A kind of fluorescent film sensing composite material and its preparation method and application

A technology of composite materials and thin films, which is applied in the direction of luminescent materials, material analysis through optical means, and analysis of materials, etc., to achieve the effects of increasing fluorescence intensity, preventing shedding, and improving response and selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A kind of preparation method of fluorescent film sensing composite material, described preparation method comprises the steps:

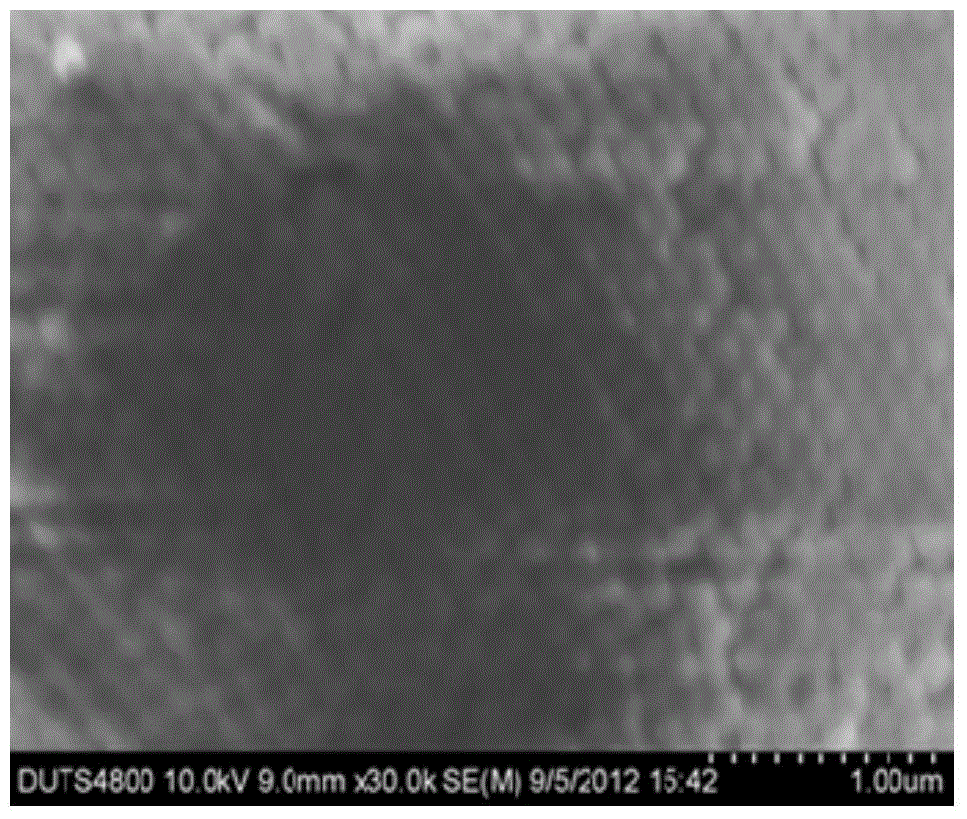

[0042]① Add 300 μL of water-soluble polystyrene microspheres with a particle size of 240 nm into 5 mL of deionized water, oscillate ultrasonically for 30 minutes, insert the vertical part of the conductive glass into the aqueous solution of water-soluble polystyrene microspheres, and react at 55 ° C for 12 hours to obtain Polystyrene microsphere photonic crystal film on the surface of conductive glass, its morphology is shown in the attached figure 1 ;

[0043] ②Dissolve 100mg of cadmium chloride in 100mL of high-purity water, add 21.7mg of thioglycolic acid and 5mL of 2mol / L sodium hydroxide solution in sequence, pass nitrogen to deoxygenate for 30min, add 1mL of quantum dot precursor, and react hydrothermally at 80°C for 12h to obtain mercapto Acetic acid-modified cadmium telluride solution; soak the product obtained in step ① vertically i...

Embodiment 2

[0045] A kind of preparation method of fluorescent film sensing composite material, described preparation method comprises the steps:

[0046] ① Add 300 μL of silica microspheres with a particle size of 240 nm into 5 mL of deionized water, oscillate ultrasonically for 30 minutes, insert the vertical part of the conductive glass into the aqueous solution of silica microspheres, and react at 55 ° C for 12 hours to obtain a microsphere covering the surface of the conductive glass. Silica microsphere photonic crystal thin film;

[0047] ②Dissolve 100mg of cadmium chloride in 100mL of high-purity water, add 25.0mg of 3-mercaptopropionic acid and 5mL of 2mol / L sodium hydroxide solution in sequence, pass nitrogen to deoxygenate for 30min, add 1mL of quantum dot precursor solution, and react with water at 80℃ for 3h. Obtain a cadmium telluride solution modified with 3-mercaptopropionic acid; soak the product obtained in step ① vertically in 1wt% gamma-aminopropyltrimethoxysilane absol...

Embodiment 3

[0049] A kind of preparation method of fluorescent film sensing composite material, described preparation method comprises the steps:

[0050] ① Add 300μL of water-soluble polystyrene microspheres with a particle size of 240nm into 5mL of deionized water, and oscillate ultrasonically for 30 minutes. Water-soluble polystyrene microsphere photonic crystal film on glass surface;

[0051] ②Dissolve 100mg of cadmium chloride in 100mL of high-purity water, add 25.0mg of 2-mercaptopropionic acid, 5mL of 2mol / L sodium hydroxide solution in turn, pass nitrogen to deoxygenate for 30min, add 1mL of quantum dot precursor solution, and react with hydrothermal reaction at 80℃ for 7h. Obtain a cadmium telluride solution modified with 2-mercaptopropionic acid; vertically immerse the product obtained in step ① in 1 wt% N-β-aminoethyl-γ-aminopropyltrimethoxysilane absolute ethanol solution for activation for 30 minutes, and dry , vertically soaked in 2-mercaptopropionic acid-modified cadmium t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com