Water-based adhesive used in silicon anode of lithium ion battery and preparation method of silicon anode

A water-based adhesive, lithium-ion battery technology, applied in conductive adhesives, battery electrodes, adhesive types, etc., can solve problems such as restricting commercial applications, damage to the conductive network inside electrodes, material particle pulverization, etc. Achieve excellent electrochemical performance, stable cycle performance and good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The first aspect of this embodiment relates to a water-based binder for silicon negative electrodes of lithium-ion batteries, the water-based binder is carbonylated β-cyclodextrin;

[0022] The second aspect of this embodiment relates to a method for preparing a silicon negative electrode, the preparation method comprising the following steps:

[0023] Step 1: Add 1g of β-cyclodextrin to 5g of 10wt% H 2 o 2 In an aqueous solution, keep warm at 50°C for 48 hours to form a carbonylated β-cyclodextrin aqueous solution, adjust the pH to 7 with LiOH, and then dry to remove water and hydrogen peroxide to obtain a carbonylated β-cyclodextrin;

[0024] Step 2: Evenly disperse silicon material (particle size: 200nm), carbonylated β-cyclodextrin, and acetylene black in water at a mass ratio of 60:20:20, and then coat it on a copper current collector. After drying, a A silicon negative electrode for lithium-ion batteries.

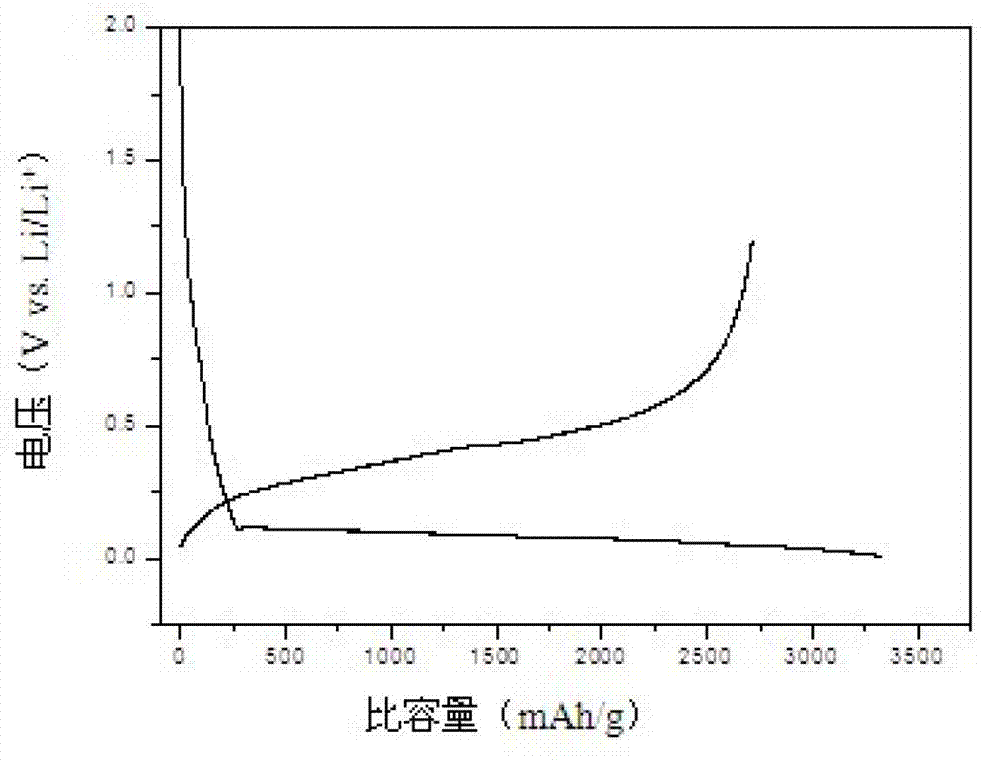

[0025] Implementation effect: use metal lithium as the...

Embodiment 2

[0027] The first aspect of this embodiment relates to a water-based binder for silicon negative electrodes of lithium-ion batteries, and the water-based binder is gum arabic;

[0028] The second aspect of this embodiment relates to a method for preparing a silicon negative electrode, the preparation method comprising the following steps:

[0029] Silicon material (porous silicon, particle size of 10 μm), gum arabic, and mesophase carbon microspheres are uniformly dispersed in water at a mass ratio of 20:40:40, and then coated on a copper current collector, and dried to obtain a lithium ion Silicon negative electrodes for batteries.

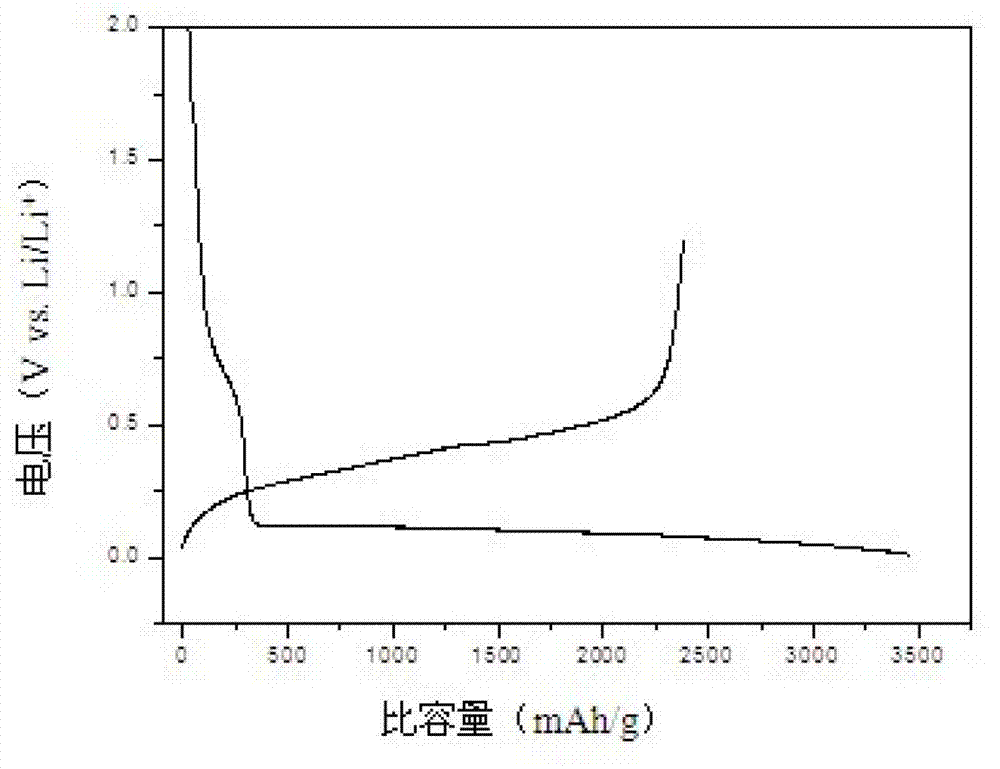

[0030] Implementation effect: use metal lithium as the counter electrode to form a half-cell. When gum arabic is used as the water-based binder, the lithium-ion battery silicon negative electrode has a first-time discharge specific capacity of 3193.7mAh / g under 0.05C discharge conditions, a charge specific capacity of 2515.2mAh / g, and an initial ...

Embodiment 3

[0032] The first aspect of this embodiment relates to a water-based binder for the silicon negative electrode of a lithium ion battery, the water-based binder is poly 3,4-ethylenedioxythiophene: polystyrene sulfonate;

[0033] The second aspect of this embodiment relates to a method for preparing a silicon negative electrode, the preparation method comprising the following steps:

[0034] Silicon material (particle size is 1 μm), poly 3,4-ethylenedioxythiophene: polystyrene sulfonate (wherein the mass ratio of poly 3,4-ethylenedioxythiophene to polystyrene sulfonate is 1:10) the two components are evenly dispersed in water at a mass ratio of 98:2, and then coated on a copper current collector, and dried to obtain a silicon negative electrode for a lithium ion battery.

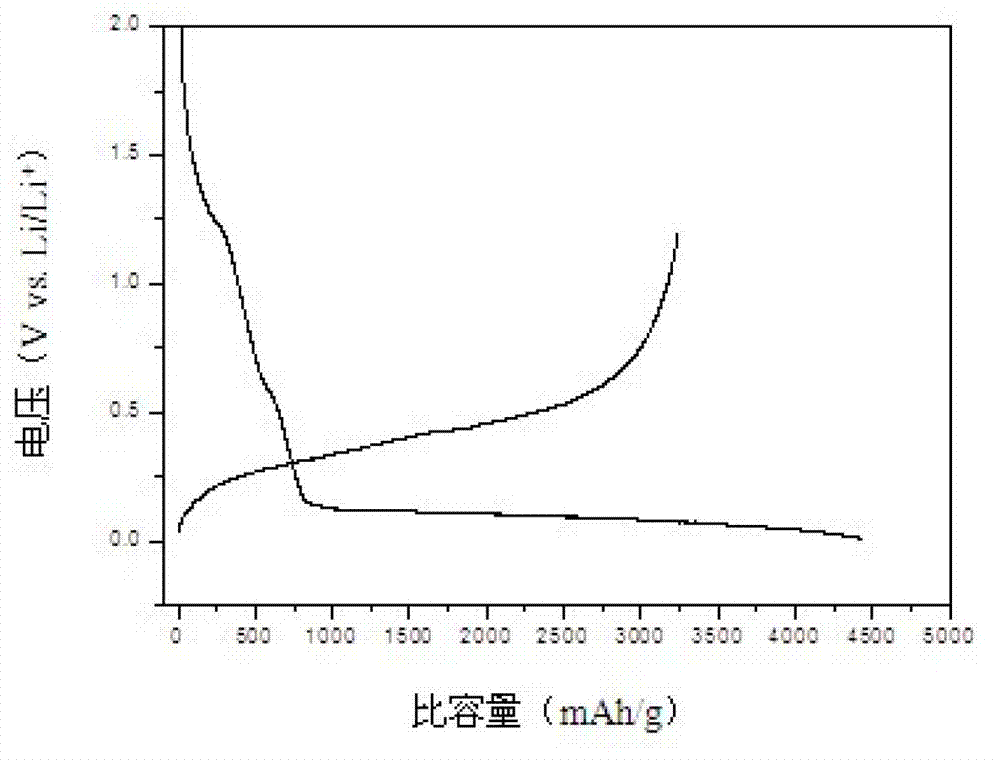

[0035] Implementation effect: use metal lithium as the counter electrode to form a half-cell. When adopting poly 3,4-ethylenedioxythiophene: polystyrene sulfonate as water-based binder, lithium-ion battery sil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com