Three-plasmid whole sealing environmentally friendly vibration fluidized bed dryer

A vibrating fluidized bed, fully enclosed technology, applied in the direction of drying solid materials, heating to dry solid materials, drying, etc., can solve the problem of large air volume required for disc fluidized beds, poor operation stability, and difficult quality assurance, etc. problems, to achieve the effect of material fluidization and conveying stability, powder reduction, and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

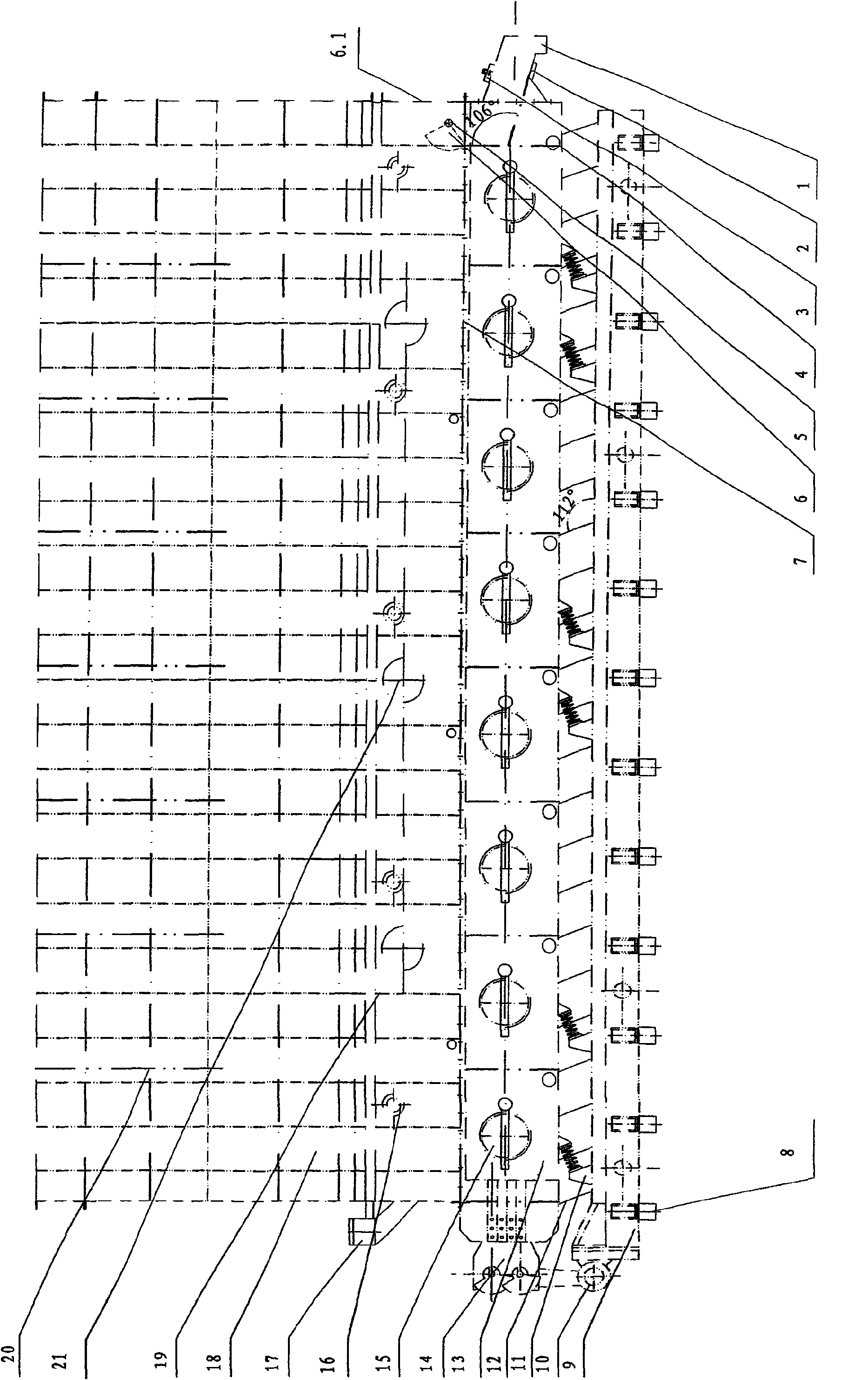

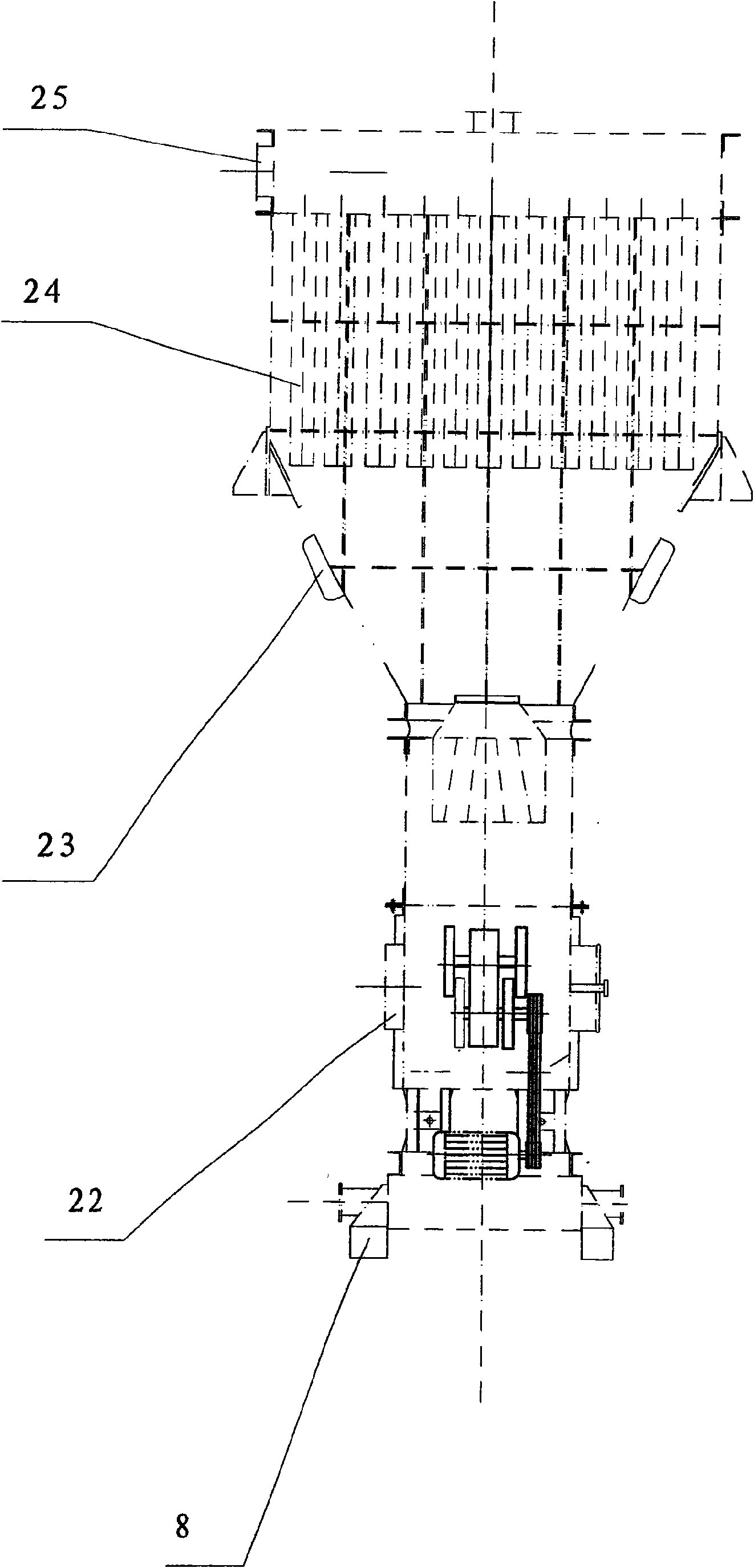

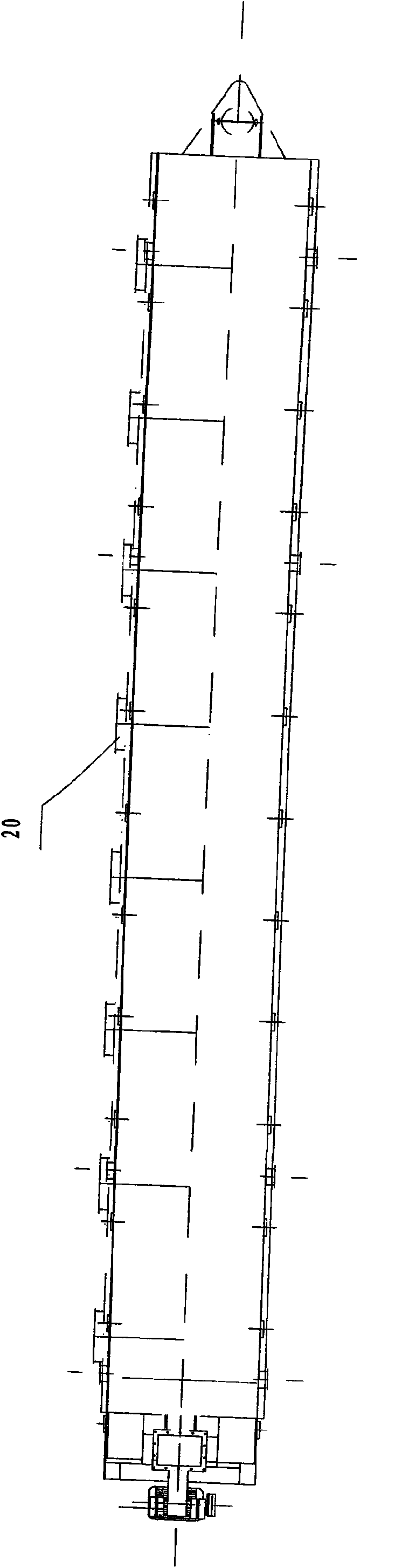

[0033] see Figure 1~3 , The three-body fully enclosed environment-friendly vibrating fluidized bed dryer of the present invention consists of four parts: the base 9, the lower box 13, the fluidized bed 6 and the upper box 18.

[0034] The lower box body 13 is an air inlet chamber, which is rectangular parallelepiped and is made of stainless steel plate. The whole lower box body 13 is supported on the base 9 by a leaf spring 12 arranged obliquely. Described lower box body 13 is provided with eight air inlets 22, cuts off with lower box body vertical dividing plate 4 between each air inlets 22, does not communicate with each other, forms eight air chambers. There are quick-opening hand holes 3 at each air chamber to facilitate inspection and cleaning of materials in the air chamber. A box-type vibration exciter 14 is installed at the front end of the lower box body 13, and the box-type vibration exciter 14 is driven by a motor 10 installed on the base 9. When the box-type vib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com