Efficient and safe garbage cracking gasification furnace

A technology for pyrolysis gasification and waste, which is applied in high-efficiency and safe waste pyrolysis gasification furnace, no pollution, low energy consumption, and can solve the problems of bulky and expensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Specific implementation plan

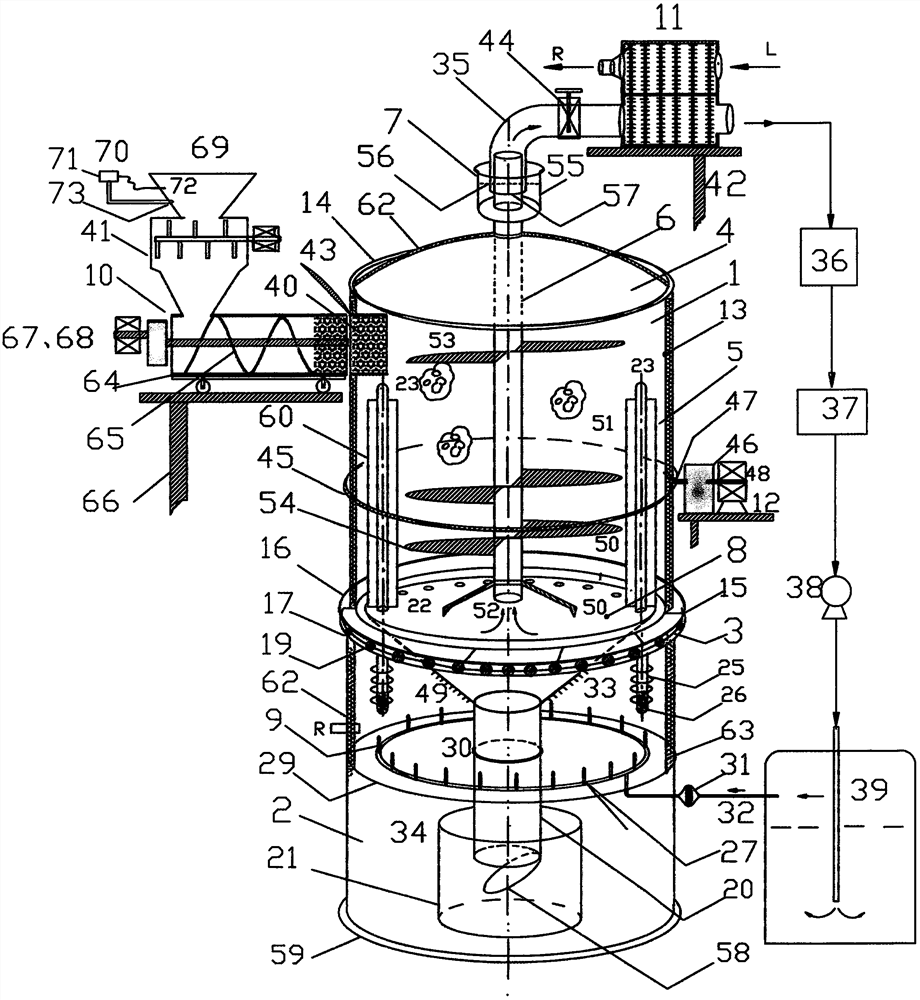

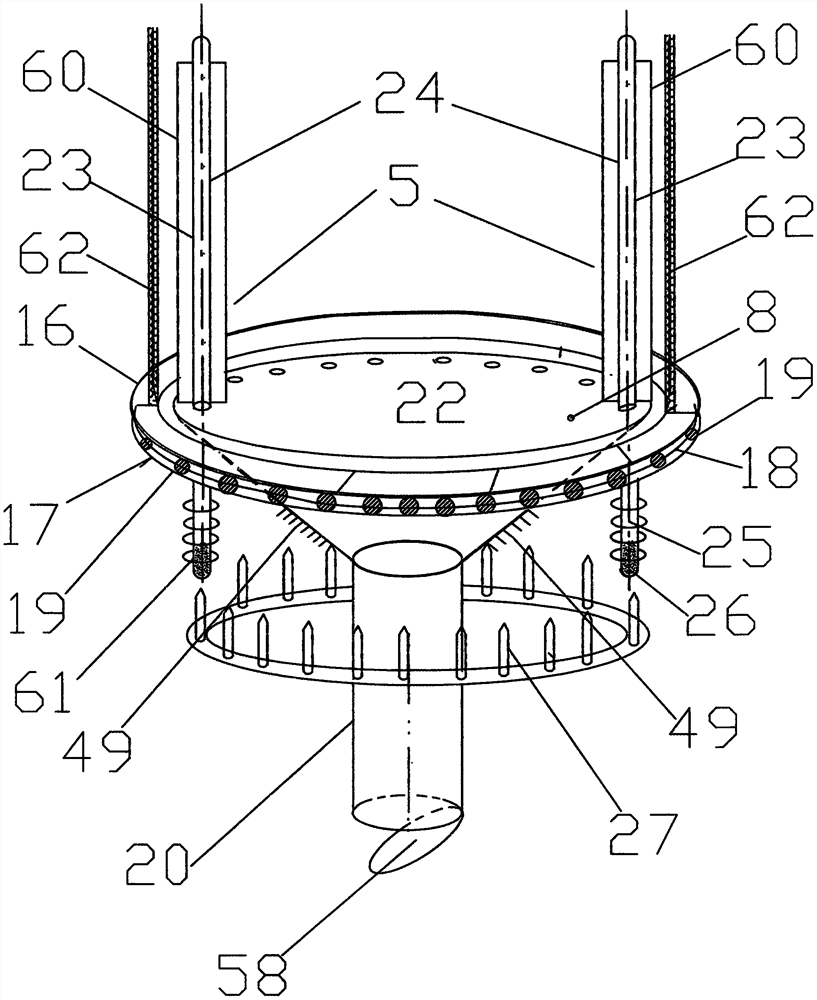

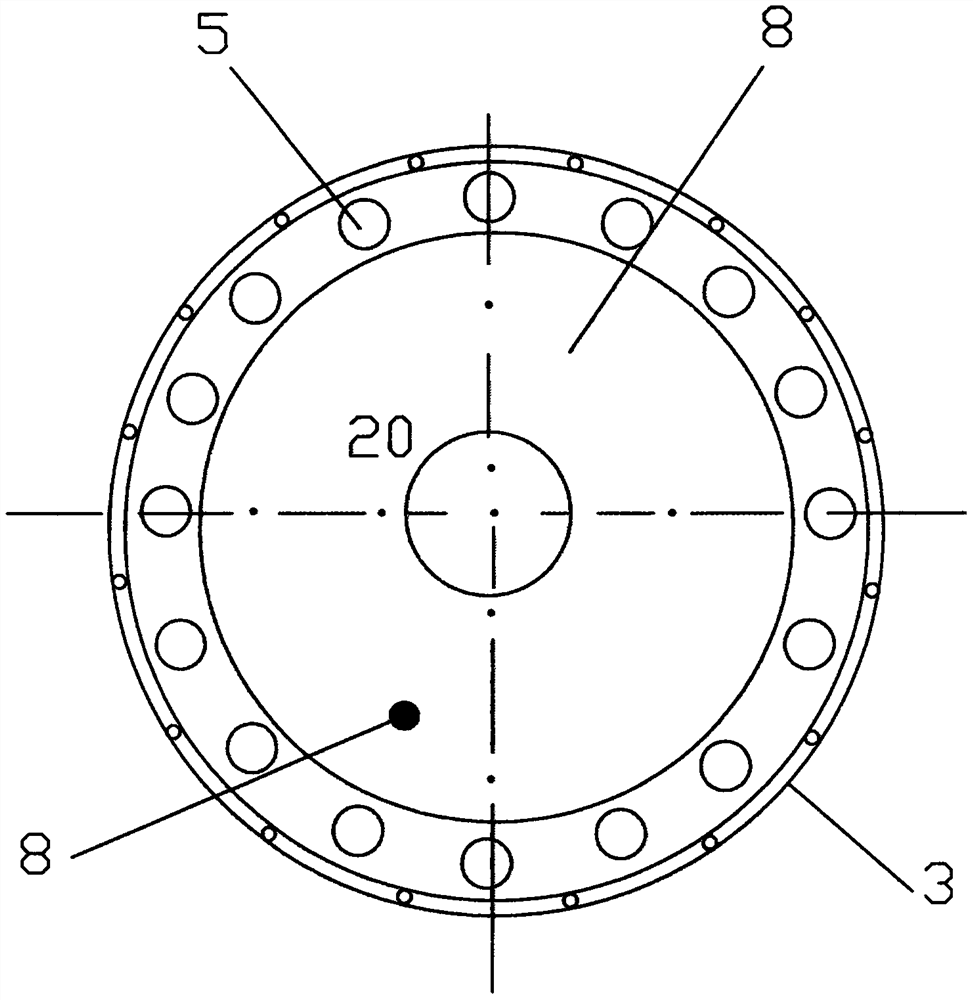

[0031] Now combined with figure 1 , 2 , 3 make specific instructions:

[0032] An efficient and safe waste cracking gasifier, which consists of a rotating furnace body 1, a furnace base 2, a ball turntable 3, a furnace cover 4, a high-temperature superconducting heat exchanger 5, a gas collecting pipe 6, a liquid sealing sleeve 7, and a cone heat exchange A device 8, a ring heater 9, a feeder 10, a superconducting waste heat recovery device 11, and a driving device 12. It is characterized in that the furnace body 1 consists of a cylindrical shell 13, an upper flange 14 and a lower flange 15 connected to the upper and lower edges of the cylindrical shell 13, and the upper flange 14 and the flange of the upper furnace cover 4 Bolt connection, the lower flange 15 and the upper rolling plate 16 of the ball turntable 3 underneath are connected by bolts, and the outer wall of the rotating furnace body 1, the furnace base 2, and the furnace cover 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com