Three-dimensional cotton water-washing-resisting bra cup pad and preparation method thereof

An upright cotton, water-resistant technology, used in bras, applications, natural resin adhesives, etc., can solve problems such as poor water-washing resistance, and achieve excellent heat resistance and anti-aging properties, good adhesion, and fast drying. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

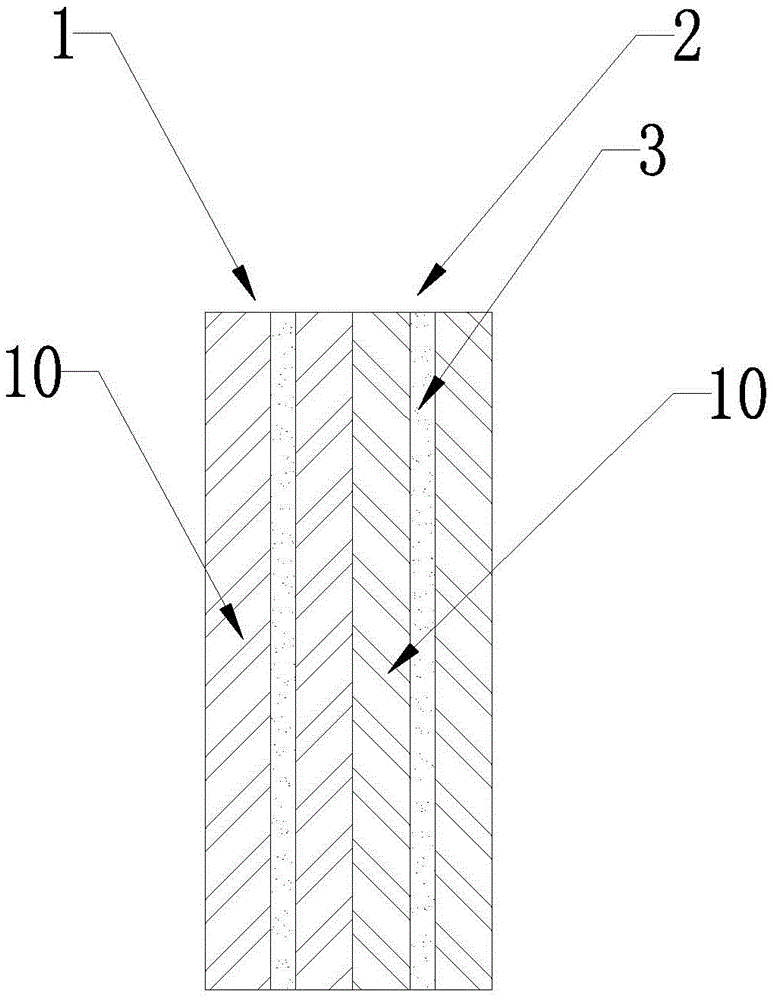

[0054] like figure 1 Shown is a kind of upright cotton washable bra coaster, including an inner upright cotton interlayer 1 and an outer upright cotton interlayer 2 that are sequentially fitted, and the inner upright cotton interlayer 1 and the outer upright cotton interlayer 2 are composed of at least two upright cotton layers 10, each upright cotton layer 10 is provided with a glue layer 3.

[0055] The total thickness of the inner upright cotton interlayer 1 is 3-5 mm, and the total thickness of the outer upright cotton interlayer 2 is 3-5 mm.

Embodiment 2

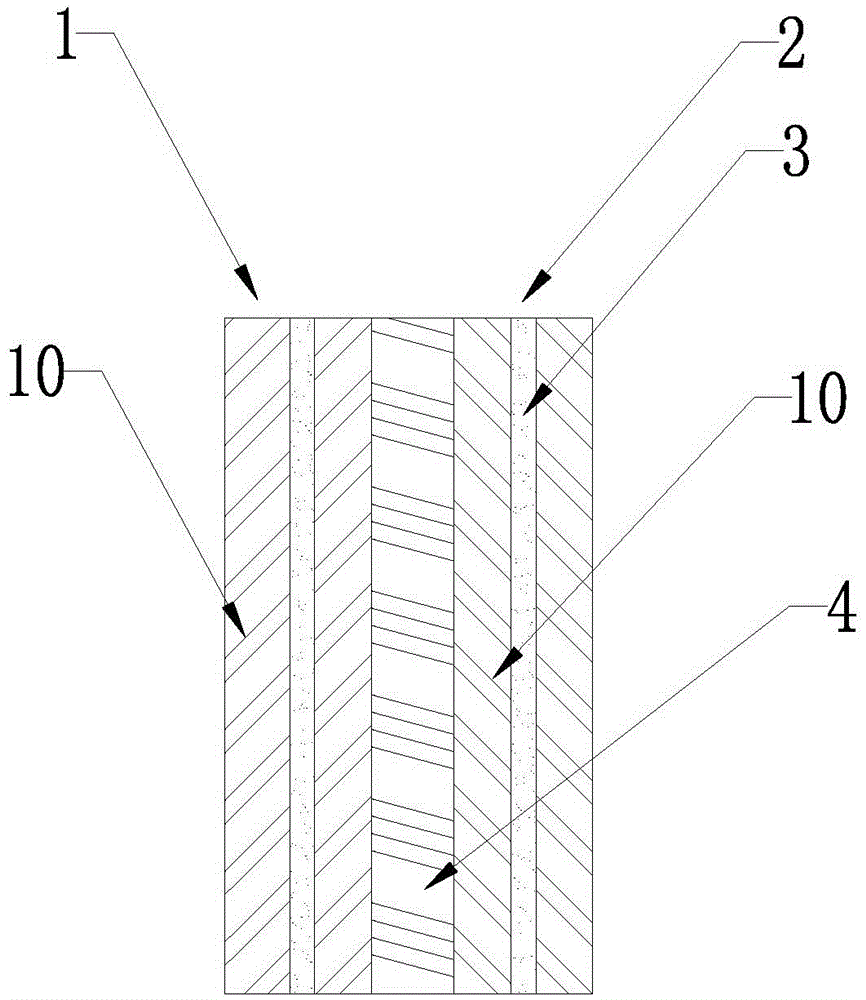

[0057] The difference between this embodiment and embodiment 1 is: as figure 2 As shown, a layer of upright cotton core layer 4 is arranged between the inner upright cotton interlayer 1 and the outer upright cotton interlayer 2 .

[0058] The maximum thickness of the upright cotton core layer 4 is 4-10mm, and the edge thickness of the upright cotton core layer 4 is 1-2mm.

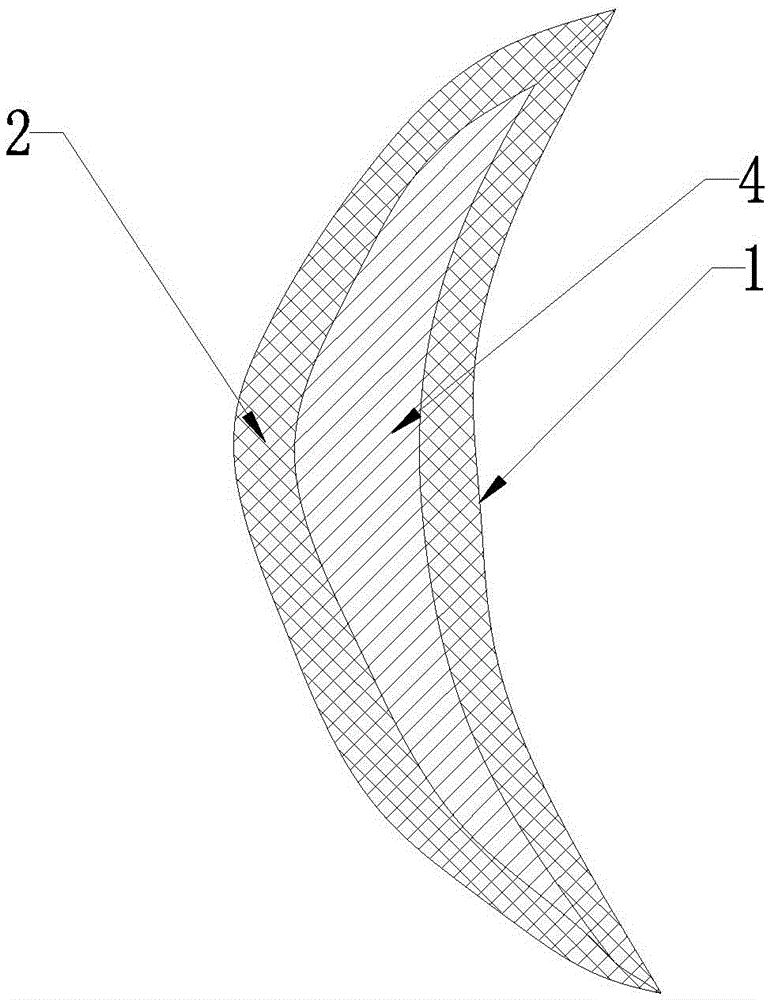

[0059] like image 3 As shown, the thickness of the upright cotton core layer 4 gradually decreases from the middle to the surrounding.

[0060] The inner upright cotton interlayer 1 and the outer upright cotton interlayer 2 are provided with four upright cotton interlayers.

[0061] The thickness of each standing cotton interlayer is 0.5-1mm.

[0062] Other technical features of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

Embodiment 3

[0064] The difference between this embodiment and embodiment 1 or embodiment 2 is that the glue in the glue layer 3 is mixed with the following raw materials in parts by weight:

[0065] Neoprene latex 10 parts

[0066] 5 parts n-butanol

[0067] 25 parts deionized water

[0068] 1 part emulsifier

[0069] Acrylic emulsion 5 parts

[0070] Butyl acrylate 1 part

[0071] Ethylene-vinyl acetate copolymer emulsion 10 parts

[0072] 3 parts hide glue

[0073] Polyurethane associative thickener 2 parts

[0074] 1 part calcium stearate

[0075] Propolis 15 parts

[0076] 9 parts of starch

[0077] 1 part silicone defoamer.

[0078] The mixing ratio of the neoprene latex, acrylic emulsion, and ethylene-vinyl acetate copolymer emulsion is 1:0.5:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com