Punching mechanism for honeycomb paper core automatic production line

An automatic production line, honeycomb paper core technology, applied in the direction of cardboard articles, etc., can solve the problems of difficult discharge of hot and humid gas, paper core bonding and detachment, honeycomb paperboard foaming, etc., to prevent surface foaming and poor bonding, The effect of ensuring quality, eliminating paper force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

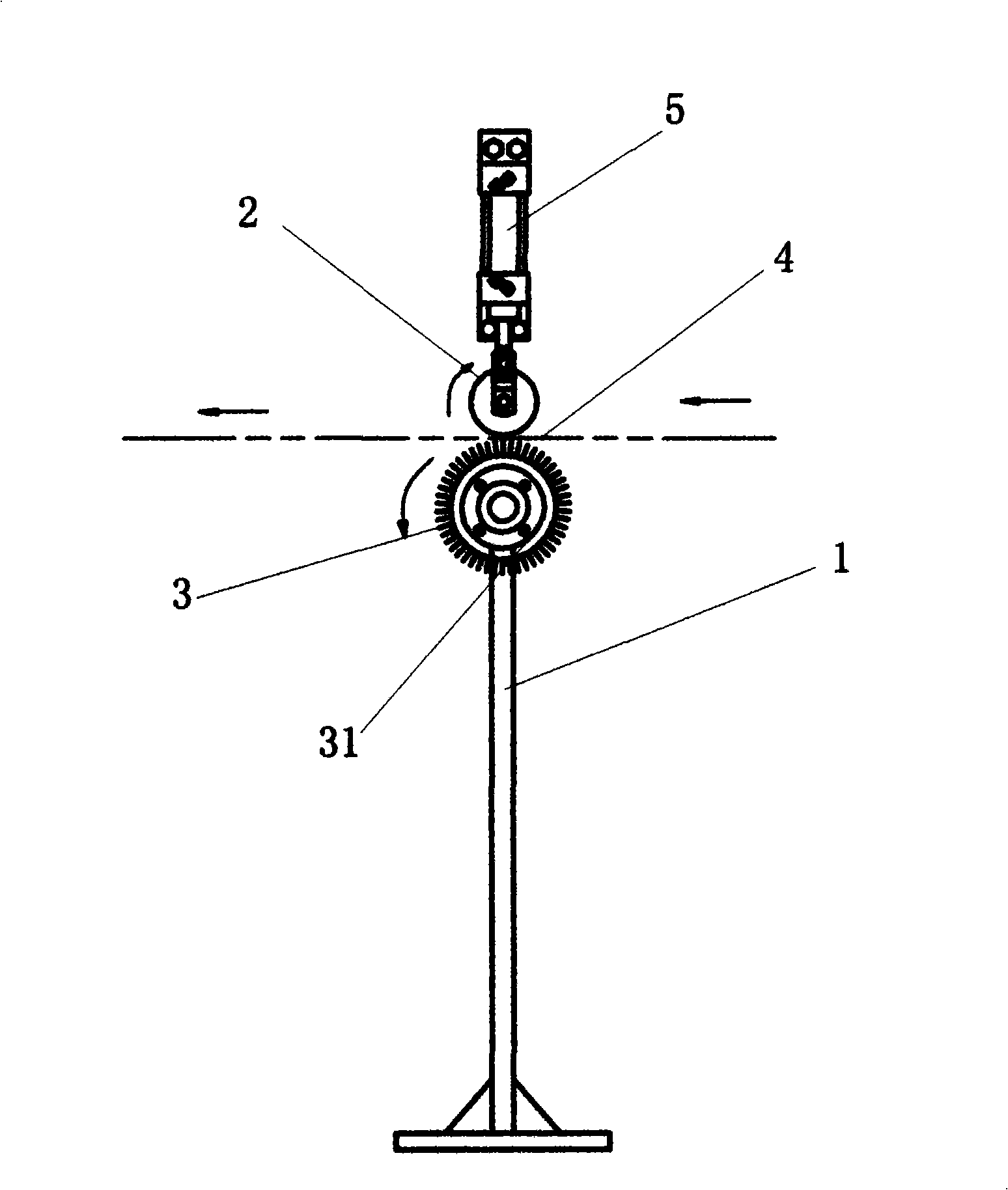

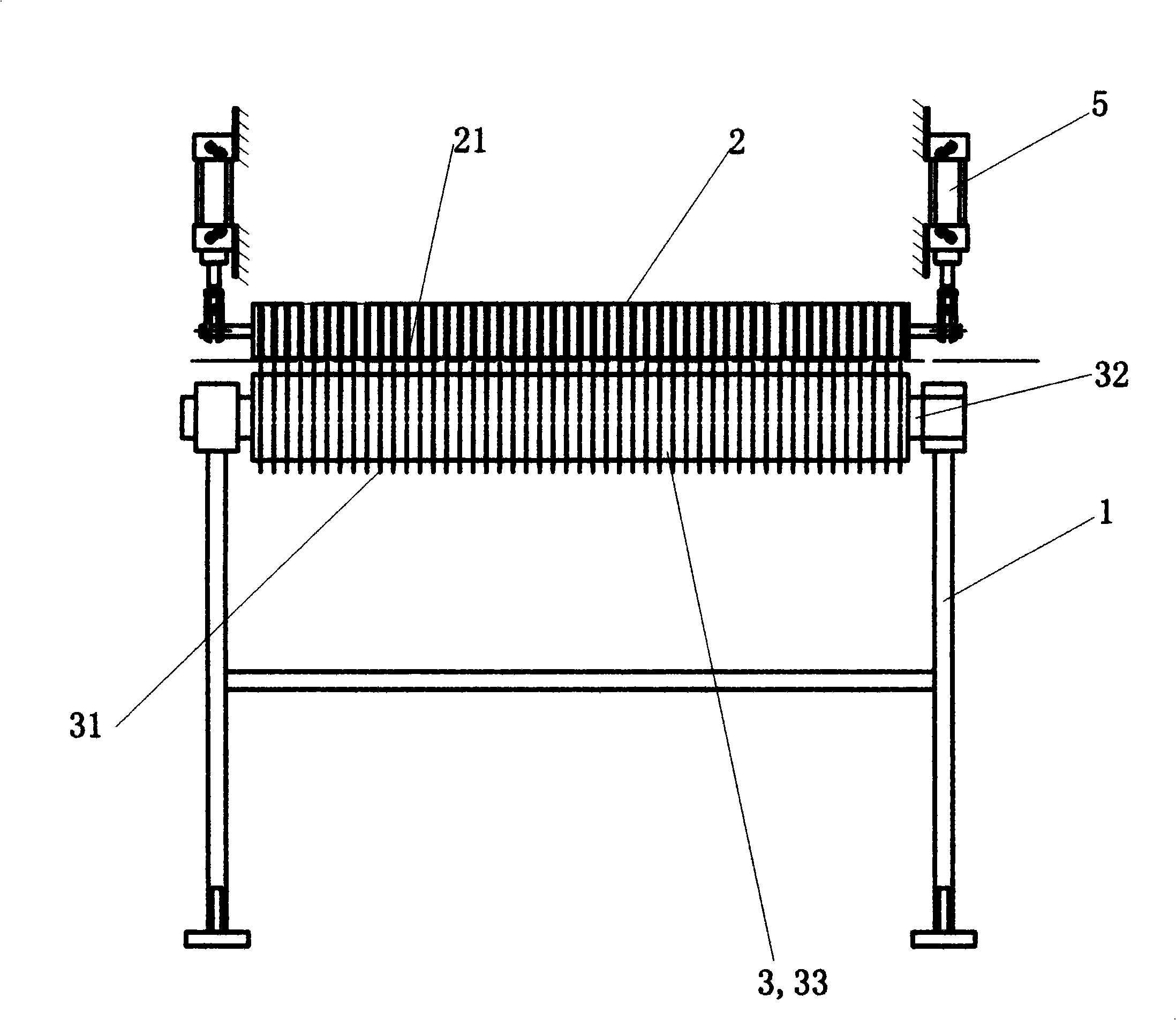

[0010] The present invention as figure 1 , figure 2 As shown, a punching mechanism for a honeycomb paper core automatic production line, the punching mechanism includes a frame 1, an upper pressing roller 2 and a lower pressing roller 3, and the upper and lower pressing rollers 2 and 3 are rotatably installed respectively On the frame 1, a paper feed channel 4 is arranged between the upper and lower pressing rollers 2, 3, and roller needles 31 are densely distributed on the surface of the lower pressing roller 3.

[0011] The above-mentioned roller needles 31 densely distributed on the roller surface of the lower pressure roller 3 are embedded in the roller surface of the lower pressure roller 3 in several spaced rings, and correspondingly, the roller surface of the upper pressure roller 2 corresponding to the roller needles 31 is provided with a relief groove 21 . On the frame 1 at both ends of the above-mentioned upper pressing roller 2, an air cylinder 5 connected with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com