Low alkali bean powder adhesion agent

An adhesive, soybean flour technology, applied in the direction of adhesives, adhesive types, natural resin adhesives, etc., can solve the problems of high alkali corrosion, poor water resistance of soybean glue, etc., and achieve high bonding strength, good water resistance, Simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

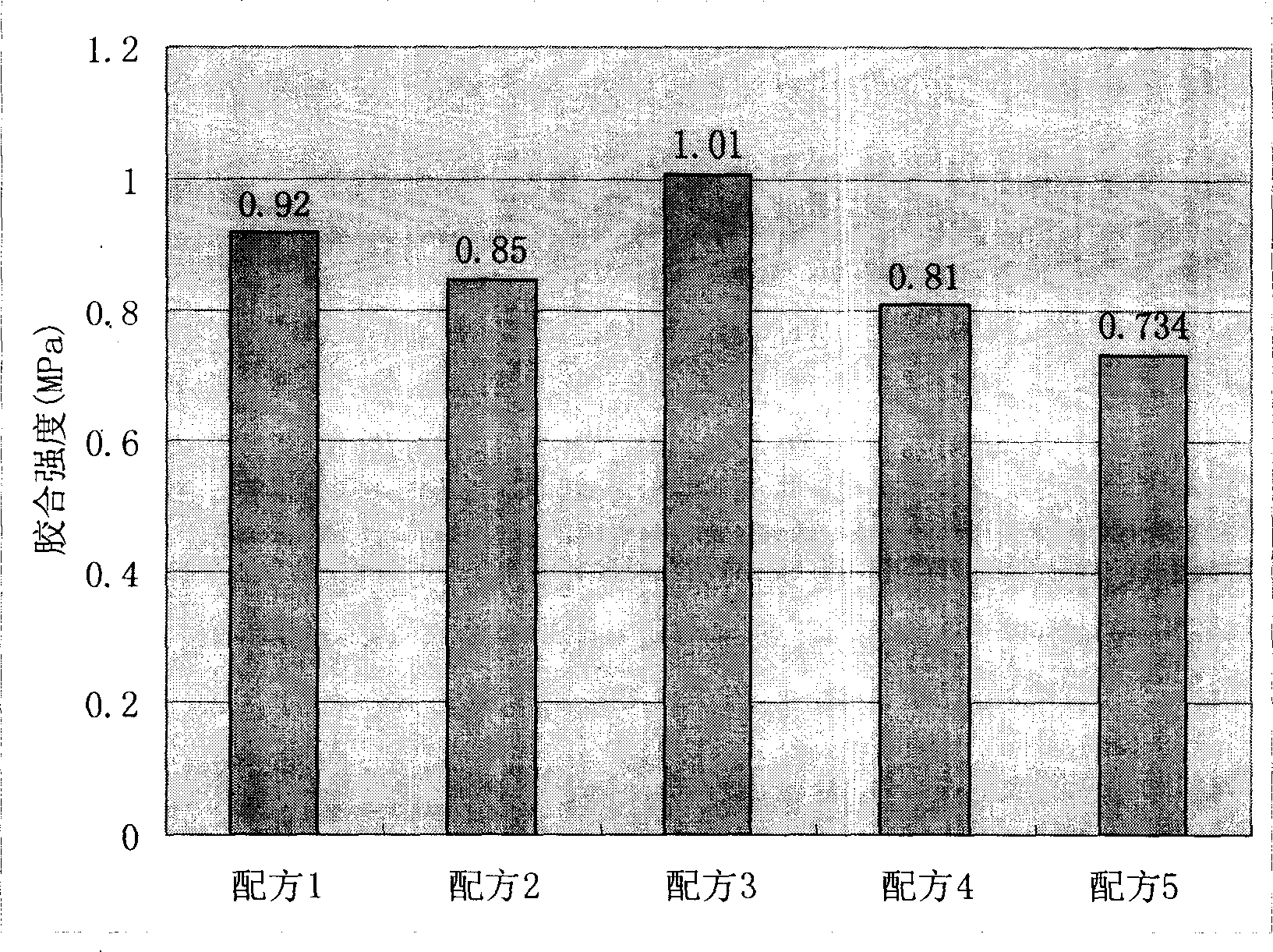

[0007] Specific embodiment one: the low-alkali soybean powder adhesive of the present embodiment is made of soybean powder, sodium hydroxide, calcium oxide and sodium silicate, wherein the weight-number ratio of each component is: soybean powder 100, sodium hydroxide 1.5 ~2, calcium oxide 2~5, sodium silicate 15~20, its preparation method is: (1) wetting and stirring: the bean flour is fully wetted with water, then add water and stir to make a uniform slurry; ( 2) Adding chemical reagents: mix according to the above ratio, and stir evenly; (3) Adjustment of concentration: According to the moisture content of the bonded materials and the bonding process, add an appropriate amount of water to adjust the concentration.

specific Embodiment approach 2

[0008] Specific embodiment two: present embodiment prepares low-alkali soybean flour adhesive through the following steps:

[0009] (1) Wetting and stirring: fully wet the bean flour with water twice the mass of the bean flour, then add water twice the mass of the bean flour and stir to make a uniform slurry.

[0010] (2) Adding chemical reagents: sodium hydroxide is made into a 30% solution, calcium oxide is made into a 1:4 lime emulsion, and sodium silicate is made into a 25% solution for later use. First, add lime emulsion with 10% weight of soybean powder into the slurry and stir for 5-10 minutes; then add sodium hydroxide with 2% weight of soybean powder and continue stirring for 5-10 minutes; finally add sodium silicate with 20% weight of soybean powder, and Stir well.

[0011] (3) Adjustment of concentration: according to the moisture content of the bonded material and the bonding process, add an appropriate amount of water to adjust the concentration.

specific Embodiment approach 3

[0012] Specific embodiment three: the difference between this embodiment and specific embodiment two is: in step (two), at first add milk of lime with 25% weight of bean flour, stir 5-10min; Then add the sodium hydroxide of 2% weight of bean flour , continue to stir for 5-10min; finally add 15% sodium silicate by weight of soybean powder and stir evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com