Crushing and classification device for light and thin metal, and treatment process thereof

A classification device and crushing device technology, which is applied in grain processing, magnetic separation, solid separation, etc., can solve the problems of manual classification of easy-to-stuck materials, time-consuming and labor-intensive problems, achieve clear classification, reduce secondary adsorption, and improve crushing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

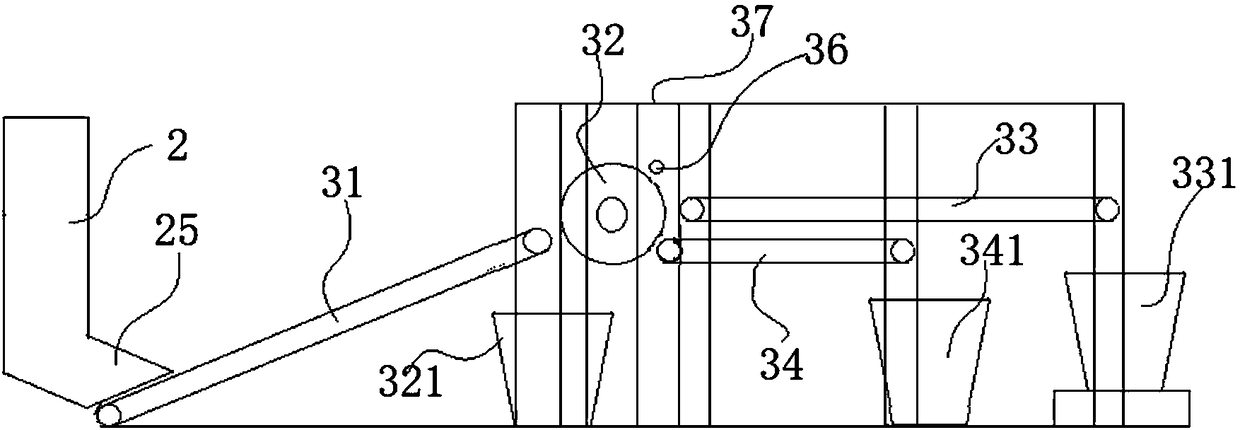

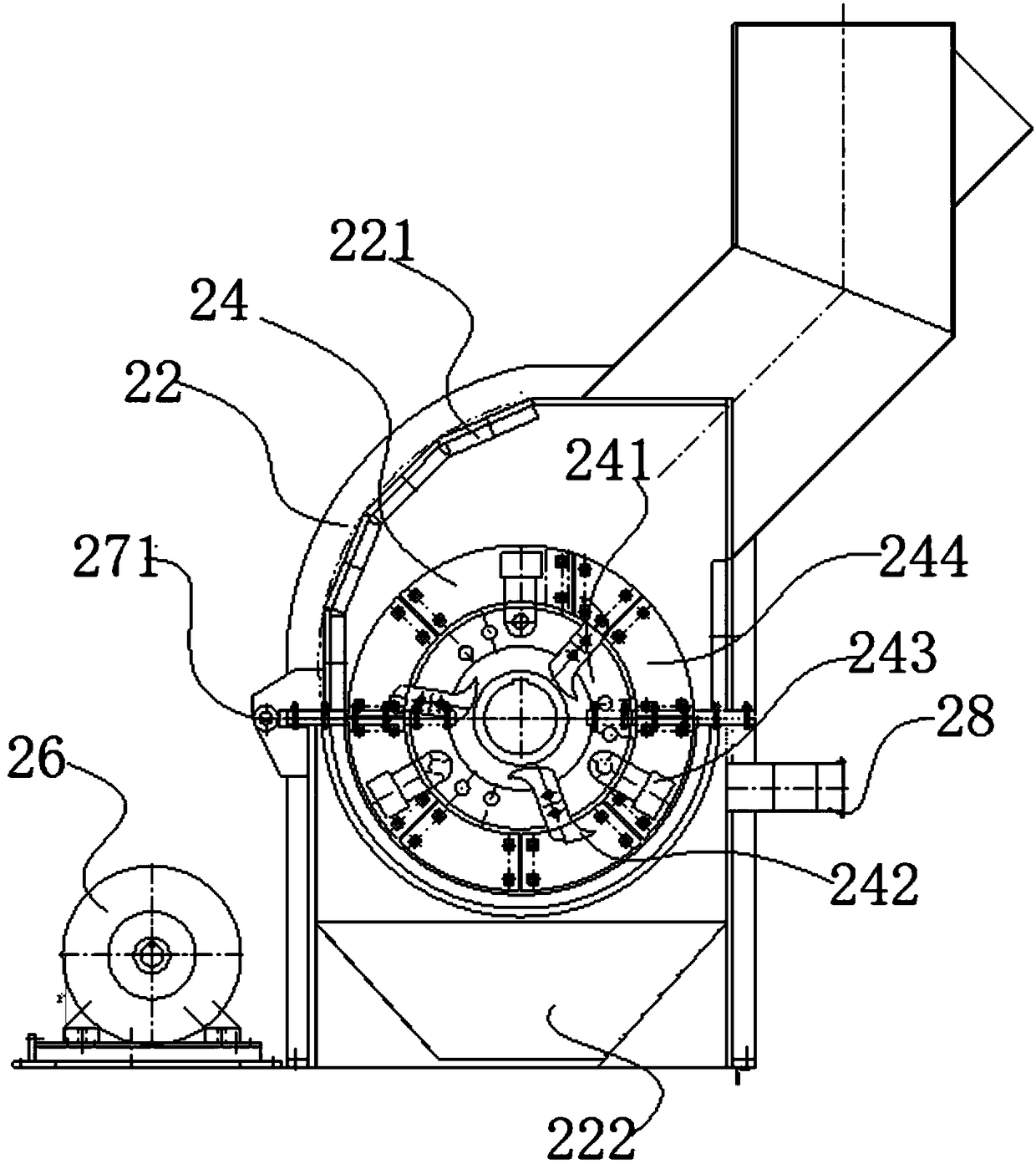

[0043] A thin metal crushing and sorting device such as figure 1 , 2 , 3, and 4, it includes crushing device 2 and classification device 3 which are arranged according to the process and connected by feeding conveyor belt 31. crushing mechanism 24; the overall diameter of the crushing mechanism 24 is slightly smaller than the width of the cabinet 22, and the crushing mechanism 24 includes a movable cutterhead 241, a movable cutter 242, a fixed cutter 243 and a fixed cutterhead 244; wherein: the movable cutterhead 241 Both the fixed cutter head 244 and the fixed cutter head are ring-shaped, and are uniformly staggered in the chassis 22. The moving knife 242 is detachably fixed on the moving cutter head 241, and the head of the moving knife 242 protrudes upwards from the outer edge of the moving cutter head 241; The fixed knife 243 is detachably fixed on the fixed knife disc 244, and the head of the fixed knife 243 protrudes downward from the inner edge of the fixed knife disc ...

Embodiment 2

[0046] The basic structure of the light and thin metal crushing and classifying device of this embodiment is the same as that of Embodiment 1, and the improvement is that: the moving knife 242 is in the shape of a Z, and is evenly distributed on the moving knife disk 241; the end of the fixed knife 243 is The semicircle is evenly distributed on the fixed cutter disc 244 to further achieve the purpose of uniform crushing. In this example, if figure 1 As shown, there are three movable knives 242 and fixed knives 243, which are set at intervals of 120 degrees on the corresponding cutterheads, and the orientation of the ends of the movable knives 242 is consistent with the direction of rotation of the movable knife shaft 23 during crushing. The material can be eaten by grabbing after rotation, thereby improving the crushing efficiency. There are 2 discharge conveyor belts, which are arranged in parallel up and down. The upper and lower sides are respectively a large-grain iron ma...

Embodiment 3

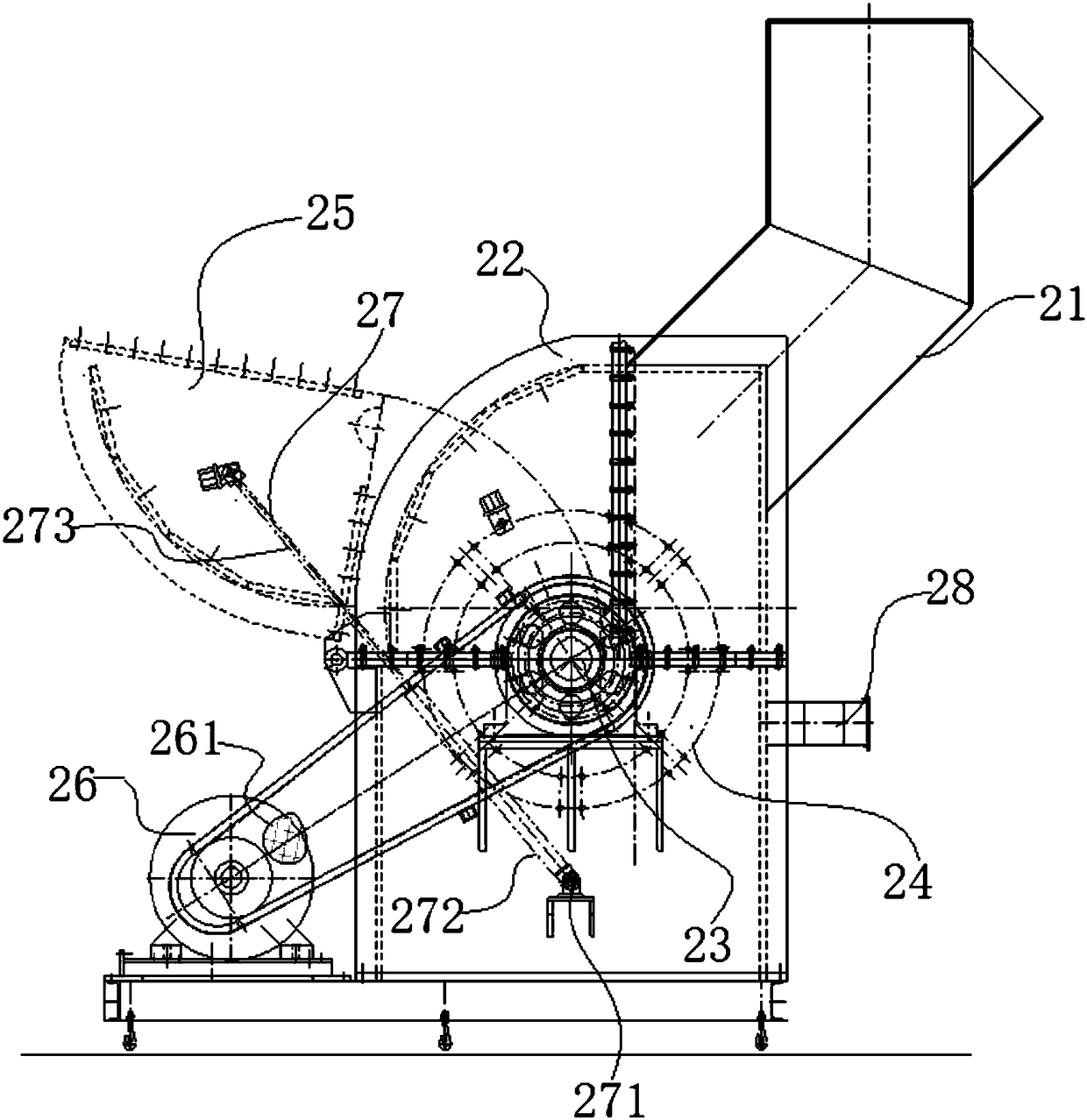

[0050] The light and thin metal crushing and classification device of this embodiment has the same basic structure as that of Embodiment 2. The improvement is that the discharge hopper 25 is liftable, and is fixedly connected with the chassis 22 through a lift adjustment mechanism 27. According to the position of the discharge conveying device, The height is adjusted accordingly to improve its adaptability. The lifting adjustment mechanism 27 includes a hydraulic cylinder 272 and a telescopic rod 273; the hydraulic cylinder 272 and the telescopic rod 273 are respectively fixed on the bottom of the cabinet 22 and the top of the discharge hopper 25 through a hinge 271, and are lifted by a hydraulic method for easy adjustment. The delivery speed of the discharge conveyor belt is greater than the feeding speed of the feeding conveyor belt 31. The advantage is that the iron material after the adsorption can be intercepted respectively by the large particle iron material conveyor bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com