Self-regulating powder-feeding device by fluidizing gas

An automatic adjustment and powder supply device technology, applied in the direction of liquid supply device, etc., can solve the problems of large fluidization gas consumption, inability to provide fluidization effect, and inability to guarantee the powder supply stability of electrostatic powder spray guns, etc., and achieve powder level alarm Accurate and convenient adjustment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

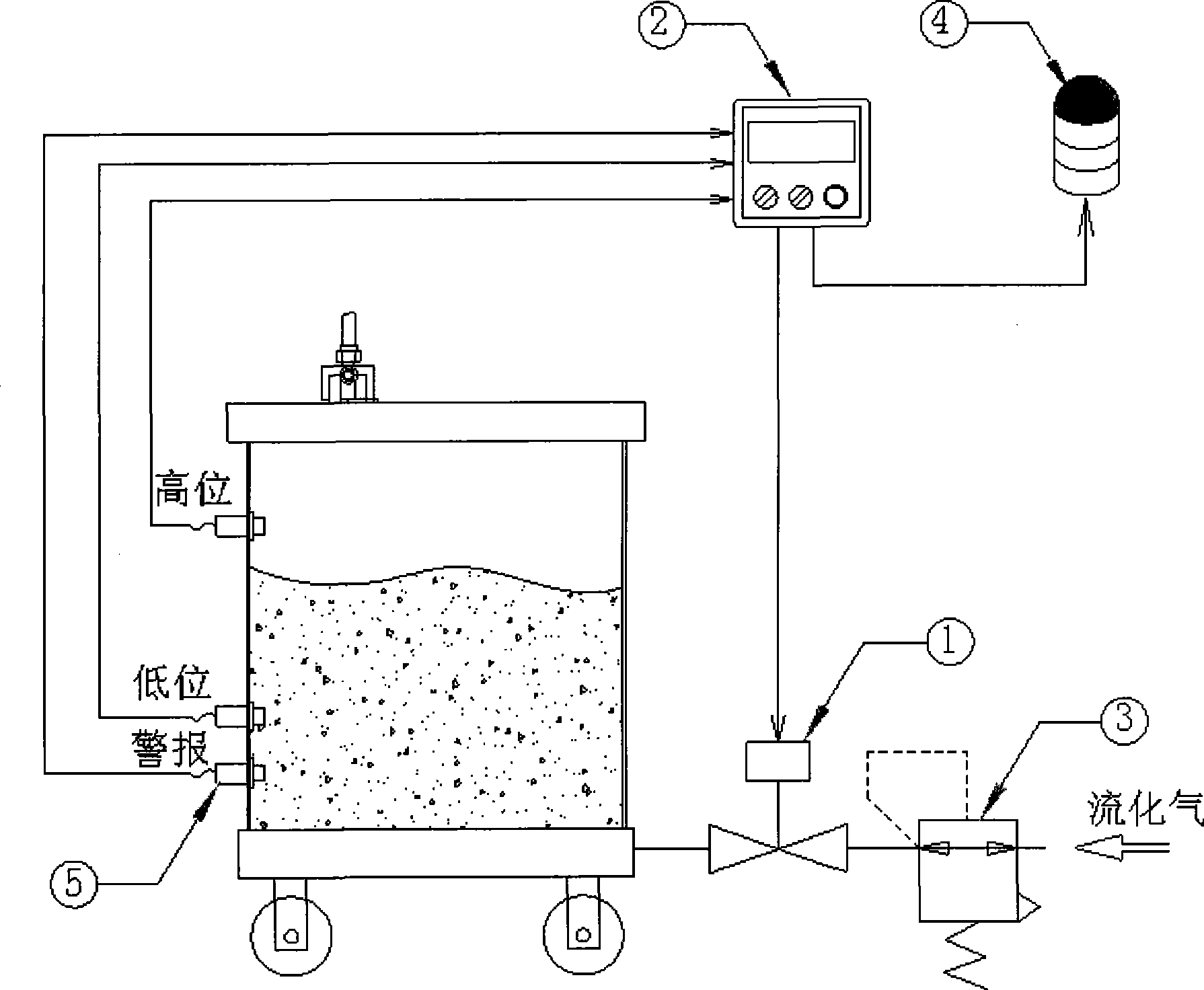

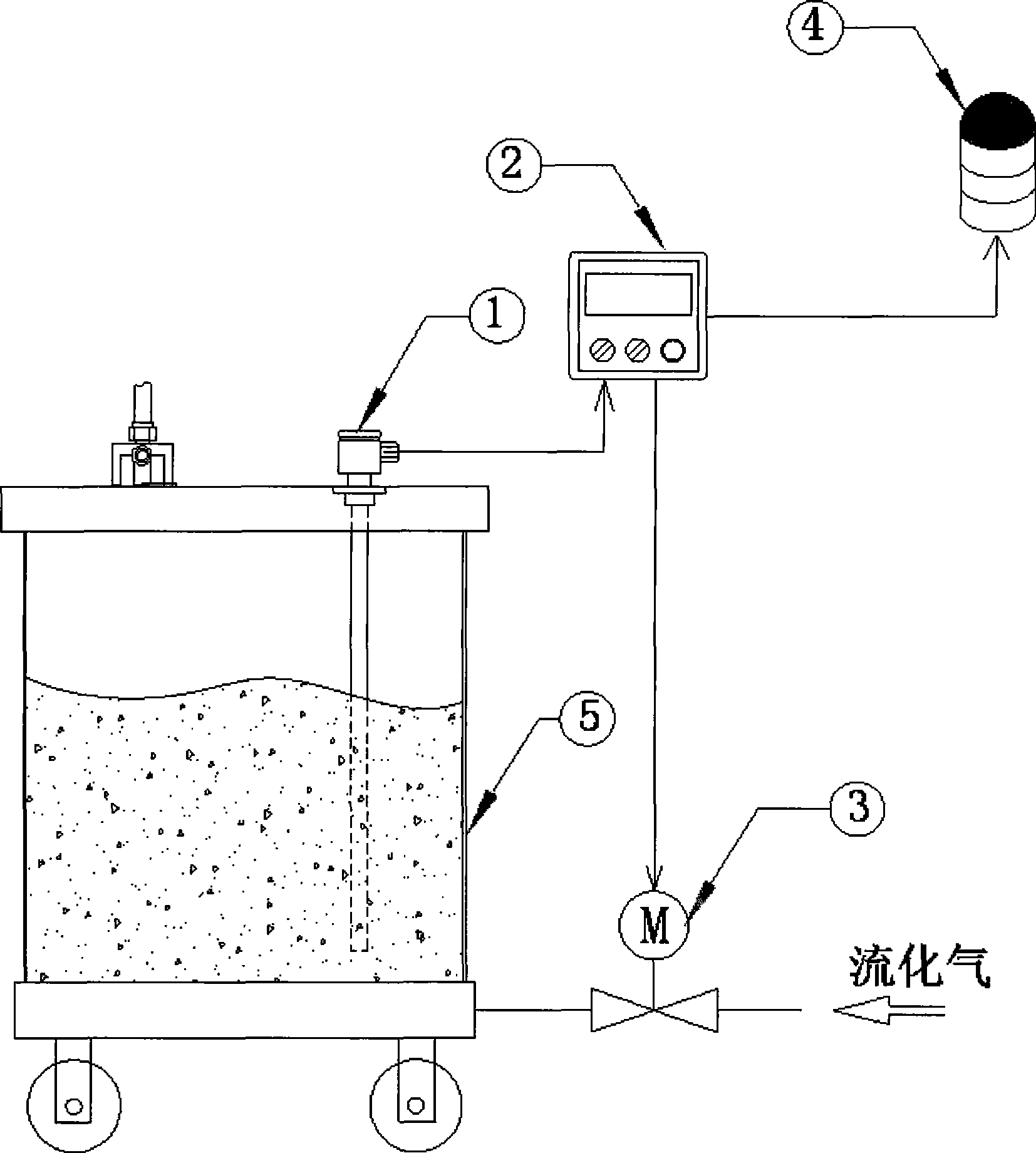

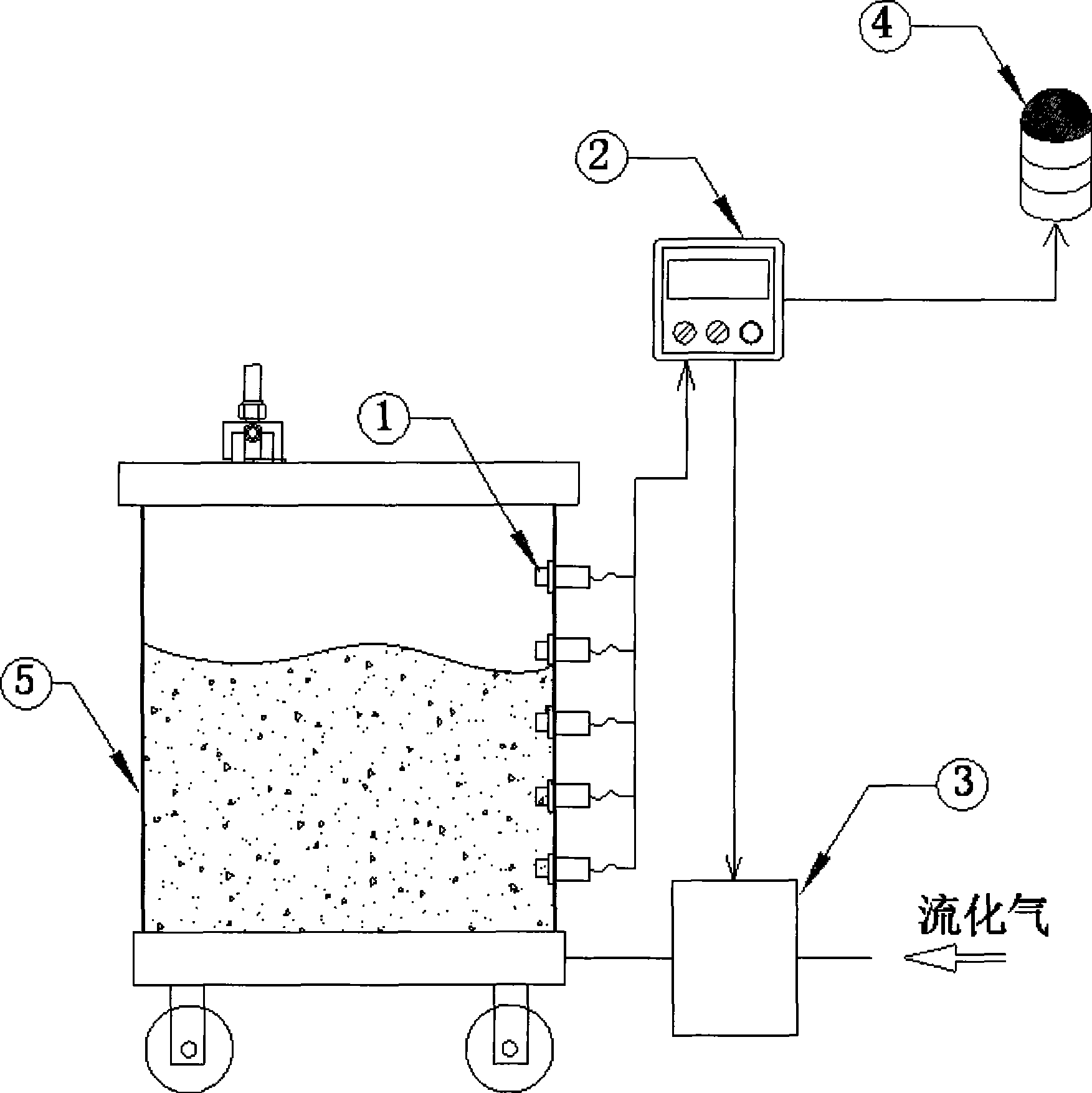

[0022] Such as figure 2 As shown, the figure shows a fluidized bed powder supply device that automatically adjusts the air supply pressure and / or flow rate according to the present invention, which consists of a material level sensor 1, a controller 2, a proportional regulating valve 3 and an alarm 4 components, the height of the powder in the powder bucket 5 is measured by the material level sensor 1, and then the height signal is compared with the set value of the powder level height of the controller, and then the opening of the proportional regulating valve 3 is continuously adjusted to automatically adjust the flow rate. The pressure or flow of gasification (the corresponding curve of pressure or flow adjustment can be preset according to actual requirements). If the measured height is lower than the low powder level alarm setting value, a signal is output to the alarm 4 for low powder level alarm. If the measured height is higher than the high powder level alarm settin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com