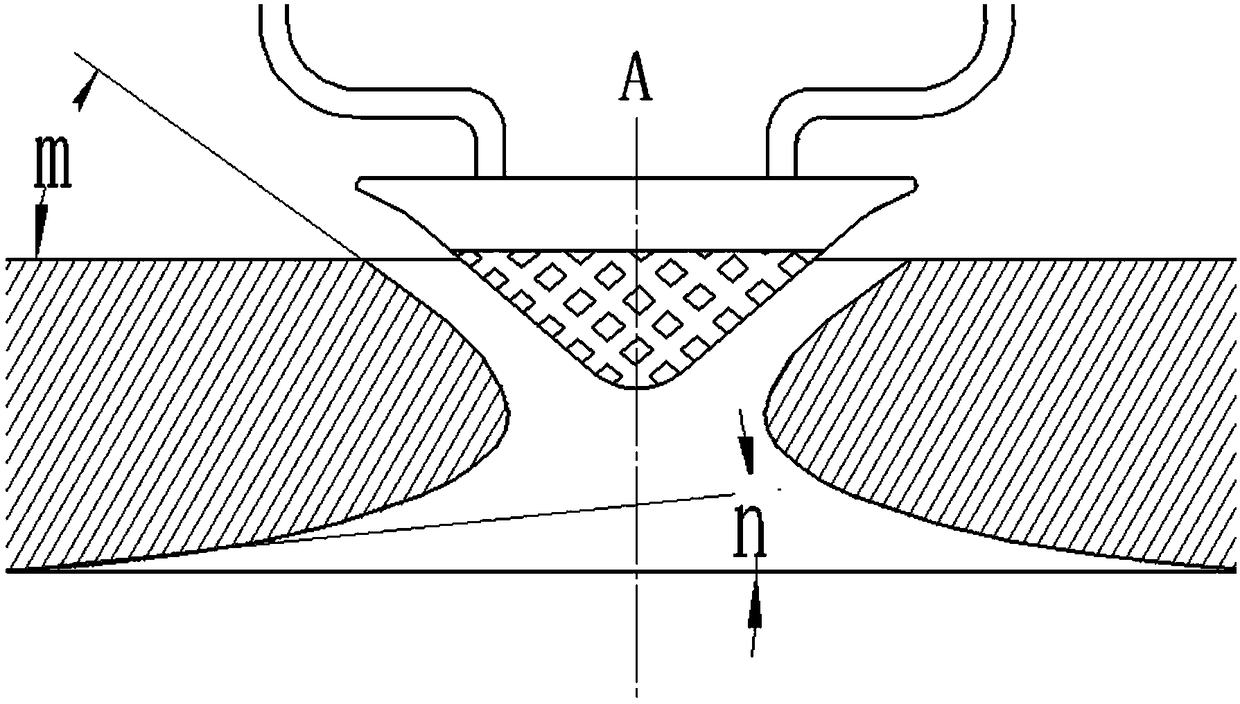

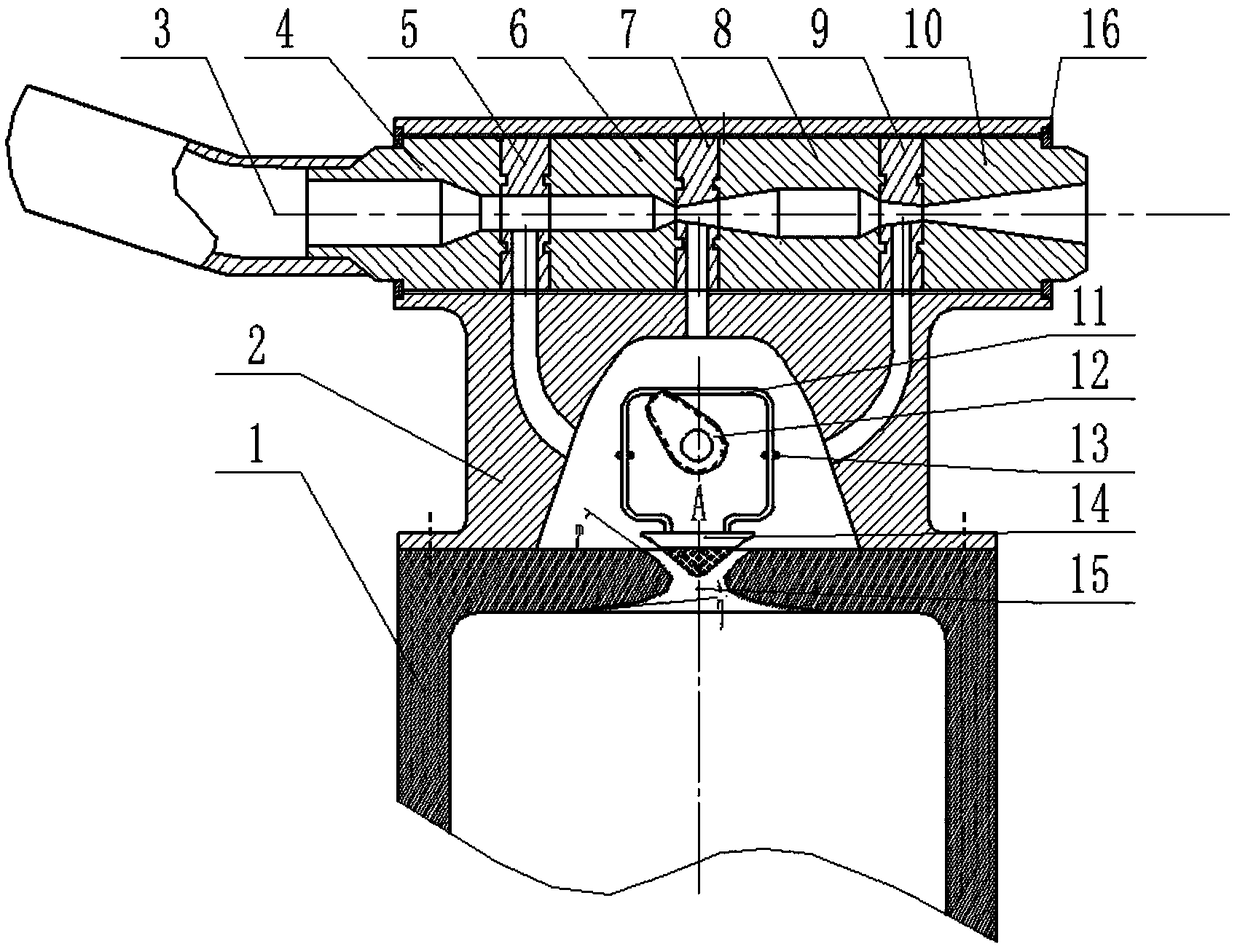

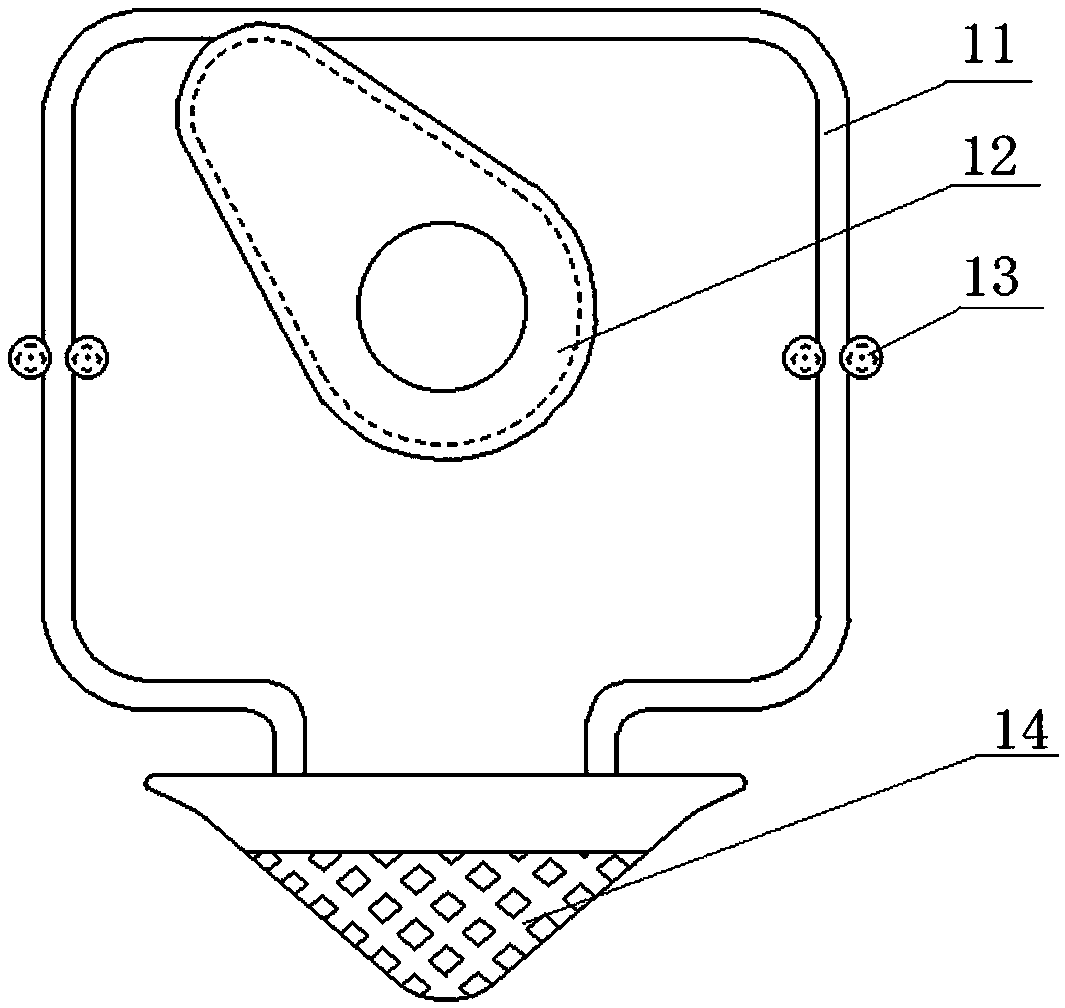

[0041] Such as figure 1 As shown, a jet self-priming system with adjustable opening according to the present invention includes a lower suction chamber 1, an upper suction chamber 2, a primary ejector 4, a primary graphene ring 5, and a secondary jet The thickness of the inner wall of the lower suction chamber 1 is 15mm, and the top wall of the lower suction chamber 1 A throat 15 is provided on the upper opening. The inner diameter of the throat 15 first decreases and then increases from the bottom end to the top end. The angle n of the contraction section of the throat 15 along the bottom end to the top end gradually increases from 12° to 33 °, the divergent section angle m gradually shrinks from 53° to 35°, and the transition between the contraction section and the divergent section is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com