Process method for treating refractory CODs (chemical oxygen demands) in produced water of high-sulfur-content gas field

A gas field produced water and treatment technology technology, applied in sedimentation treatment, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of high population density and poor reinjection capacity of reinjection wells, and achieves low overall investment and low cost. The cost of water production and the effect of strong anti-pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

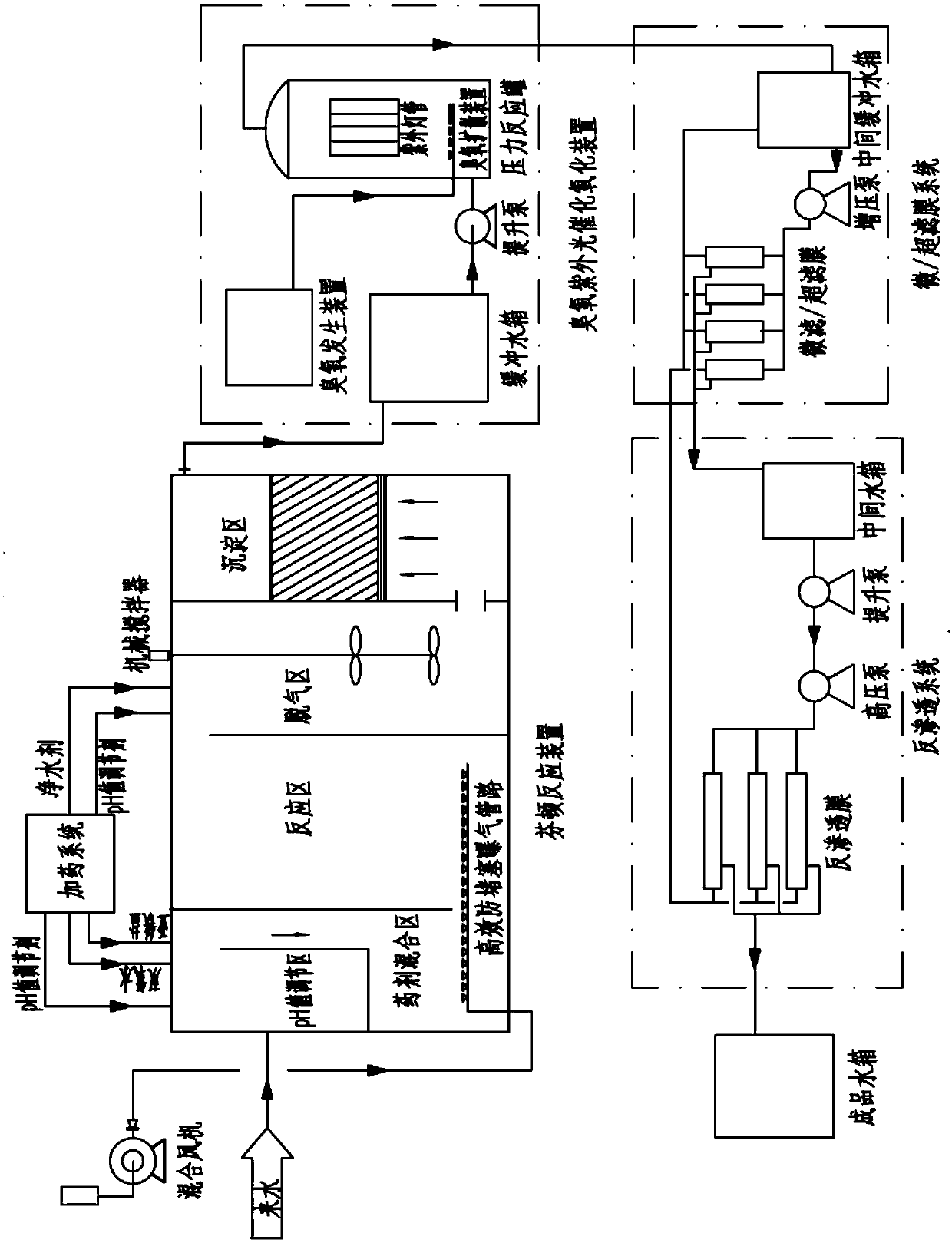

[0044] A treatment process for refractory COD in produced water from high-sulfur gas fields, comprising the following specific steps:

[0045] Step 1: Fenton oxidation treatment of produced water from high-sulfur gas fields;

[0046] The second step: the produced water treated in the first step is subjected to ozone ultraviolet photocatalytic oxidation treatment;

[0047] The third step: the produced water treated in the second step is subjected to micro / ultrafiltration membrane treatment;

[0048] Step 4: Treat the produced water after the treatment in the third step with a reverse osmosis membrane to obtain qualified produced water after treatment.

[0049] Specifically, if figure 1 As shown, the main equipment used in this embodiment includes: Fenton advanced oxidation device, ozone ultraviolet photocatalytic oxidation device, micro / ultrafiltration membrane system and reverse osmosis system.

[0050] The specific operation process steps are as follows:

[0051] The pret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com