Patents

Literature

130results about "Natural resin adhesives" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

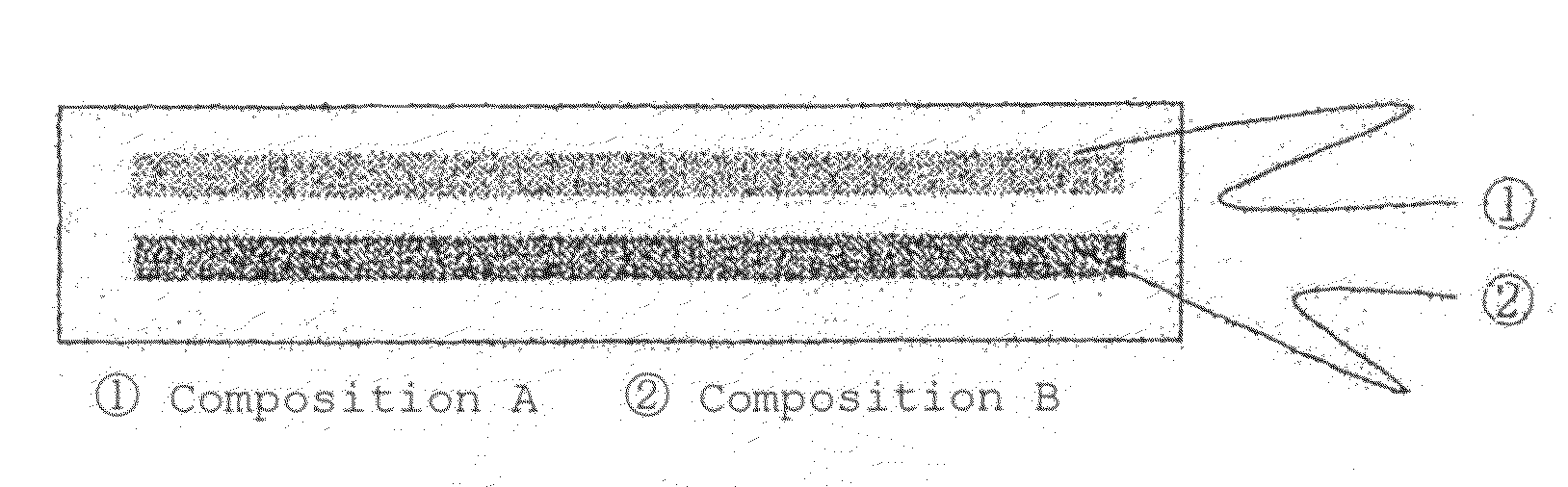

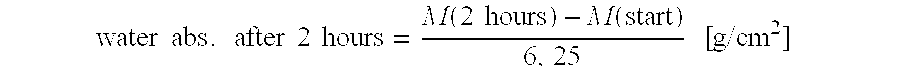

Cellulose acylate film and method for producing same

InactiveUS20050150426A1Change unevennessVisibility changeNatural resin coatingsPolarising elementsCelluloseVisibility

Disclosed is a cellulose acylate film produced according to a melt casting process and having an Re unevenness of from 0 to 10%. When built in a liquid-crystal display device, the film significantly solves the problem of display unevenness and humidity-dependent visibility change.

Owner:FUJIFILM CORP

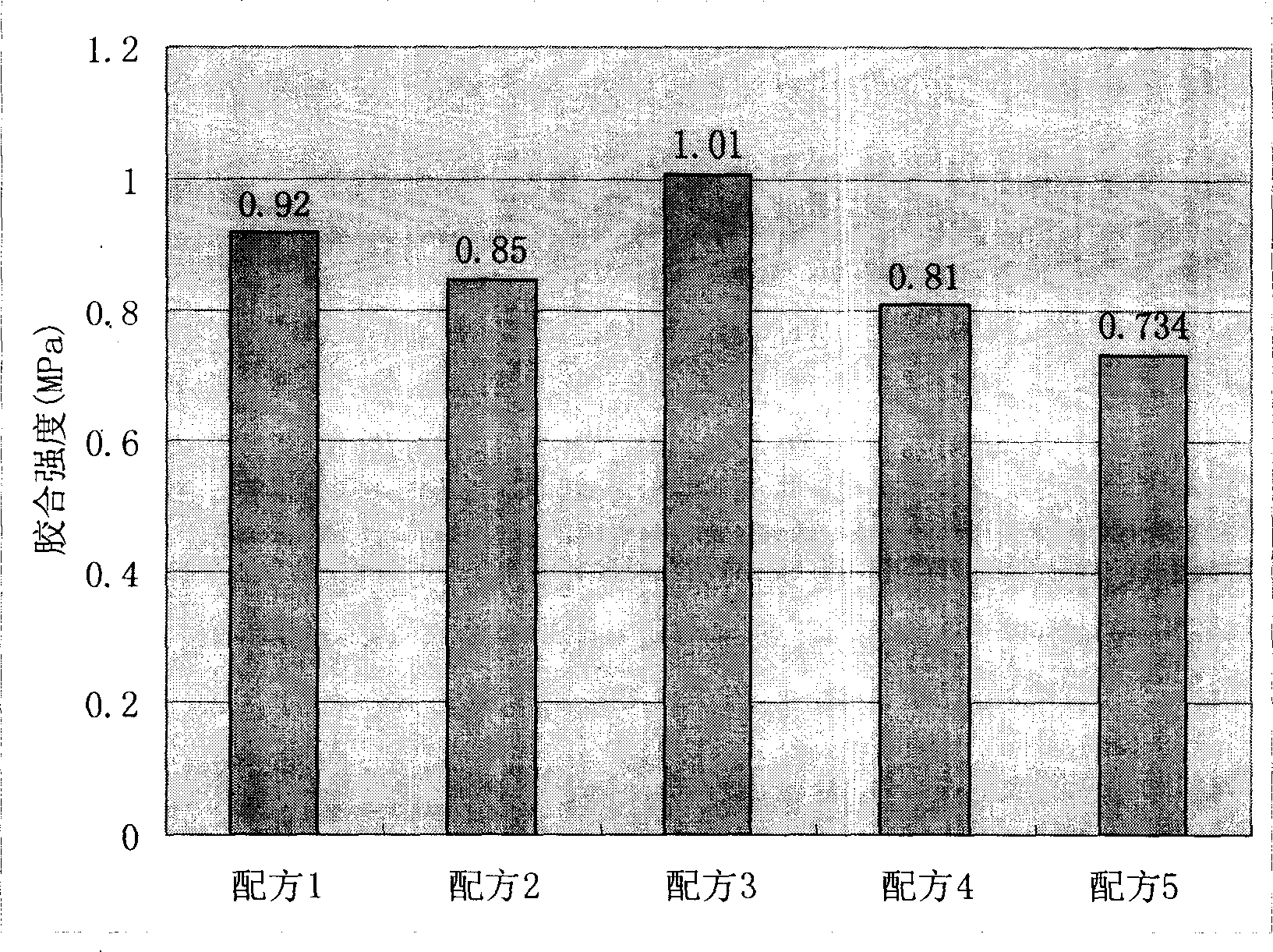

Hot melt adhesive used for automotive interiors, and preparation method of hot melt adhesive

InactiveCN102618211AHarmless to healthHigh bonding strengthWax adhesivesNatural resin adhesivesPolyethylene vinyl acetateParaffin wax

The invention discloses a hot melt adhesive used for automotive interiors, and a preparation method of the hot melt adhesive. The hot melt adhesive used for automotive interiors is characterized by comprising a proportion of paraffin, polyethylene wax, a thermoplastic elastic body SBS, random polyolefin, polyethylene vinyl acetate, C5 petroleum resin, rosin pentaerythritol ester, antioxygen, coupling agent and filler. The preparation method comprising the following steps: heating a stirring kettle to 140 to 160 DEG C, and adding the paraffin and the polyethylene wax; adding the thermoplastic elastic body SBS, vacuum-pumping and keeping warm, adding HMW(high molecular weight) random polyolefin I, HMW random polyolefin II and the antioxygen; adding the coupling agent and the filler; cooling, and adding polyethylene vinyl acetate I and polyethylene vinyl acetate II; cooling and adding the C5 petroleum resin; adding the rosin pentaerythritol ester and keeping warm; and emptying the stirring kettle, pressurizing, discharging and forming. No pollution or poison is produced during the production process of the hot melt adhesive; and the hot melt adhesive has the advantages of high adhesion strength, long opening time, good temperature resistance, strong ageing resistance, good tenacity, strong waterproofness and the like.

Owner:浙江固特新材料科技股份有限公司

Stable Soy/Urea Adhesives and Methods of Making Same

InactiveUS20100069534A1Good compatibilityImprove stabilityProtein adhesivesPaper coatingAdhesiveDiluent

The present invention provides an improved method of producing a stable heat denatured soy / urea adhesive having improved wet and dry strengths, with more efficient production and lower production costs. The method comprises combining urea with soy flour that has been heated until denatured and substantially free from urease activity. The soy flour is preferably heated to a temperature of at least 81° C. up to 100° C. for at least 15 to 500 minutes. Optionally, the method may also include adding a crosslinking agent, diluent or both to the soy flour / urea adhesive and / or adding an emulsified or dispersed polymer. Adhesives and dispersions prepared according to the methods of this invention offer increased stability and strength properties.

Owner:SOLENIS TECH CAYMAN

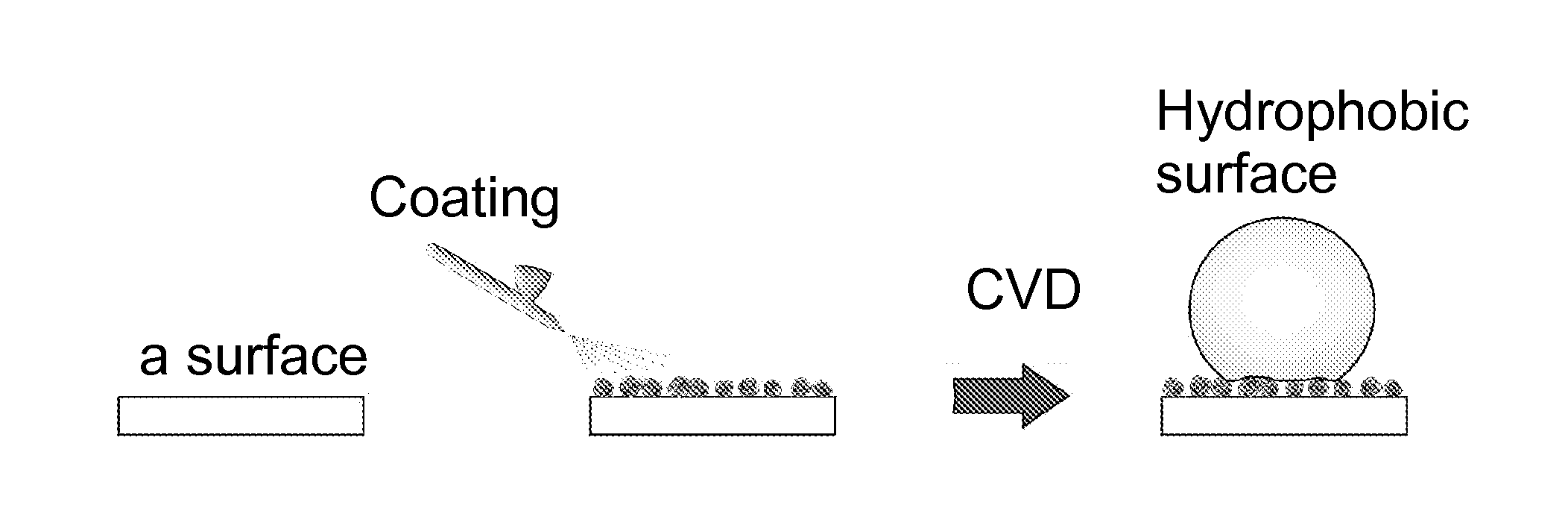

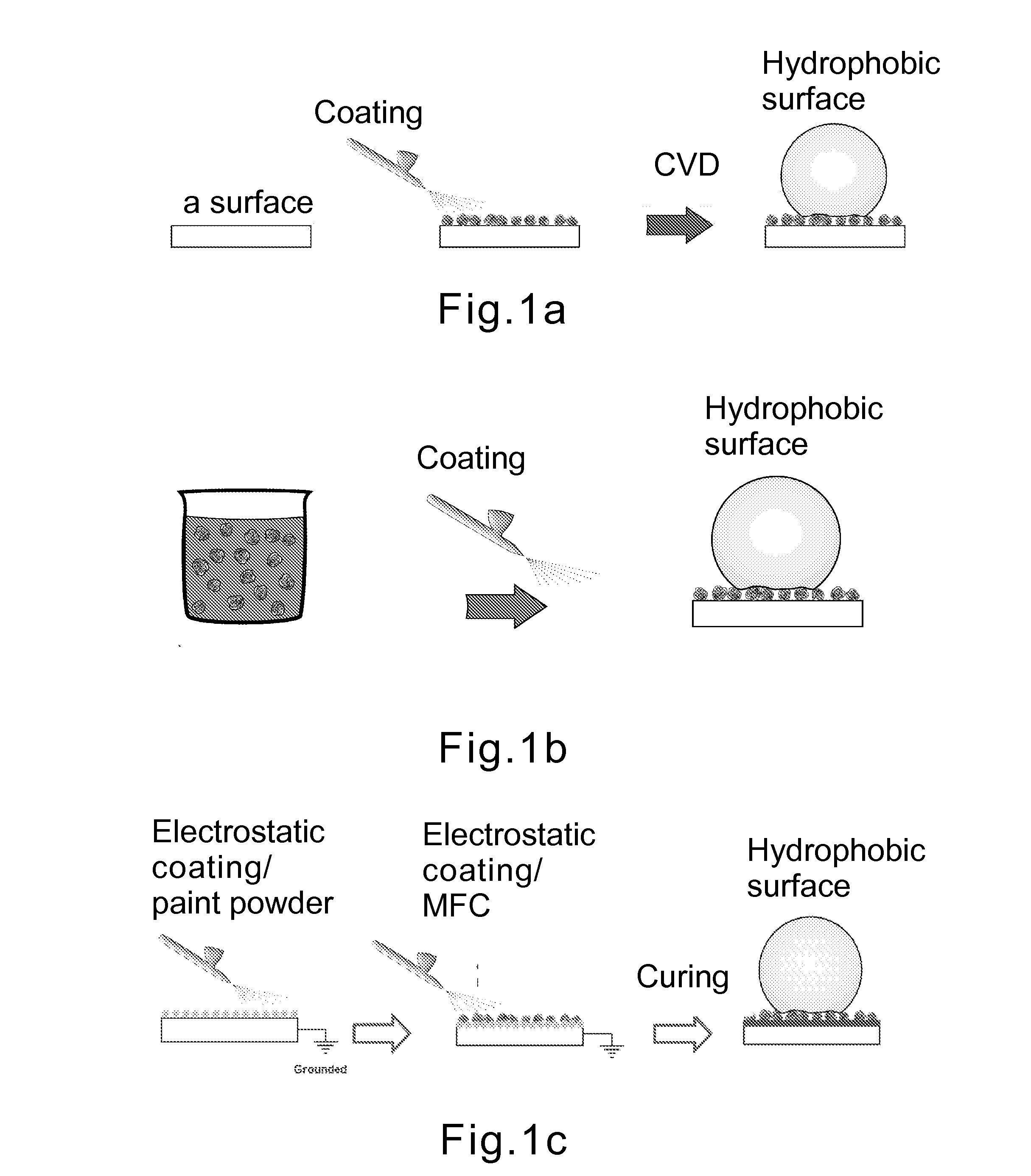

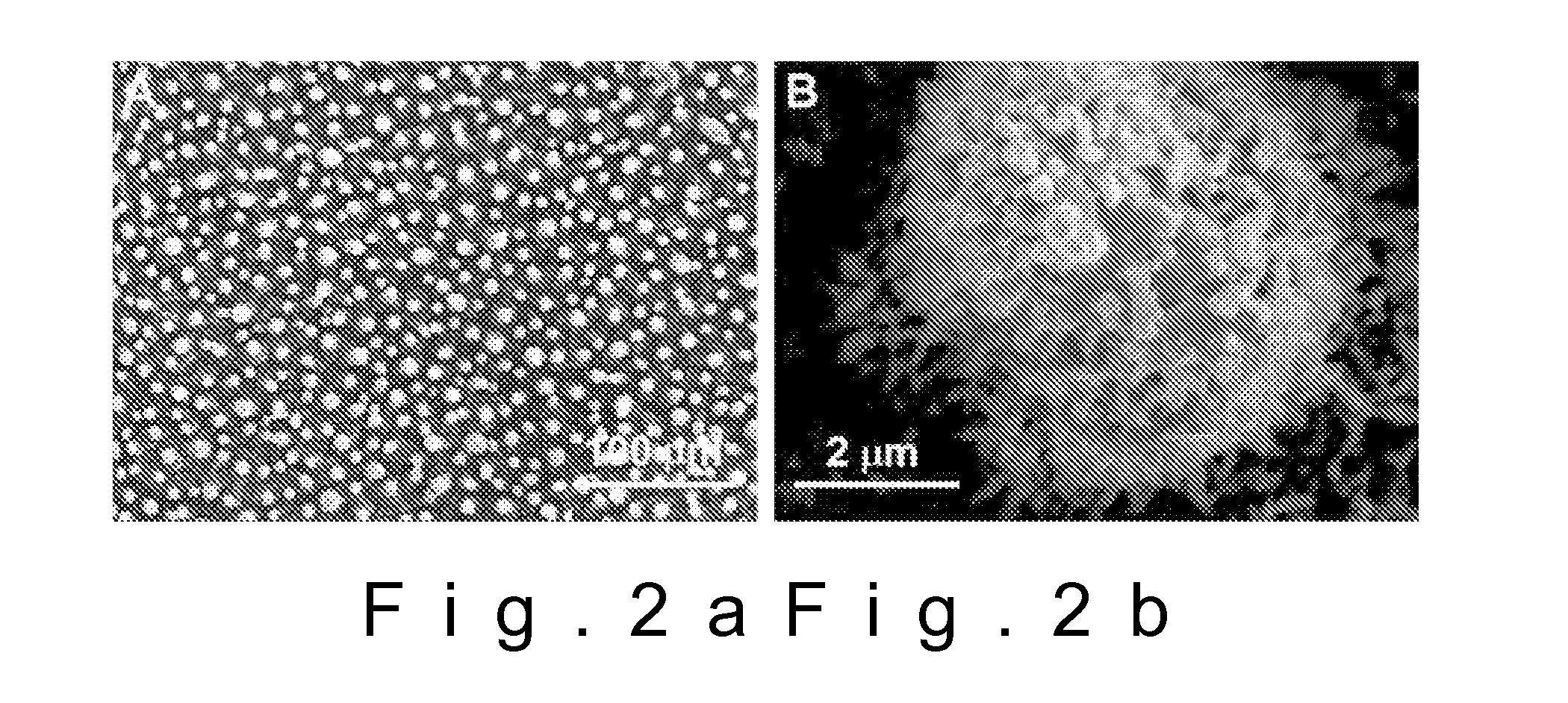

Hydrophobic coating and a method for producing hydrophobic surface

InactiveUS20140130710A1Similar in sizeIncrease contact angleElectric shock equipmentsWater-repelling agents additionPolymer chemistryHydrophobic surfaces

A method for producing a superhydrophobic surface, which includes cellulosic material. The cellulosic material includes nanocellulose particles and the method includes adding the nanocellulose particles to a surface and hydrophobizing the nanocellulose particles with a modifier before, during and / or after the addition of the particles. The invention further relates to a hydrophobic coating.

Owner:UPM-KYMMENE OYJ

Ink Composition for Sensing Gas Exposure and Gas Exposure Indicator

InactiveUS20080267811A1Good flexibilitySpaceNatural resin coatingsMaterial analysis by electric/magnetic meansTreatment statusThiazine dye

An object of the present invention is to provide a material for more easily and accurately detecting treatment status using gas exposure. The present invention relates to an ink composition for detecting an oxidizing gas, or the like, comprising at least one type of azo dye, methine dye, triarylmethane dye and thiazine dye.

Owner:SAKURA COLOR PRODUCTS CORPORATION

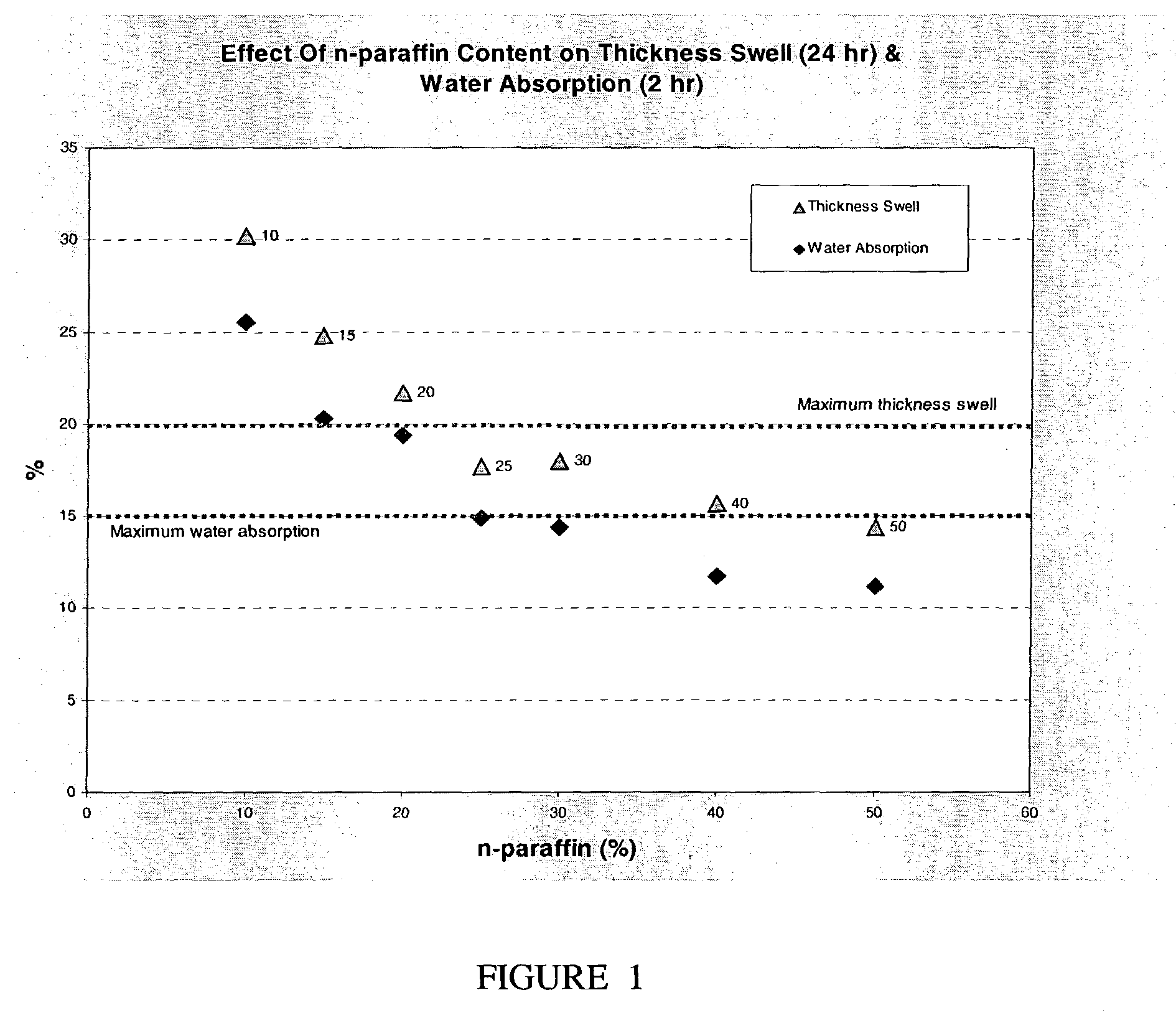

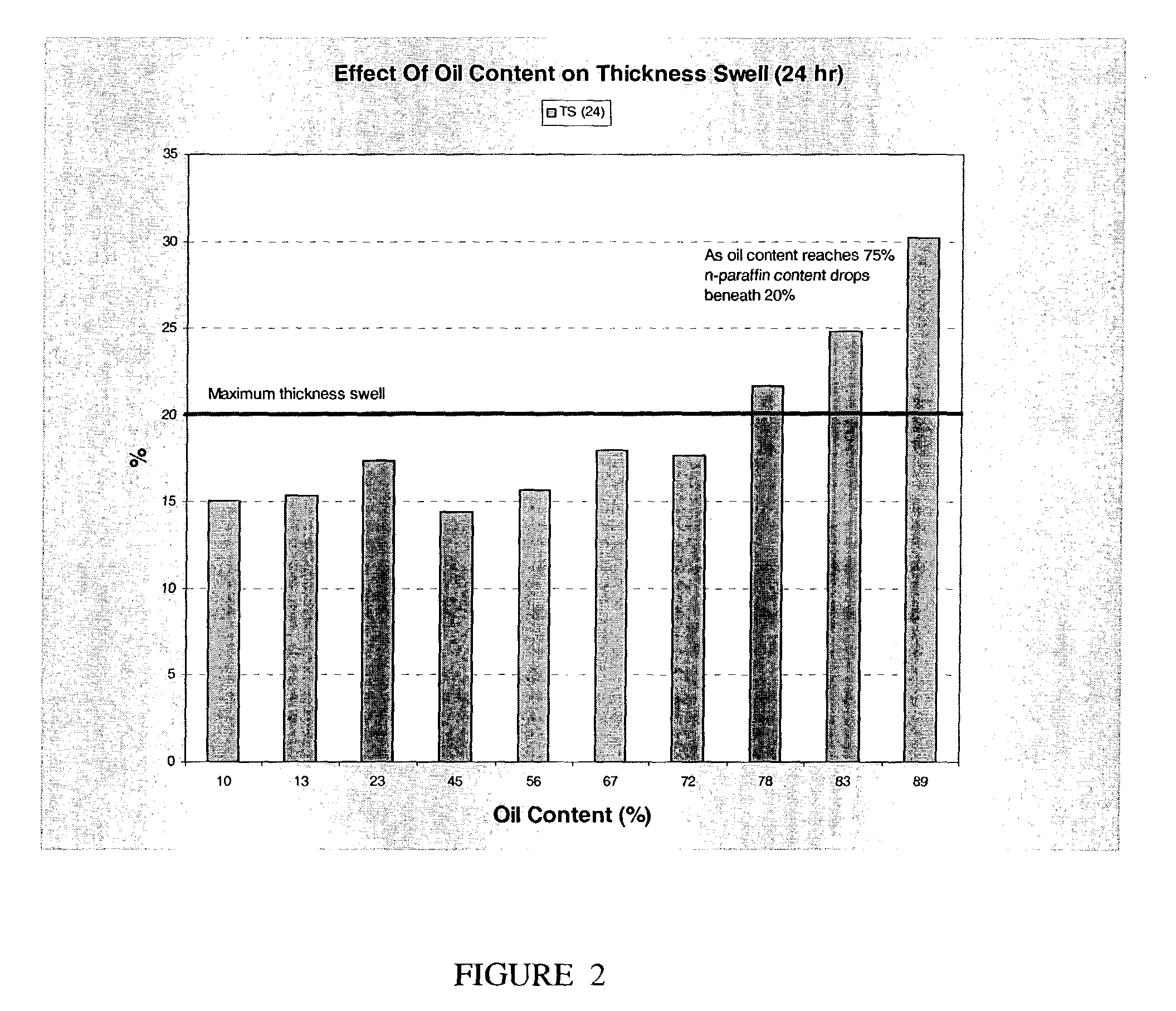

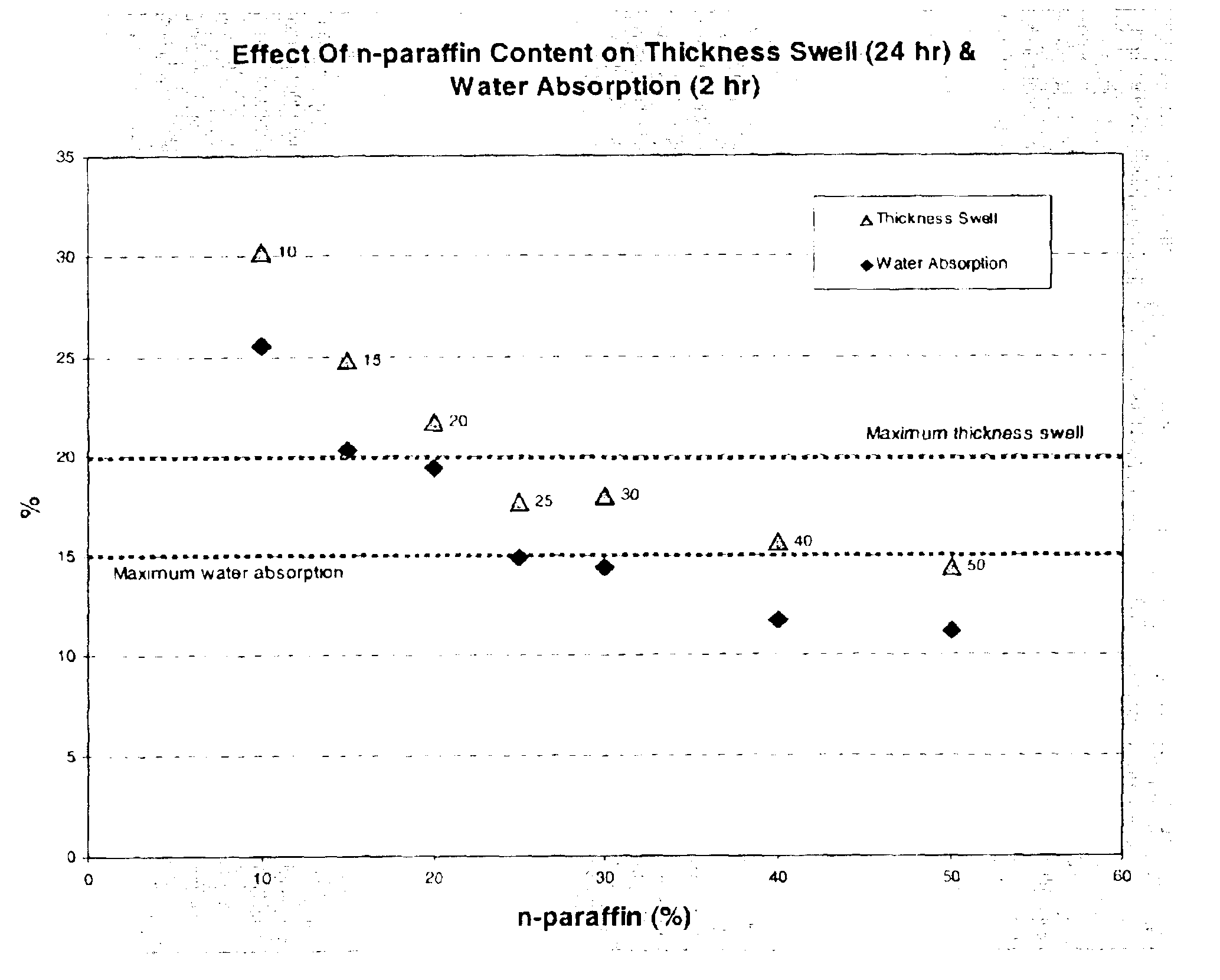

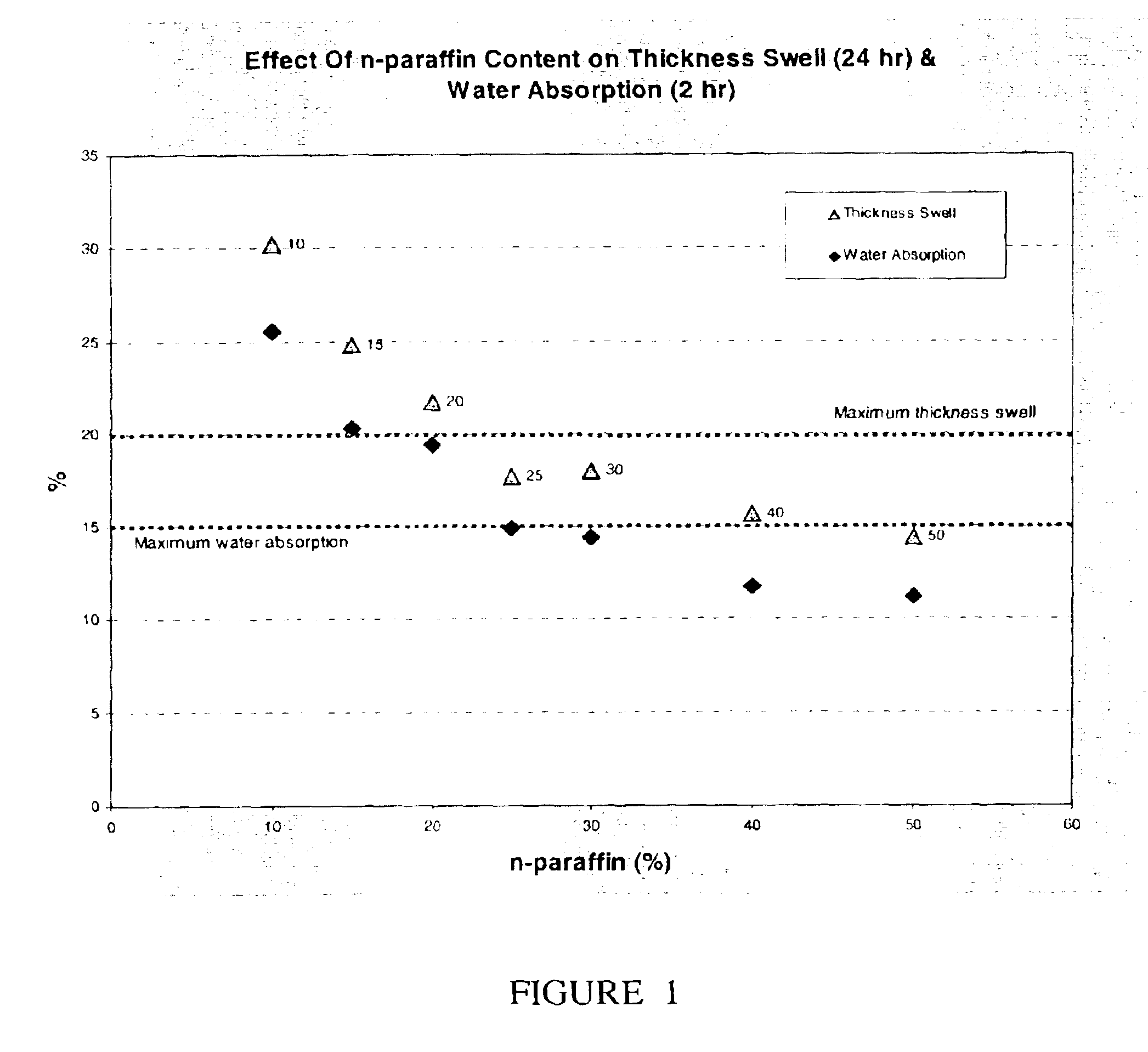

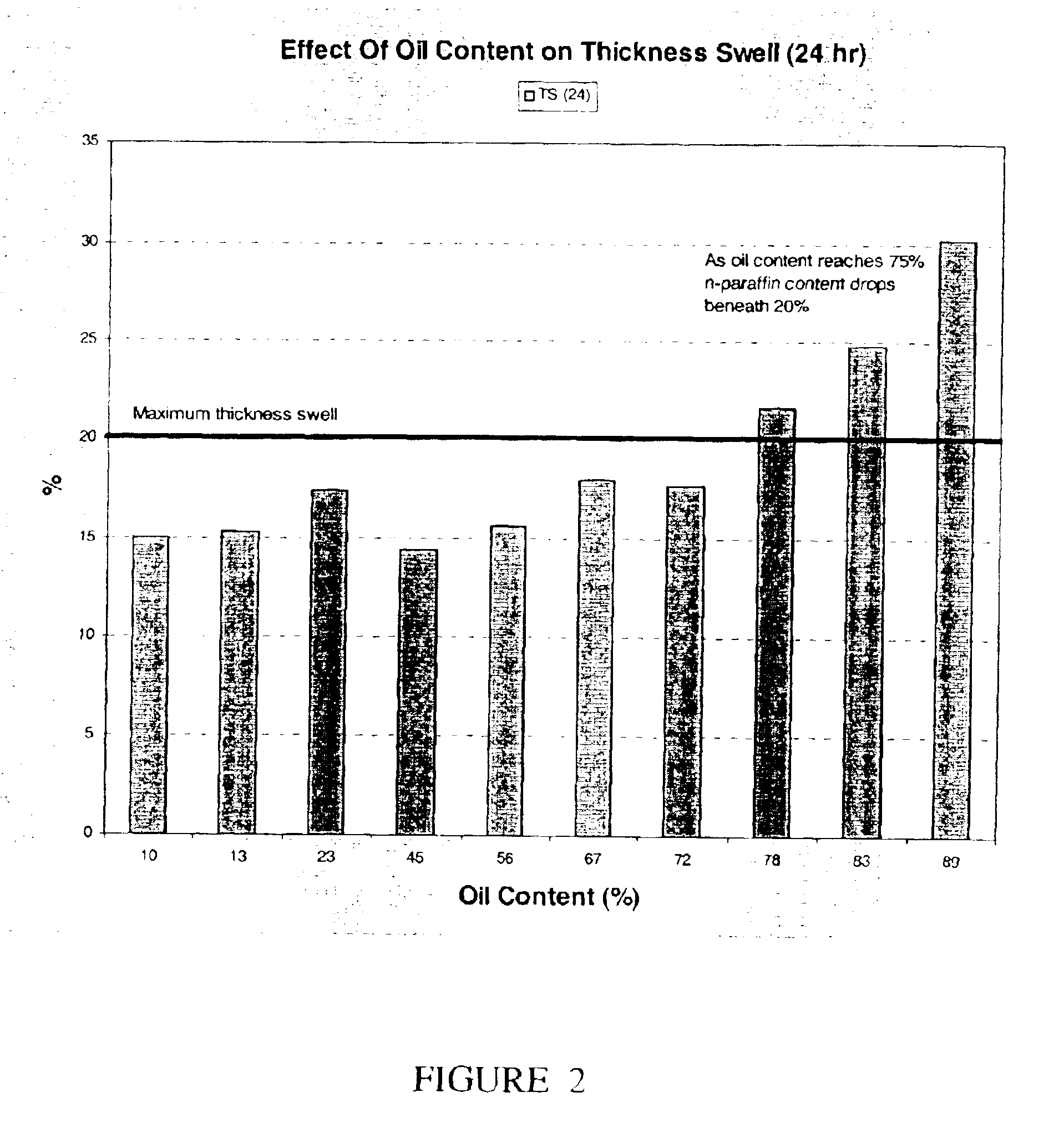

Emulsions for lignocellulosic products, methods of their manufacture, improved lignocellulosic products and methods for their manufacuture

Emulsions are provided which are useful in imparting water-resistance to lignocellulosic products. In one embodiment, the emulsions contain a nonsaponifiable wax, a saponified wax, an alkyl phenol component, a dispersant / surfactant such as a salt of polynaphthalenesulfonic acid, and a carboxymethylcellulose. Such emulsions may be added to hot, even boiling, water without the emulsion separating or curdling. Various embodiments are stable for extended periods of time when stored at room temperature, do not require the addition of a preservative biocide to avoid contributing to biodegradation in a lignocellulosic product. The emulsions are pourable liquids at room temperature. Optionally, the emulsions may be added to lignocellulosic products with a preservative to inhibit the preservative from leaching out.

Owner:HEXION INC

Cellulose acylate-based dope, cellulose acylate film, and method of producing a cellulose acylate film

A cellulose acylate-based dope, which has an exothermic peak giving a calorific value of 1 to 10 J / g (inclusive), between 0 and 40° C.; wherein collected wastes of cellulose acylate which are obtained by collecting and crushing a cellulose acylate film edge trimmed when raw material of the film is cast, are used in an amount of 5 to 60% by weight of the whole of the cellulose acylate or; wherein the dope comprises a solvent, wherein a recovery solvent is used in an amount of 20 to 100% of the entire solvent and; a cellulose acylate film produced by using the same.

Owner:FUJIFILM CORP

Adhesive composition

InactiveUS6933342B2Well mixedEnhanced interactionMonocarboxylic acid ester polymer adhesivesAdhesive processesEthylene-vinyl acetateTerpene

The present invention relates to a composition which comprises at least one triblock copolymer, one terpene resin, one liquid component and one ethylene-vinyl acetate copolymer, and also to a process for preparing this composition, and to its use.

Owner:LANXESS DEUTDCHLAND GMBH

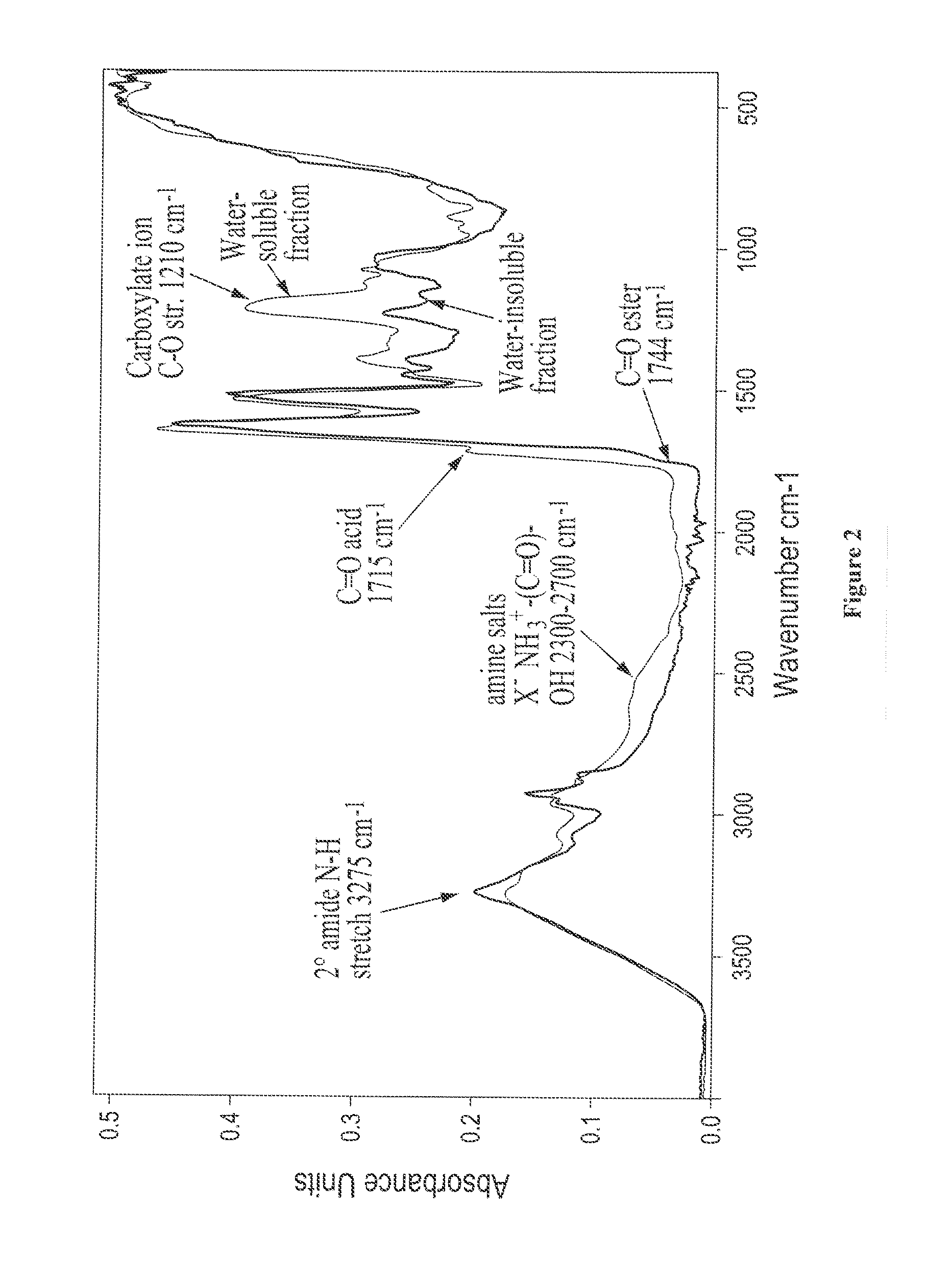

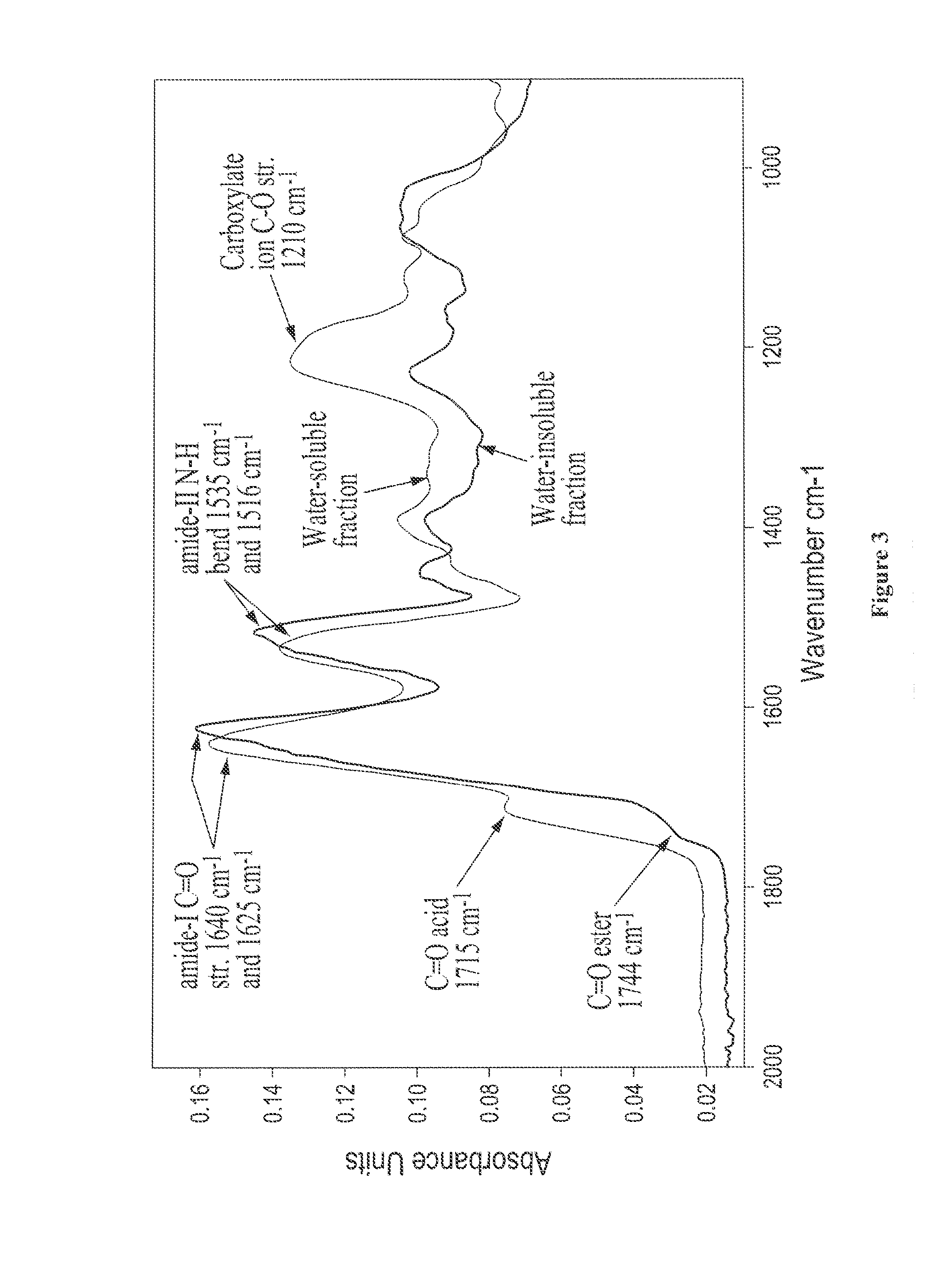

Protein adhesives containing an anhydride, carboxylic acid, and/or carboxylate salt compound and their use

ActiveUS20150267095A1Improve adhesionDegree of adhesionNon-macromolecular adhesive additivesNatural resin coatingsCelluloseAdhesive

The invention provides protein adhesives, and methods of making and using such adhesives. The protein adhesives contain a protein-bonding agent and plant protein composition, such as an isolated water-soluble protein fraction or ground plant meal obtained from plant biomass. The protein-bonding agent can be an anhydride compound, carboxylic acid compound, carboxylate salt compound, or combinations thereof. The protein adhesives are useful in bonding together lignocellulosic materials and other types of materials.

Owner:EVERTREE

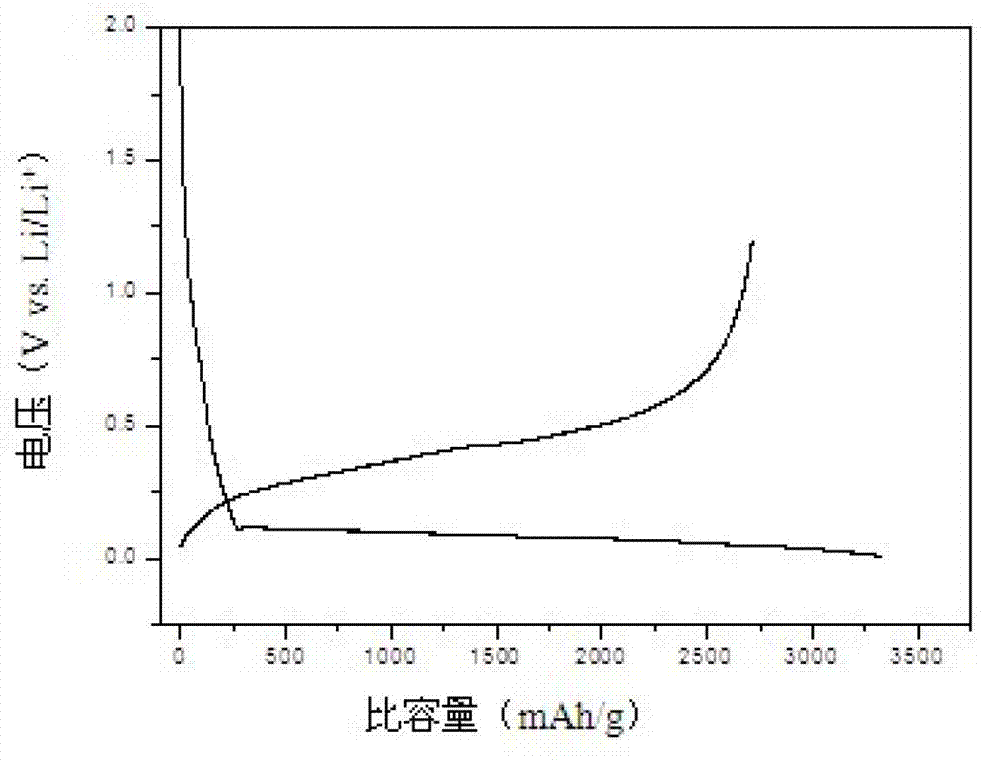

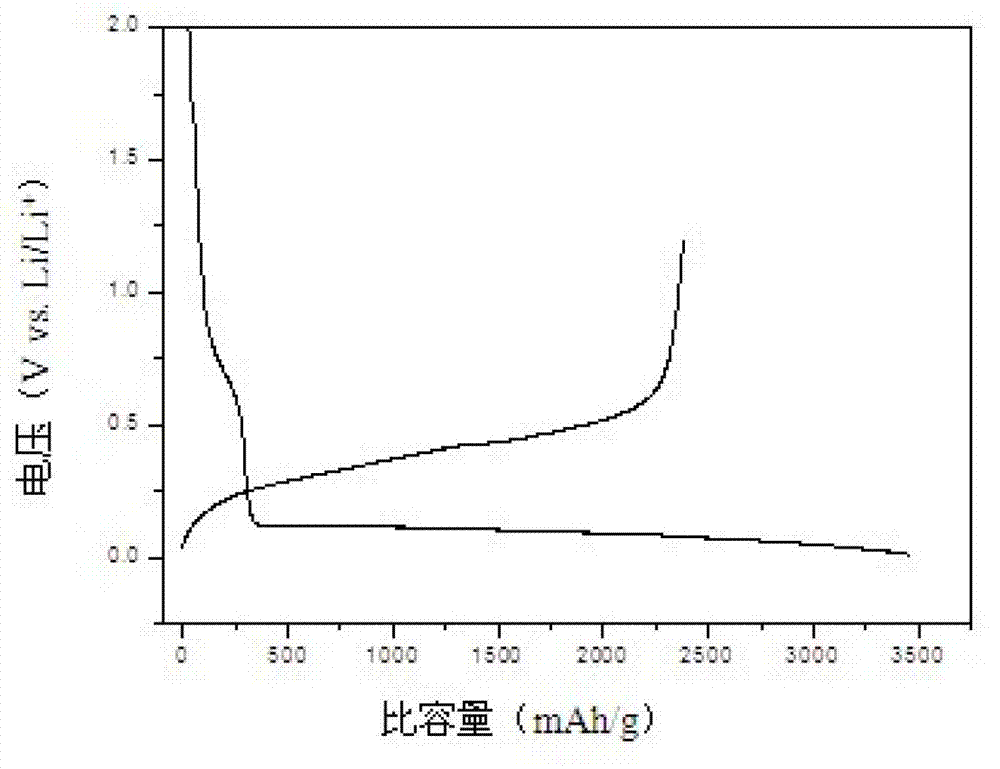

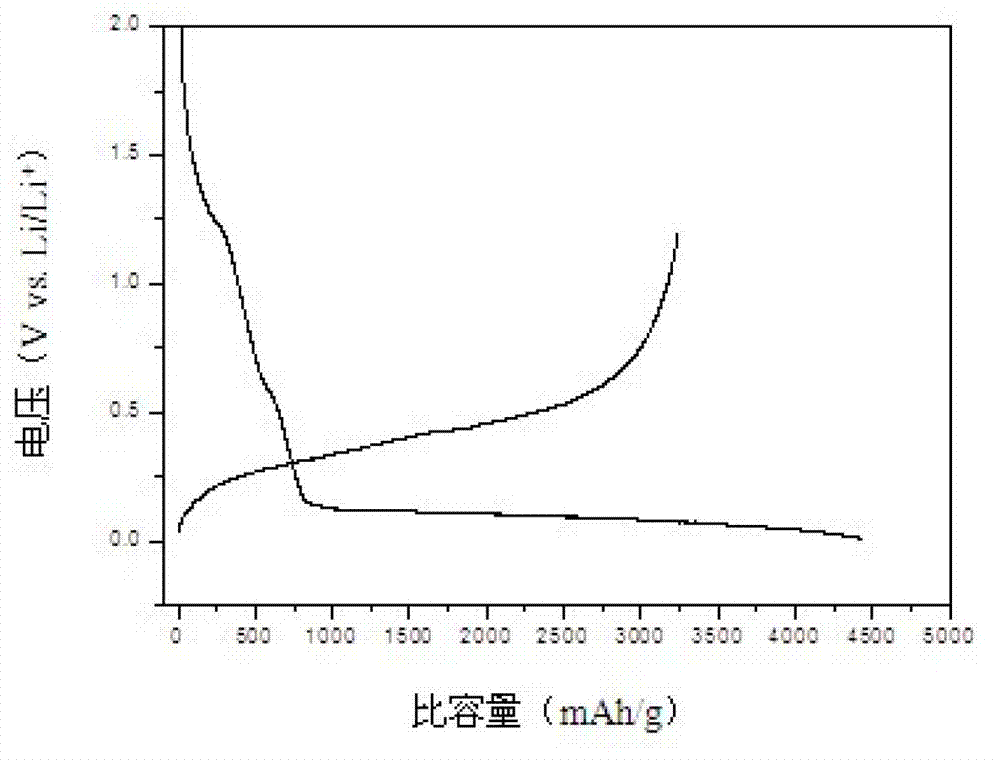

Water-based adhesive used in silicon anode of lithium ion battery and preparation method of silicon anode

ActiveCN103074007AImprove conductivityIncrease contactCell electrodesCyclodextrin adhesivesSolubilityWater based

The invention discloses a water-based adhesive used in a silicon anode of a lithium ion battery and a preparation method of the silicon anode. The adhesive is one or more than one mixture of carbonylation Beta-cyclodextrin, poly 3 and 4-ethylene dioxy thiophene, polystyrene sulfonate and gum arabic. The invention further relates to the preparation method of the silicon anode. The preparation method comprises the following steps: firstly uniformly dispersing a silicon material, the adhesive and conductive carbon in water; and then coating the mixture on a copper collector to obtain a final product of the silicon anode of the lithium ion battery after drying. According to the adhesive, Beta-cyclodextrin is adopted, so that the solubility of the adhesive in water can be improved after the carbonylation treatment of the Beta-cyclodextrin; at the room temperature and under the condition of 0.05 C, the silicon anode starts to charge and discharge, the first time discharge specific capacity can reach up to 4440.2 mAh / g, the charging specific capacity can reach up to 3238.7 mAh / g, the charge and discharge efficiency is 72.9 percent, the charge and discharge specific capacity in one hour is 1770 mAh / g, and the cycle performance is very stable. The water-based adhesive and the silicon anode provided by the invention have the advantages of low costs, environmental friendliness, obvious effects, good conductivity, good recycling and good application prospects.

Owner:SHANGHAI JIAO TONG UNIV

Cellulose acylate and solution thereof

InactiveUS20040059106A1Improve stabilityLow viscositySugar derivativesPhotosensitive materialsCellulosePolymer

A cellulose acylate which is a polymer obtained by substituting cellulose with acyl groups in 2-, 3-, 6-positions. The total degree of acyl substitution in the 2- and 3-positions is regulated to from 1.70 to 1.90. The degree of 6-position acyl substitution is regulated to 0.88 or higher.

Owner:FUJIFILM CORP

Two-component structural adhesive having high initial adhesion

InactiveUS20060157196A1Cosmetic preparationsNon-macromolecular adhesive additivesWater dispersibleAdhesive

Owner:HENKEL KGAA

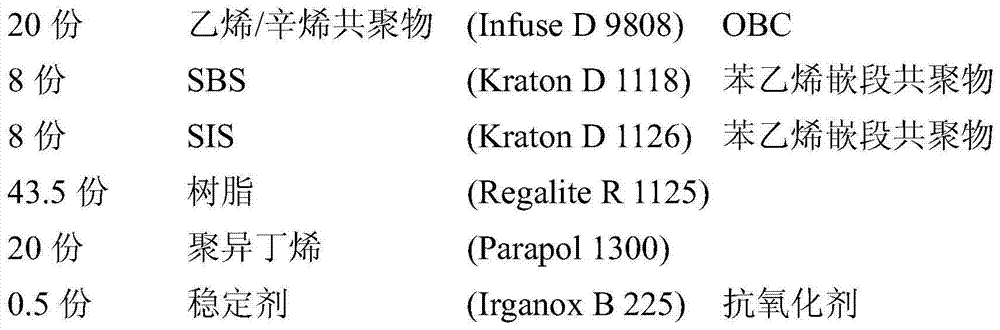

Psa containing olefin block copolymers and styrene block copolymers

ActiveUS20140256867A1Suitable viscosityGood elastic behavior in bondingFilm/foil adhesivesNatural resin adhesivesPolystyreneHot melt

The invention relates to storage-stable hot-melt adhesive containing 15 to 70 wt % of a mixture of at least one copolymer based on ethylene and / or propylene and at least one C4 to C20 α-olefin which is obtainable as a block copolymer by metallocene-catalysed polymerisation, and at least one styrene block copolymer, 10 to 70 wt % of at least one tackifying resin, 0 to 40 wt % of further additives, wherein the total of the percentages should amount to 100% and the tackifying resin is entirely or in part a soft resin.13

Owner:HENKEL KGAA

Psa containing olefin block copolymers and styrene block copolymer

The invention relates to a storage-stable hot-melt adhesive containing 15 to 70 wt% of a mixture of at least one copolymer based on ethylene and / or propylene and at least one C4 to C20 alpha-olefin, which can be obtained as a block copolymer by metallocene-catalyzed polymerization, and at least one styrene block copolymer, 10 to 70 wt% of at least one tackifying resin, and 0 to 40 wt% of additional additives, wherein the sum of the % shares should equal 100% and the tackifying resin is completely or partially a soft resin.

Owner:HENKEL KGAA

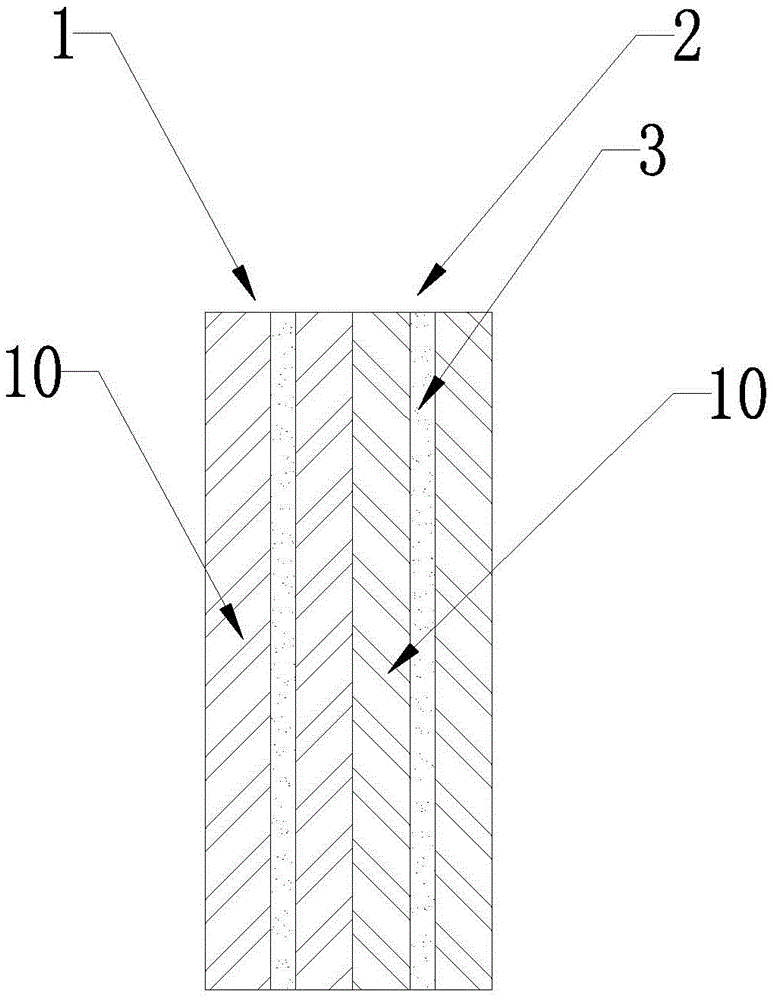

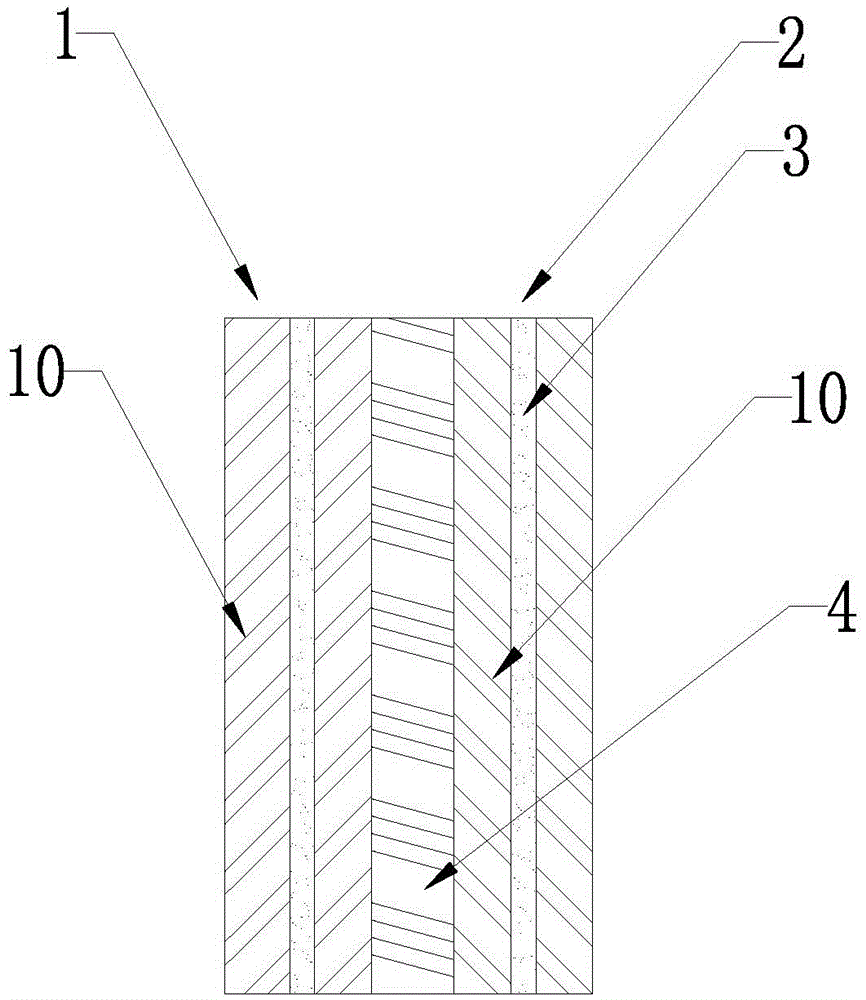

Three-dimensional cotton water-washing-resisting bra cup pad and preparation method thereof

ActiveCN105768252AGood flexibilityStable structureNon-macromolecular adhesive additivesStarch adhesivesEngineeringMechanical engineering

The invention relates to the technical field of bra underwear and particularly relates to a three-dimensional cotton water-washing-resisting bra cup pad and a preparation method thereof. The longitudinal cotton water-washing-resisting bra cup pad comprises an inner three-dimensional cotton interlayer and an outer three-dimensional cotton interlayer, which are fitted in sequence, wherein each of the inner three-dimensional cotton interlayer and the outer three-dimensional cotton interlayer is composed of at least two layers of three-dimensional cotton layers; and a glue layer is arranged between each two three-dimensional cotton layers. The preparation method comprises the following steps: step 1: coating the surface of one piece of three-dimensional cotton with glue; carrying out hot press fitting to obtain a planar material with the inner three-dimensional cotton interlayer and the outer three-dimensional cotton interlayer; step 2: taking the inner three-dimensional cotton interlayer and carrying out pre-die-pressing by utilizing die pressing equipment; step 3: covering the surface of the inner three-dimensional cotton interlayer subjected to the pre-die-pressing with the outer three-dimensional cotton, and carrying out die pressing and forming by utilizing a pressing die; and step 4: cooling, carrying out pressing fitting, and shaping a cup prototype obtained by the die pressing in the step 3, and cutting to obtain the three-dimensional cotton water-washing-resisting bra cup. The three-dimensional cotton water-washing-resisting bra cup is wholly made of the three-dimensional cotton material so that the three-dimensional cotton water-washing-resisting bra cup pad has the advantages of good air permeability, excellent antibacterial performance and good water-washing resistance.

Owner:HONGJI UNDERWEAR CO LTD

Polymeric film or coating comprising hemicellulose

ActiveUS20100129642A1Improve resistance performanceImprove the immunityPigmenting treatmentWater-repelling agents additionCross-linkOligomer

A film forming composition and a polymeric film or coating comprising hemicellulose and at least one component selected from the group consisting of plasticizers, cellulose, and an oligomer or polymer, is disclosed, said polymeric film or coating further comprising at least one additive / reactant increasing the liquid / moisture resistance and mixed with and / or reacting with the hemicellulose and said at least one component before or in conjunction with the forming of the film or coating. The use of said film or coating is also disclosed. Further, a method for the manufacture of said polymeric film or coating is disclosed, as well as a method for improving the liquid / moisture resistance of hemicellulose. Said at least one additive / reactant increasing the liquid / moisture resistance is either a cross-linking agent or a hydrophobizing agent. In another preferred embodiment the additive is a 2:1 layered phyllosilicate. The additive forms a nanocomposite with the hemicellulose as a matrix. The hemicellulose / phyllosilicate nanocomposite reinforced material provides excellent liquid / moisture resistance. Heat treatment of all of the films increases their liquid / moisture resistance and reduces their oxygen permeability.

Owner:SEELUTION AB

Styrenated terpene resin as well as methods of making and using the same

ActiveUS7829630B2Facilitates minimizing and eliminatingLow polymerization temperatureNatural resin coatingsProtein adhesivesChemistryTerpene

The present invention relates to styrenated terpene resin, as well as methods of making an using the same.

Owner:KRATON CHEM LLC

Hot-melt adhesives based on polyamide-block graft copolymers

InactiveUS6846874B2Simpler to useExceptional thermomechanical resistance propertyInksGraft polymer adhesivesPolyolefinPolyamide

The present invention relates to a hot-melt adhesive composition comprising:20 to 80% of a blend comprising: 50 to 100% of (A), which denotes a polyamide-block graft copolymer consisting of a polyolefin backbone and at least one polyamide graft, 0 to 50% of at least one polymer (B) chosen from polyolefins and polyamides;80 to 20% of a blend comprising at least one tackifying resin and optionally at least one product chosen from waxes, plasticizers and mineral fillers; in which:the said graft is attached to the backbone via the residues of an unsaturated monomer (X) chosen from unsaturated carboxylic acids, anhydrides of unsaturated carboxylic acids and unsaturated epoxides;the residues of the unsaturated monomer (X) are attached to the backbone by grafting or copolymerization from its double bond;the molar mass {overscore (M)}n of the grafts is between 1000 and 5000;the melting point of the grafts is between 100 and 190° C.; andthe MFI of (A) is between 1 and 500 (g / 10 mm at 190° C. under a load of 2.16 kg).

Owner:ARKEMA INC

Ink composition for sensing gas exposure and gas exposure indicator

InactiveUS7981687B2Natural resin coatingsMaterial analysis by electric/magnetic meansTreatment statusThiazine dye

An object of the present invention is to provide a material for more easily and accurately detecting treatment status using gas exposure. The present invention relates to an ink composition for detecting an oxidizing gas, or the like, comprising at least one type of azo dye, methine dye, triarylmethane dye and thiazine dye.

Owner:SAKURA COLOR PRODUCTS CORPORATION

Ostomy pouch attachment adhesives resistant to stomal effluent

InactiveUS20050080155A1Monocarboxylic acid ester polymer adhesivesCosmetic preparationsAdhesiveEthylene-vinyl acetate

An adhesive for use in an ostomy device. The adhesive is resistant to stomal effluent and includes a multi-block copolymer of vinyl aromatic and olefin comonomers, poly(ethylene vinyl acetate), or combinations thereof. The adhesive helps secure the effluent containment component or pouch to the body attachment component or wafer.

Owner:CONVATEC TECH INC

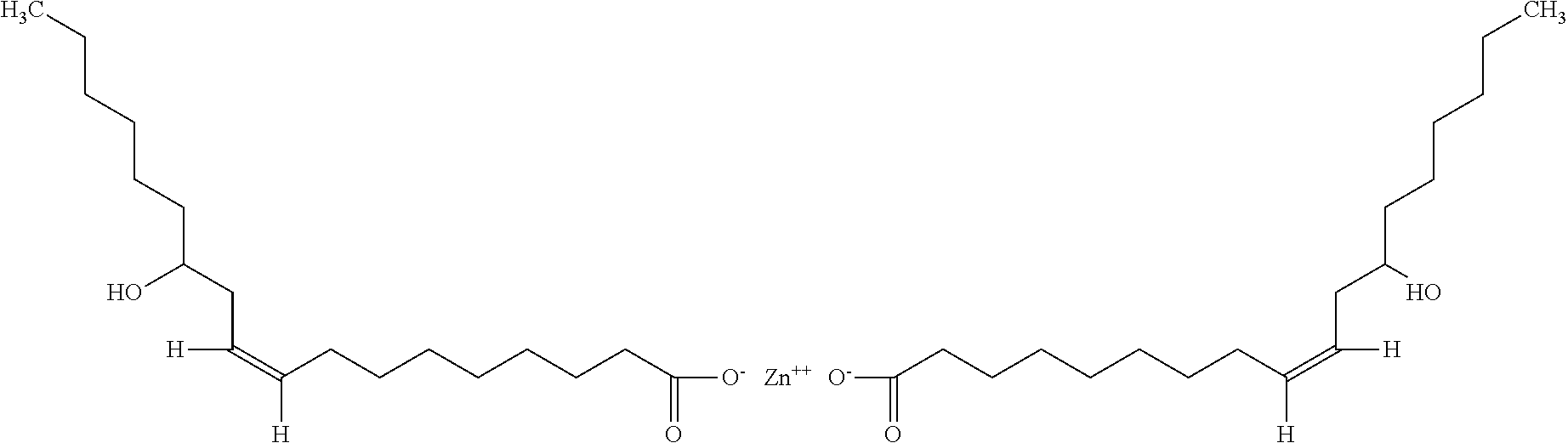

Deodorized asphalt additive composition

ActiveUS20120204760A1Good processing characteristicsEasy to retouchNatural resin coatingsWorking-up pitch/asphalt/bitumen by chemical meansZinc ricinoleateAlkaline earth metal

This invention is based upon the discovery that a hydroxylated carboxylic acids which contain at least 17 carbon atoms and alkaline earth metal salts thereof, such as zinc ricinoleate, act effectively as deodorants in asphalt and asphalt containing compositions. The present invention more specifically discloses an asphalt additive composition which is comprised of (1) an asphalt, (2) 0.05 weight percent to about 4 weight percent of a partitioning agent, and (3) at least 0.1 weight percent of a deodorant selected from the group consisting of (a) a hydroxylated carboxylic acid which contains at least 17 carbon atoms and (b) an alkaline earth metal salt of a hydroxylated carboxylic acid which contains at least 17 carbon atoms. In many applications it is beneficial for the asphalt additive composition to further include 0.5 weight percent to about 50 weight percent of a polymer additive.

Owner:FLOW POLYMERS

Thermal smelting adhesive based on polyamide block graft copolymer

The present invention relates to a thermal smelting adhesive composition containing components mentioned in the description. Said composition has many virtues: said composition is processed at about 180 DEG C, a general temperature of the thermal smelting adhesive; it is not necessary to wait for a cross-linking after said composition is applied; by utilizing a two-component adhesive such as epoxy resin or other constitution sclerosing agent more simply, said composition exhibits improved remarkably shearing adhesion destruction temperature (SAFT examination), in contrast to a crosslinkable thermal smelting adhesive.

Owner:ATOFINA

Low alkali bean powder adhesion agent

The invention is a low-alkalinity bean powder adhesive for improving the existing bean flour adhesive, made from bean flour 100 shares, sodium hydroxide 1.5-2 shares, calcium oxide 2-5 shares and sodium silicate 15-20 shares. As compared with the existing techniques, the dosage of sodium hydroxide and sodium silicate in it is less, its alkalinity is low, and it reduces production cost and improves adhesiveness. And it can be used in veneer board production. And it has a certain water resistance, environmental-protection.

Owner:NORTHEAST FORESTRY UNIVERSITY

Adhesive composition comprising tannin, polyethylene glycol, and water, lower alcohol or mixture thereof

ActiveCN103459542ANot easily soluble inNo toxicitySurgical adhesivesPharmaceutical delivery mechanismControlled releaseAlcohol

Owner:KOREA ADVANCED INST OF SCI & TECH +1

Liquid composition, shaped article, and shaped article production method

ActiveUS20160145455A1Good reproducibilityImprove accuracyAdditive manufacturing apparatusNatural resin coatingsDouble bondIonic liquid

A liquid composition contains a cellulosic material constituted by a material containing at least one of cellulose and a cellulose derivative, and an ionic liquid having a functional group with reactivity. It is preferred that the ionic liquid has an imidazolium salt structure. It is also preferred that the functional group with reactivity contains a carbon-carbon double bond.

Owner:SEIKO EPSON CORP

soft shapeable adhesive paste

The present invention relates to a pressure sensitive paste composition for skin application. The paste comprises 10-50% (w / w) based on the total paste formulation of a blend of polar polyethylene copolymer(s) and polar oil.

Owner:COLOPLAST AS

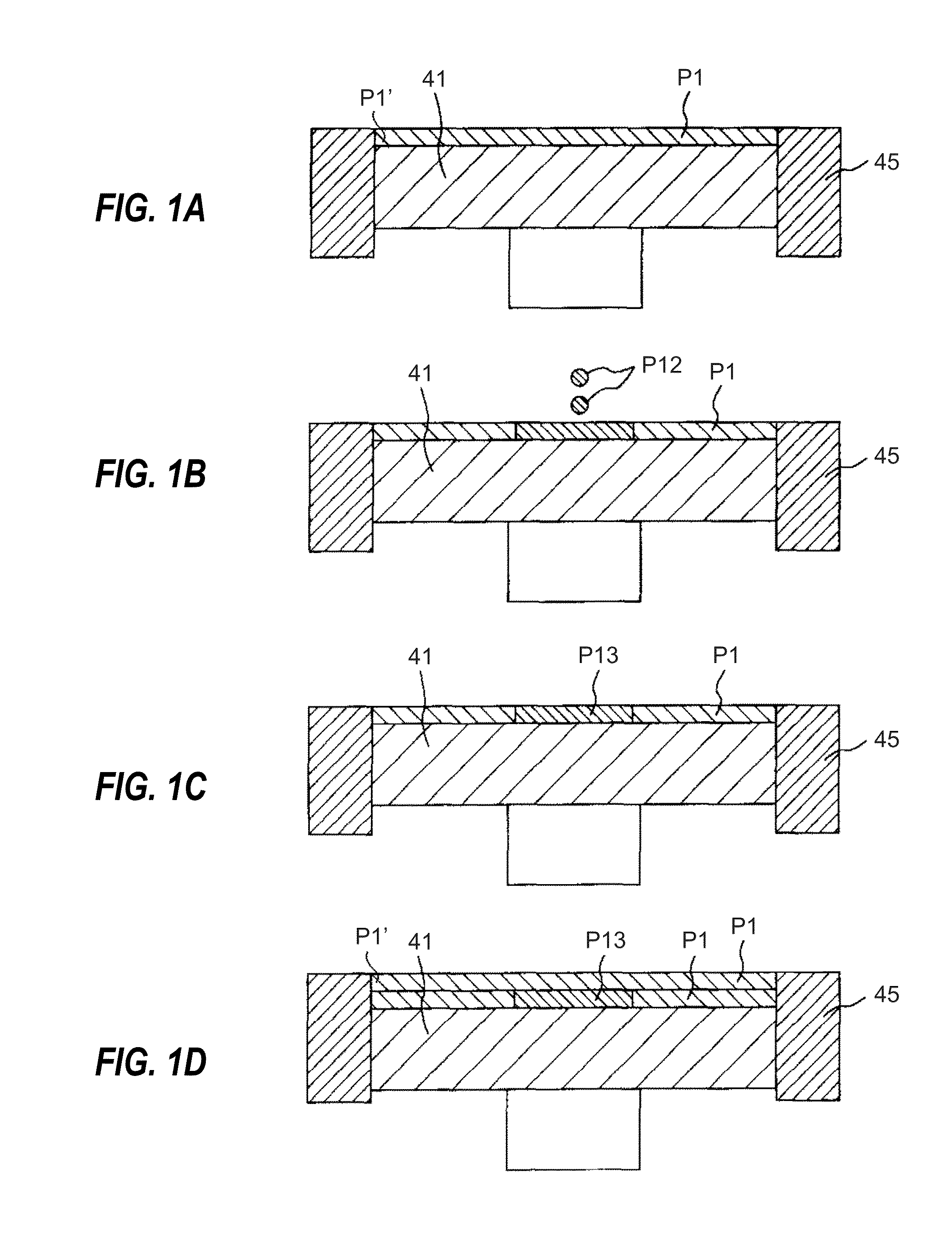

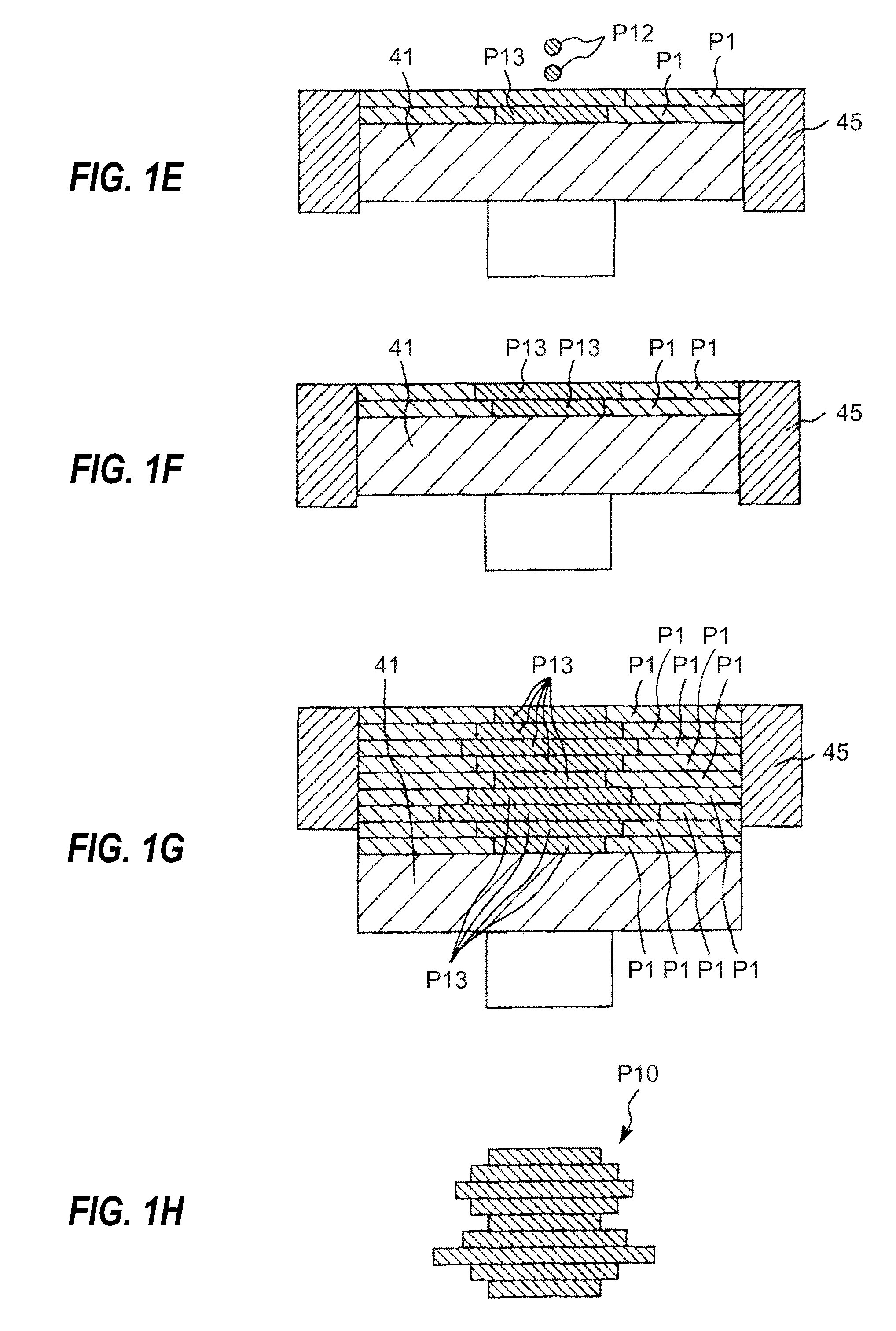

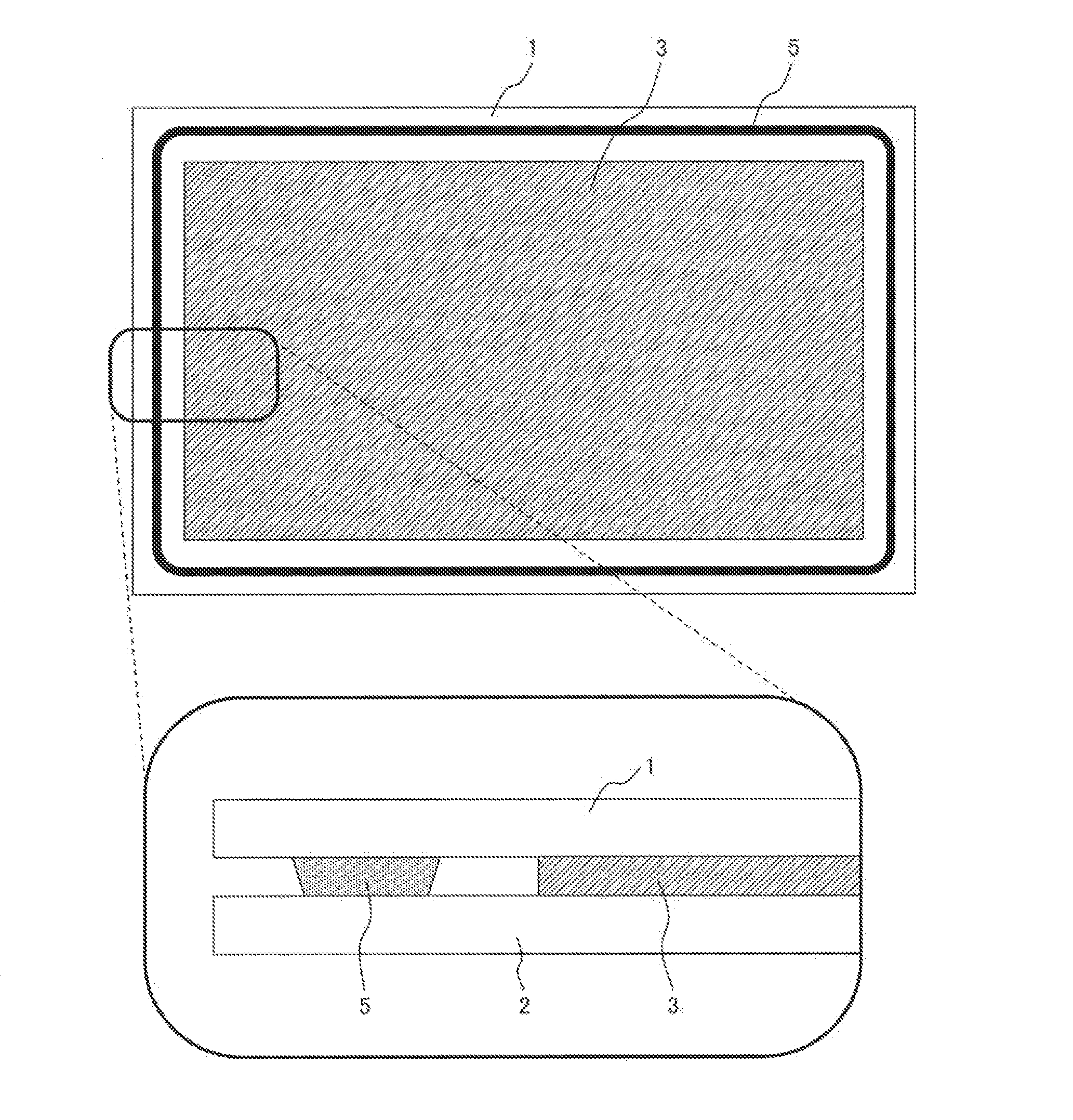

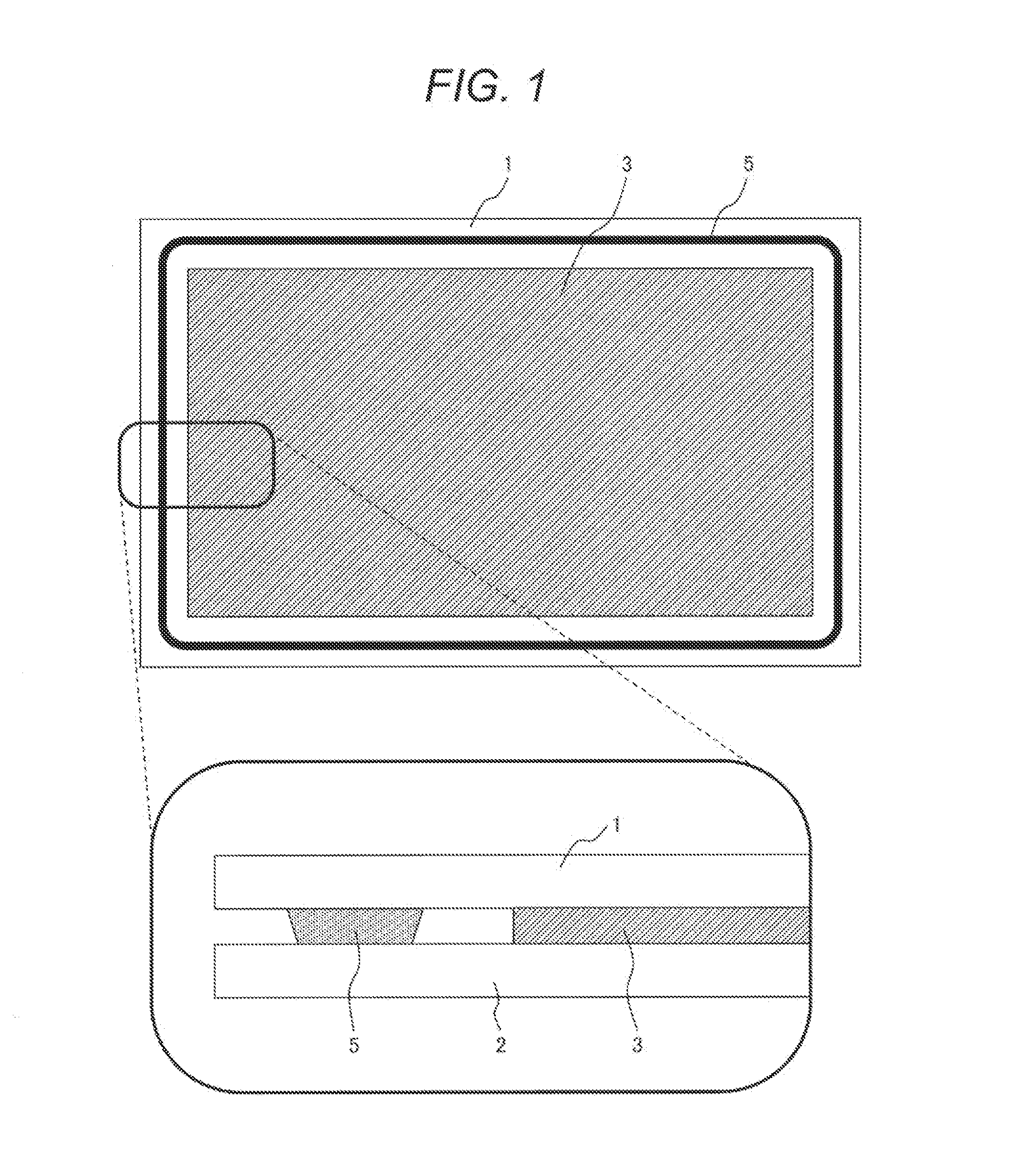

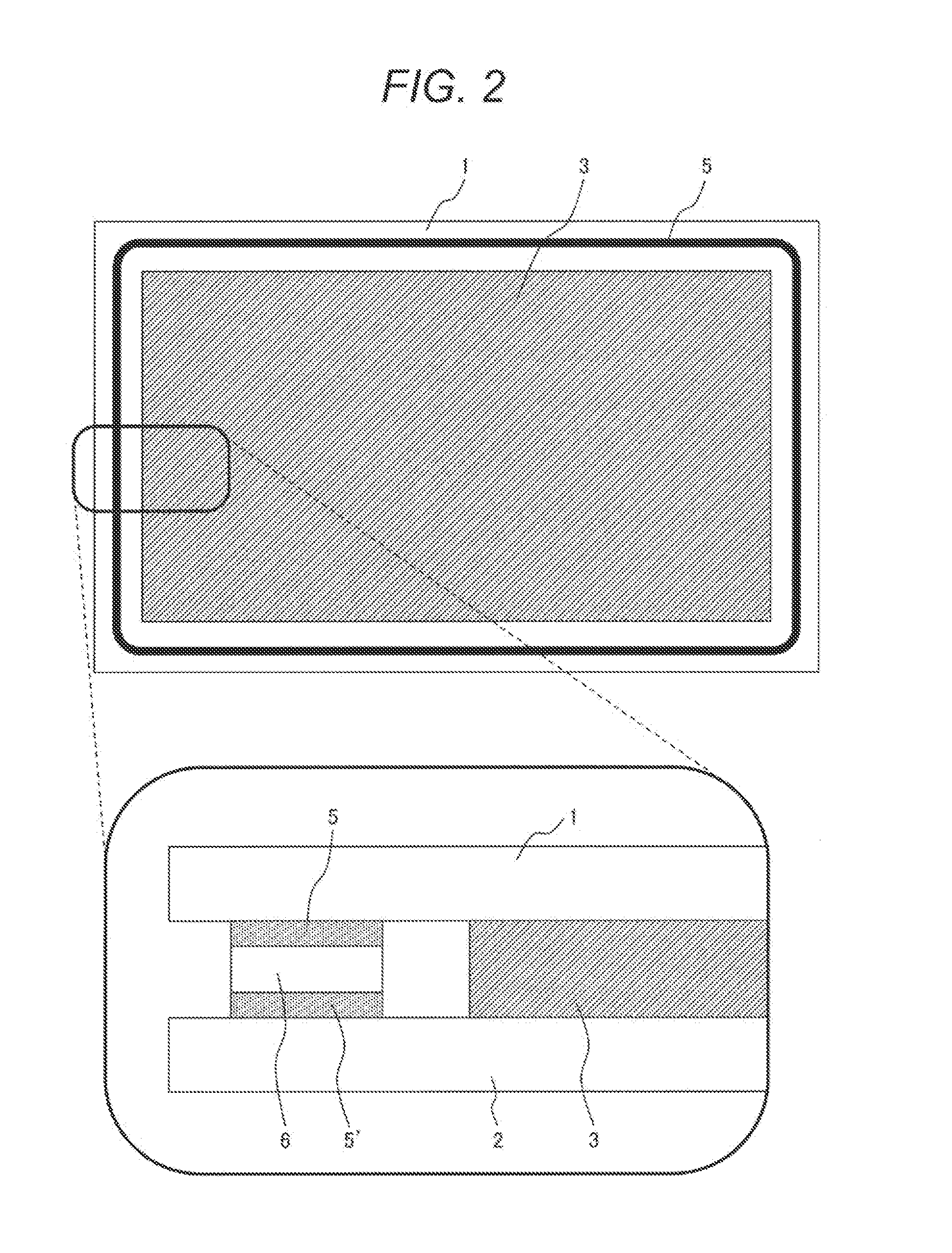

Electronic Component, Method for Producing Same, and Sealing Material Paste Used in Same

ActiveUS20150187510A1Reduce heat damageImprove reliabilityNon-macromolecular adhesive additivesNatural resin coatingsPhosphoric acidSolvent

An electronic component has an organic member between two transparent substrates, in which outer peripheral portions of the two transparent substrates are bonded by a sealing material containing to melting glass. The low melting glass contains vanadium oxide, tellurium oxide, iron oxide and phosphoric acid, and satisfies the following relations (1) and (2) in terms of oxides. The sealing material is formed of a sealing material paste which contains the low melting glass, a resin binder and a solvent, the low melting glass containing vanadium oxide, tellurium oxide, iron oxide and phosphoric acid, and satisfies the following relations (1) and (2) in terms of the oxides. Thereby, thermal damages to an organic element or an organic material contained in the electronic component can be reduced and an electronic component having a glass bonding layer of high reliability can be produced efficiently.V2O5+TeO2+Fe2O+P2O5≧90(mass %) (1)V2O5>TeO2>Fe2O3>P2O5(mass %) (2)

Owner:RESONAC CORP

Hot melt adhesive containing a neutralizing additive

InactiveUS20050032963A1Efficiently neutralizedMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesHot meltFeminine Hygiene Products

Hot melt adhesives comprising an effective amount of a neutralizing additive is useful in the manufacture of absorbent articles, such as diapers / training pants and feminine hygiene products. The added material has a closed cup flash point of greater than 100° F., most preferably a closed cup flash point of greater than 200° F.

Owner:HENKEL KGAA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com