Efficient and safe waste pyrolysis gasifier

A technology for pyrolysis gasification and waste, applied in non-polluting, high-efficiency and safe waste pyrolysis gasification furnace, low energy consumption field, can solve the problems of bulky, expensive, etc., and achieve small thermal resistance, low operation failure, and balanced reaction temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] specific implementation plan

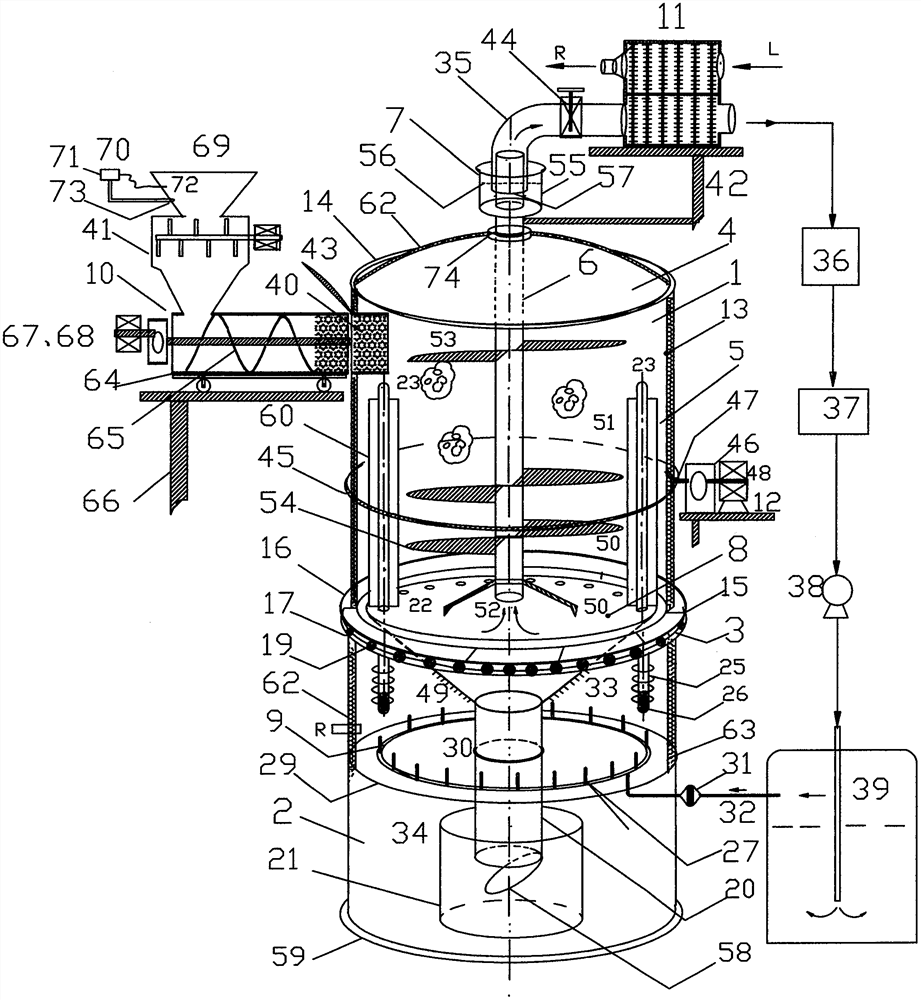

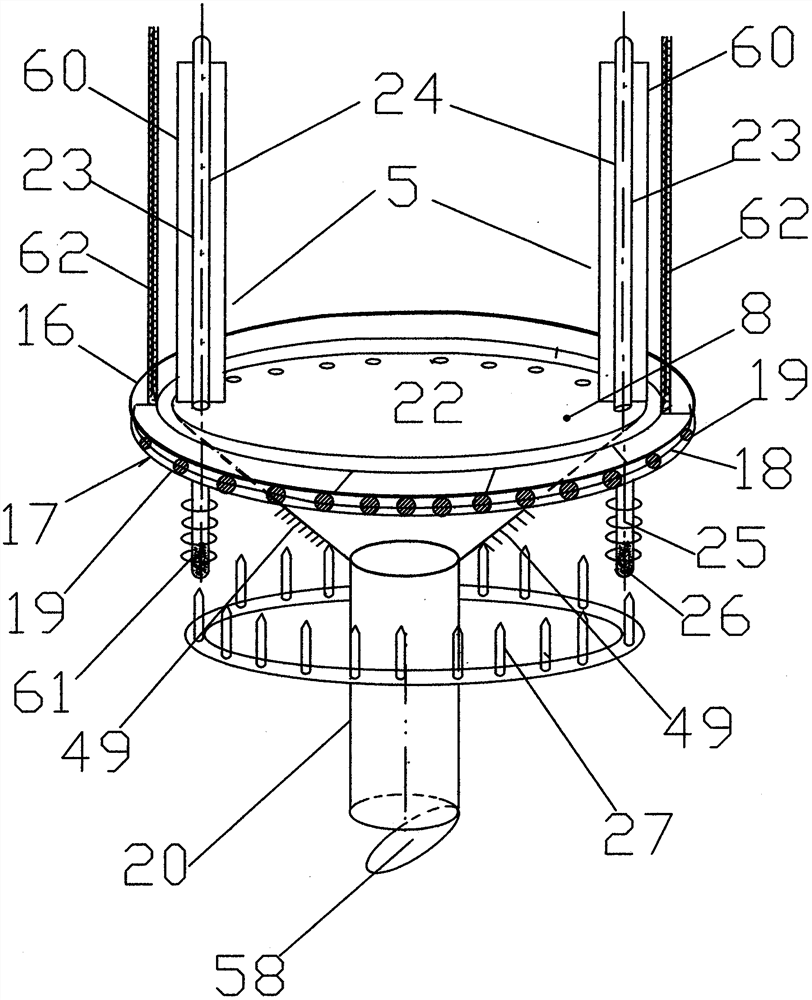

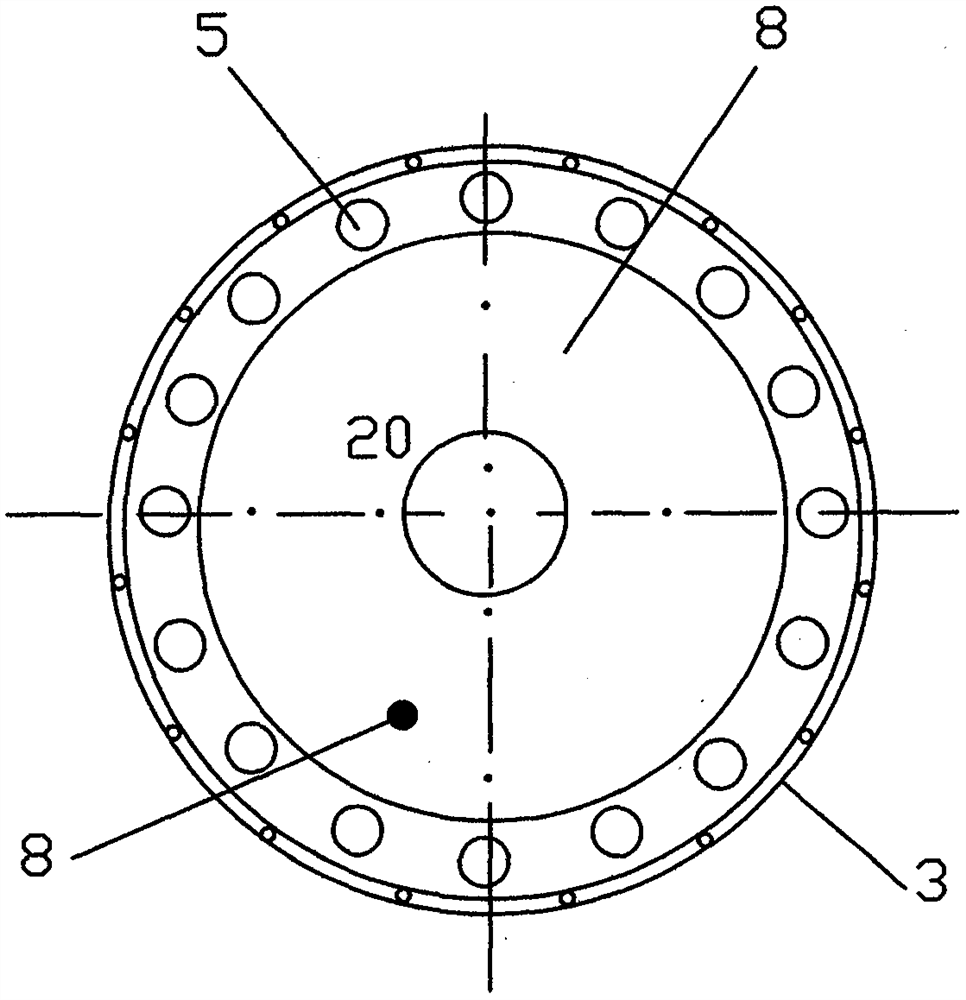

[0031] now attached figure 1 , 2 , 3 make specific instructions:

[0032] A high-efficiency and safe garbage pyrolysis gasification furnace consists of a rotary furnace body 1, a furnace base 2, a ball turntable 3, a furnace cover 4, a high-temperature superconducting heat exchanger 5, a gas collecting pipe 6, a liquid sealing sleeve 7, and a conical body for heat exchange 8, annular heater 9, feeding machine 10, superconducting waste heat recovery device 11, and driving device 12. It is characterized in that the furnace body 1 is composed of a cylindrical shell 13, an upper flange 14 connected to the upper and lower edges of the cylindrical shell 13, a lower flange 15, and the upper flange 14 and the flange of the furnace cover 4 above it are used. Bolt connection, the lower flange 15 and the upper raceway disk 16 of the ball turntable 3 below are connected with bolts, and the outer walls of the rotating furnace body 1, furnace seat 2,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com