Zinc-oxide resistor-piece side insulation package device and packing method

A technology of zinc oxide resistance sheet and packaging device, which is applied in the direction of resistor shell/packaging shell/potting, varistor, varistor core, etc., which can solve the problem of insufficient density of liquid insulating materials, glass Poor glaze uniformity and other problems, to achieve the effect of an excellent insulating protective layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

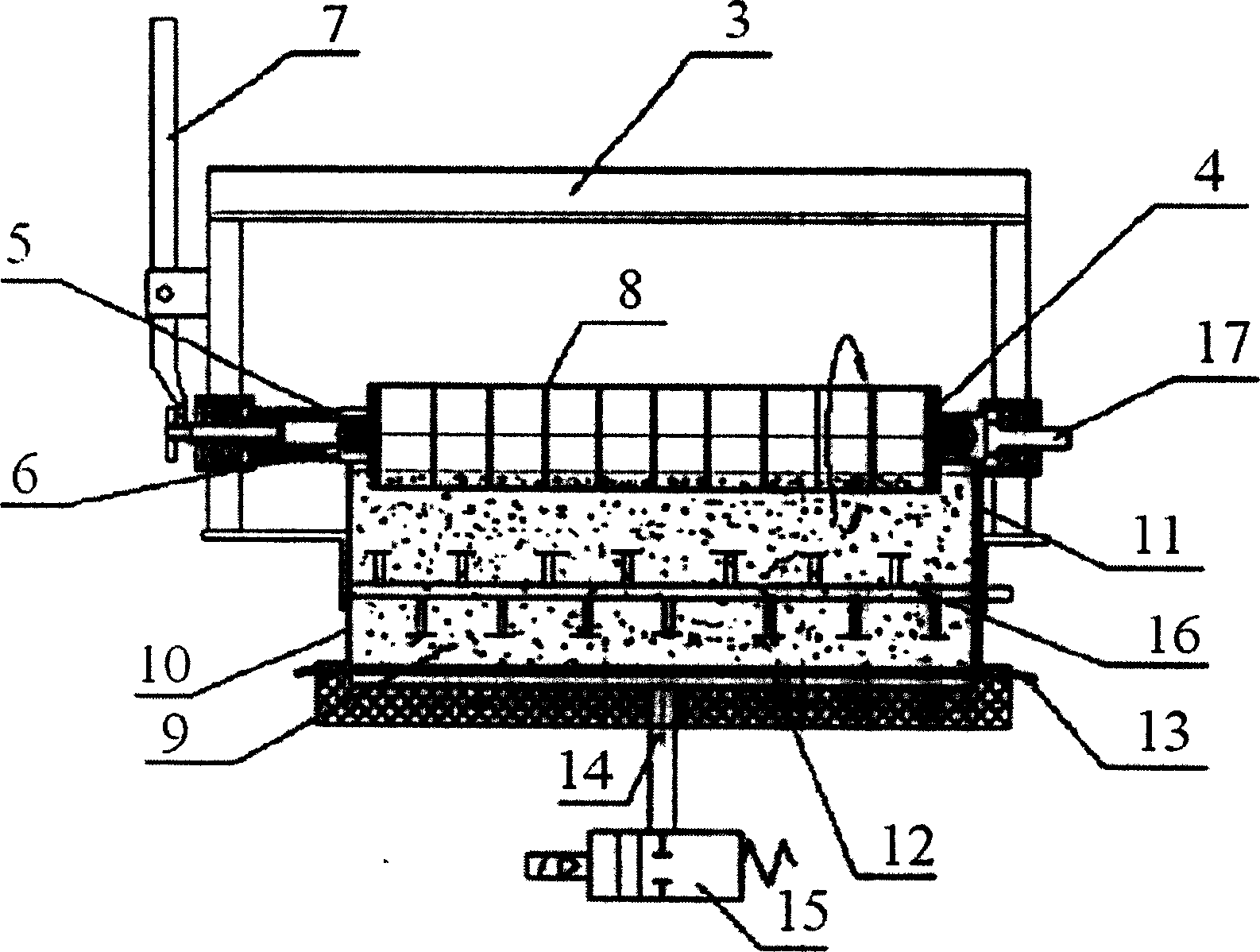

[0010] The present invention will be described in further detail below in conjunction with the accompanying drawings.

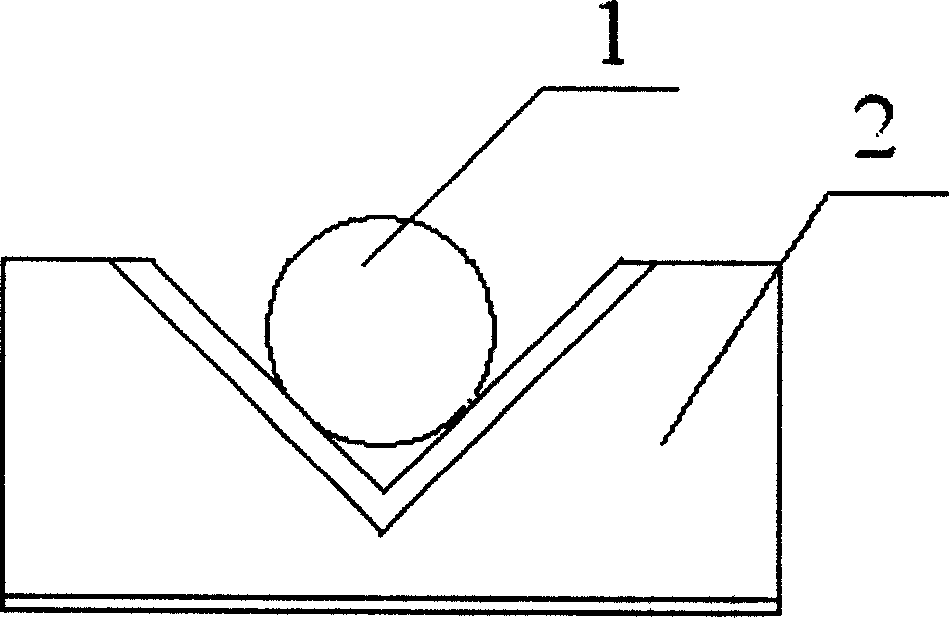

[0011] see figure 1 , 2. The present invention includes a fluidized bed 10 and a clamp 3 installed on the fluidized bed 10. The fluidized bed 10 includes an upper box 11 for placing epoxy insulating powder 9, a lower box 12, and a lower box 12 arranged on the upper box 11. The distribution plate 13 between the lower box body 12 is also provided with a stirring device 16 in the upper box body 11, and an air inlet nozzle 14 communicating with the air flow control valve 15 is also provided on the lower box body 12, and the clamp 3 includes a set On both sides of the upper end of the upper box body 11, the same diameter as the zinc oxide resistance sheet 1, chucks 4, 5, and a wrench 7 connected to the chuck 5 are also arranged on the chuck 5, and the chuck 5 is also provided with There is a spring 6, the collet 4 is connected with the rotating shaft 17, a V-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com