Organic hazardous waste gasification melting treatment system and method

A hazardous waste, gasification and melting technology, applied in the direction of combustion methods, incinerators, indirect carbon dioxide emission reduction, etc., can solve the problems of unstable system operation, low fuel circulation, high local temperature, etc., and achieve a good fluidization state and no harmful Less smoke, good applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

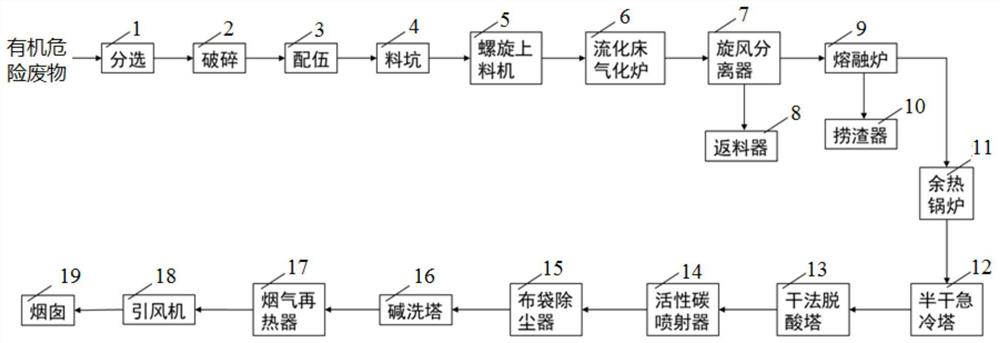

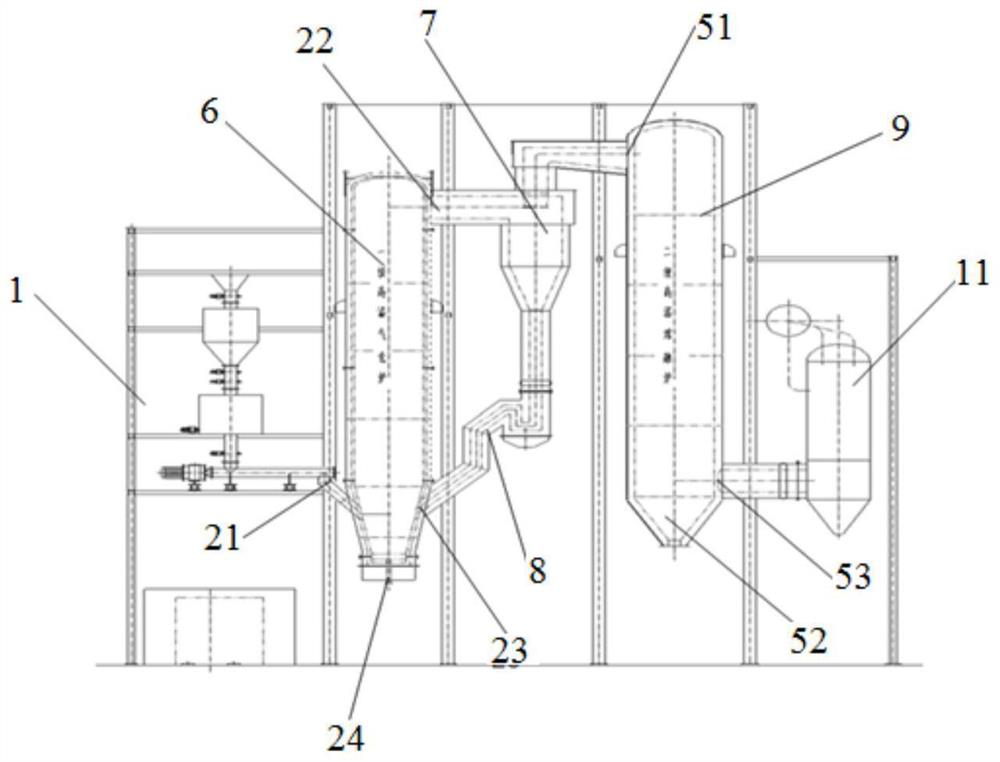

[0040] Please refer to figure 1 and figure 2 As shown, this embodiment provides a circulating fluidized bed gasification melting furnace, which includes: a feeding device 1, a circulating fluidized bed gasification furnace 6, a cyclone separator 7, a feeder 8, a melting furnace 9 and Waste heat boiler 11.

[0041] The middle part of the circulating fluidized bed gasification furnace 6 is the hearth, and the lower end is conical. The lower part of the hearth is provided with a gas distributor. One side inside the hearth of the circulating fluidized bed gasifier 6 is provided with a feed inlet 21, and the feed inlet 21 is located above the gas distributor. A material return port 23 is provided below one side inside the furnace, and the material return port 23 is higher than the gas distributor, but lower than the feed port 21 . The lower end of the furnace is provided with an air inlet 24 . A smoke outlet 22 is arranged above the inner side of the furnace, and the smoke out...

Embodiment approach 2

[0048] This embodiment provides a gasification and melting treatment system for organic hazardous waste, which includes:

[0049] The material compatibility and feeding system is used to mix the materials and transport them to the circulating fluidized bed gasifier 6, including the sequentially connected sorting device 1, crushing device 2, compatibility device 3, material pit 4 and screw feeding Machine 5.

[0050] The circulating fluidized bed gasification melting system includes a circulating fluidized bed gasification furnace 6 , a cyclone separator 7 , a feeder 8 , a melting furnace 9 and a slag catcher 10 connected in sequence. The circulating fluidized bed gasification furnace 6 is connected with the screw feeder 5 of the feeding system, and is used for pyrolysis and gasification of organic hazardous waste to obtain pyrolysis gas, carbonized coarse particles, and carbonized fine particles. The cyclone separator 7 is used to separate pyrolysis gas, carbonized fine parti...

Embodiment approach 3

[0054] This embodiment provides a method for treating organic hazardous waste using the organic hazardous waste gasification and melting treatment system of Embodiment 2, which includes the following steps:

[0055] Step S1: Compatibility of organic waste. After preliminarily sorting and crushing the collected organic hazardous waste, according to the elemental composition and calorific value of the material, it is formulated into a compatible material with reasonable elemental composition and stable calorific value. After the compatible material is mixed, it is sent into the circulation by the screw feeder 5 The feed port of the fluidized bed gasifier 6. According to one embodiment of the present invention, the calorific value of the compatible material is between 4000-4500Kcal / Kg, and the particle size of the material is 5mm-10mm.

[0056] Step S2: Compatible material circulating fluidized bed gasification. At a certain temperature, the material is gasified in the circulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com