Vibrated type disposing machine and the mechanization disposing and processing method

A vibrating and blowing machine technology, which is applied to the device for straightening hair, and the processing field of mechanized blowing, can solve the problems of affecting health, high labor intensity, difficult technical mastery, etc., so as to reduce labor intensity, improve processing efficiency, and operation difficulty. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

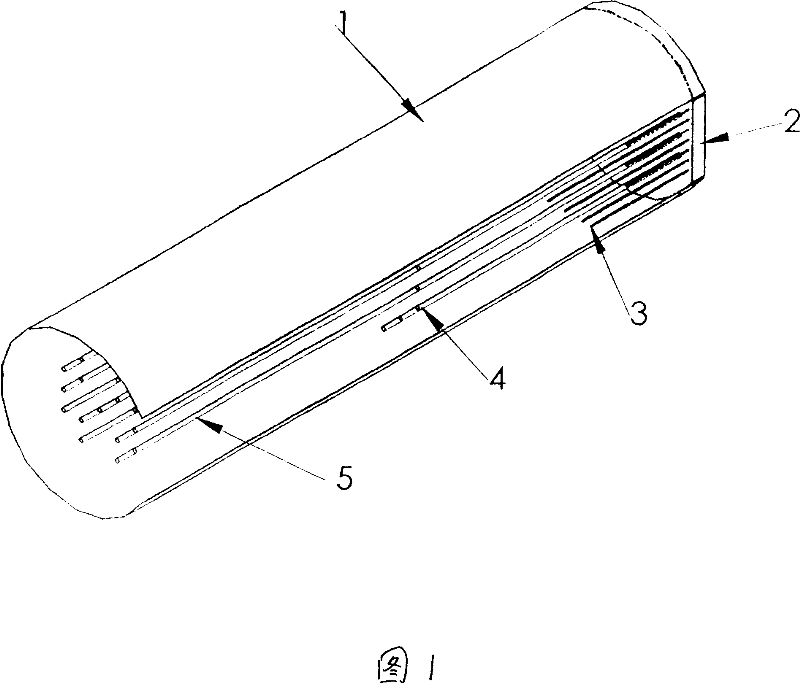

[0032] Embodiment 1: Referring to Fig. 1 , a syringe container for sending hair, comprising an outer cylinder 1 and a needle plate 2, the needle plate 2 is composed of a bottom plate and an array of thin needles of different lengths arranged at a certain interval on the bottom plate, And the base plate of the needle plate 2 is fixedly connected with the lower end surface of the outer cylinder 1, and the thin needles on the base plate are sleeved in the inner cavity of the outer cylinder; the outer cylinder 1 is a stainless steel thin-walled cylinder, and the diameter of the outer cylinder 1 will be according to The production requirement is selected, and its height is about 2 inches less than the length of the hair that is ready to beat. The needle plate 2 is made of a cylindrical plane base plate and arranged on it according to the different fine needles arranged at a certain interval.

[0033] For the convenience of production, the distribution of the needles adopts a chessbo...

Embodiment 2

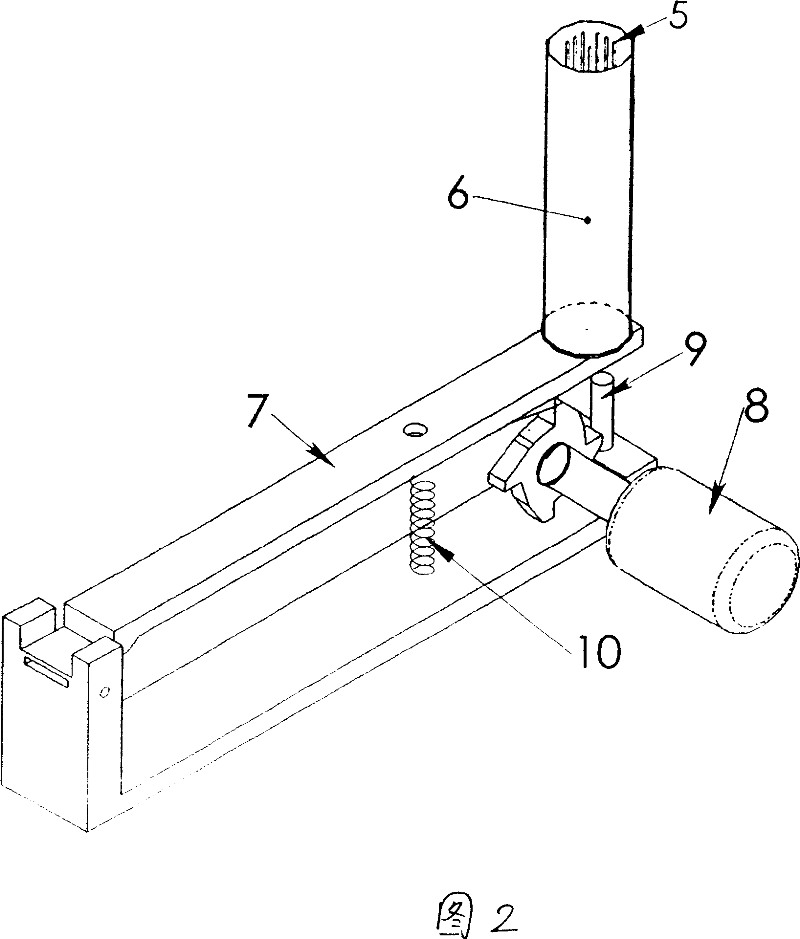

[0035] Embodiment 2: Referring to FIG. 2, a vibrating sender containing the syringe container for sending described in Embodiment 1, the vibrating sender also includes a bracket, a swing rod 7 and a vibration source 8, the swing rod 7 One end is hinged or fixedly connected to one end of the bracket, and a syringe container 6 is installed on the other end, and a vibration source 8 that makes the swing rod 7 swing up and down is installed on the other end of the bracket. It is composed of a needle plate 2, the needle plate 2 is composed of a bottom plate and thin needles of different lengths arranged at a certain distance on the bottom plate, and the bottom plate of the needle plate 2 is fixedly connected with the lower end surface of the outer cylinder 1, The thin needle on the bottom plate is set in the inner cavity of the outer cylinder; the limit block 9 is installed on the support of the vibrating whisk, and a tension spring 10 is installed between the support and the swing ...

Embodiment 3

[0038] Embodiment 3: A vibration-type whisk containing the syringe container for sending described in Embodiment 1, and also includes a vibration source with a fixed amplitude, the syringe container is directly connected to the vibration source with a fixed amplitude, and the syringe container It is composed of an outer cylinder and a needle plate. The needle plate is composed of a bottom plate and thin needles of different lengths arranged at a certain distance on the bottom plate, and the bottom plate of the needle plate is fixedly connected with the lower end surface of the outer cylinder. The bottom plate The thin needle on the upper is set in the inner cavity of the outer cylinder.

[0039] When in use, put hair into the syringe container, start a vibration source with a fixed amplitude to vibrate the syringe container, use a timer to set the time, stop the machine when the timing ends, take out the hair, and bind it.

[0040] The vibration source is divided into 6Hz-10Hz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com