Positioning structure of circuit board

A positioning structure and circuit board technology, applied in metal processing and other directions, can solve the problems of not meeting the requirements of mechanization, inability to disassemble at will, inconvenient picking and placing of materials, etc., to achieve improved efficiency, convenient positioning, and easy picking and placing of materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

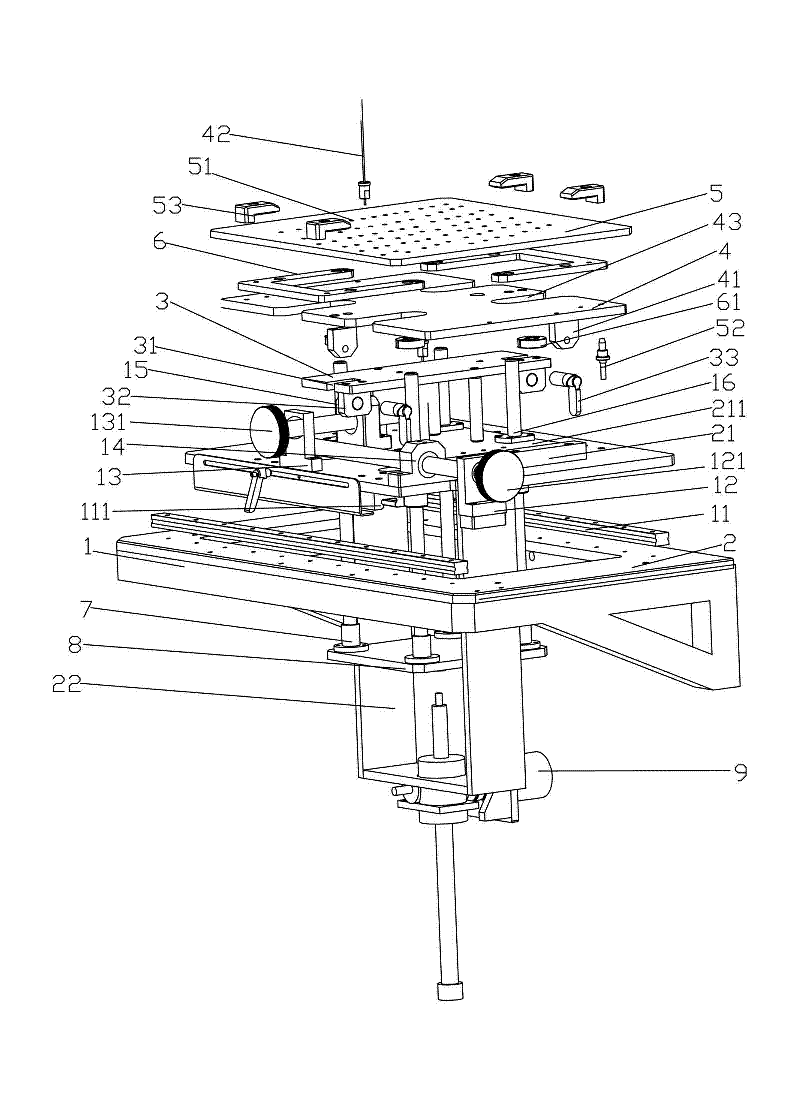

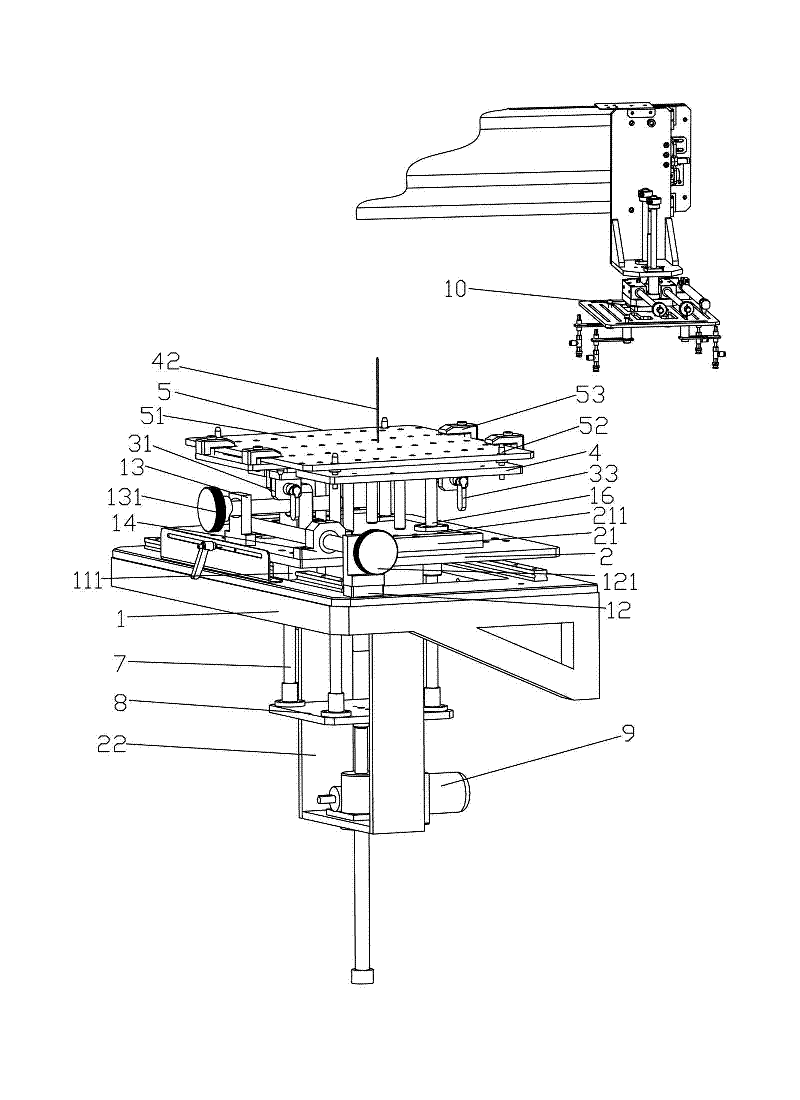

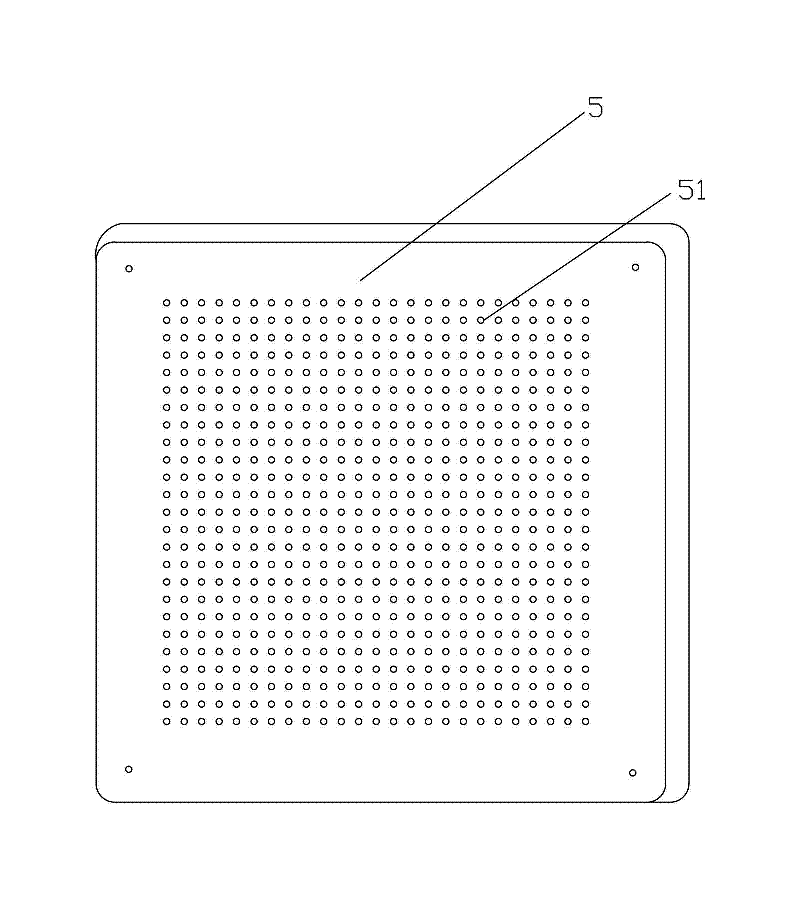

[0019] Such as Figure 1~Figure 3 As shown, a circuit board positioning structure, a circuit board positioning structure, including a base plate 1, a slide plate 2 fixed on the base plate 1, a guide rail 11 with a chute is installed on the base plate 1, and the bottom of the slide plate 2 A slide block 111 engaged with the guide rail 11 is fixed, so that the slide block 11 can drive the slide plate 2 to move in the guide rail 11, and a support 12 is fixed on the base plate 1, and a support for X is installed in the support 12. A fine-tuning screw 121 for direction adjustment, a support 13 is fixed on the slide plate 2, a fine-tuning screw 131 for adjusting the Y direction is installed in the support 13, and a fine-tuning screw 131 that matches the fine-tuning screw 121 is fixed on the slide 2. The threaded connector 14, the sliding sleeve 21 is fixed on the sliding plate 2, and the support plate 22 is connected to the bottom, and the sliding sleeve 21 is equipped with a moving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com