Hot melt adhesive used for automotive interiors, and preparation method of hot melt adhesive

A technology of automotive interior parts and hot melt adhesives, applied in the direction of adhesives, adhesive types, wax adhesives, etc., can solve the problems of affecting the operator's sight and producing white smoke, and achieve good toughness, strong waterproof, high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

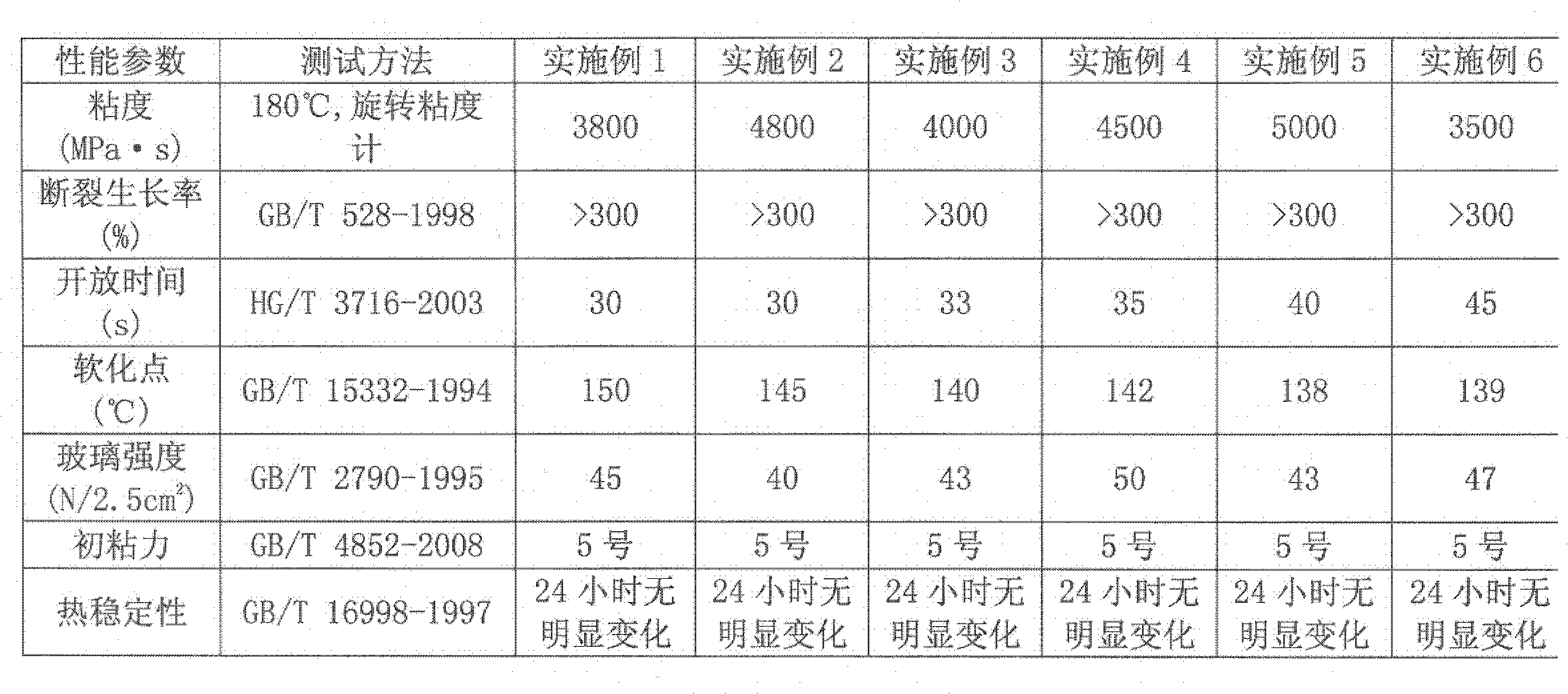

Examples

Embodiment 1

[0044] Weigh 50kg of paraffin wax, 40kg of polyethylene wax, 45kg of thermoplastic elastomer SBS, 25kg of high molecular weight random polyolefin, 95kg of high molecular weight random polyolefin, 45kg of polyethylene vinyl acetate, 40kg of polyethylene vinyl acetate, C5 Petroleum resin 50kg, rosin pentaerythritol ester 100kg, antioxidant 5kg, coupling agent 3kg and filler 2kg.

[0045] preparation:

[0046] Step 1: Heat the stirring tank to 150°C, add paraffin wax and polyethylene wax, and stir until completely melted;

[0047] The second step: Add thermoplastic elastomer SBS to the mixture obtained in the first step, immediately evacuate the stirring tank to a vacuum of 0.3MPa, stir until it is completely melted, and keep it warm for 10 minutes;

[0048] The third step: adding low-molecular-weight random polyolefin, high-molecular-weight random polyolefin and antioxidant to the mixture obtained in the second step, stirring until completely melted;

[0049] Step 4: Add coupli...

Embodiment 2

[0055] Weigh 20kg of paraffin wax, 35kg of polyethylene wax, 50kg of thermoplastic elastomer SBS, 50kg of high molecular weight random polyolefin, 100kg of high molecular weight random polyolefin, 50kg of polyethylene vinyl acetate, 45kg of polyethylene vinyl acetate, C 5 Petroleum resin 95kg, rosin pentaerythritol ester 50kg, coupling agent 2kg antioxidant 3kg.

[0056] preparation:

[0057] The first step: raise the humidity of the stirring tank to 150°C, add paraffin wax and polyethylene wax, and stir until completely melted;

[0058] The second step: Add thermoplastic elastomer SBS to the mixture obtained in the first step, immediately evacuate the stirring tank to a vacuum of 0.3MPa, stir until it is completely melted, and keep it warm for 10 minutes;

[0059] The third step: adding low-molecular-weight random polyolefin, high-molecular-weight random polyolefin and antioxidant to the mixture obtained in the second step, stirring until completely melted;

[0060] Step 4:...

Embodiment 3

[0066] Weigh 10kg of paraffin wax, 45kg of thermoplastic elastomer SBS, 45kg of high molecular weight random polyolefin, 125kg of high molecular weight random polyolefin, 30kg of polyethylene vinyl acetate, 25kg of polyethylene vinyl acetate, C 5 Petroleum resin 92.5kg, rosin pentaerythritol ester 100kg, antioxidant 2.5kg, coupling agent 15kg and filler 10kg.

[0067] preparation:

[0068] Step 1: Heat the stirring tank to 150°C, add paraffin wax and polyethylene wax, and stir until completely melted;

[0069] The second step: Add thermoplastic elastomer SBS to the mixture obtained in the first step, immediately evacuate the stirring tank to a vacuum of 0.3MPa, stir until it is completely melted, and keep it warm for 10 minutes;

[0070] Step 3: Add high-molecular-weight random polyolefin 1, high-molecular-weight random polyolefin 2 and antioxidant to the mixture obtained in the second step, and stir until completely melted;

[0071] Step 4: Add coupling agent and filler to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent viscosity | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com