Liquid composition, shaped article, and shaped article production method

a technology of shaped articles and liquid compositions, applied in the direction of manufacturing tools, additive manufacturing processes, natural resin coatings, etc., can solve the problems of difficult preparation of high concentration solutions, low solubility of cellulose, and insufficient utilization of various advantageous characteristics of cellulos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

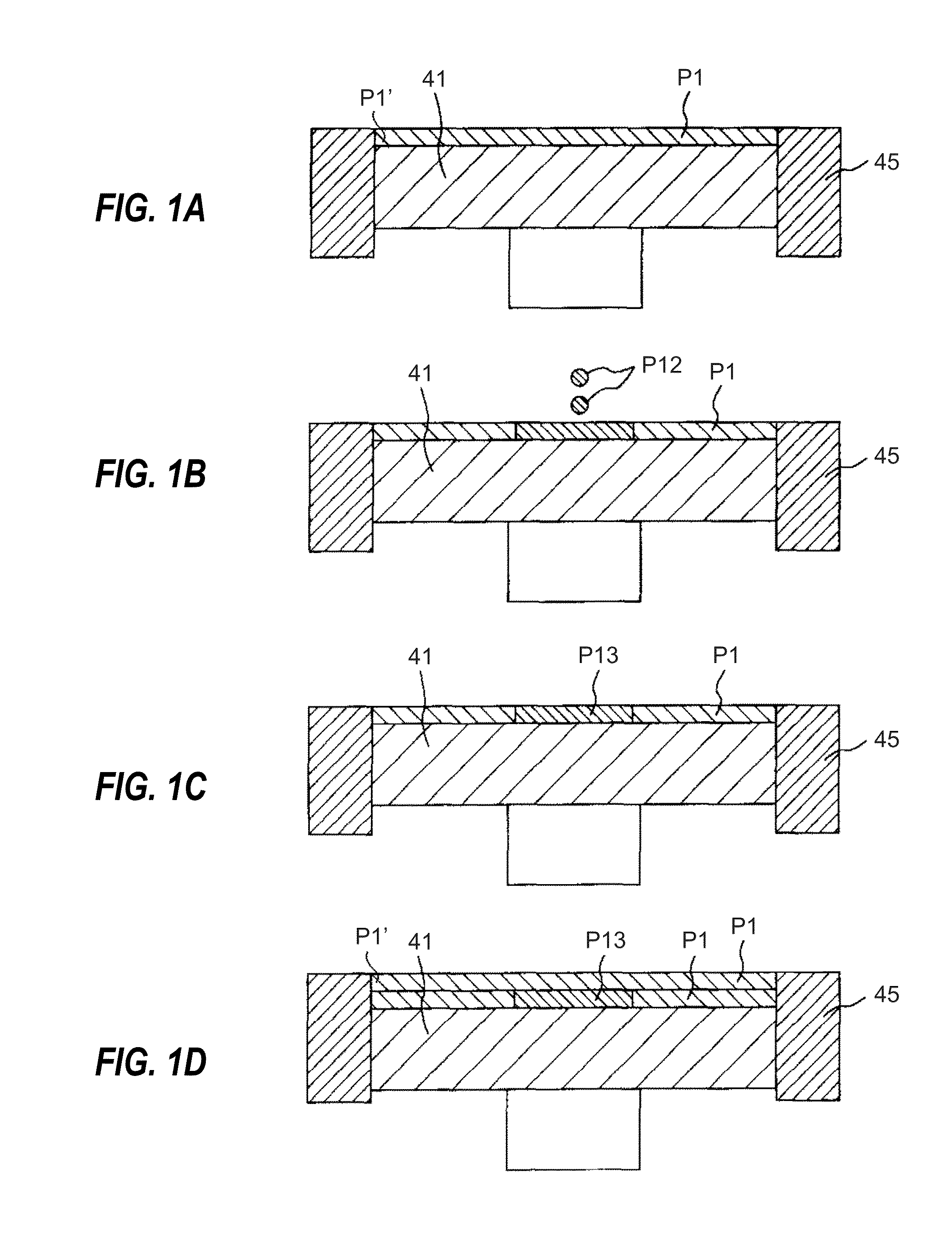

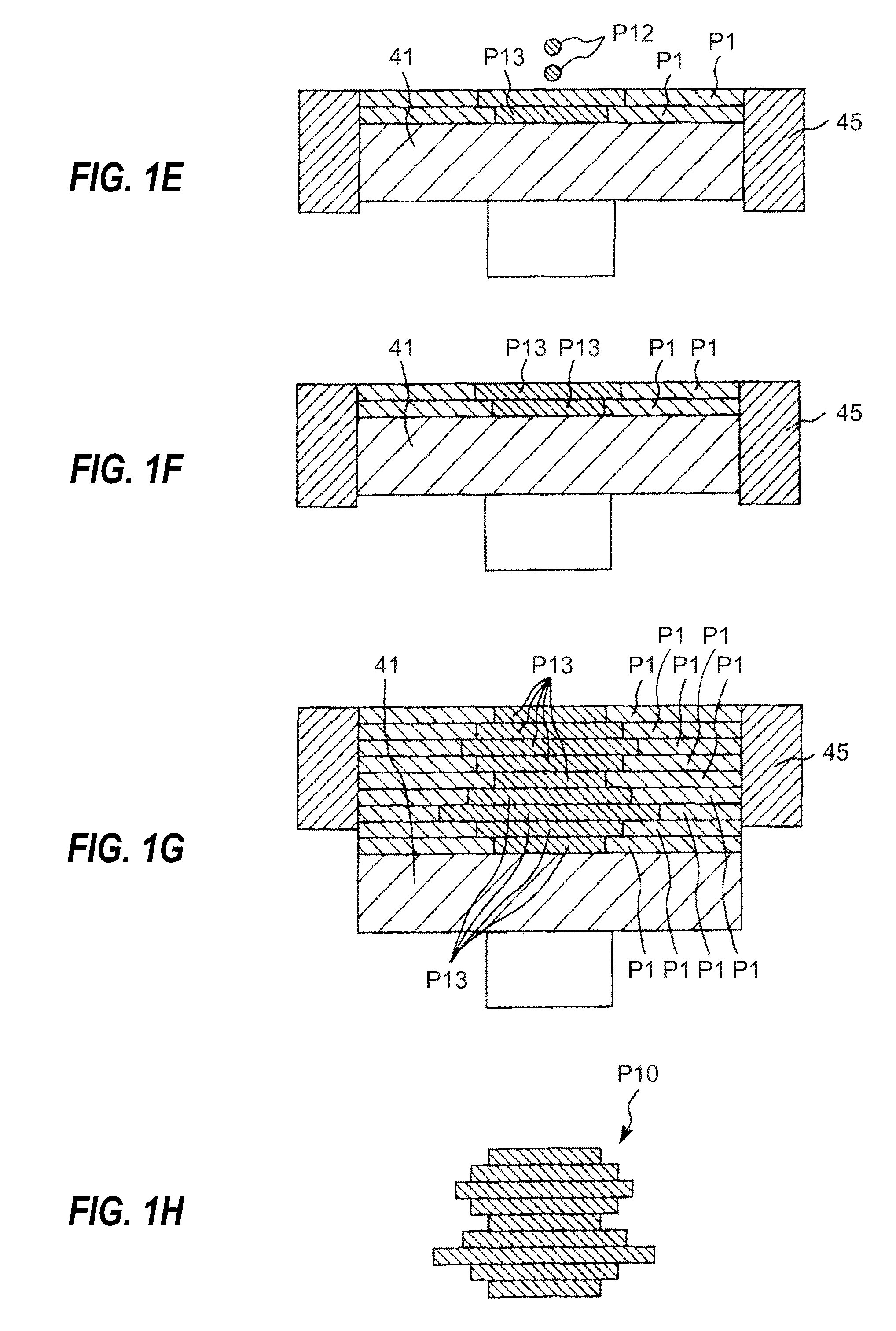

[0342]Hereinafter, the composition containing particles (particle-containing composition) P1′ as described in the production method and the shaped article production apparatus of the first embodiment mentioned above will be described.

[0343]The composition (particle-containing composition) P1′ contains at least a three-dimensional shaping powder containing a plurality of particles.

Three-Dimensional Shaping Powder (Particles)

[0344]Examples of a constituent material of the particles constituting the three-dimensional shaping powder include an inorganic material, an organic material, and a composite of these materials.

[0345]Examples of the inorganic material constituting the particles include various metals and metal compounds. Examples of the metal compounds include various metal oxides such as silica, alumina, titanium oxide, zinc oxide, zirconium oxide, tin oxide, magnesium oxide, and potassium titanate; various metal hydroxides such as magnesium hydroxide, aluminum hydroxide, and ca...

second embodiment

[0393]Hereinafter, the composition (layer forming composition) to be ejected by an inkjet method as described in the production method and the shaped article production apparatus of the second embodiment mentioned above will be described.

[0394]In this embodiment, as the composition, a tangible part forming ink P16′ and a support part forming ink P17′ are used.

[0395]The tangible part forming ink P16′ has been described in detail as the liquid composition containing a cellulosic material and a reactive ionic liquid, and therefore, hereinafter, the support part forming ink P17′ will be described in detail.

Support Part Forming Ink

[0396]The support part forming ink P17′ contains at least a curable resin (curable component).

Curable Resin

[0397]Examples of the curable resin (curable component) constituting the support part forming ink P17′ include the same curable resins (curable components) as those exemplified as the constituent component (curable component as another component) of the ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com