Biological desulphurization processing reactor, biological desulphurization processing system, and processing method

A biological desulfurization and reactor technology, applied in the field of environmental engineering, can solve the problems of increasing the difficulty of separation and purification of elemental sulfur, short solid residence time, and blockage of elemental sulfur, and achieves extended solid residence time, low operation and maintenance costs, and avoidance of blockage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

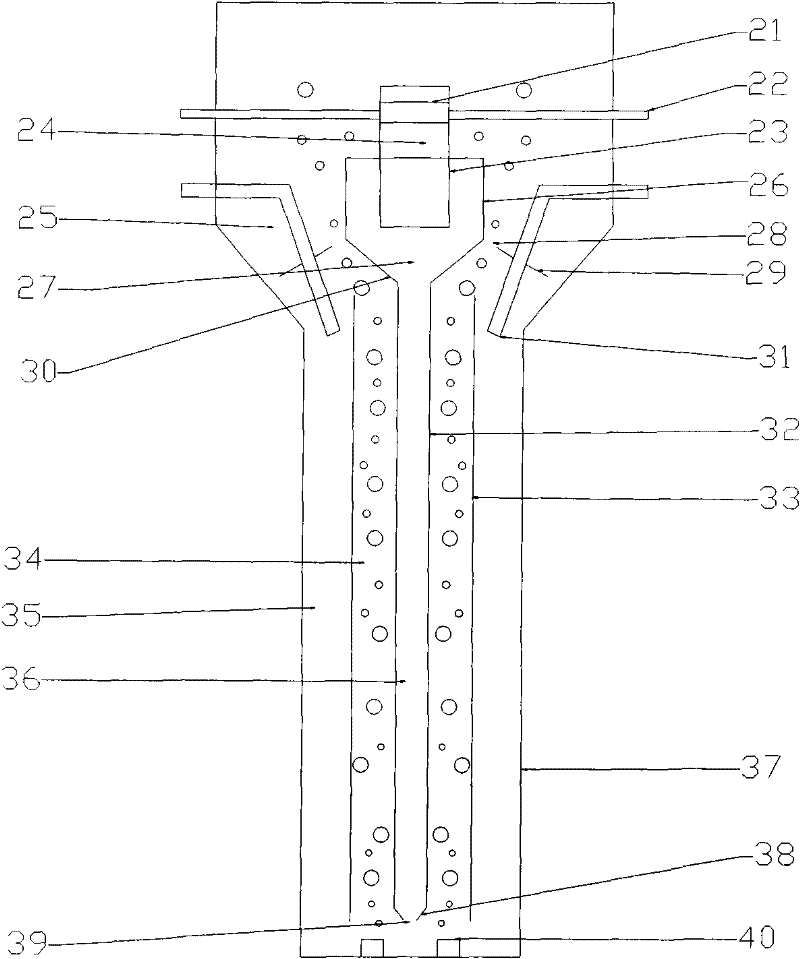

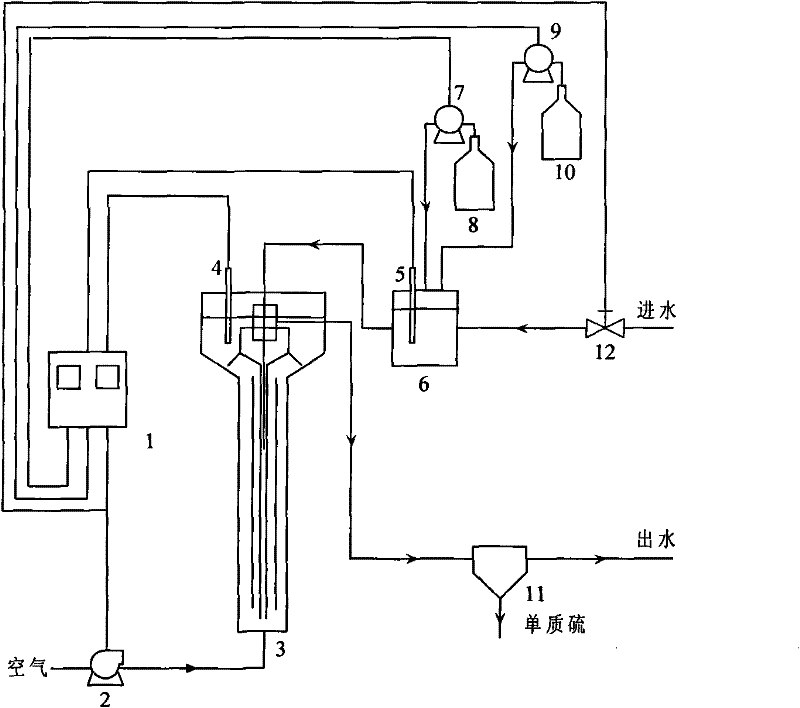

Method used

Image

Examples

Embodiment 1

[0079] Example 1: Simulation of sulfide-containing wastewater

[0080] 1) Immobilized Thiobacillus, with Na 2 S 2 o 3 5~10g / L, KNO 3 5~10g / L, NaHCO 3 2g / L, KH 2 PO 4 0.1g / L culture medium at 30°C for 14 days, mix the bacterial solution with the immobilized carrier, continue to culture in the above method for 10-14 days, replace the medium every 3-4 days;

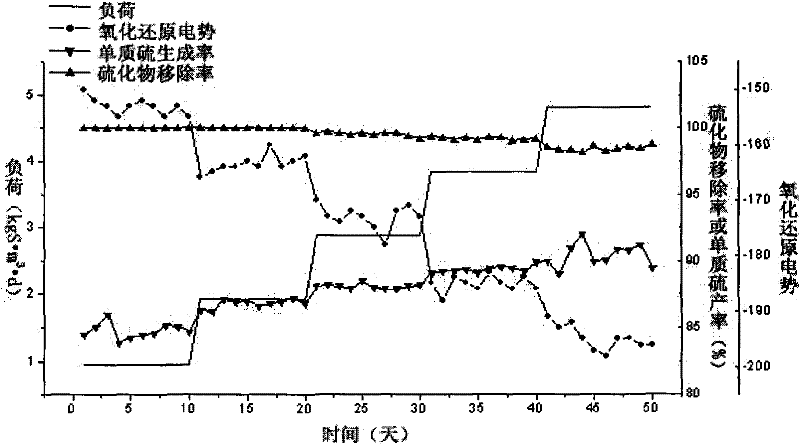

[0081] 2) The reactor is started, and the activated immobilized Thiobacillus is placed in the reactor, and the initial load of the reactor is controlled at 1~3kgS / (m 3 d), the load is increased by 2kgS / (m every 3 days 3 d).

[0082] 3) Inlet water temperature is 30-35°C, and the oxidation-reduction potential value (redox potential) is controlled at -150--100mV. When the redox potential value is lower than the set value, increase the ventilation and reduce the water intake; When the potential value is higher than the set value, the water intake will be increased and the air flow will be reduced.

[0083] Below are t...

Embodiment 2

[0090] Embodiment 2: the absorbing liquid that gas removes hydrogen sulfide

[0091] Simulated hydrogen sulfide-containing gas (v / v): 4% H 2 S, 96%N 2

[0092] 1) With pH10~11, 0.1M NaHCO 3 / Na 2 CO 3 It is the absorption liquid, after being absorbed by the packed gas-liquid exchange tower, the concentration of sulfide is 100mmolS / L absorption liquid, the pH is 7.5-8.0, and the sulfide content is 60-100mmol. The absorption liquid is pumped to the mixer and enters the reaction device.

[0093] 2) According to the concentration of sulfide in the influent, adjust the hydraulic retention time of the reactor to keep the load of the biological desulfurization device at 12kgS / (m 3 d) or so, the sulfide removal rate of the treated absorption liquid is >98%, the elemental sulfur generation rate is >80%, the pH value of the treated absorption liquid rises to 10, and can be used again for the absorption and purification of hydrogen sulfide gas.

[0094] The sulfide-containing wast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com