Moisture-curable polyurethane hot melt adhesive as well as preparation method and application thereof

A polyurethane hot-melt adhesive and moisture-curing technology, which is applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problem of poor compatibility of polyurethane, difficult to uniform and stable systems, and inability to adapt to textiles. Industry development needs and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

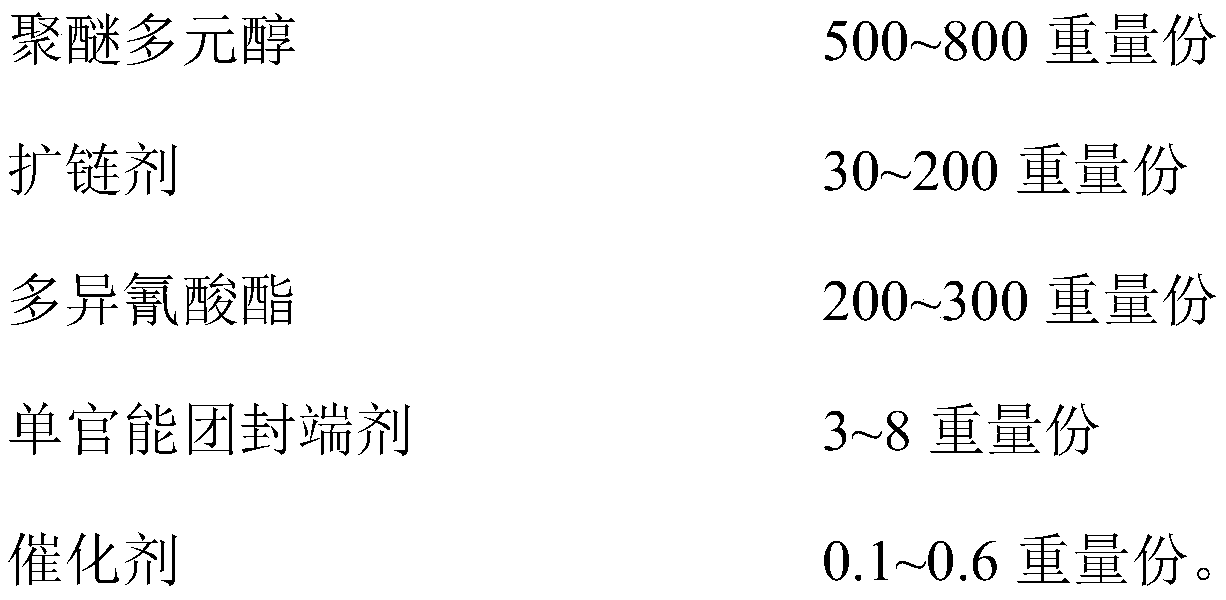

[0071] This embodiment provides a moisture-curing polyurethane hot-melt adhesive, and the preparation raw materials are as follows:

[0072]

[0073] Concrete preparation steps are as follows:

[0074] (1) 650 parts by weight of polyoxypropylene glycol (4000), 150 parts by weight of polyester polyol, 0.22 parts by weight of antioxidant YS245 and 0.05 parts by weight of phosphoric acid are added to the reaction vessel and mixed and dehydrated so that the water content≤500ppm, Then add 117 parts by weight of MDI, react at 75°C for 3h, then raise the temperature to 95°C for 1h;

[0075] (2) Add 126 parts by weight of MDI to the reacted material in step (1), stir for 0.5 h and mix well, then add 67.87 parts by weight of chain extender polyoxypropylene glycol (400), and react at 95°C for 2 hours;

[0076] (3) Cool the material after the reaction in step (2) to 75°C, then add 3.17 parts by weight of isopropanol, and react at 75°C for 0.5h;

[0077] (4) Add 0.55 parts by weight ...

Embodiment 2

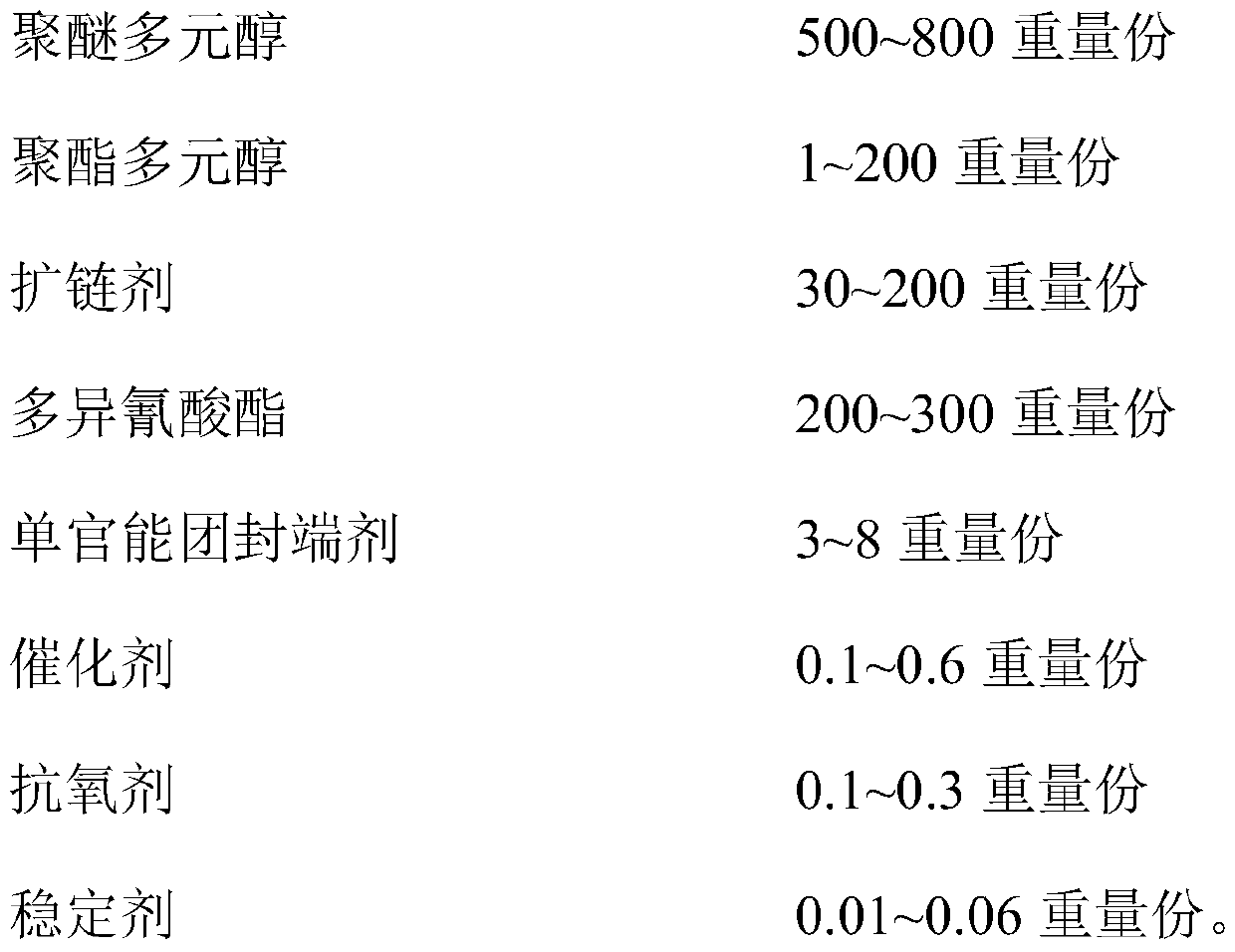

[0079] This embodiment provides a moisture-curing polyurethane hot-melt adhesive, and the preparation raw materials are as follows:

[0080]

[0081] Concrete preparation steps are as follows:

[0082] (1) 700 parts by weight of polyoxypropylene glycol (4000), 100 parts by weight of polyester polyol, 0.21 parts by weight of antioxidant YS245 and 0.05 parts by weight of phosphoric acid are added to the reaction vessel and mixed and dehydrated so that the water content≤500ppm, Then add 103.12 parts by weight of MDI, react at 70°C for 3h, then raise the temperature to 90°C for 1h;

[0083] (2) Add 146.58 parts by weight of MDI to the reacted material in step (1), stir for 0.5 h to mix, add 38 parts by weight of chain extender dipropylene glycol, and react at 90° C. for 1 h;

[0084] (3) Cool the material after the reaction in step (2) to 70°C, then add 3.02 parts by weight of isopropanol, and react at 70°C for 0.5h;

[0085] (4) Add 0.52 parts by weight of bismorpholinyl die...

Embodiment 3

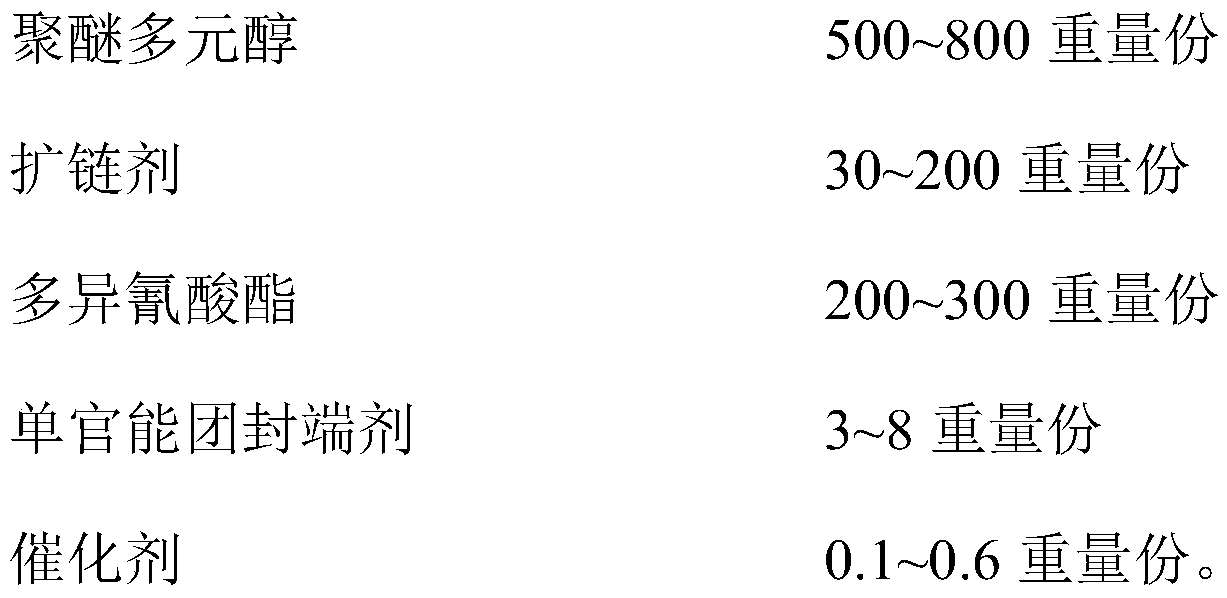

[0087] This embodiment provides a moisture-curing polyurethane hot-melt adhesive, and the preparation raw materials are as follows:

[0088]

[0089] Concrete preparation steps are as follows:

[0090] (1) 800 parts by weight of polyoxypropylene diol (4000), 0.25 parts by weight of antioxidant YS245 and 0.06 parts by weight of phosphoric acid are added to the reaction vessel and mixed and dehydrated to make the water content≤500ppm, then add 75 parts by weight of MDI, 80 ℃ for 3 hours, and then heated to 100 ℃ for 1 hour;

[0091] (2) Add 217.5 parts by weight of MDI to the reacted material in step (1), stir for 0.5 h to mix, add 181.8 parts by weight of chain extender polyoxypropylene glycol (400), and react at 100 ° C for 2 h;

[0092] (3) Cool the material after the reaction in step (2) to 80°C, then add 5.27 parts by weight of morpholine, and react at 80°C for 0.5h;

[0093] (4) Add 0.6 parts by weight of bismorpholino diethyl ether to the reacted material in step (3)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com