Bipyramid rotary superconducting waste cracking furnace

A double-cone, rotary furnace technology, applied in the direction of incinerators, lighting and heating equipment, combustion methods, etc., can solve the problems of non-continuous operation, non-shielding, carcinogenicity, etc., to achieve curb generation and emission, reaction temperature balance, shielding The effect of secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] specific implementation plan

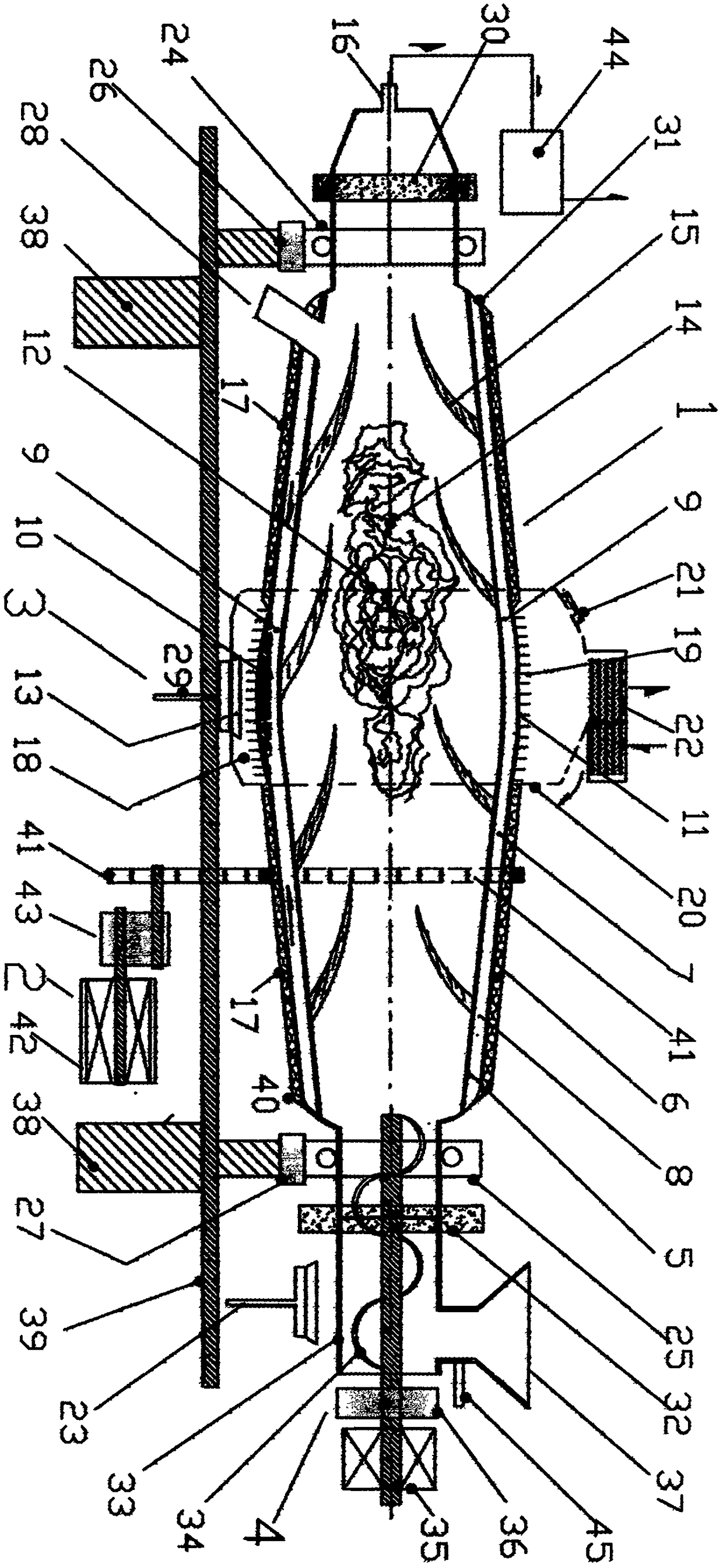

[0023] A double-cone rotary superconducting garbage pyrolysis furnace is composed of a double-cone superconducting isothermal rotary furnace body 1, a rotary furnace body driver 2, a heater 3 and a feeder 4. It is characterized in that the double-cone superconducting isothermal rotary furnace body 1 is composed of a concentric metal inner tube 5 and a metal outer tube 6, a double-cone composite tube 7 with a small middle and a thick rotary furnace body, and a double-cone composite tube 7 at both ends Sealing, a concentric cavity 8 is formed between the inner and outer tube walls of the double-cone composite tube 7, and the wide middle part of the concentric cavity 8 is a heating pool 9, and a superconducting phase change working medium 10 is installed in the heating pool 9, and garbage When the cracking furnace is not working, the concentric cavity 8 is in a vacuum negative pressure state, and in dynamic state, the concentric cavity 8 is i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com