Integrated fluidized bed device for gradient ozone catalyzing and application of integrated fluidized bed device

An ozone-catalyzed, integrated technology, applied in the direction of oxidized water/sewage treatment, chemical instruments and methods, special compound water treatment, etc., can solve the problems that the wastewater treatment effect is difficult to meet the requirements, improve the effect of the catalytic oxidation series limit, etc., to achieve Improve the utilization rate, improve the treatment effect, and ensure the effect of the treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

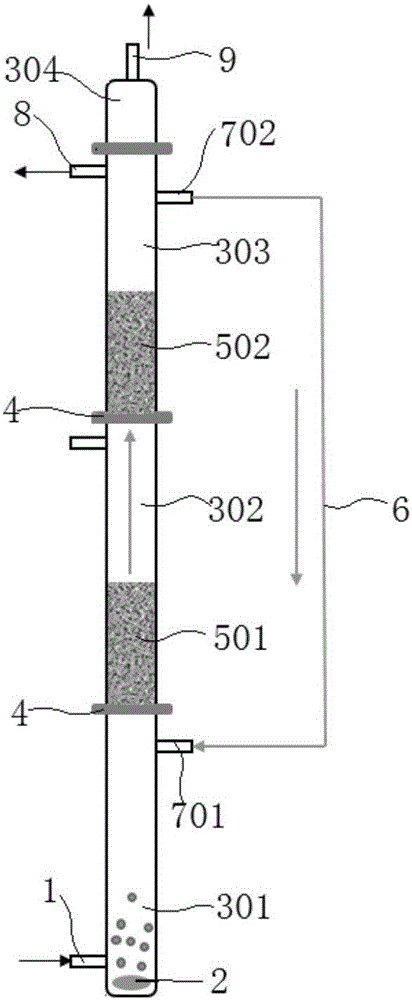

[0039] The integrated gradient ozone catalytic fluidized bed device of the present embodiment comprises a first-stage reactor 301 (ozone oxidation zone), a second-stage reactor 302 (ozone catalytic reaction zone), and a third-stage reactor 303 arranged sequentially from bottom to top. (ozone catalytic reaction zone) and the fourth-stage reactor 304, supporting filter plates 4 are arranged between adjacent reactors, and the bottom of the supporting filter plates 4 is connected with a uniform water distribution device, and the supporting filter plates 4 Made of stainless steel. Wherein, the bottom of primary reactor 301 is provided with water inlet 1 and ozone aeration device 2, and its top is provided with circulating water inlet 701, and ozone aeration device 2 is made of titanium alloy material and is connected with ozone generator, and ozone The preparation needs to use pure oxygen as the raw material for ozone generation. The first catalyst layer 501 and the second catalys...

Embodiment 2

[0042] Adopt the reaction device identical with embodiment 1, change each operation parameter, concrete operation is as follows: the filling height of catalyst in secondary reactor 302 accounts for the ratio of secondary reactor 302 height and the filling height of catalyst in tertiary reactor 303 accounts for The height ratio of the three-stage reactor 303 is 1 / 4, the reflux ratio is controlled to be 50%, the circulating water flow rate is 1.0m / min, so that the expansion ratio of the catalyst is 20%. The cut angle between the circulating water inlet 701 and the reactor main body is 30°. After ozone treatment, the wastewater enters the secondary and tertiary reactors in turn. The residence time of the wastewater in the reactor is 40 minutes. The COD of the original influent is 60mg / L on average, and the COD value after treatment is 35mg / L. The COD removal rate is 42%, compared with the original ozone catalytic fixed bed, the effluent COD is 45mg / L, and the COD removal rate has...

Embodiment 3

[0044] Adopt the same reaction device as embodiment 1, change each operating parameter, concrete operation is as follows: the filling height of catalyst in secondary reactor 302 accounts for the ratio of secondary reactor 302 height and the filling height of catalyst in tertiary reactor 303 accounts for three The ratio of the height of the first-stage reactor 303 is 1 / 5, and the catalyst in the second-stage reactor 302 is a synthetic ozone catalyst. This embodiment is an iron-manganese composite catalyst, and the catalyst in the third-stage reactor 303 is activated alumina supported copper and nickel. At the same time, the reflux ratio of the circulating water is controlled to be 100%, and the flow rate of the circulating water is 2.5m / min, so that the catalyst is expanded, and the expansion rate is 50%. The upward cutting angle between the circulating water inlet 701 and the reactor main body is 45°. After ozone treatment, the wastewater enters the secondary and tertiary rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com