Adhesive composition comprising tannin, polyethylene glycol, and water, lower alcohol or mixture thereof

A polyethylene glycol and synthetic technology, applied in the direction of polyether adhesives, adhesive types, natural resin adhesives, etc., can solve the problems of needing a thermosetting curing agent and difficult to maintain adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0185] Manufacture of adhesives including tannin, polyethylene glycol (PEG) and water (adhesive)

[0186] Tannic acid (tannic acid, chemical formula 1) was dissolved in 1x PBS (Phosphate-buffered saline) buffer solution (buffer: pH 8.5) at a concentration of 1 g / mL. Finally, the linear or multi-branched ( Multi branched) polyethylene glycol (Polyethylene Glycol, PEG) was dissolved in 1x PBS (Phosphate-buffered saline) buffer solution (buffer: pH 8.5) at a concentration of 1 g / mL.

[0187] chemical formula 1

[0188]

[0189] Mix tannin with PEG, mPEG-SH, mPEG-AM, mPEG-SS, PEG-AM, 4-arm-PEG-AM, 4-arm-PEG-SS, and 6-arm-PEG-AM. After standing for about ten minutes, a brown adhesive (adhesive) precipitated below, and the upper layer was a transparent liquid. After decanting the supernatant, the lower brown adhesive was used. figure 1 Indicates extraction of the underlying brown adhesive.

[0190] The adhesive composition of the present invention was produced by using ...

Embodiment 2

[0194] Determination of Adhesion

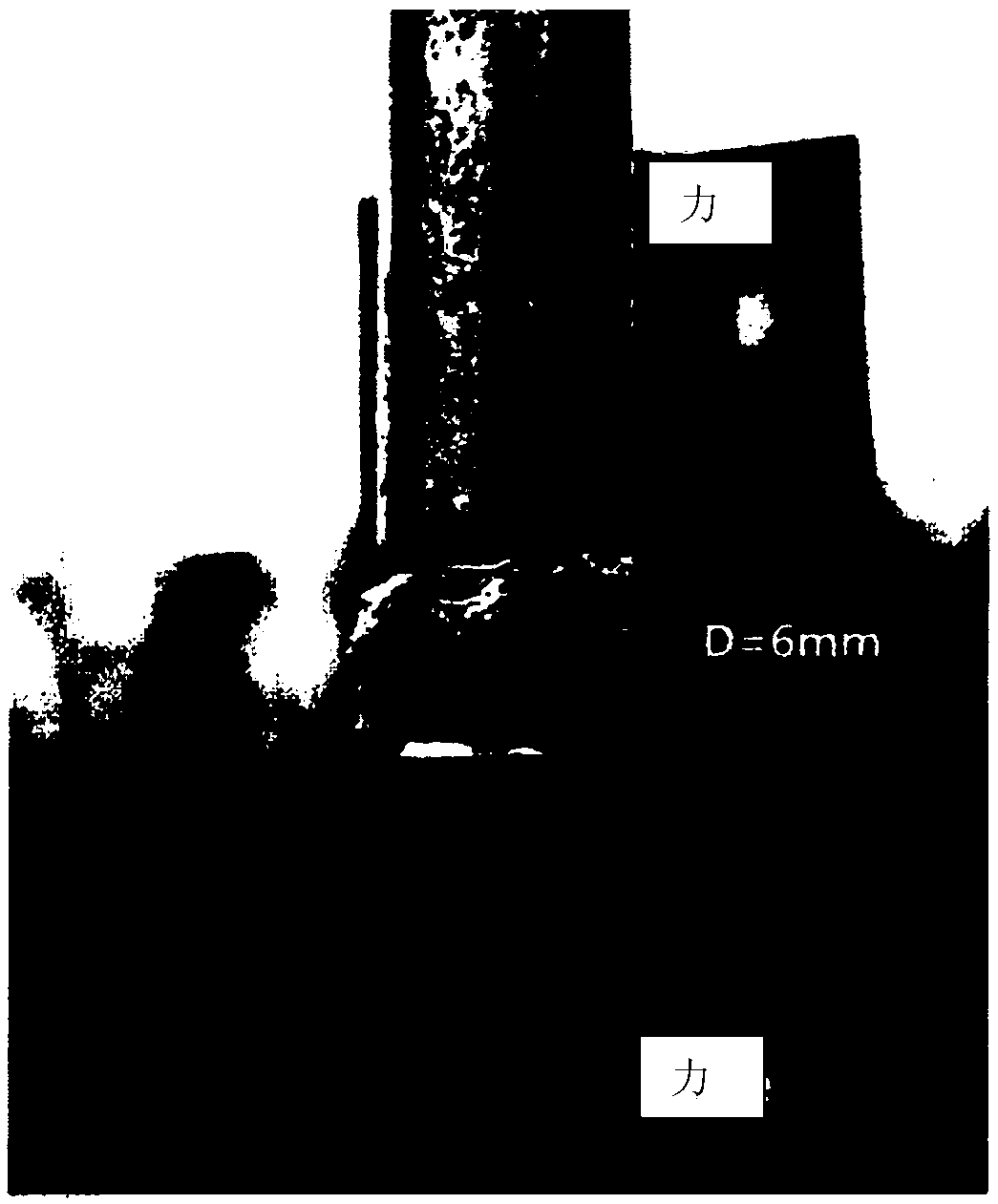

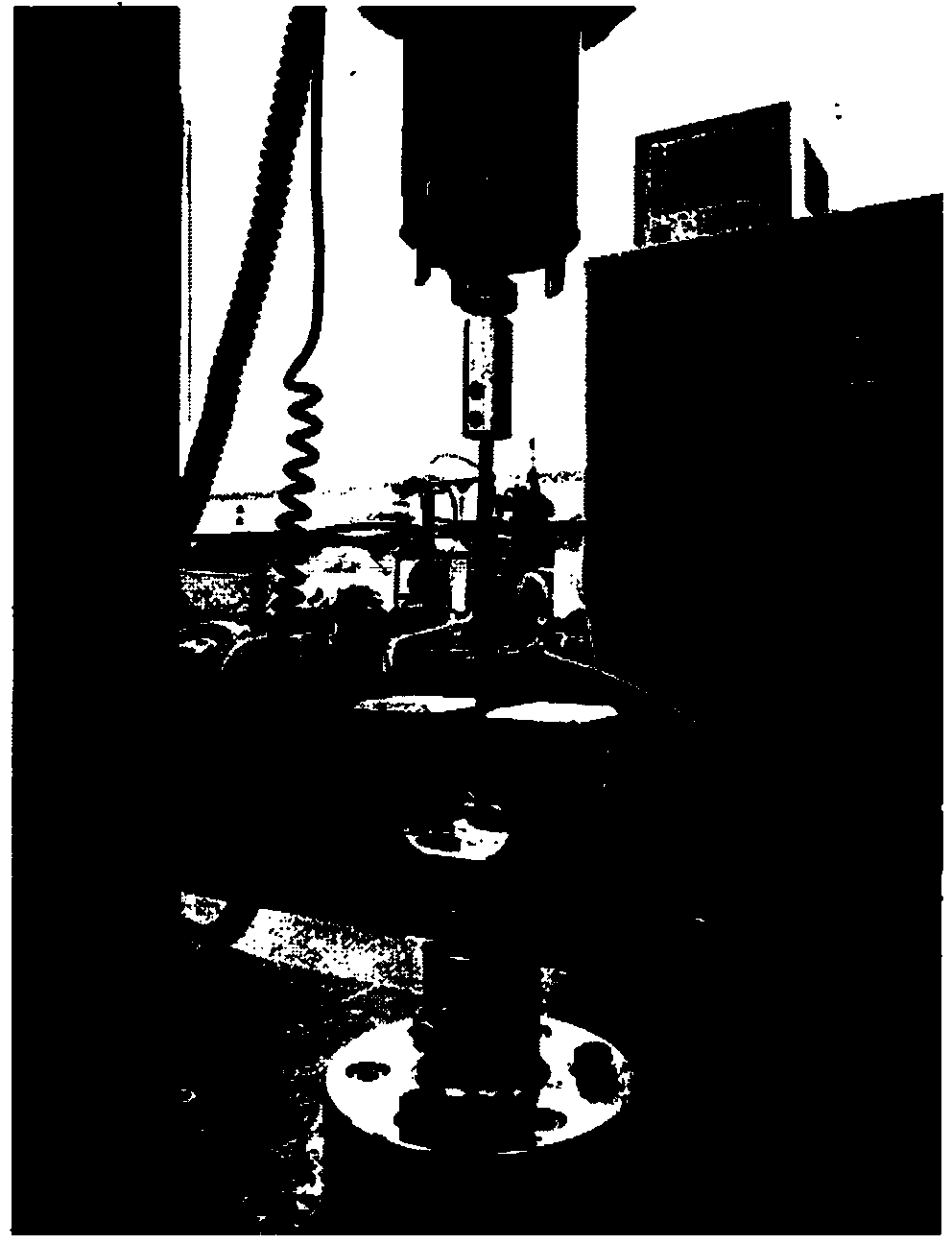

[0195] Using a biopsy punch (Biopsy punch, Miltex REF33-36), the porcine skin tissue was cut out with a diameter of 6 mm. Between the two porcine skin tissues, about 3 g of the adhesive (adhesive) produced in the above-mentioned Example 1 was evenly applied, and the instant adhesive was bonded on the back side, and sticks for measuring the adhesive force were respectively pasted. After applying a force of 20 N to the sample for 1 minute using a universal testing machine (Universal Testing Machine, INSTRON 5583), a tensile force was applied at a speed of 1 mm / min to measure the adhesive force. For adhesives (adhesives) manufactured using different polyethylene glycols (Polyethylene Glycol, PEG), three or more consecutive samples were measured, and the average adhesive force and the maximum adhesive force were obtained.

[0196] results, such as Figure 4 , Figure 5 As shown, when the solvent is water, the adhesion of 4-arm-PEG-AM (10kDa)...

Embodiment 3

[0200] Determination of the relationship between bonding times and bonding force and duration

[0201] 4-arm-PEG-OH (10 kDa) and 4-arm-PEG-AM (10 kDa) adhesives were produced in the same manner as in Example 1. In the same manner as in Example 2, porcine skin tissue was cut out with a diameter of 6 mm. Between the two porcine skin tissues, about 3 g of the adhesive (adhesive) prepared above was evenly applied, and the instant adhesive was adhered on the back side, and sticks for measuring the adhesive force were respectively pasted. After a universal testing machine (Universal Testing Machine, INSTRON5583) was used to apply a force of 20 N to the sample for 1 minute, the tensile force was applied at a speed of 10 mm / min to measure the adhesive force. This process was repeated thereafter, and changes in the adhesive (adhesive) associated with the number of times were detected. 4-arm-PEG-OH (10kDa) tested a sample continuously for 5 hours and 82 times. 4-arm-PEG-AM (10kDa) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com