Patents

Literature

62results about "Gasifier moving parts" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

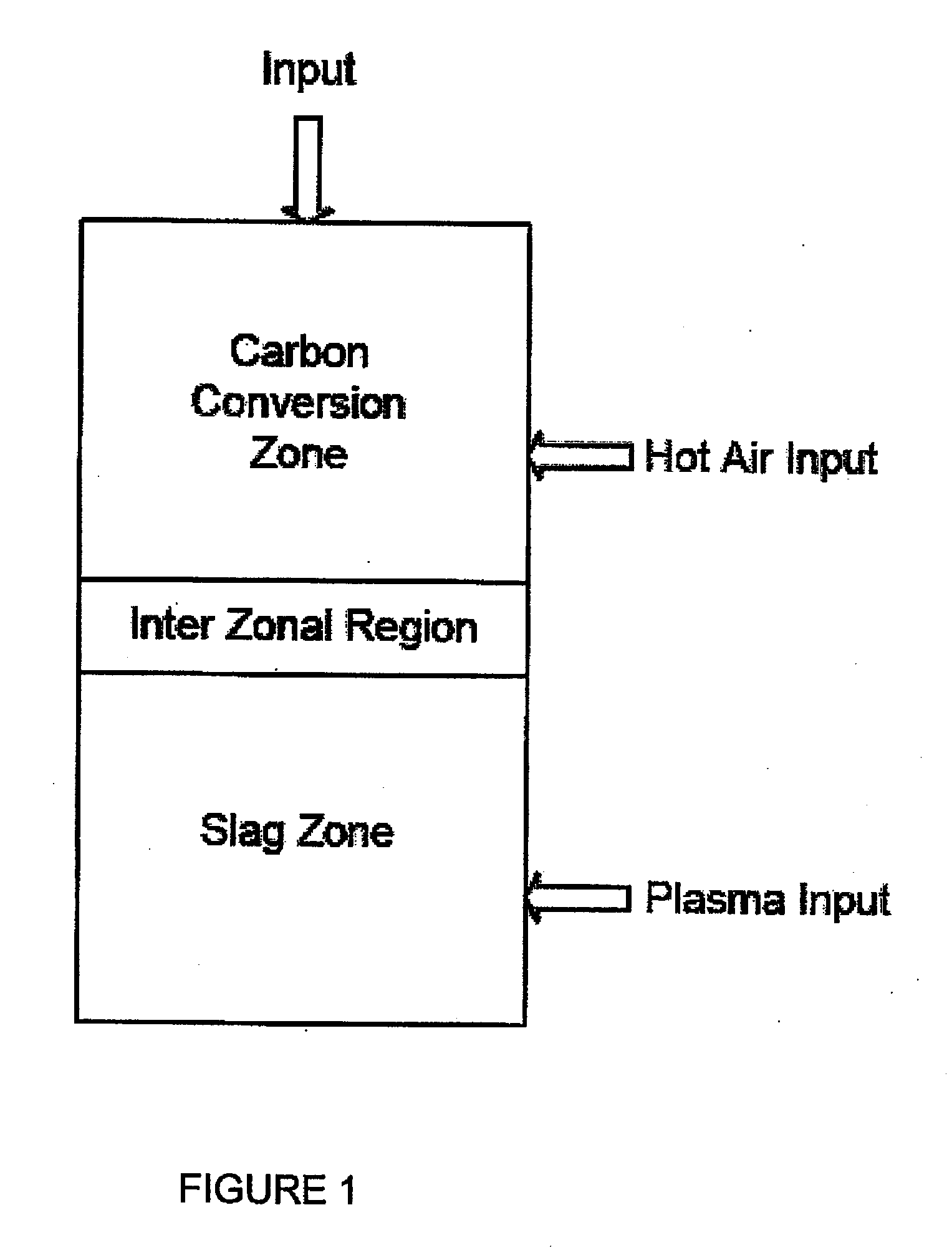

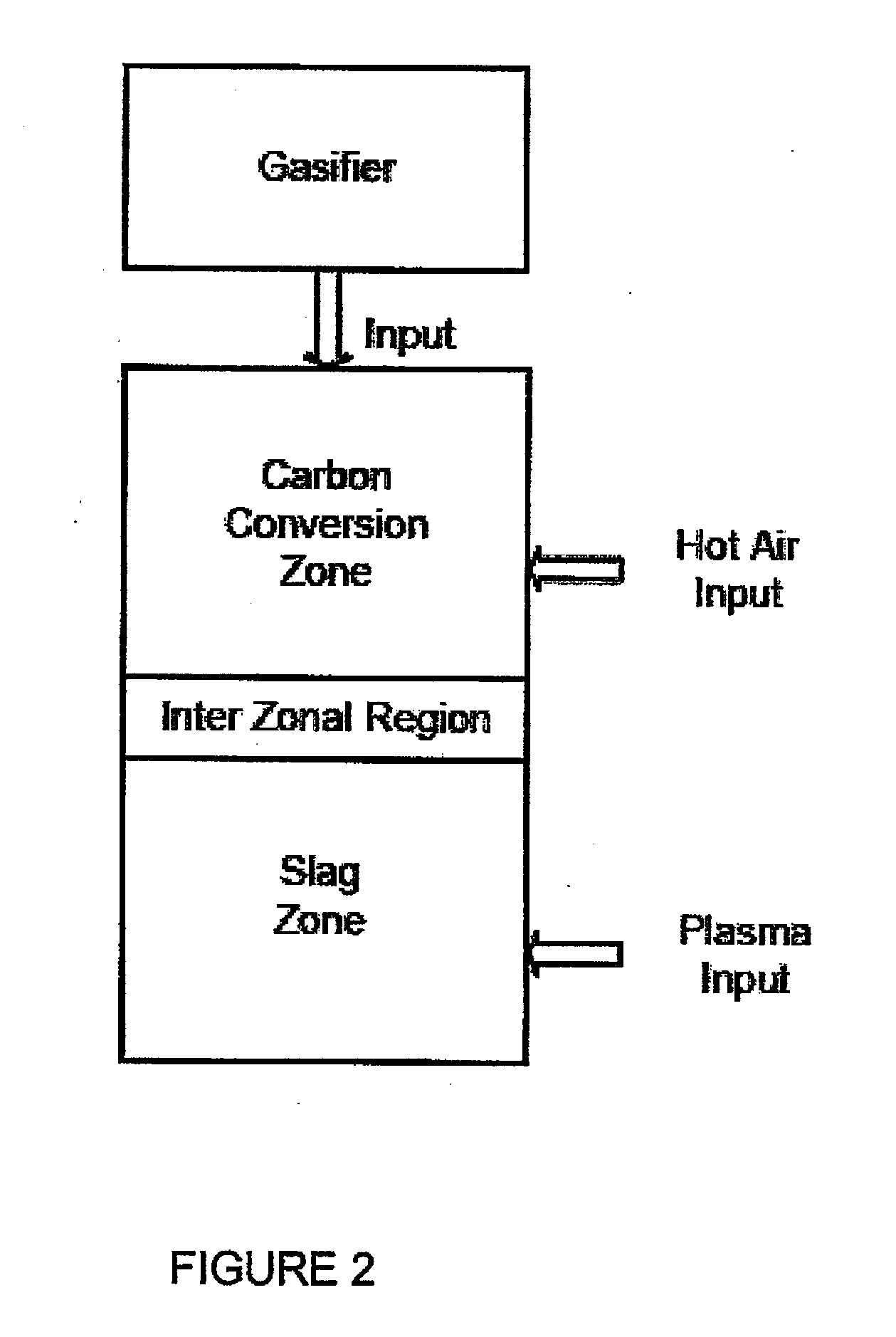

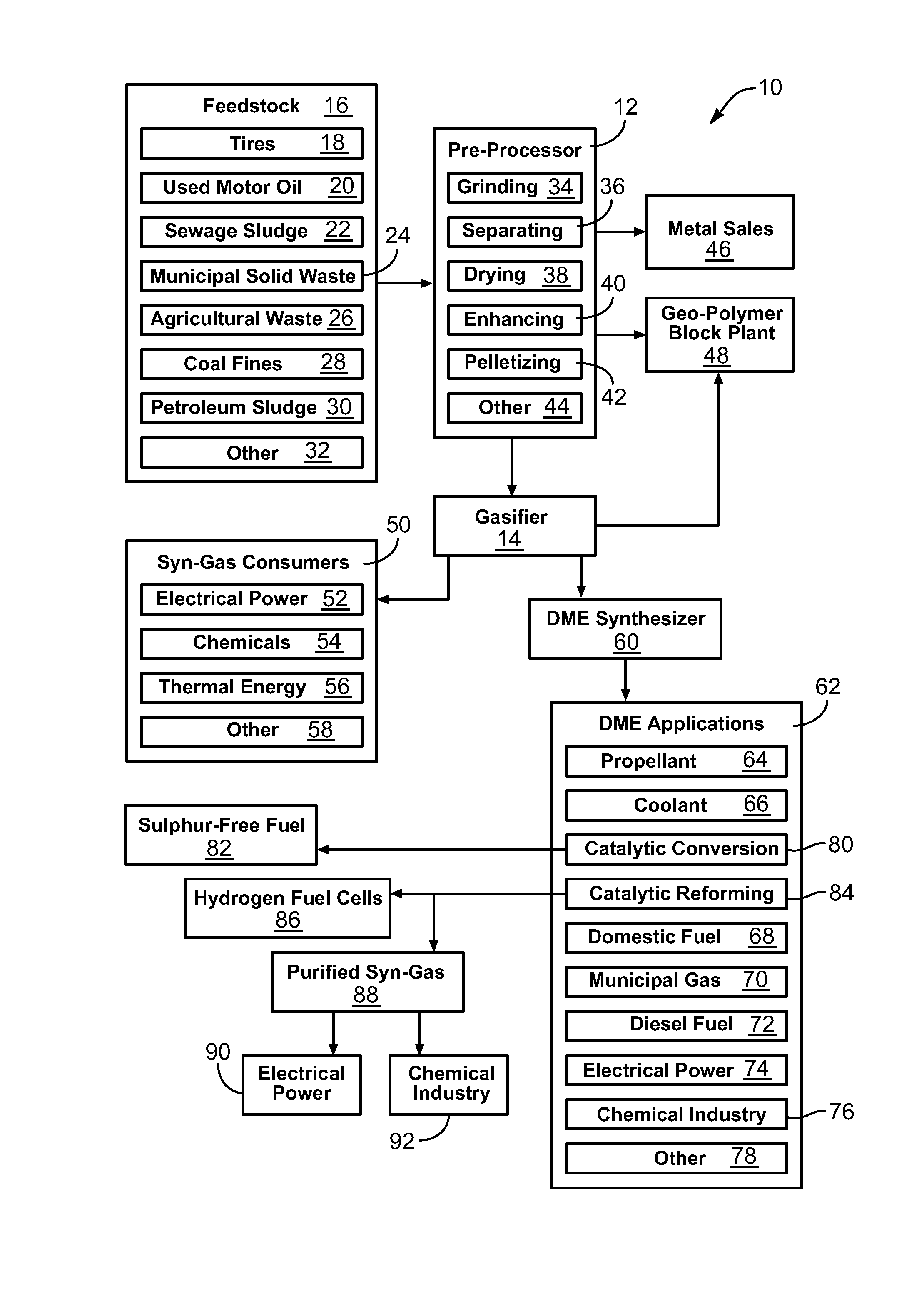

Multi-Zone Carbon Conversion System with Plasma Melting

InactiveUS20110062013A1Combustible gas coke oven heatingGasifier moving partsMolten stateMolten slag

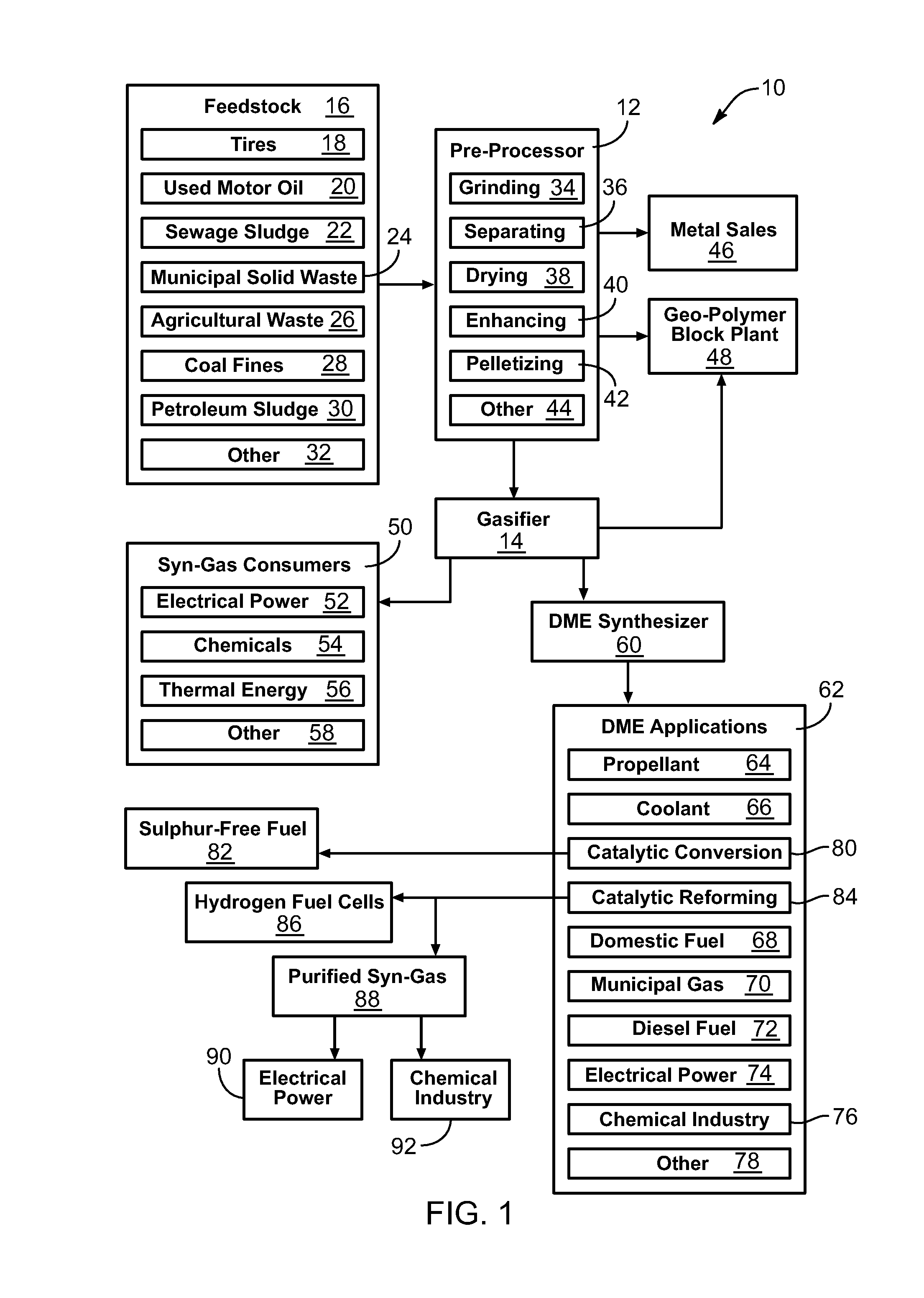

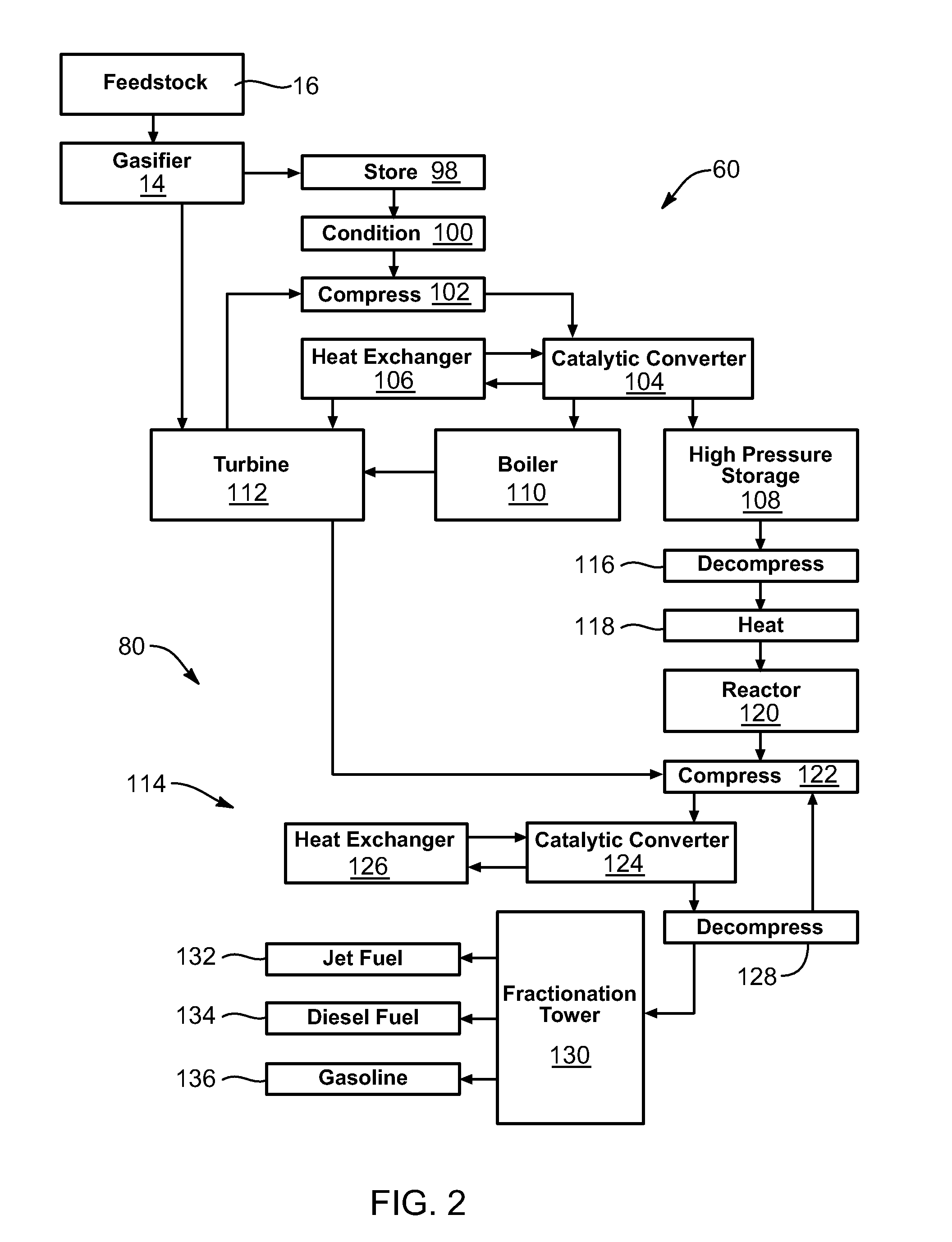

A multi-zone carbon converter for converting processed feedstock to syngas and slag is provided comprising a chamber comprising a carbon conversion zone in communication with a slag zone for melting ash into molten slag and / or for maintaining slag in a molten state by the application of plasma heat. The carbon conversion zone and the slag zone are separated by the inter-zonal region that comprises an impediment for restricting or limiting the movement of material between the two zones. The inter-zonal region may also provide for the initial melting of the ash into molten slag by affecting the transfer of plasma heat from the slag zone.

Owner:PLASCO ENERGY GROUP INC

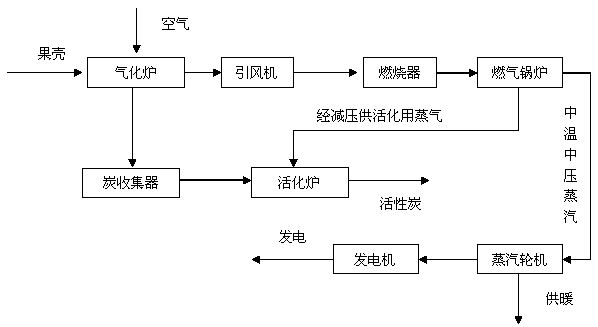

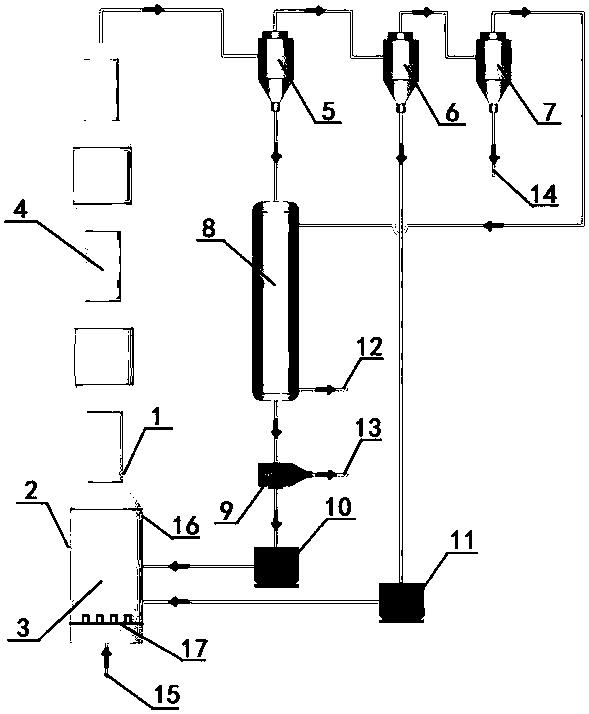

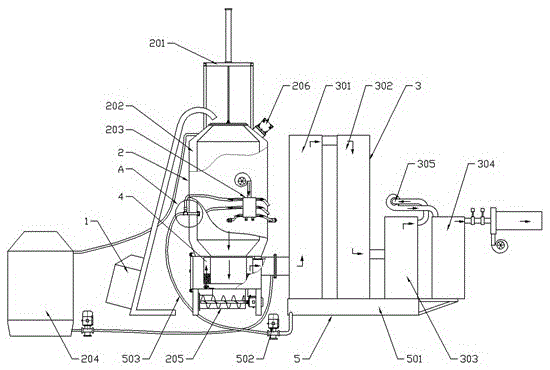

Technology for shells downdraft fixed bed gasification power generation and co-production of active carbon and heat

ActiveCN105505466ANo regeneration pollutionHigh thermal efficiencyCarbon compoundsGasifier moving partsEnvironmental resistanceHigh energy

The invention relates to a technology for shells downdraft fixed bed gasification power generation and co-production of active carbon and heat. The technology is characterized in that a large-scale gas-carbon co-production downdraft fixed bed gasifier is utilized to gasify shells biomass to prepare fuel gas which is used as fuel of a gas-fired boiler; steam generated by the gas-fired boiler drives a steam turbine to generate power; and active carbon and heat are obtained simultaneously. The invention has the following advantage: by using shells biomass as the raw material, a series of problems such as large environmental pollution, high energy consumption, poor product uniformity, low degree of automation, single product and the like existing in a traditional active carbon production device are solved. Shells resources are highly efficiently utilized, economic benefit is raised, and the environment is protected. The technology for shells downdraft fixed bed gasification power generation and co-production of active carbon and heat and complete equipment have advantages of stable operation, high thermal efficiency of hot gas combustion, various products, good economic benefit and environmental effect and large-scale application. Previous shells downdraft fixed bed gasification power generation process equipment has no shell charcoal or active carbon products.

Owner:NANJING FORESTRY UNIV

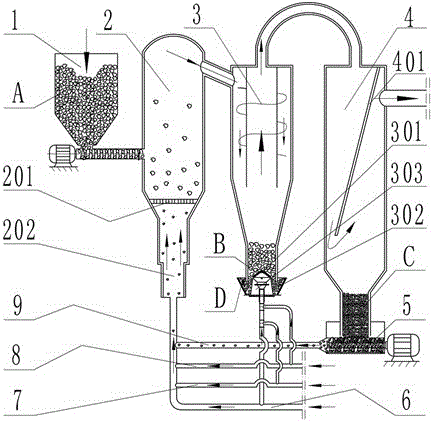

Circulating fluidized bed and pyrolysis bed combined gasification process and device

ActiveCN106635179AImprove conversion rateLarge adjustment rangeGasifier moving partsGasification processes detailsBurn outCoal gasification

The invention provides a circulating fluidized bed and pyrolysis bed combined gasification process and device, and relates to a coal gasification technology. The gasification process is characterized in that a fluidized bed technology is used for pyrolysis and gasification, and coal free of tar and other pollutants is converted into gas; semicoke coal and the like are gasified and burnt out by a pyrolysis bed; coal-containing fly ash is removed from the gas with a precipitation separation method and is returned to fluidized bed gasifier by a screw conveyor to be pyrolyzed and gasified circularly. The fluidized bed gasifier, a cyclone separator, the pyrolysis bed and a sedimentation chamber which are connected are used for combustion and transport of raw coal, the gas, the semi-coke and the coal-containing fly ash, and accordingly, the purpose of the invention is achieved. The gasification process and device have the beneficial effects that the gasification rate of the raw coal is high, and tar and other pollutants are not produced; the circulating fluidized bed is applicable to equipment with large, medium and small gasification rates, and regulation range of gas production capacity in unit time is broad.

Owner:JIANGSU HUAWEI MACHINERY MFG

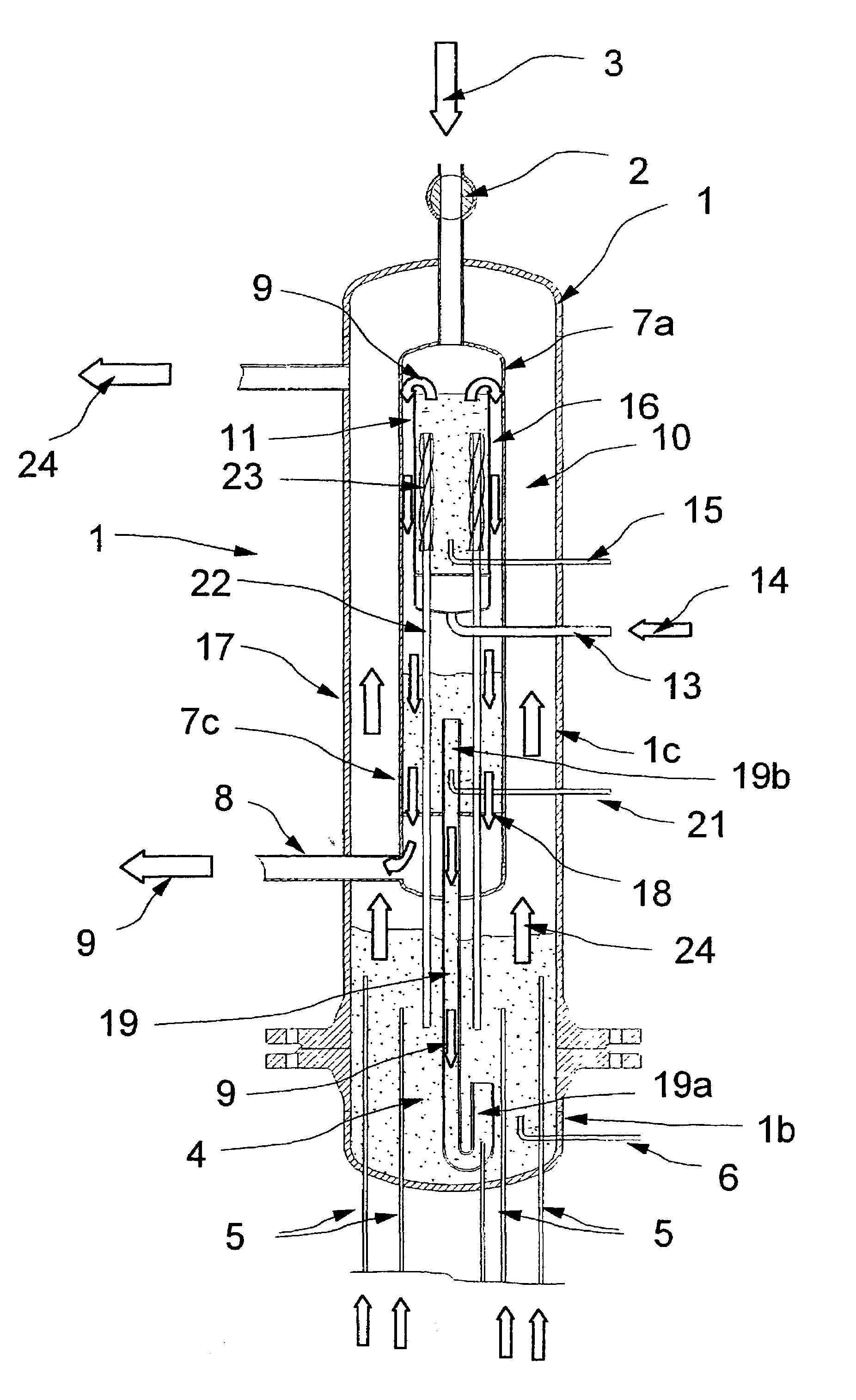

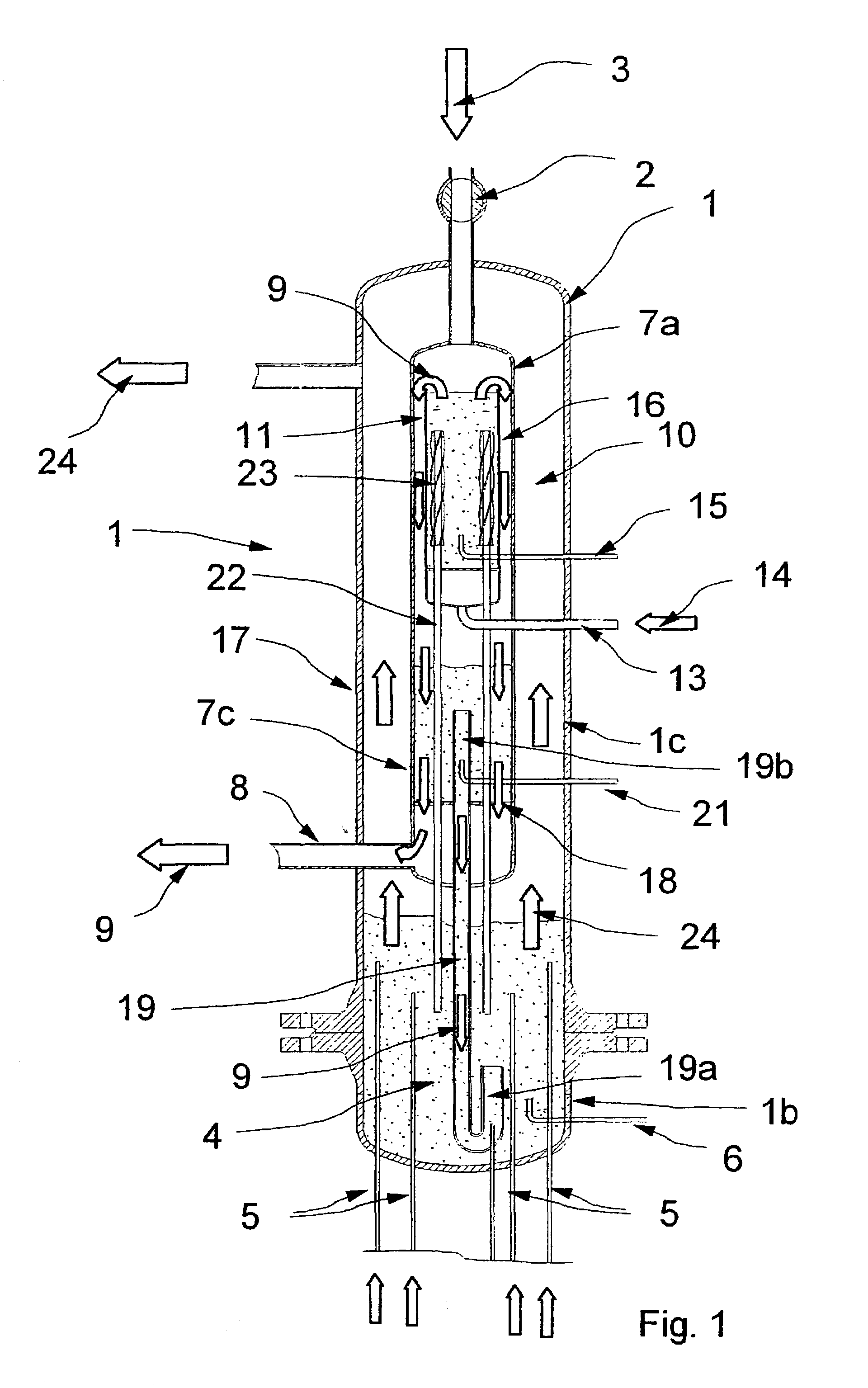

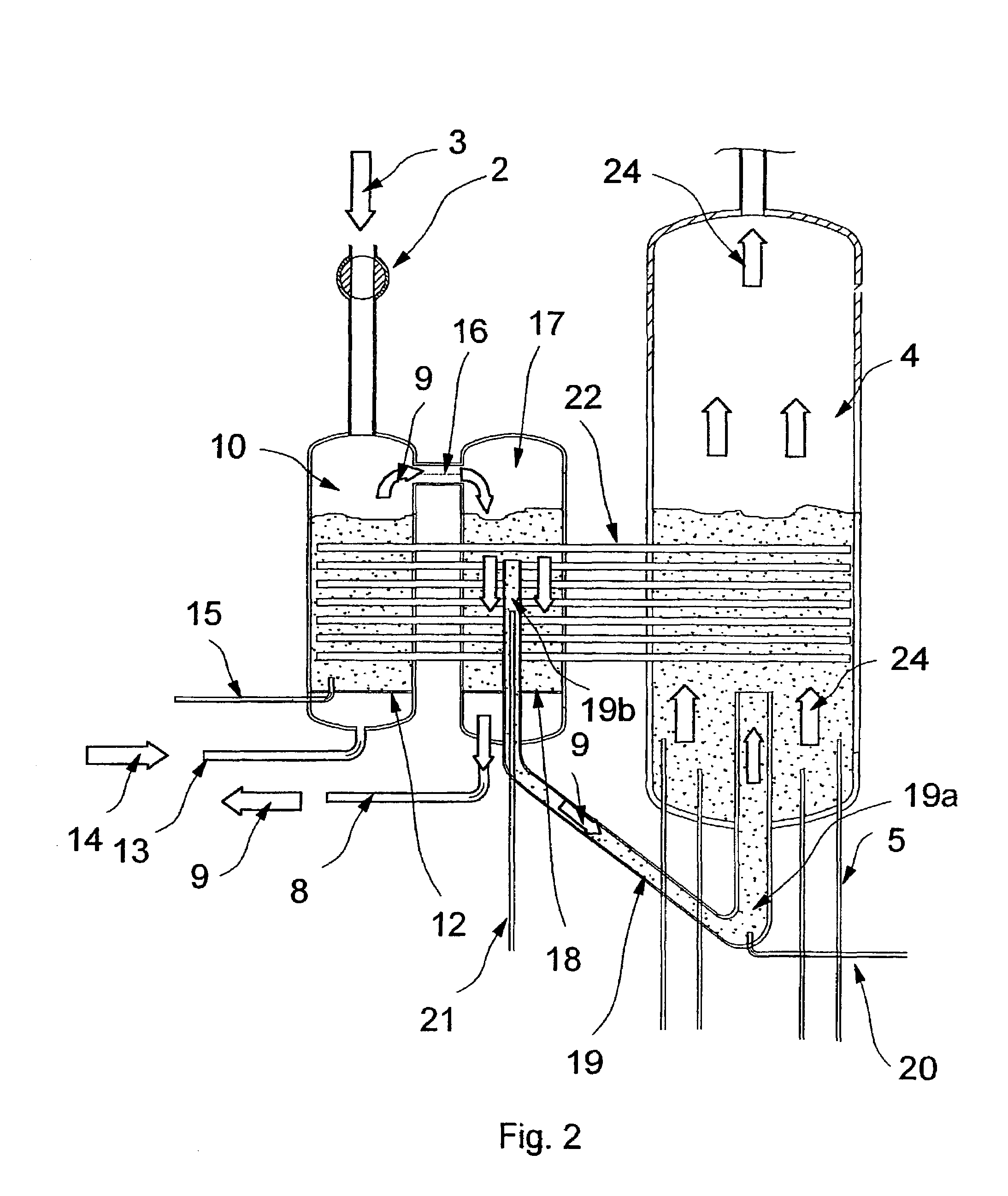

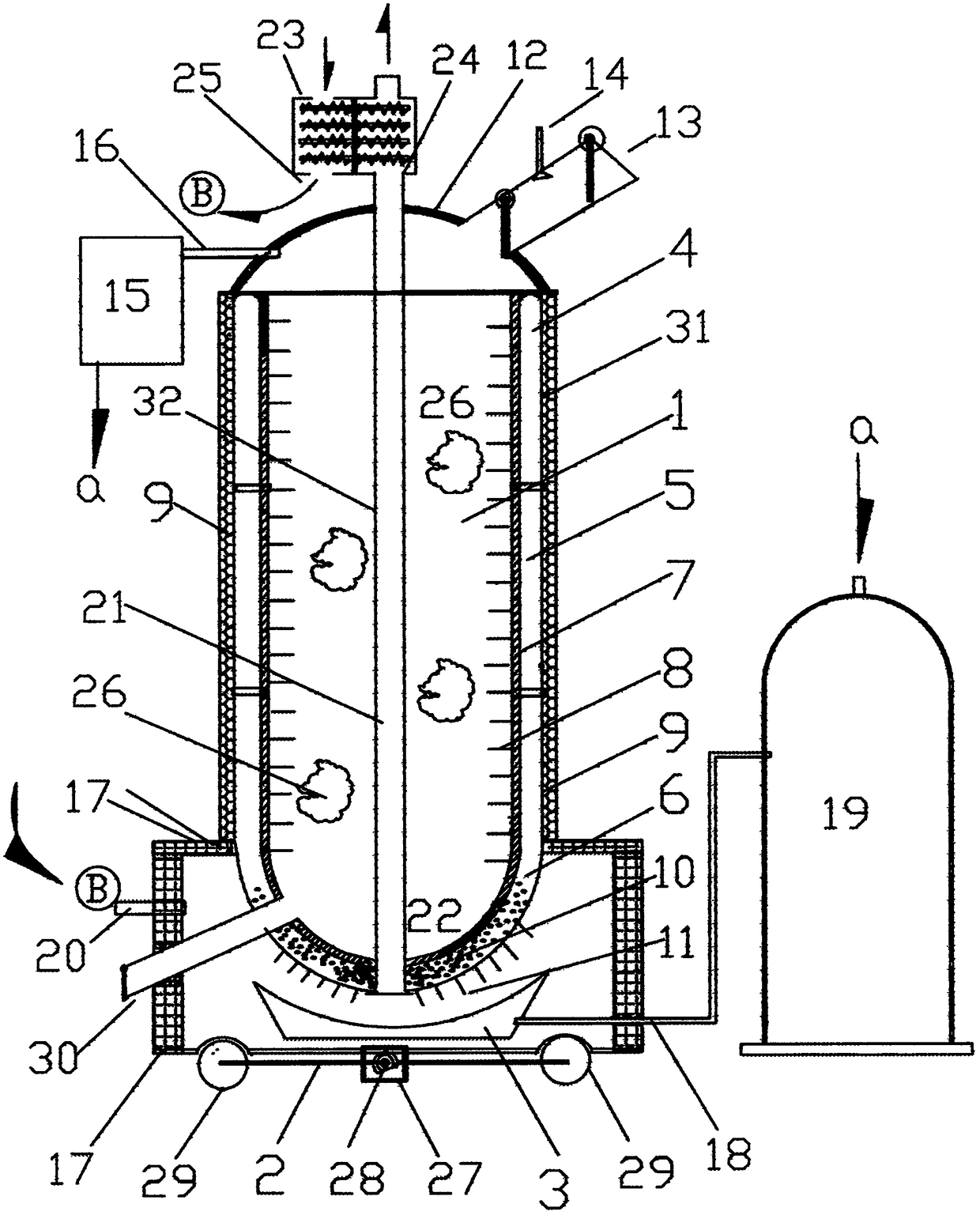

Facility for the gasification of carbon-containing feed materials

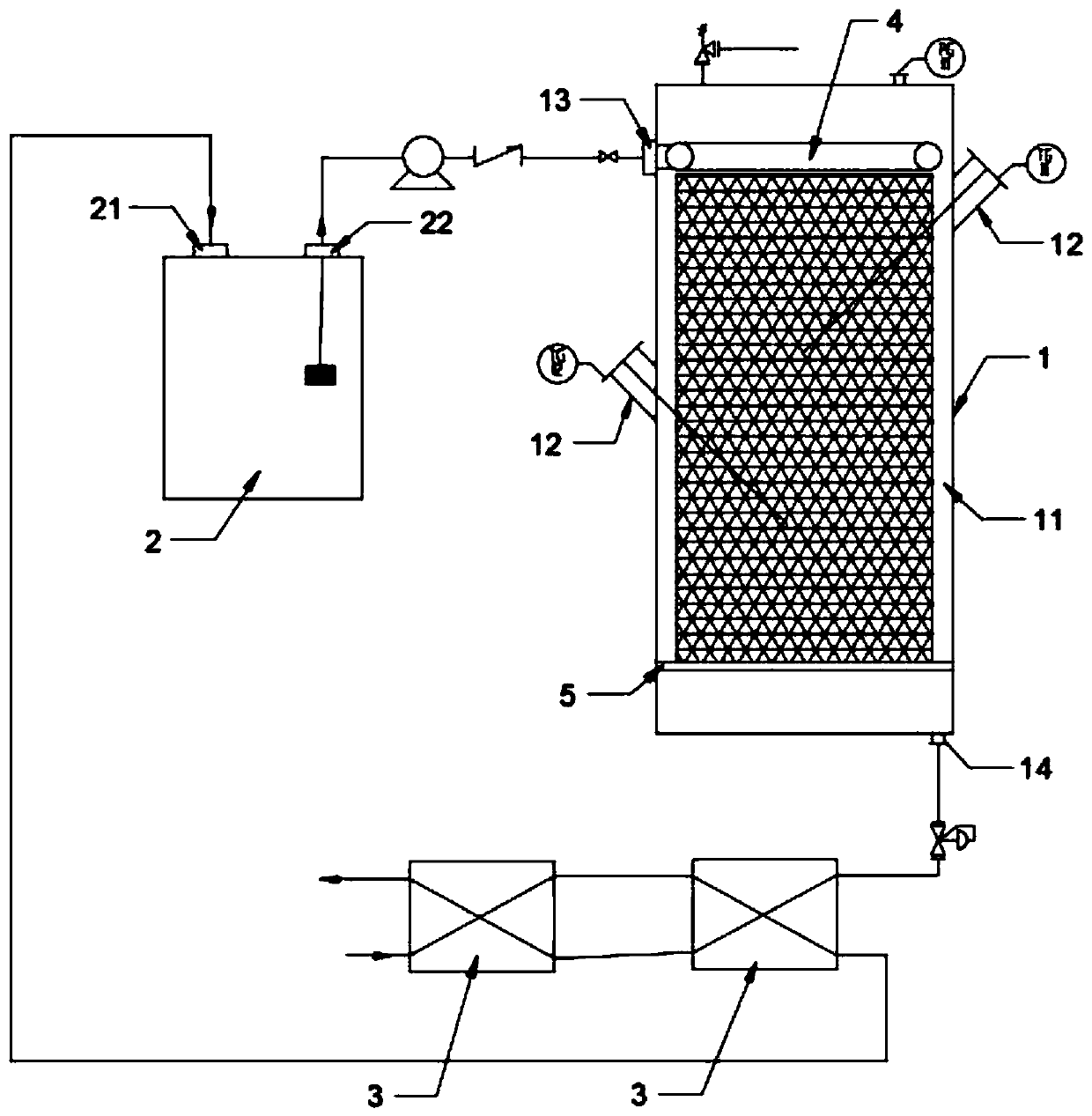

InactiveUS7087097B1Improve balanceImprove energy balanceMuffle furnacesLayered productsFluidized bedProcess engineering

A pressure-supercharged fluidized-bed gasification chamber has a pressure-tight lock for supplying the feed materials which are to be gasified. The fluidized-bed gasification chamber is connected to a filter chamber via a connecting channel, with the result that the gas produced can flow over from the fluidized-bed gasification chamber into the filter chamber, where it is directed through the filter layer. An external heat source provides the necessary heat for the allothermic gasification. A heat-pipe arrangement directs the heat from the external heat source into the gasification bed of the fluidized-bed gasification chamber, in order to provide the temperature which is necessary for the gasification.

Owner:BIOAGE

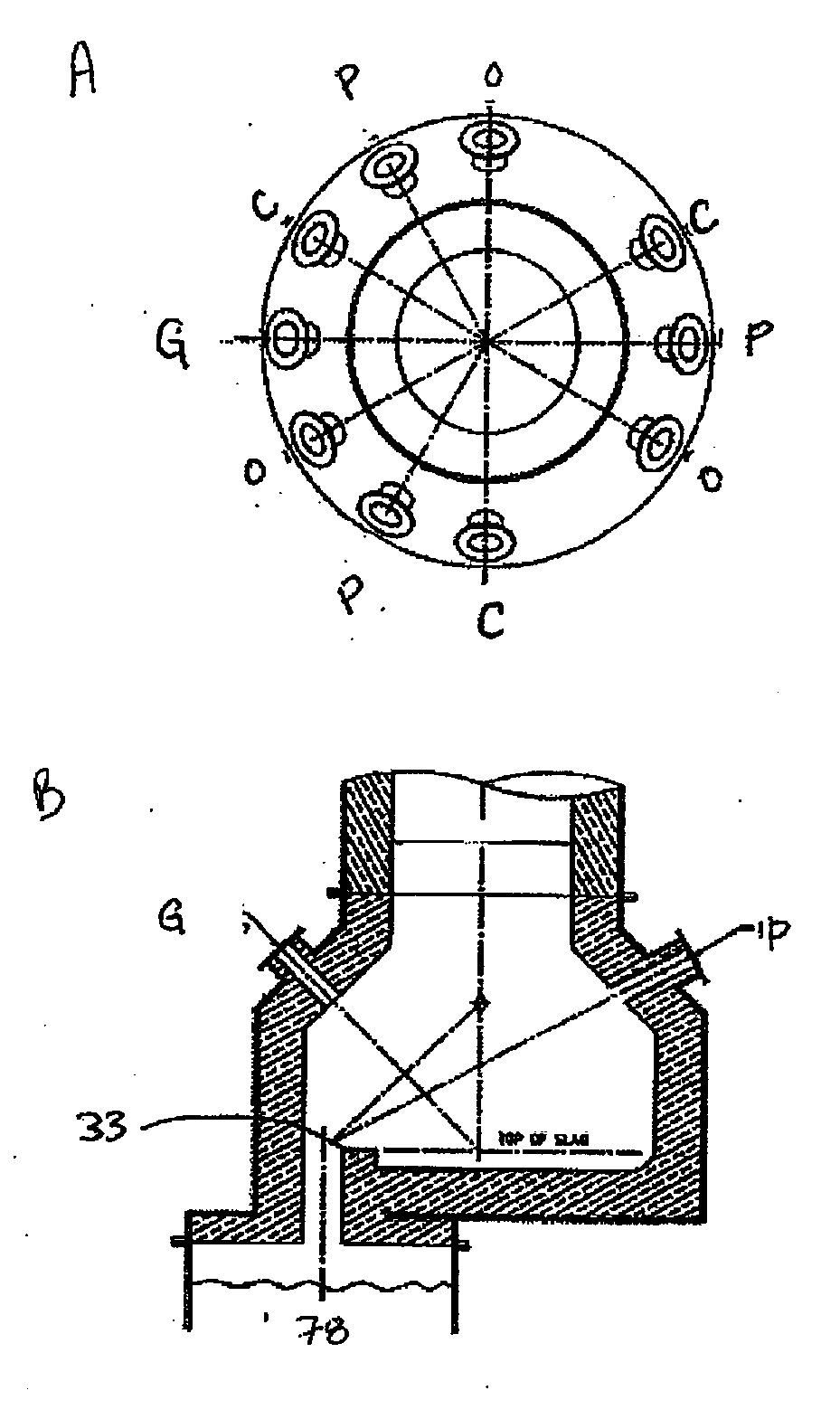

Pyrolysis apparatus

InactiveUS20090293783A1Avoid pollutionAvoid damageGasifier moving partsIndirect heating destructive distillationEngineeringWaste material

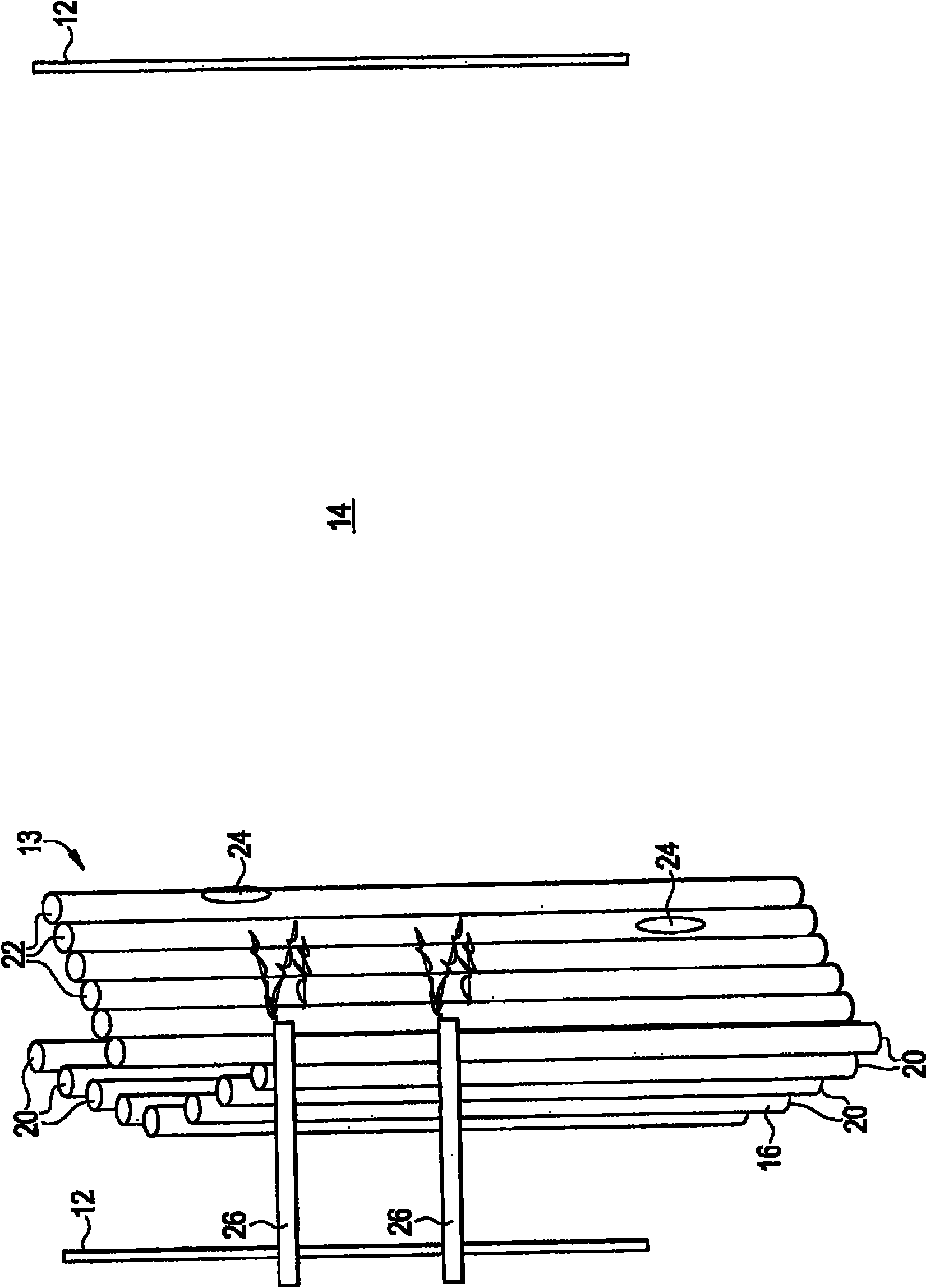

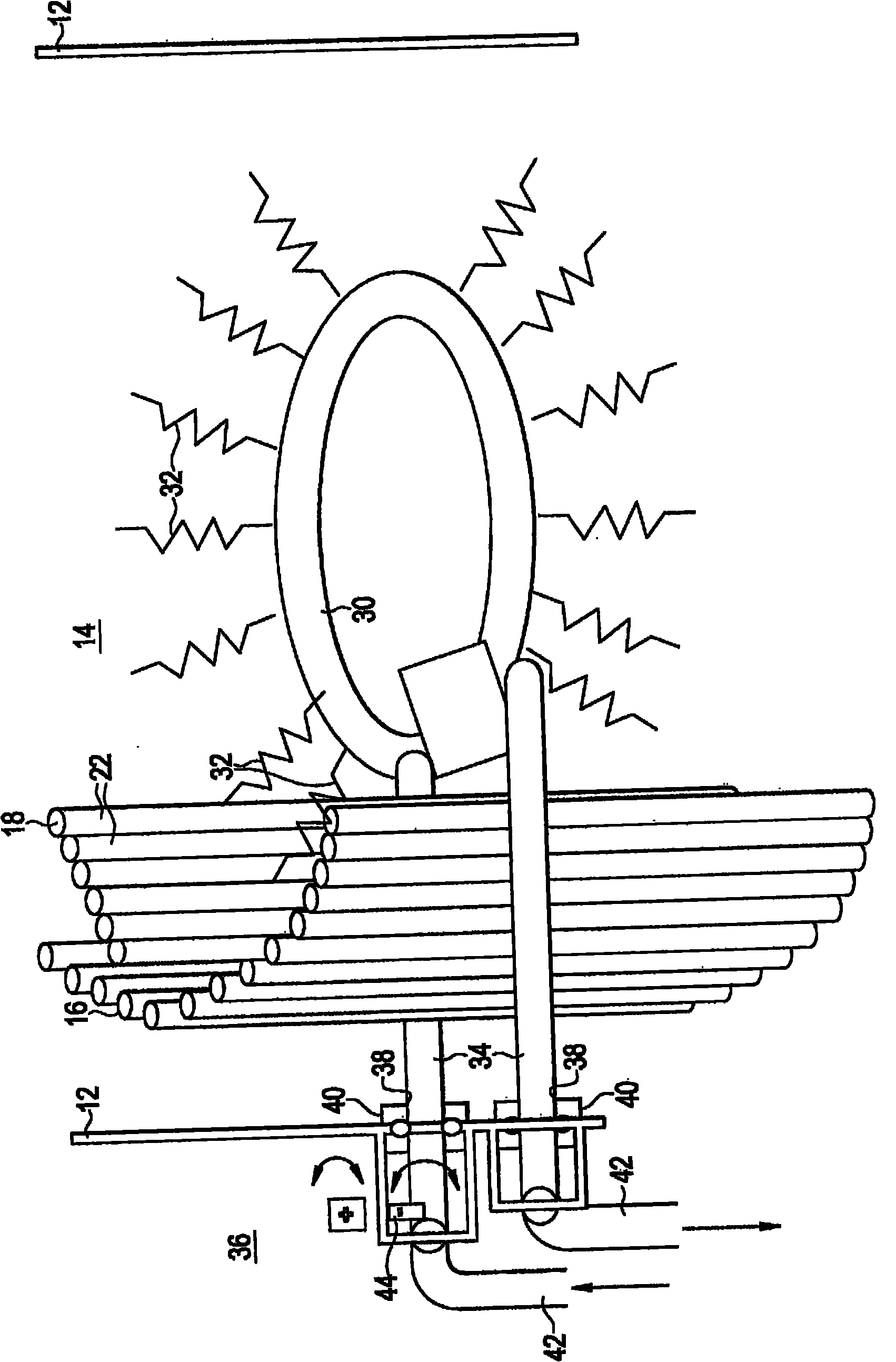

Apparatus for the pyrolysis of solid waste material includes a thermal reactor including an elongate hollow housing with a reaction chamber disposed within the housing. The thermal reactor is vertically oriented in order to cause solid waste material fed thereinto to pass through said reaction chamber by the force of gravity and a plurality of vanes are disposed for both conducting heat into said reactor chamber and for tumbling said solid waste material as said solid waste material passes through said reaction chamber.

Owner:RAINBOW CONVERSION TECH

Pyrolysis apparatus

InactiveUS7802528B2Avoid pollutionAvoid damageGasifier moving partsIndirect heating destructive distillationWaste materialReaction chamber

Apparatus for the pyrolysis of solid waste material includes a thermal reactor including an elongate hollow housing with a reaction chamber disposed within the housing. The thermal reactor is vertically oriented in order to cause solid waste material fed thereinto to pass through said reaction chamber by the force of gravity and a plurality of vanes are disposed for both conducting heat into said reactor chamber and for tumbling said solid waste material as said solid waste material passes through said reaction chamber.

Owner:RAINBOW CONVERSION TECH

Device for treating high-concentration organic wastewater by catalyzing hydrothermal gasification

ActiveCN111362336ADealing with energy saving and environmental protectionReduce energy consumptionGasification catalystsWater contaminantsPtru catalystWastewater

The invention discloses a device for treating high-concentration organic wastewater through catalytic hydrothermal gasification. The device mainly comprises a CHG reactor, a wastewater temporary storage tank and a condensation heat exchanger, wherein the CHG reactor mainly comprises a shell, a thermocouple, a water distribution device and a filler bracket, the shell is provided with a feed port and a gas outlet, the filler bracket is used for supporting a catalyst filler and is arranged in the shell, the water distribution device is arranged in the shell above the catalyst filler, and the thermocouple is inserted into the side wall of the shell and extends into the catalyst filler. The condensation heat exchanger is communicated with the air outlet through a back pressure valve and a pipeline, the liquid inlet of the wastewater temporary storage tank is connected with the condensation heat exchanger through a high-pressure feeding pump and a pipeline, and the liquid outlet of the wastewater temporary storage tank is connected with the feeding port through the high-pressure feeding pump and a pipeline. The device can quickly convert high-concentration organic wastewater into clean energy or harmless gas at a low temperature under the action of a catalyst, greatly reduces the energy consumption in the treatment process, improves the treatment efficiency, and has potential application prospects.

Owner:NANJING UNIV +1

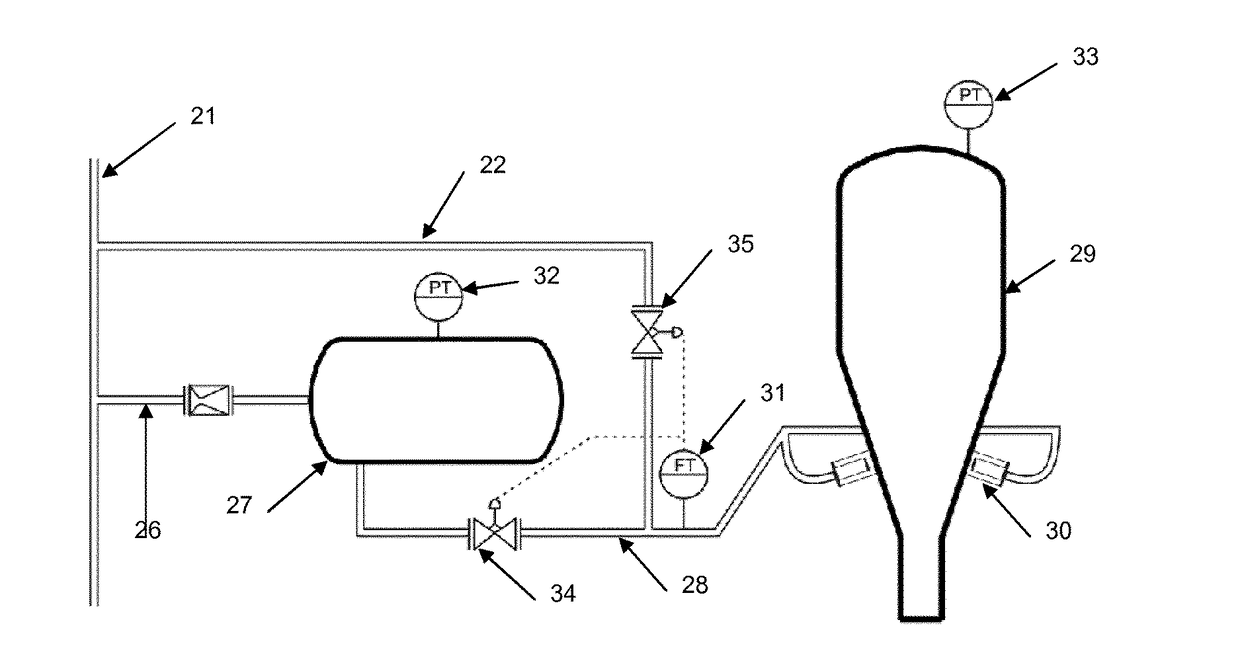

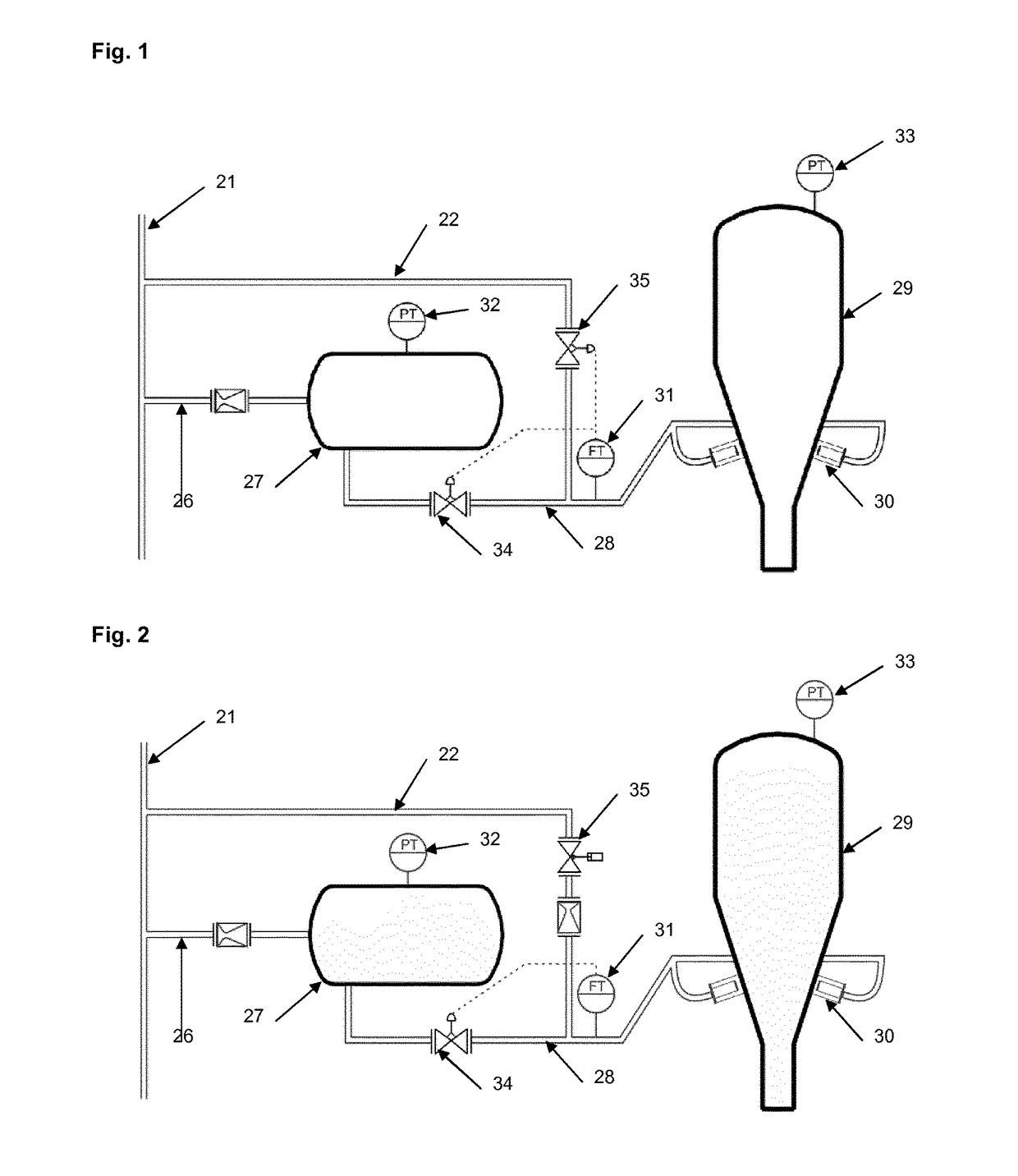

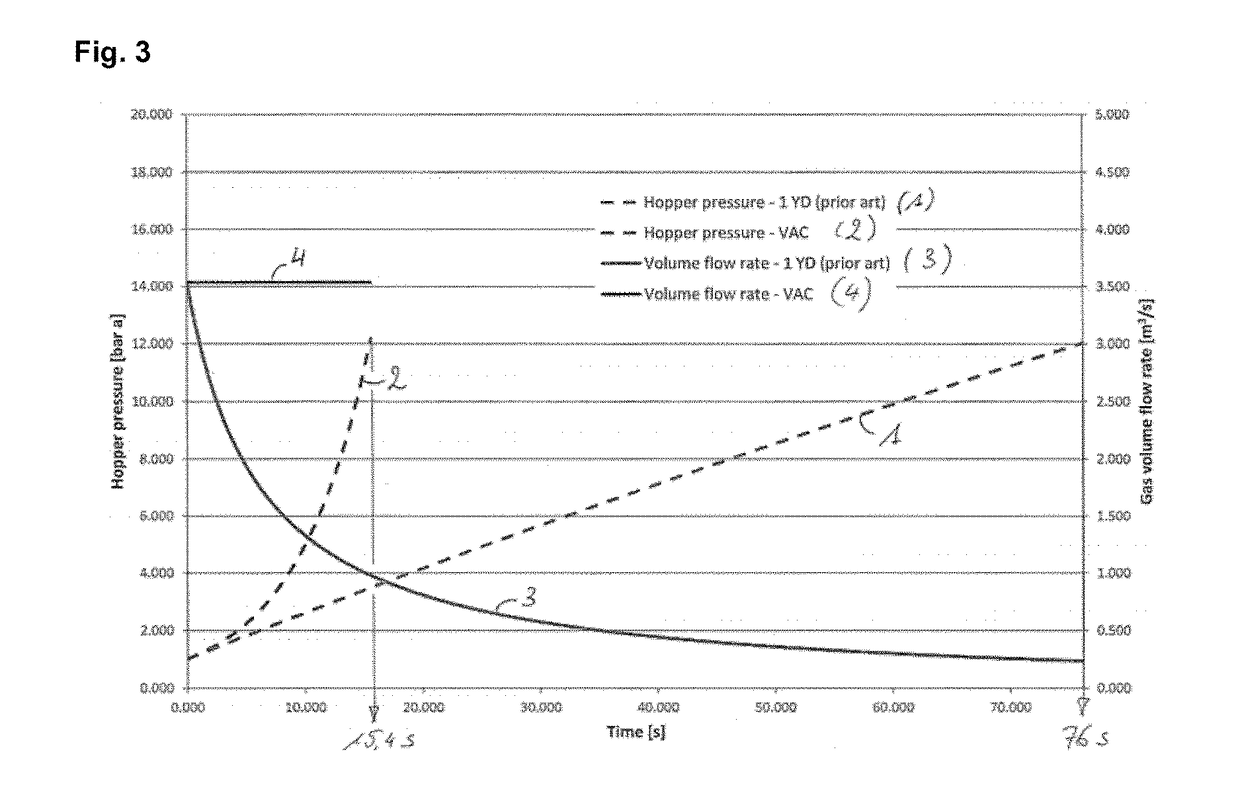

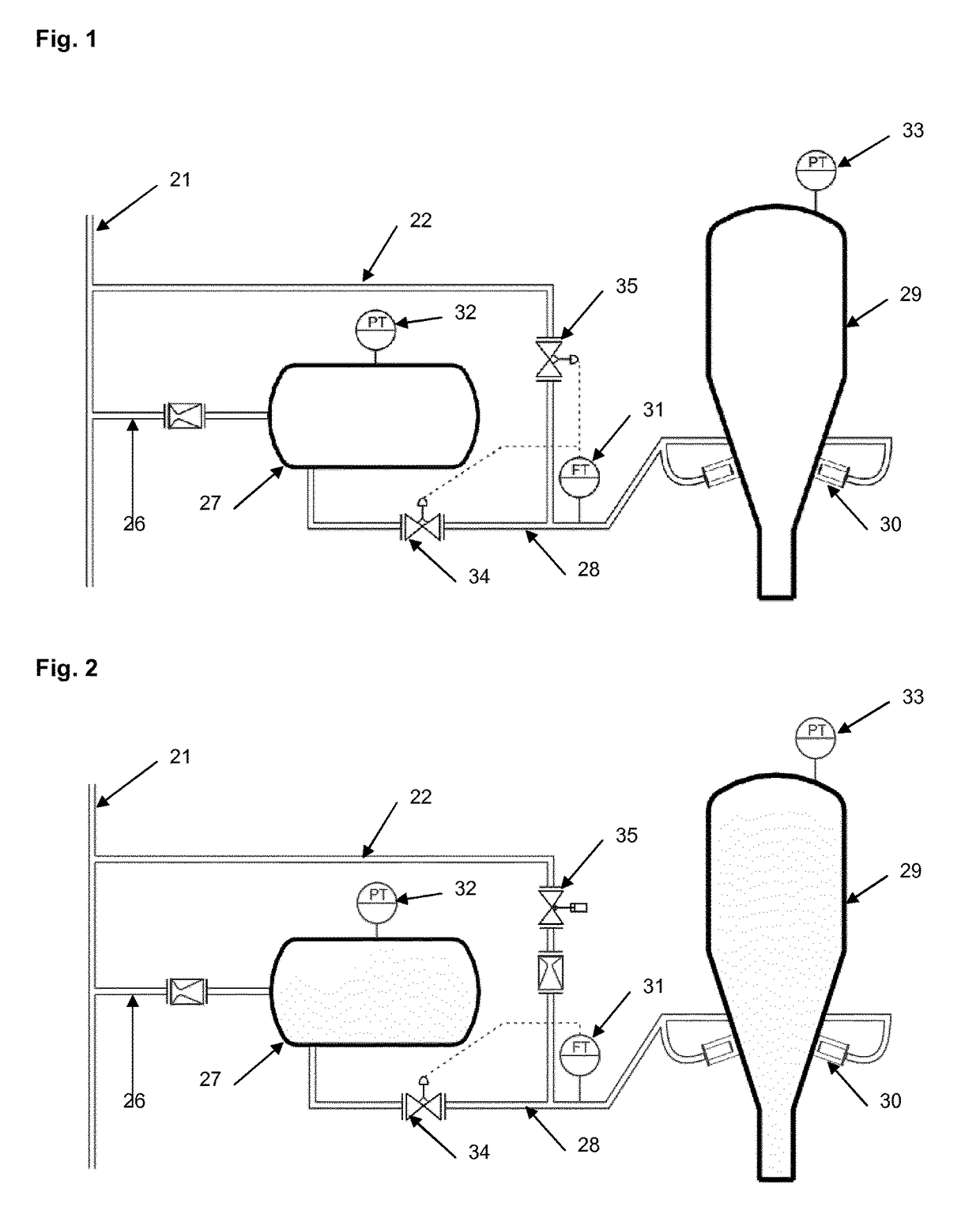

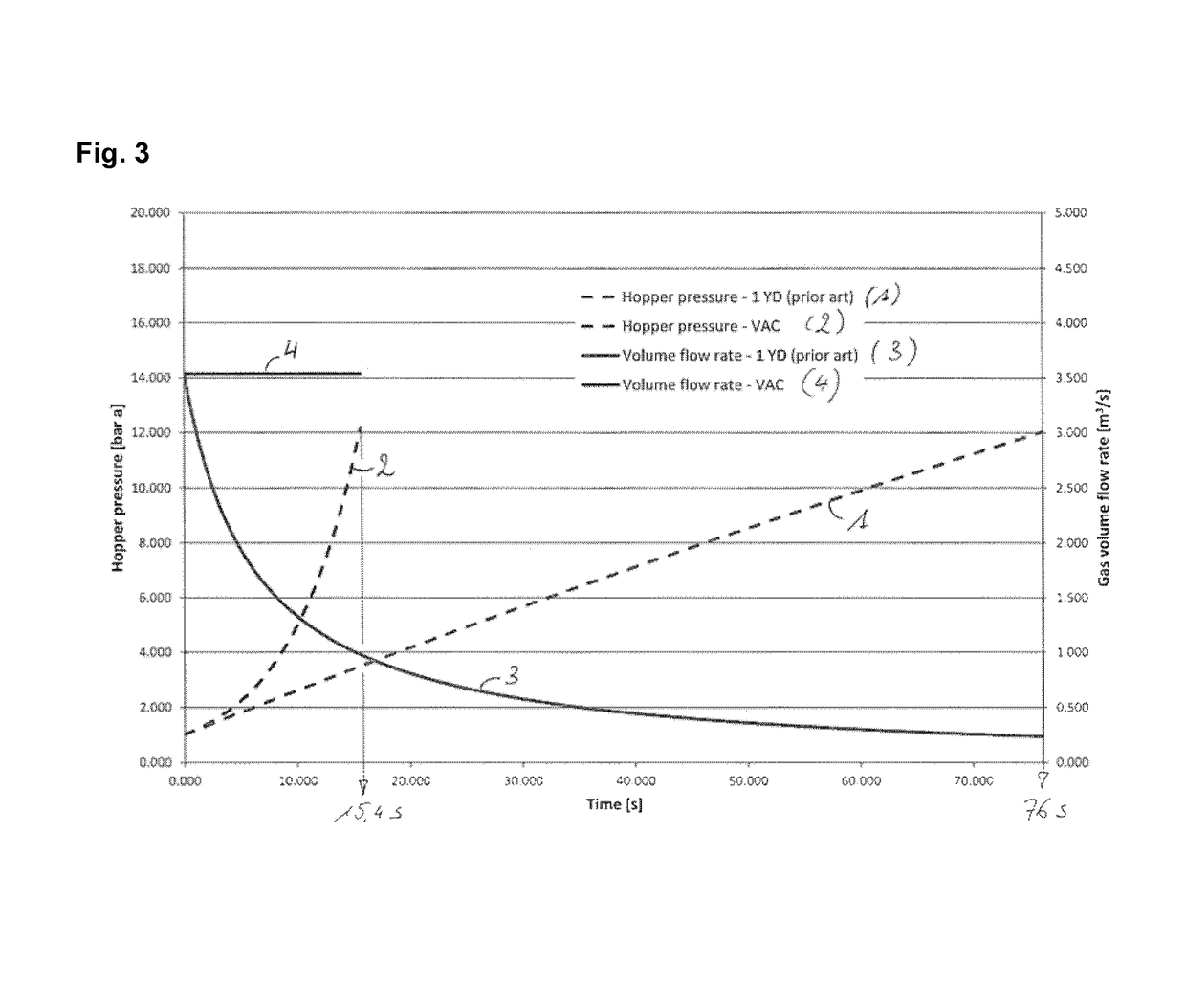

Pressurising of bulk material in lock hoppers

ActiveUS20170283720A1Shorten pressurization timeReduce noise nuisanceGasifier moving partsBulk conveyorsEngineeringElectrical and Electronics engineering

Owner:PAUL WURTH SA

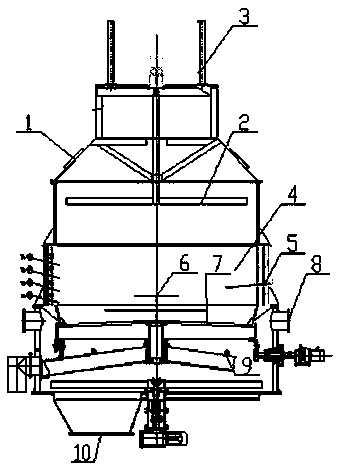

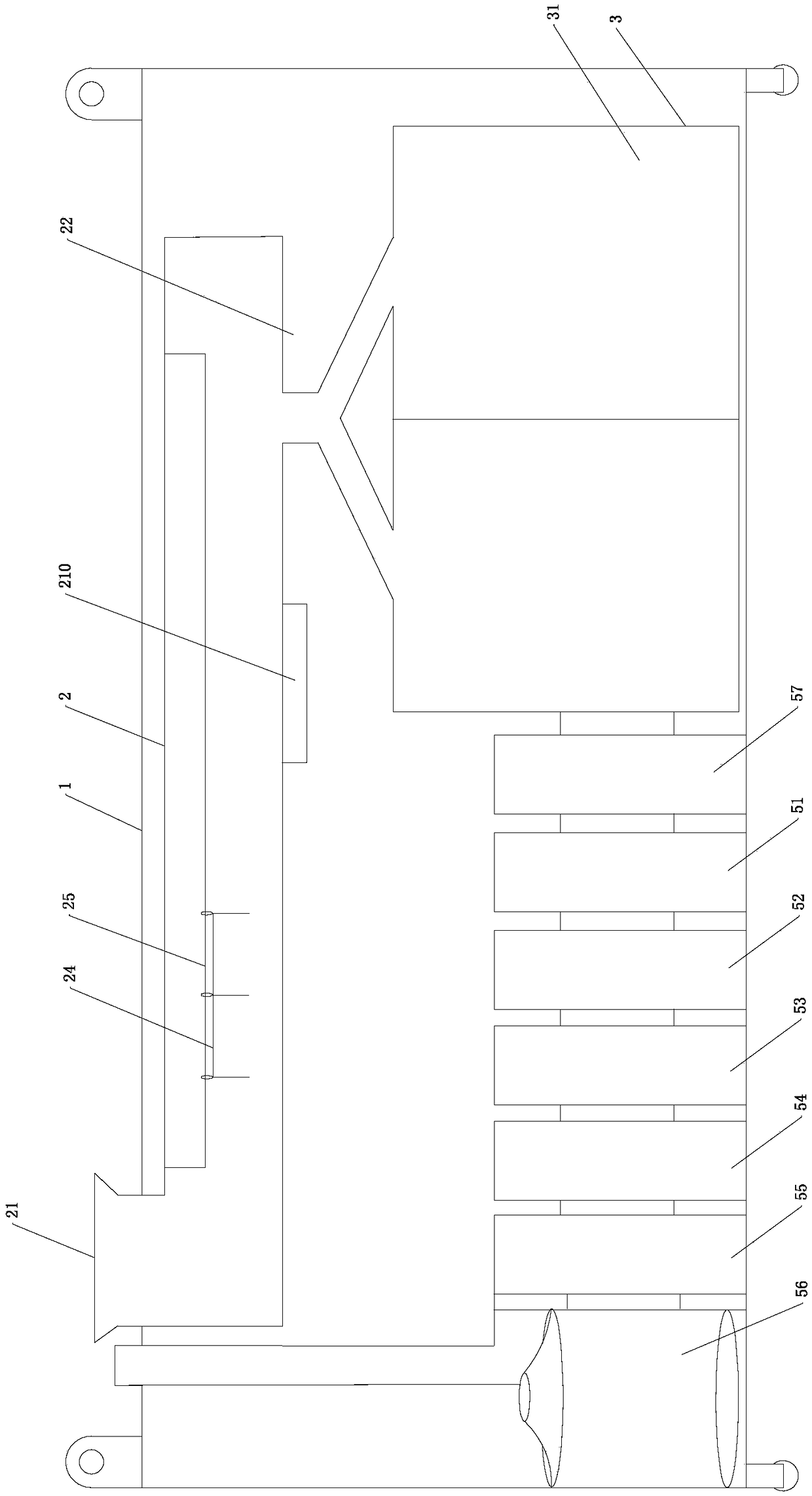

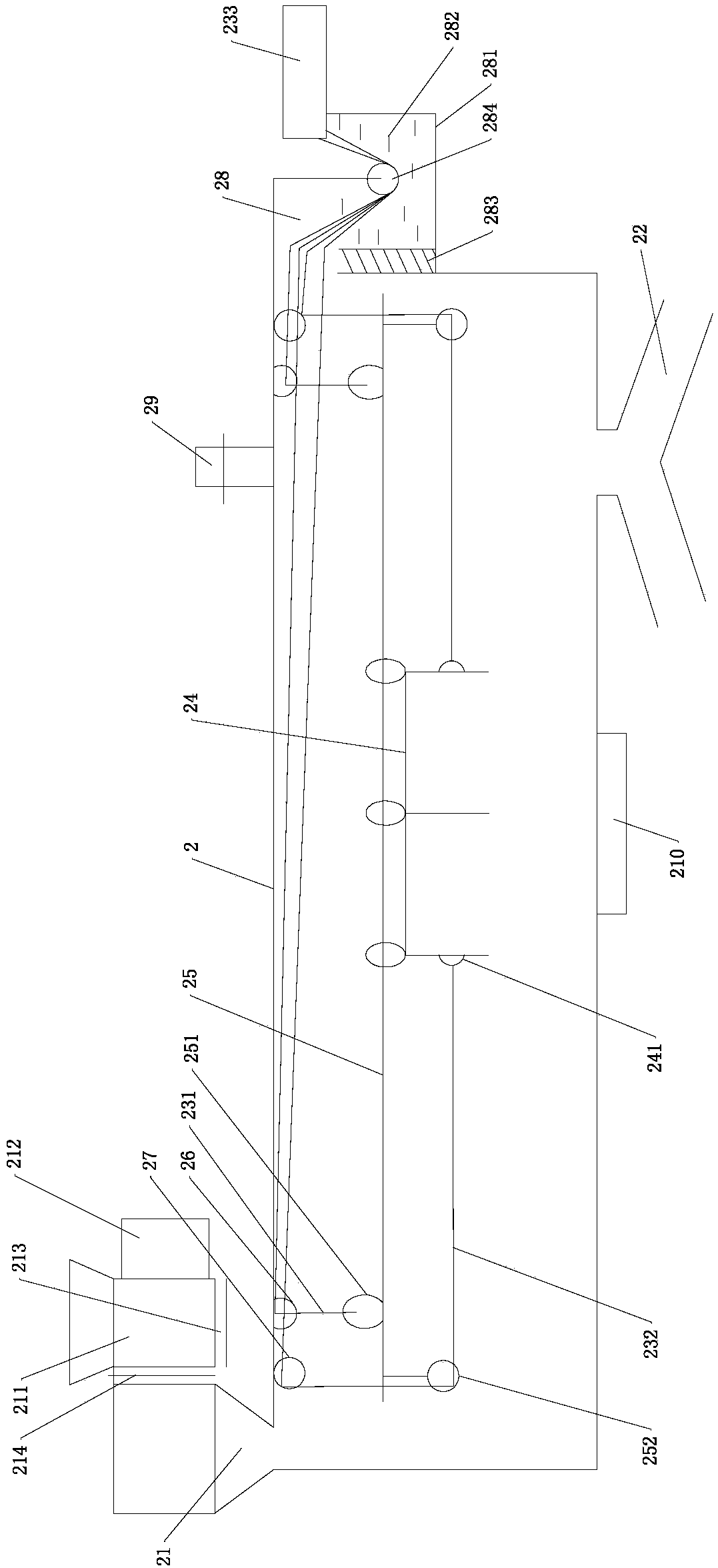

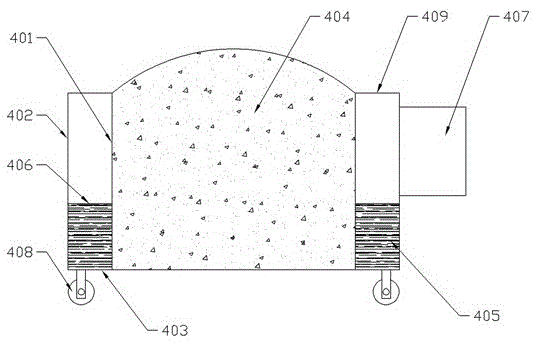

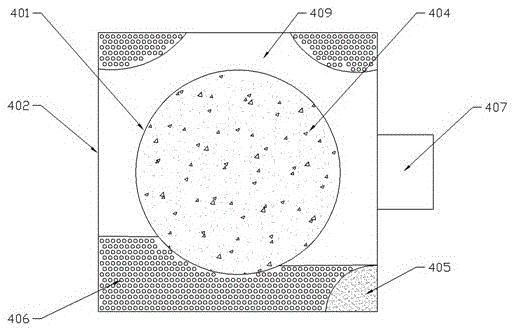

Pyrolysis gasification treatment integration box for garbage

PendingCN108251159AAvoid accumulationPrevent impact on environmental qualityGasifier feeding meansGasifier moving partsEngineeringHeating system

The invention discloses a pyrolysis gasification treatment integration box for garbage. The pyrolysis gasification treatment integration box comprises a box body, a feeding system, a pyrolysis system,a heating system and a smoke purification system, wherein the feeding system comprises a feeding channel arranged on the top in the box body; two ends of the feeding channel are respectively providedwith a feeding hole and a discharge hole; the feeding hole penetrates through the wall of the box body to be positioned on the top of the box body; a material scraping mechanism capable of driving the garbage is arranged in the feeding channel; the pyrolysis system comprises a pyrolysis furnace arranged in the box body; a pyrolysis cavity is arranged in the pyrolysis furnace; the discharge hole is communicated with the pyrolysis cavity; the heating system is arranged on the pyrolysis furnace for heating the garbage in the pyrolysis cavity; the pyrolysis furnace is provided with a smoke outlet; the smoke outlet is connected with the smoke purification system; a stirring structure capable of stirring the garbage is arranged in the pyrolysis furnace. Through the feeding system, the garbage is sent into the pyrolysis furnace in sequence to prevent a situation that a great quantity of garbage enters the pyrolysis furnace to be accumulated in one time so as to lower pyrolysis efficiency. The pyrolysis gasification treatment integration box for the garbage is applied to garbage treatment equipment.

Owner:湖南尚威新能源环保有限公司

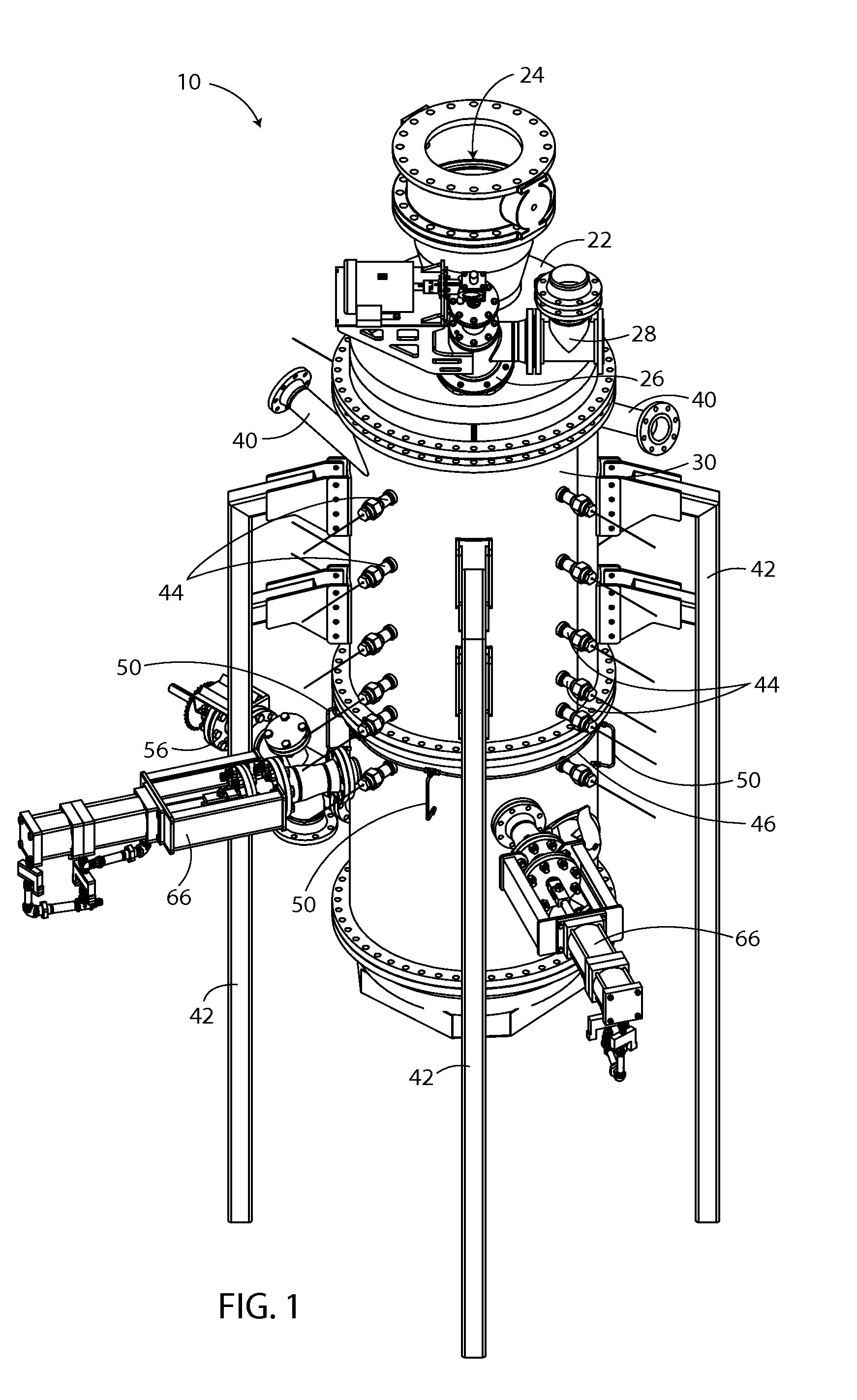

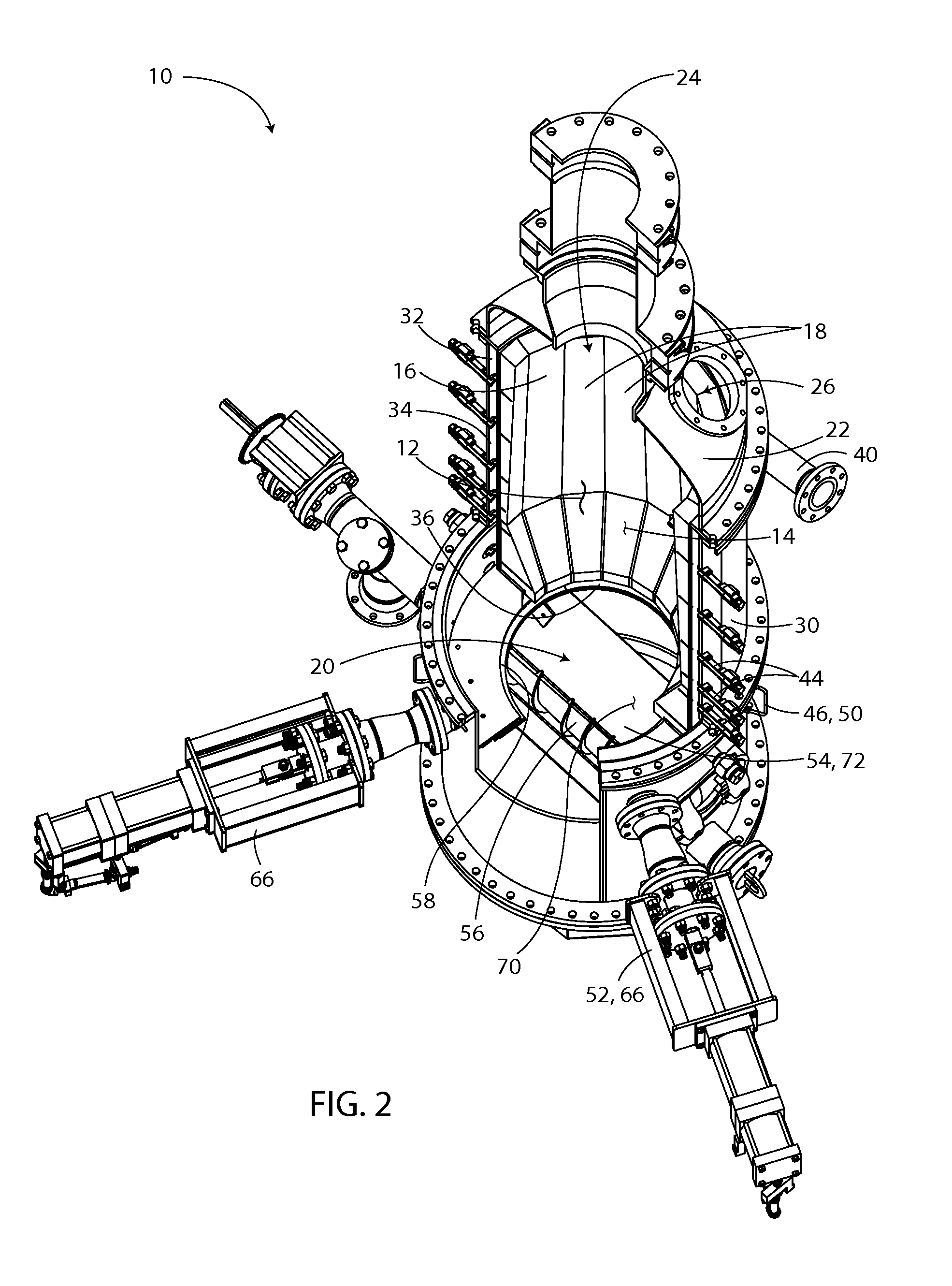

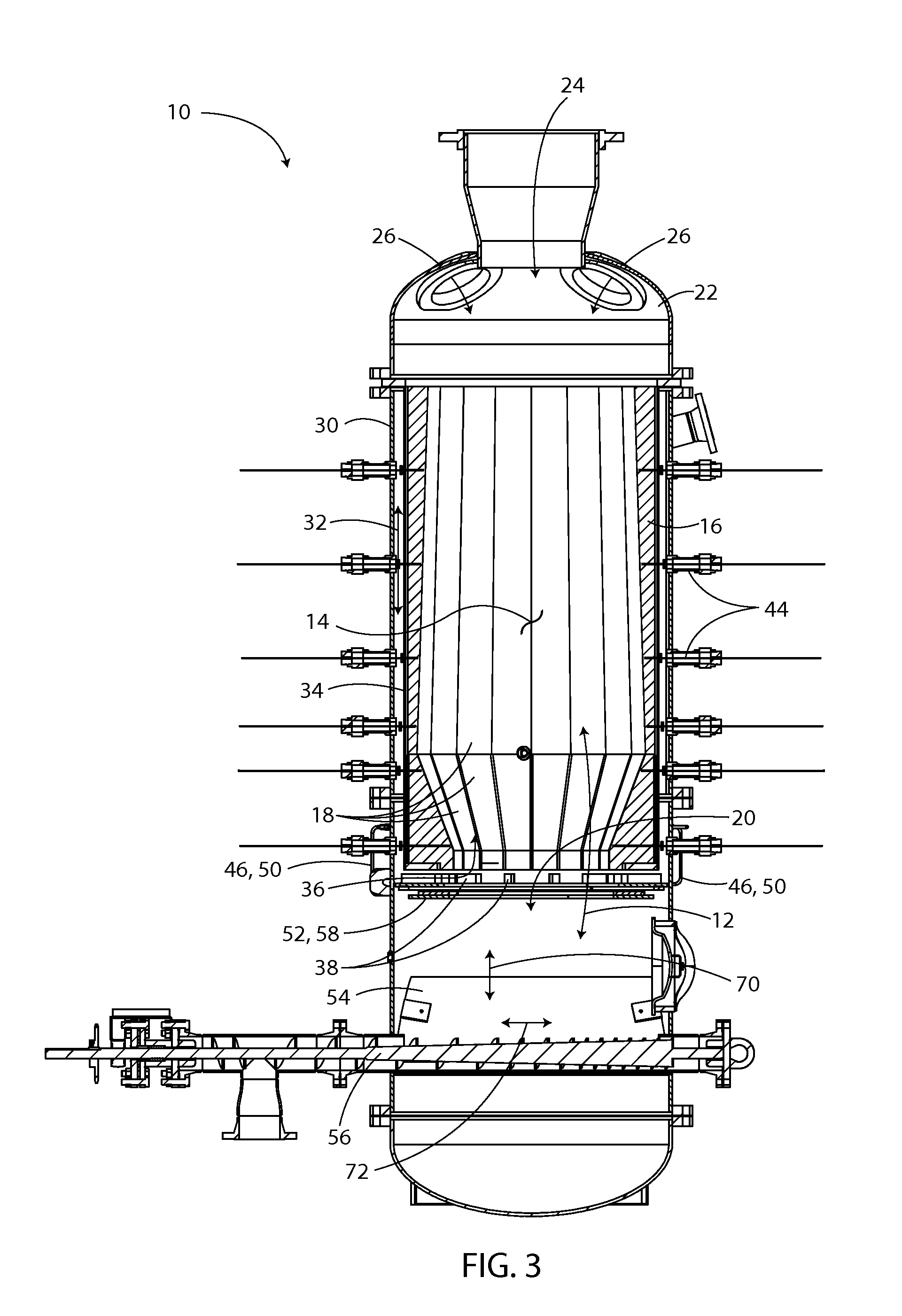

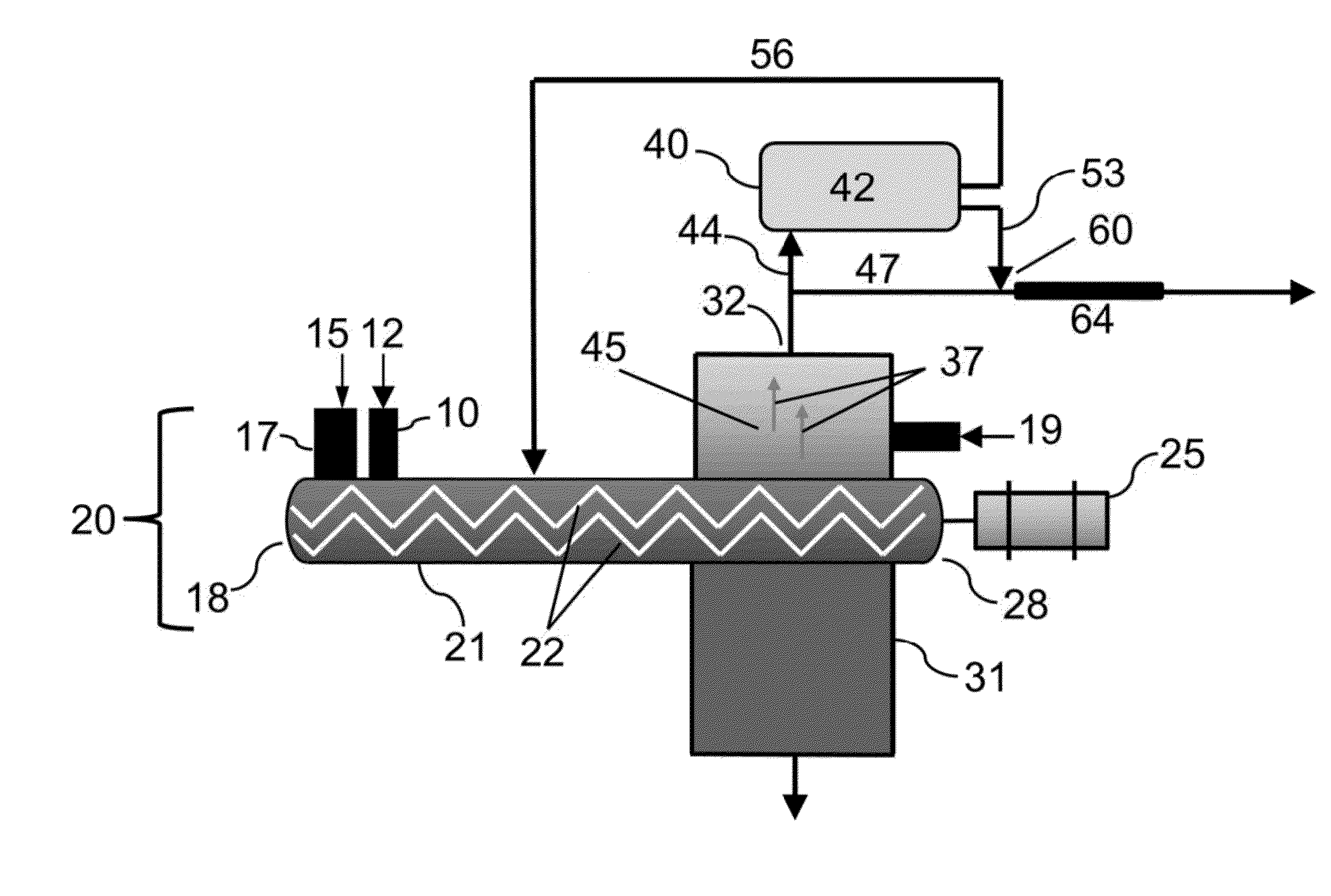

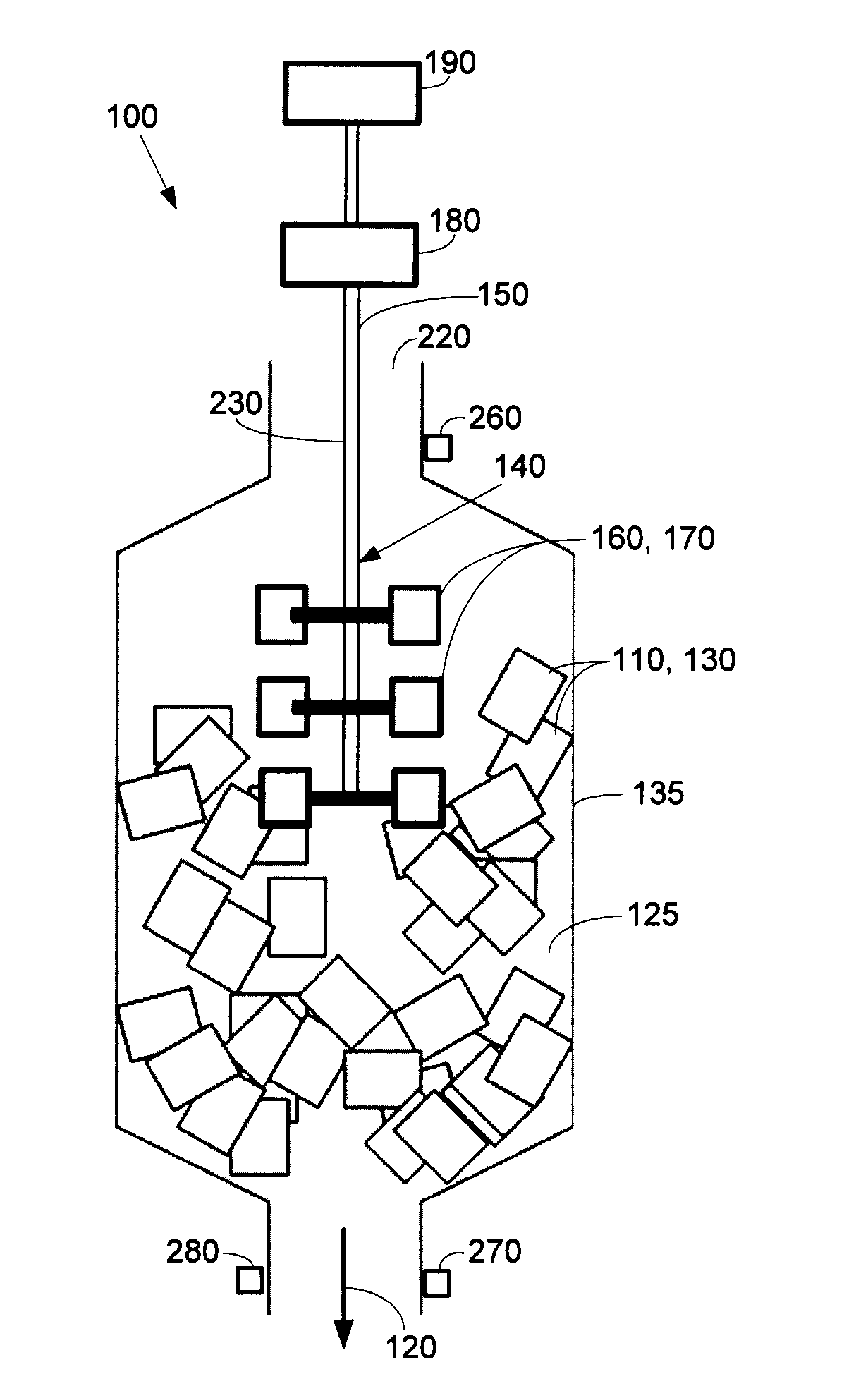

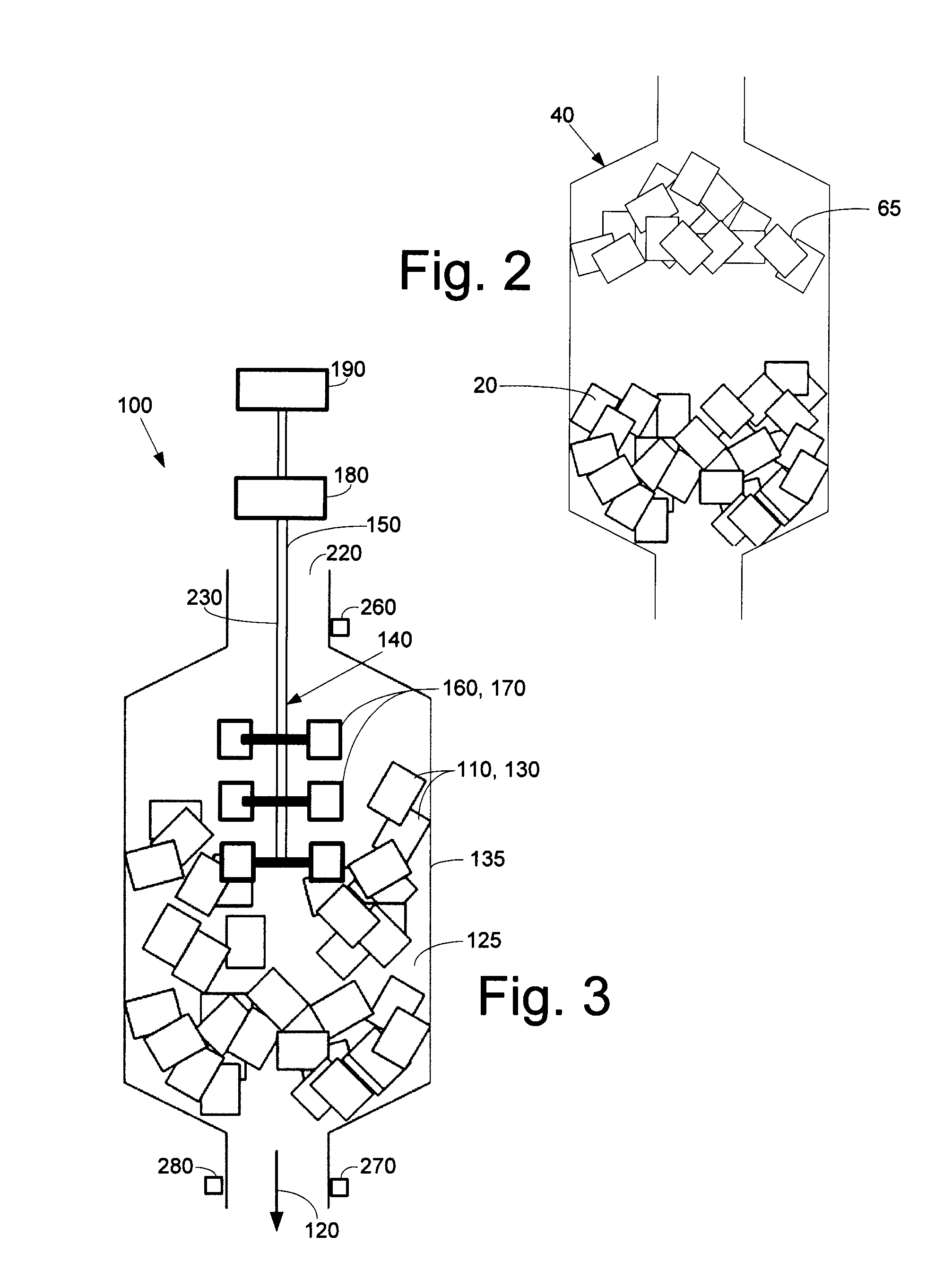

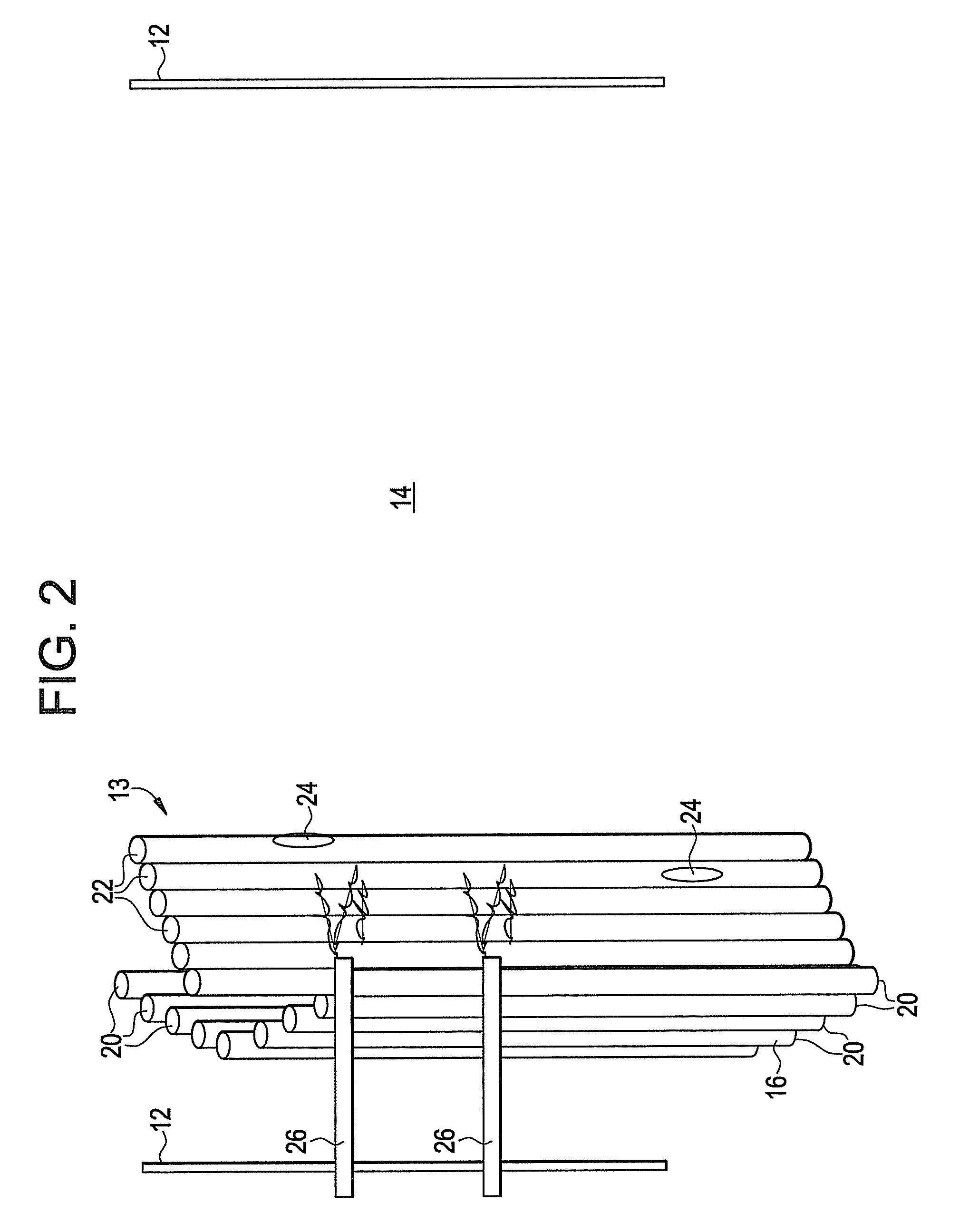

Method and apparatus of particulate removal from gasifier components

The invention relates to a method and an apparatus of particulate removal from gasifier components. Disclosed is a method of removing a particulate layer from a gasification system component including locating a shedding apparatus in operable communication with the gasification system component. A force is transmitted from the shedding apparatus into the gasification system component and the particulate layer is shed from the gasification system component as a result of the force. Further disclosed is a syngas cooler for a gasification system including a vessel and a plurality of thermal energy transfer platens located in the vessel. A shedding apparatus is in operable communication with the plurality of platens and is capable of shedding a particulate layer from the plurality of platens by transmitting a force to the plurality of platens.

Owner:AIR PROD & CHEM INC

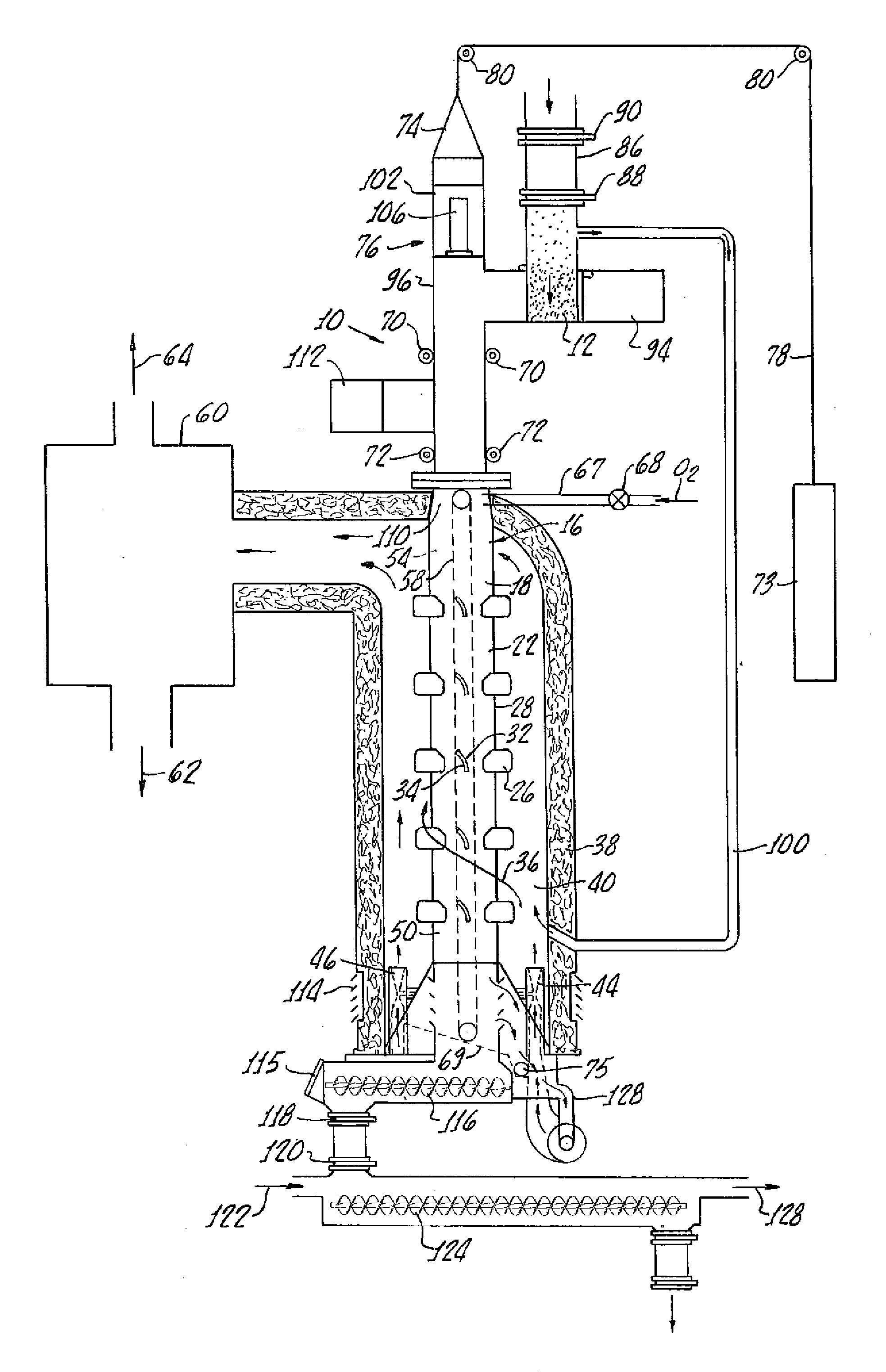

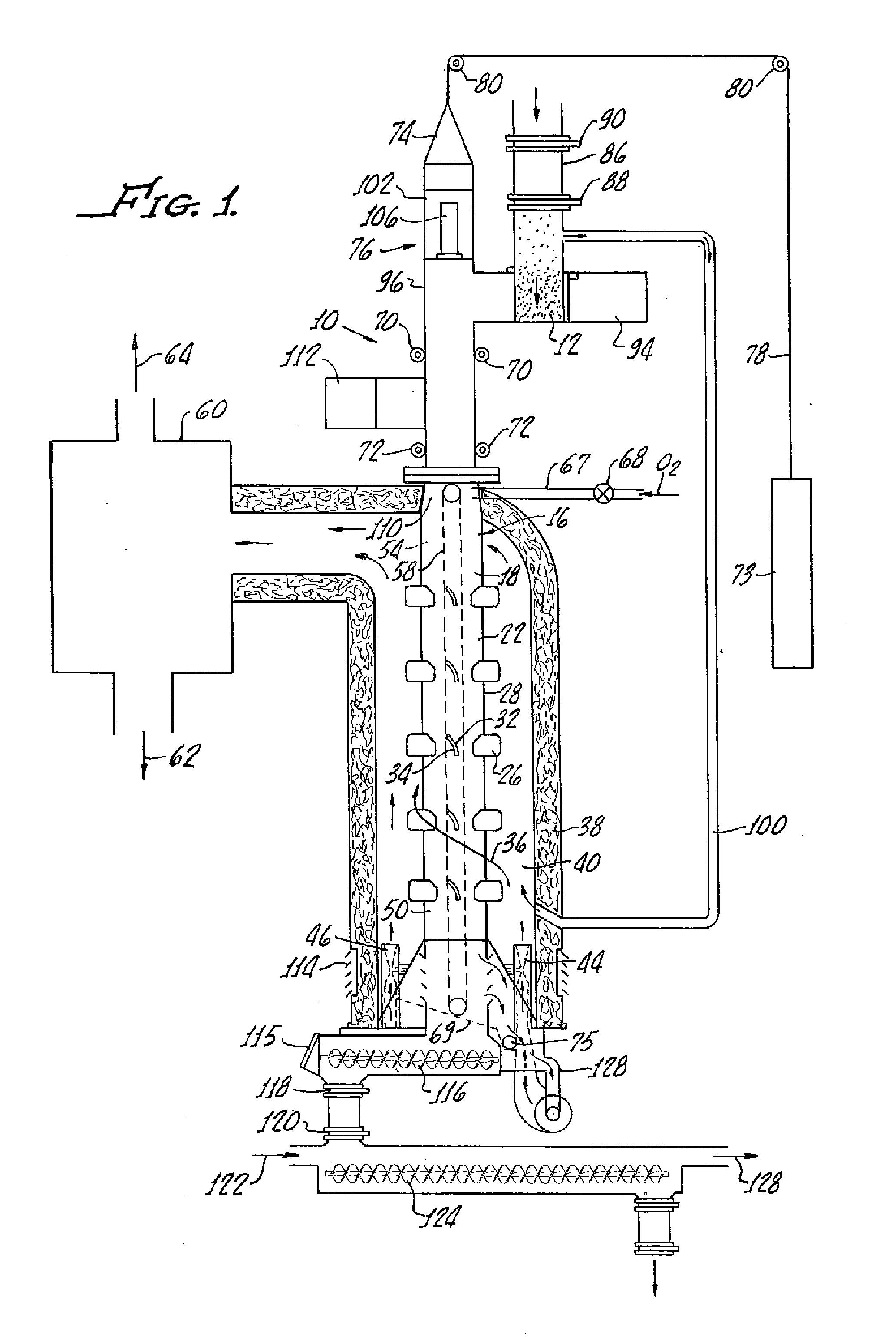

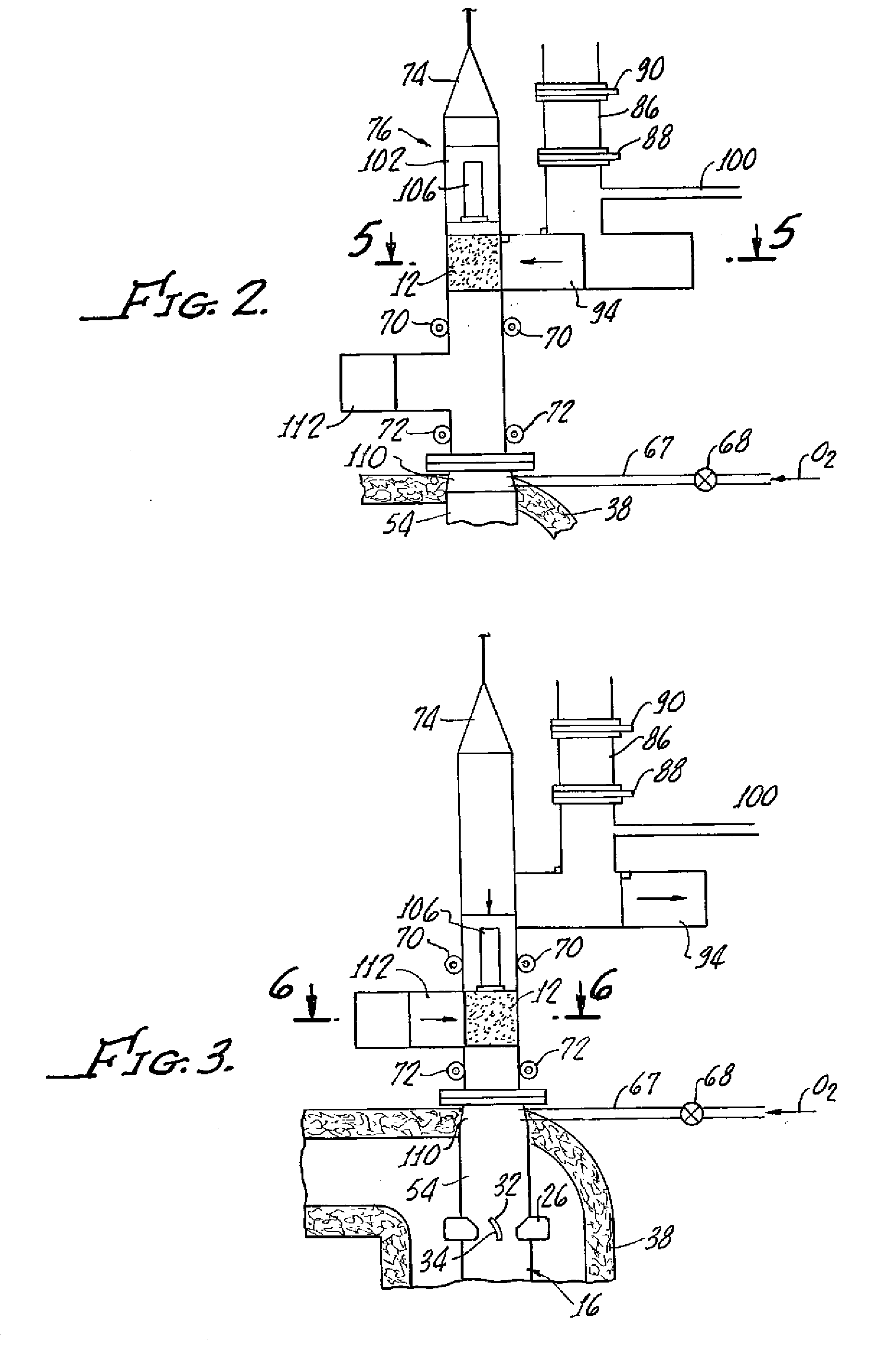

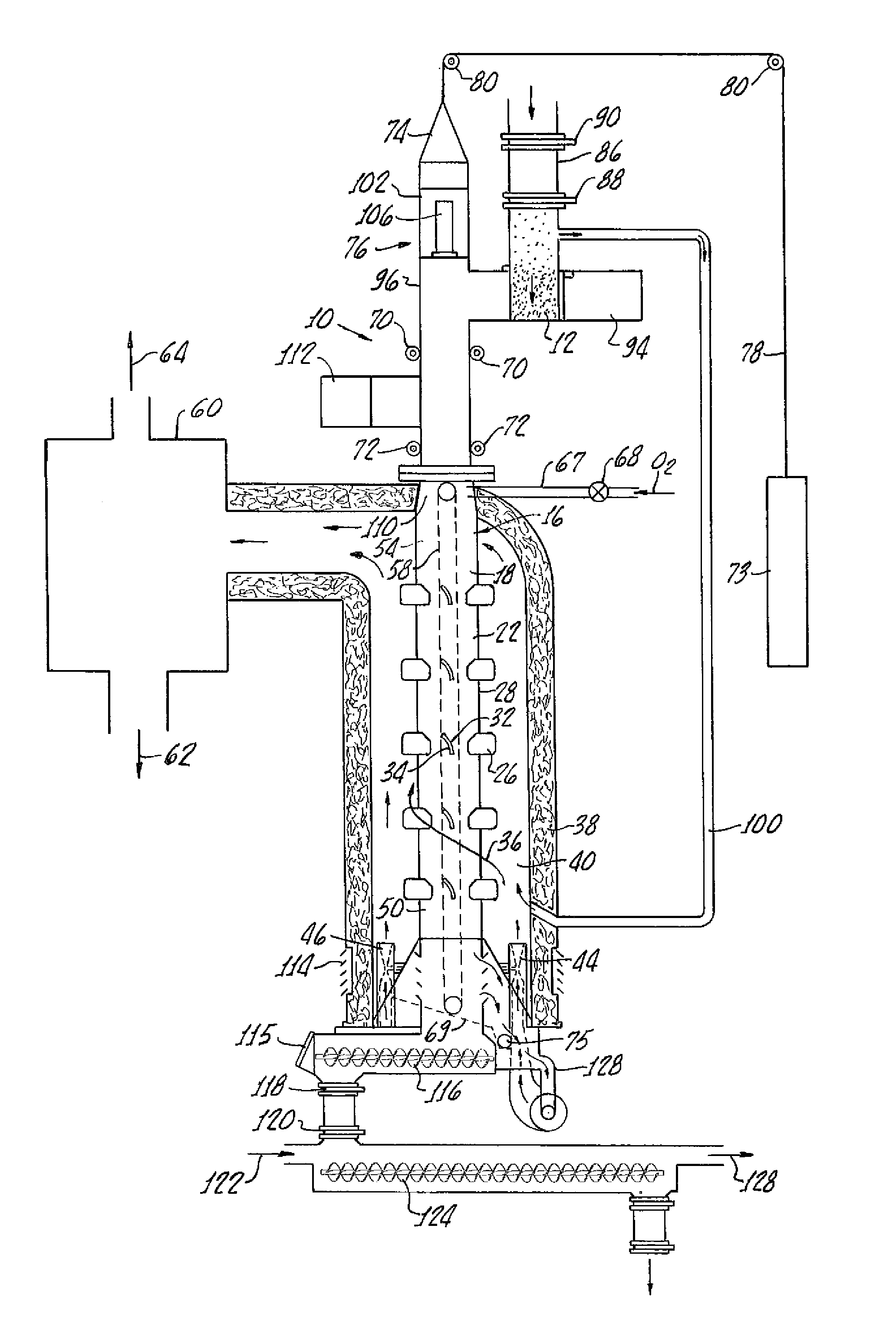

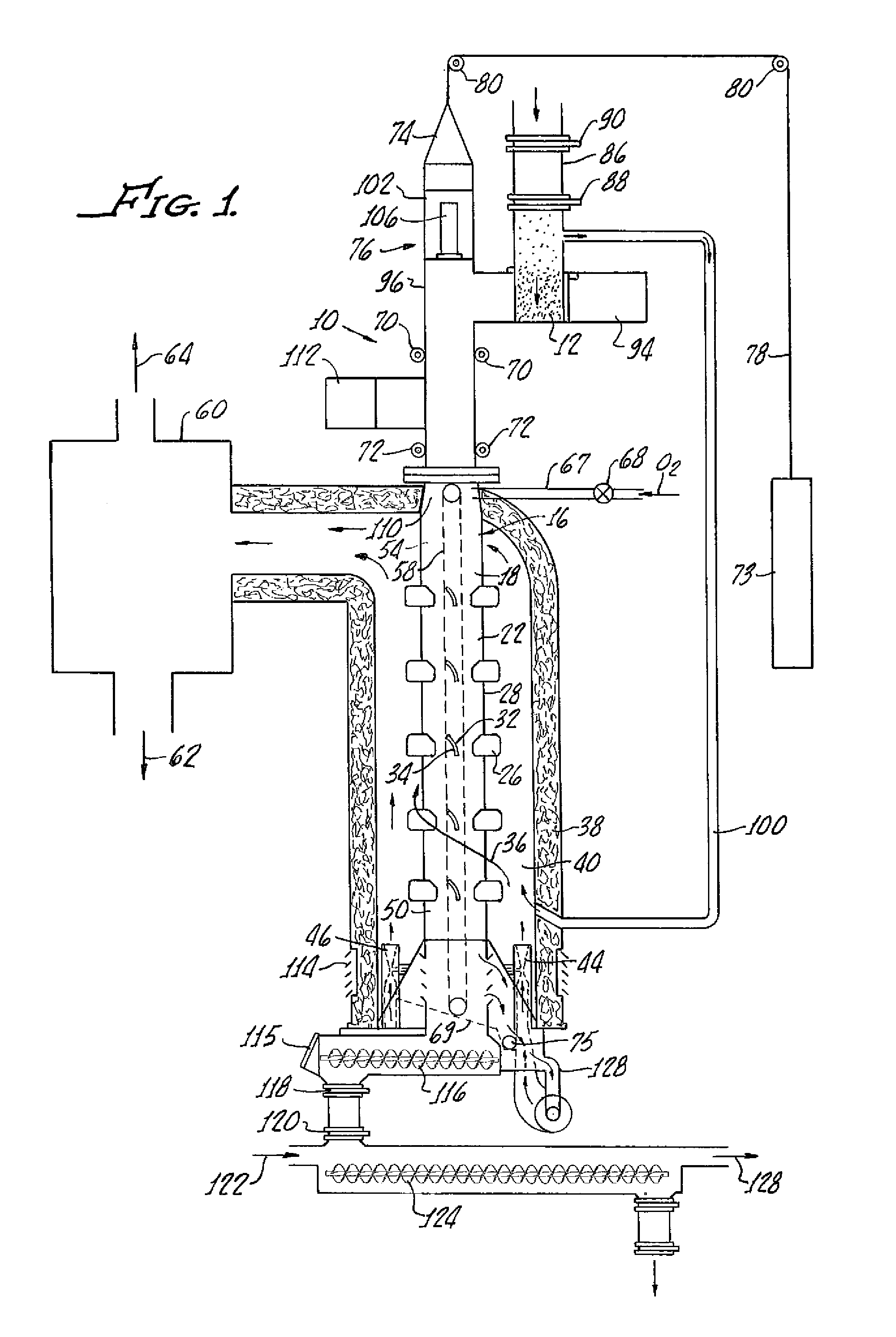

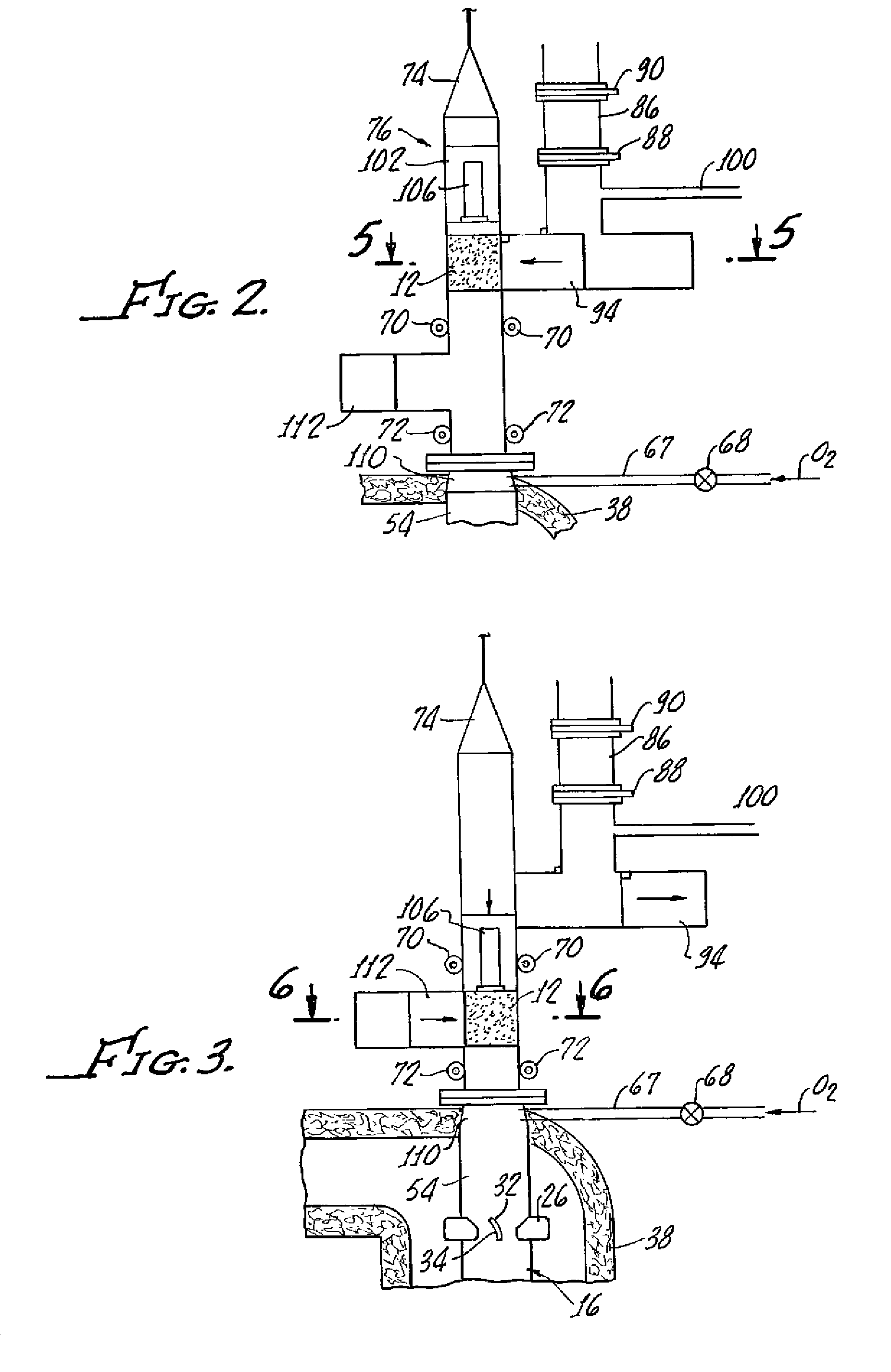

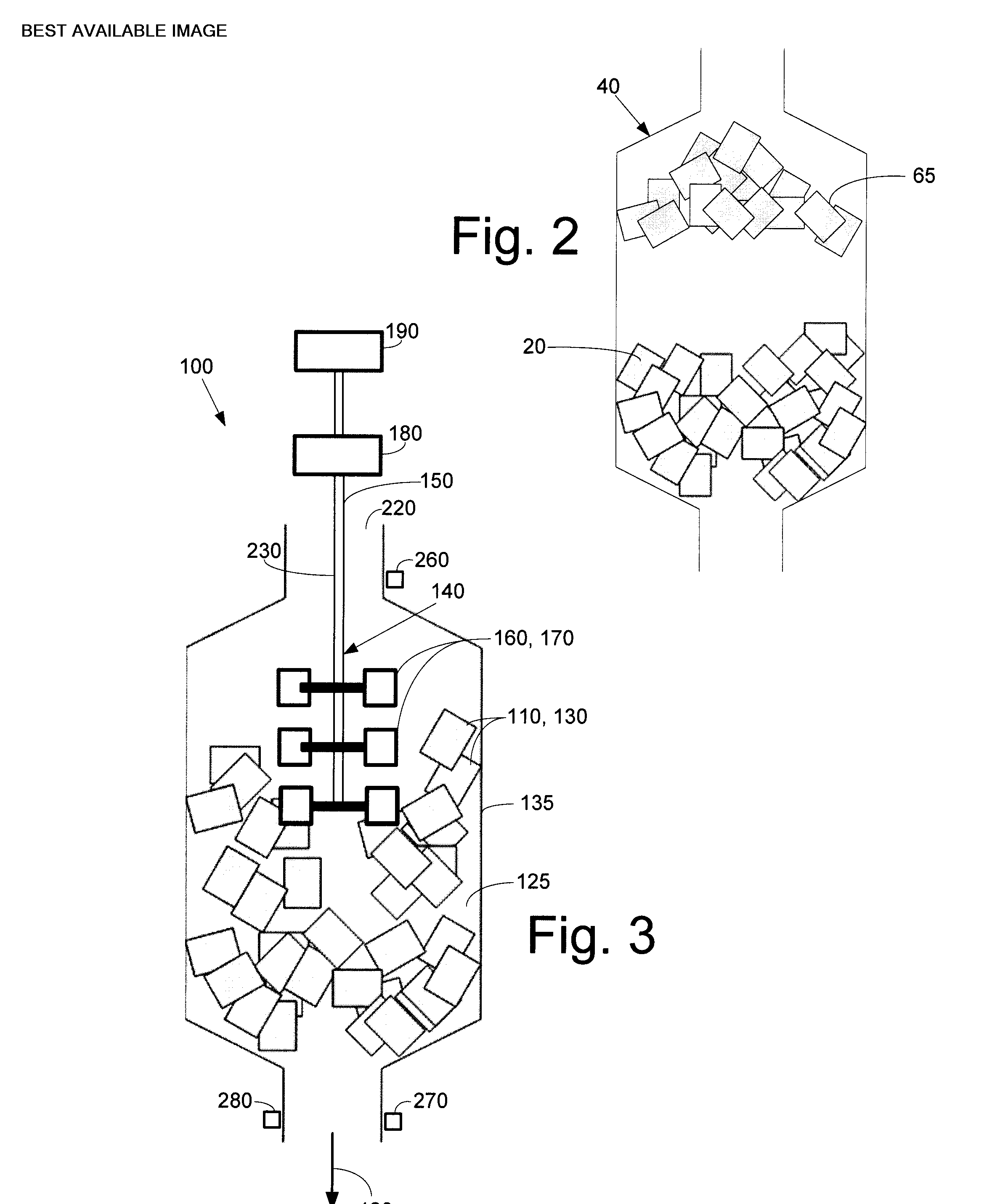

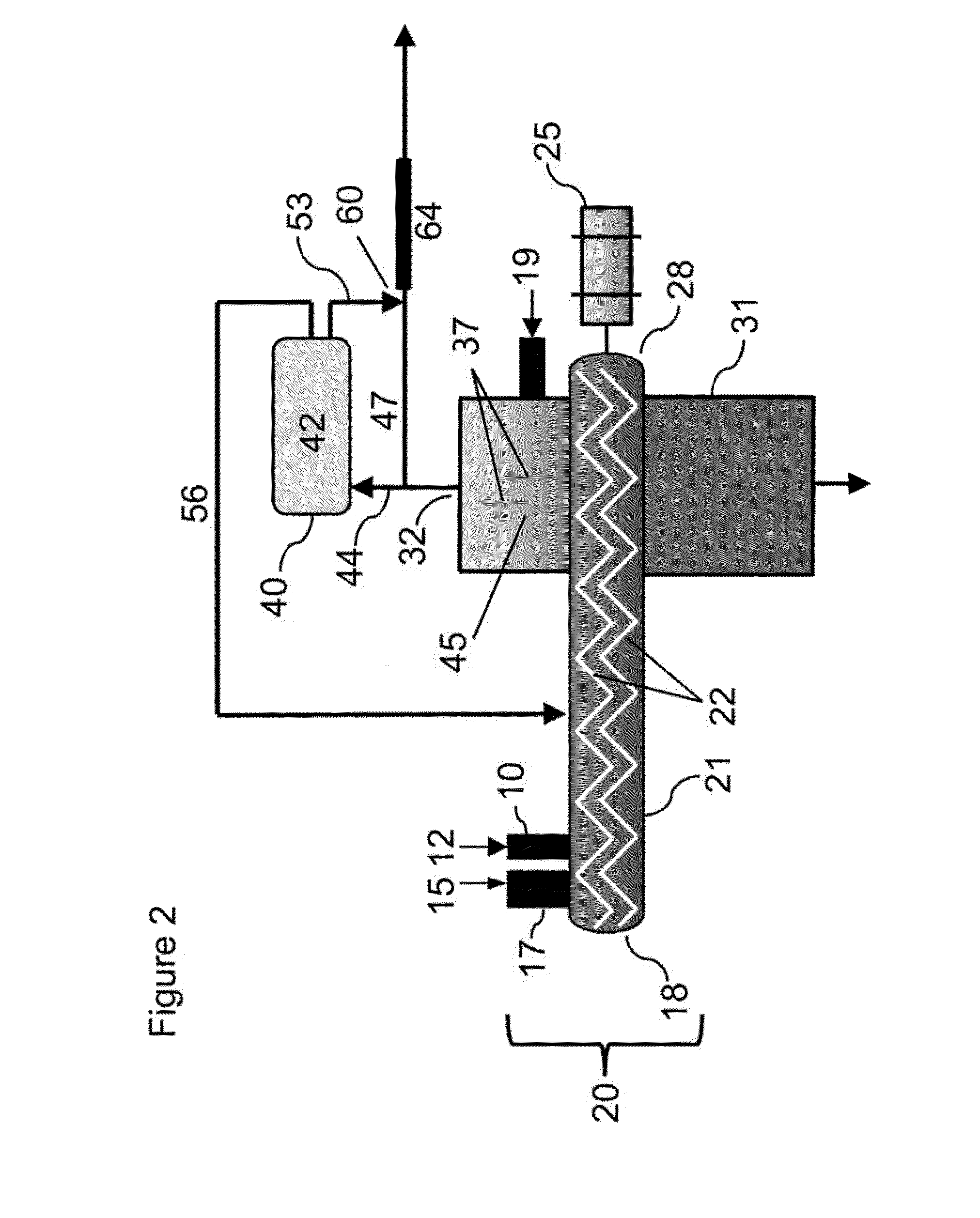

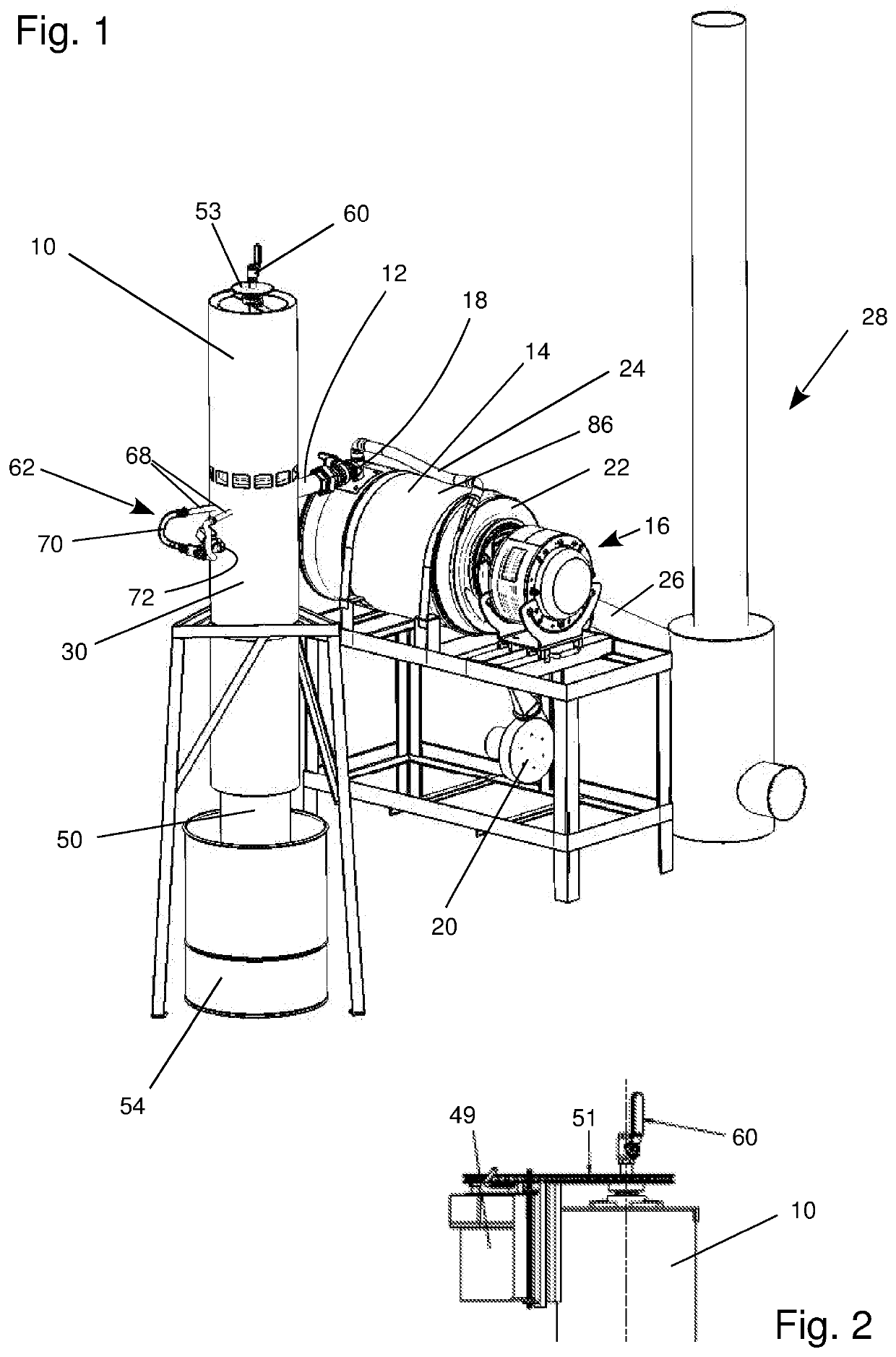

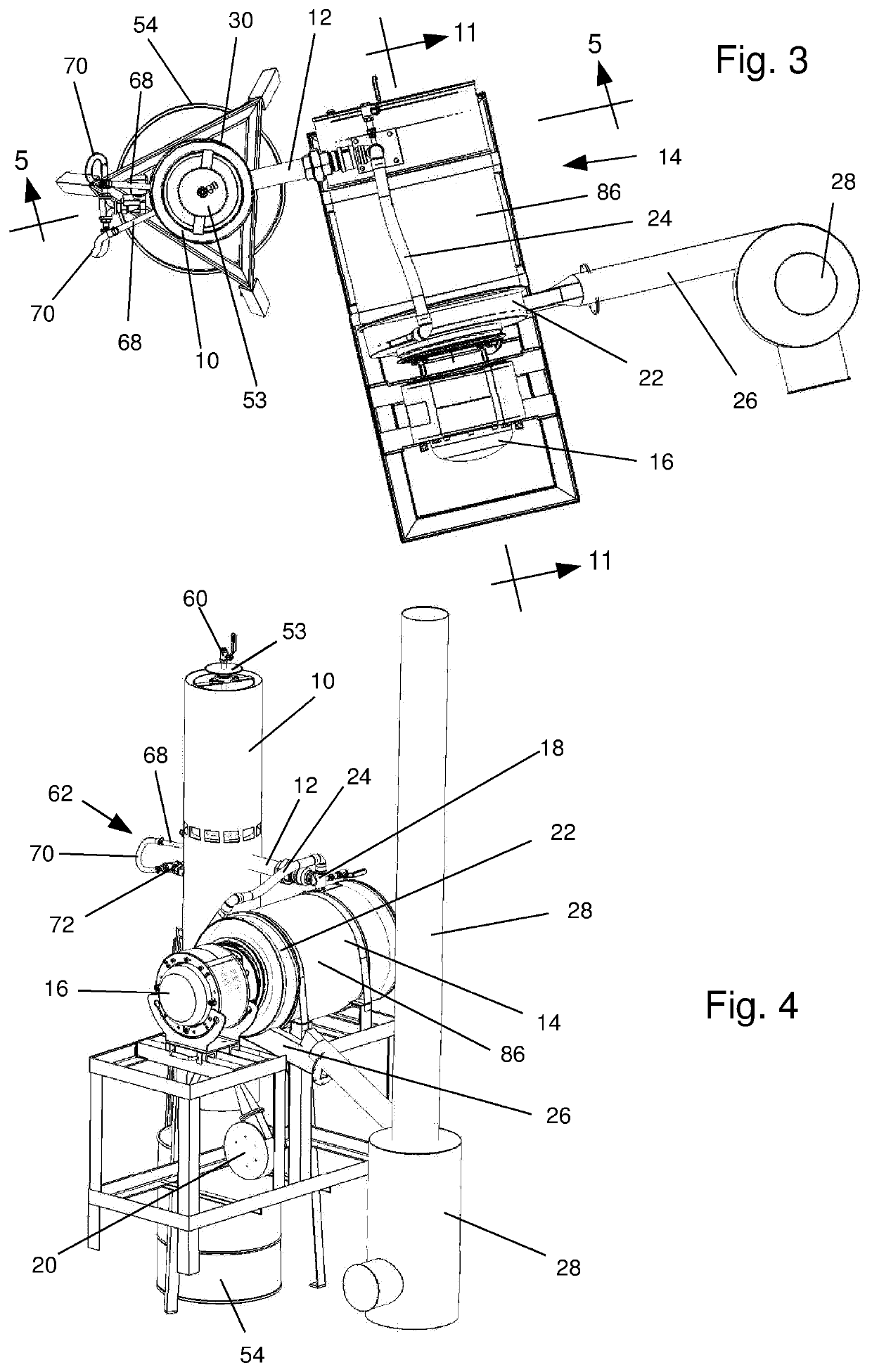

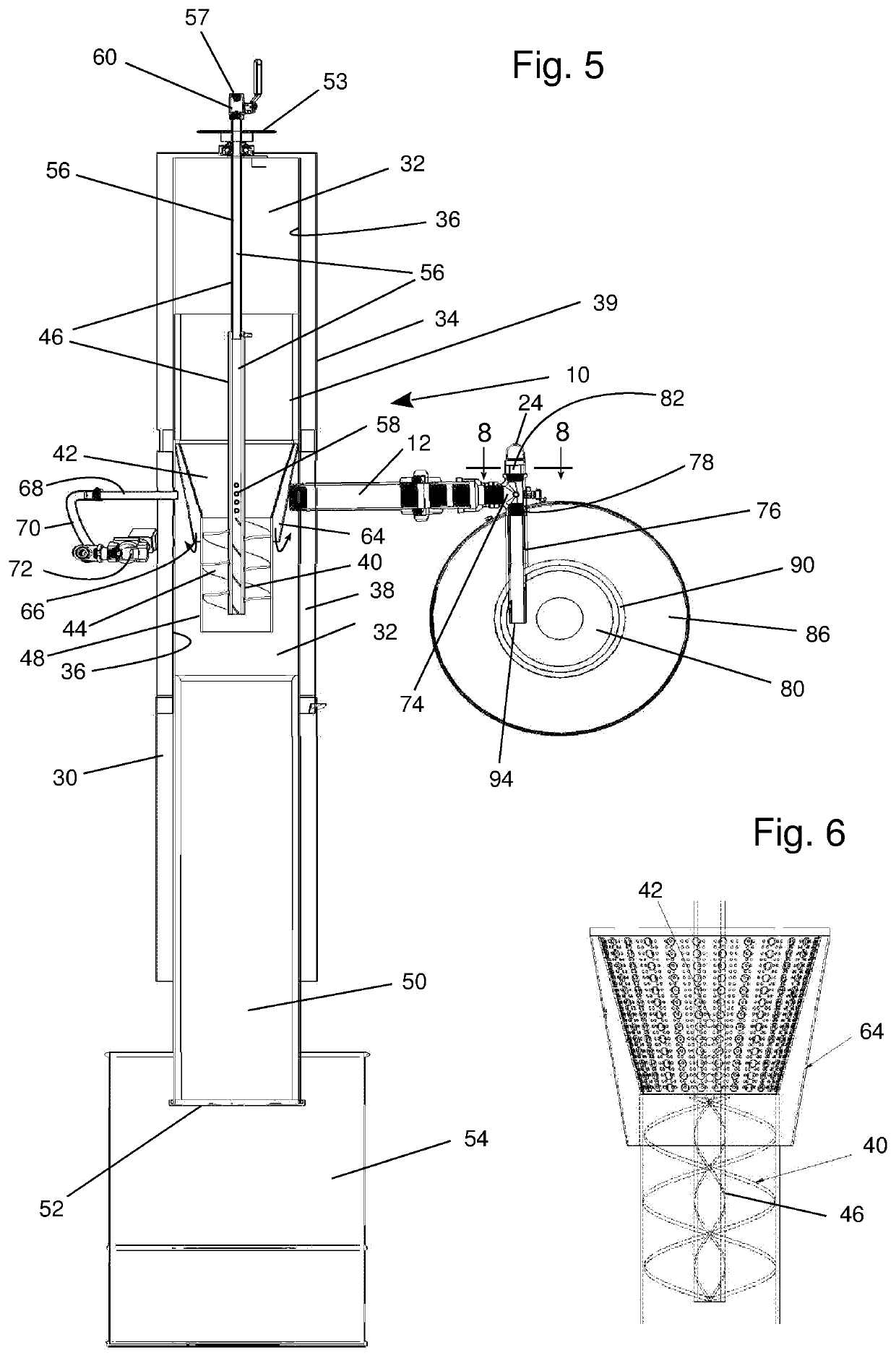

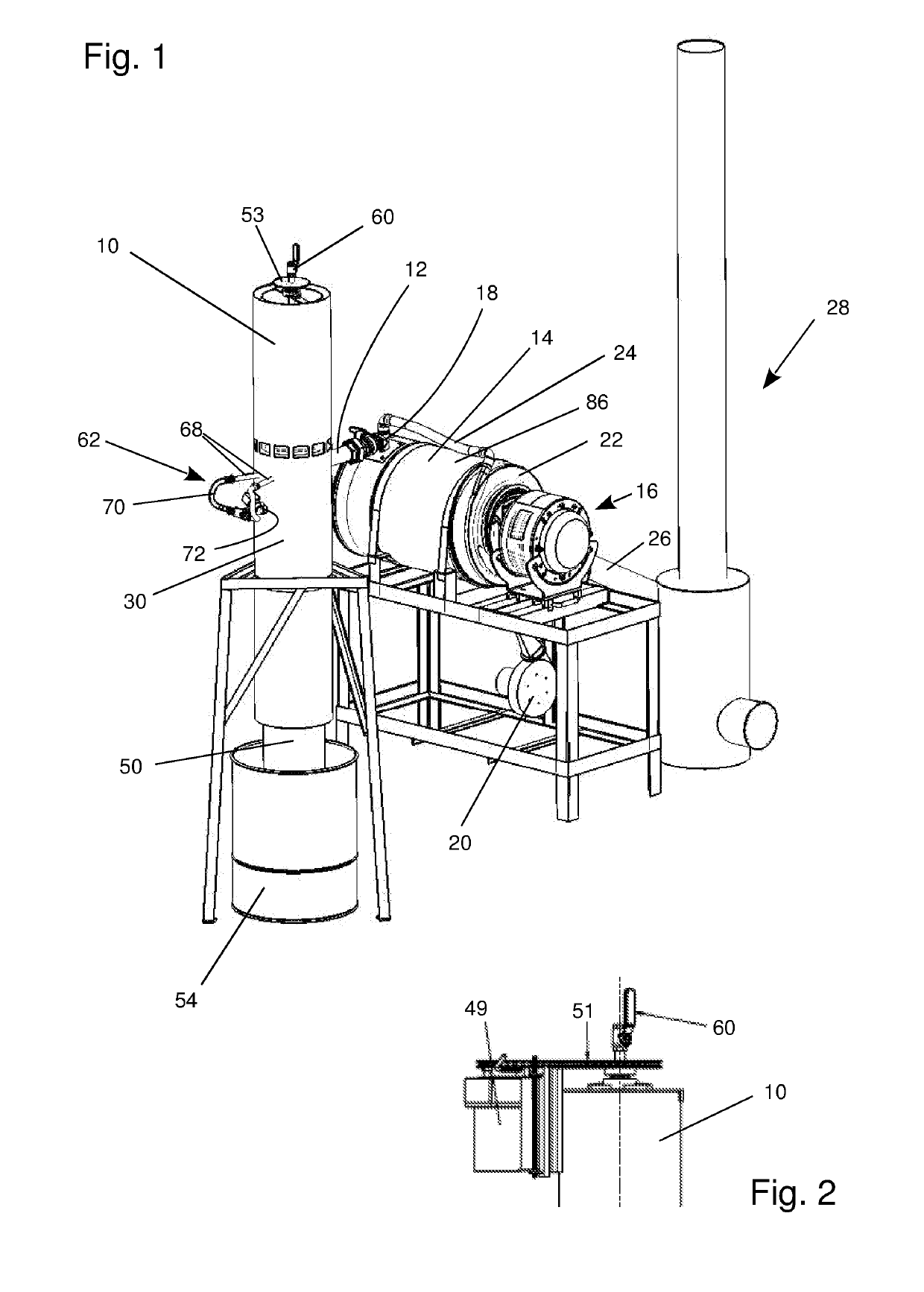

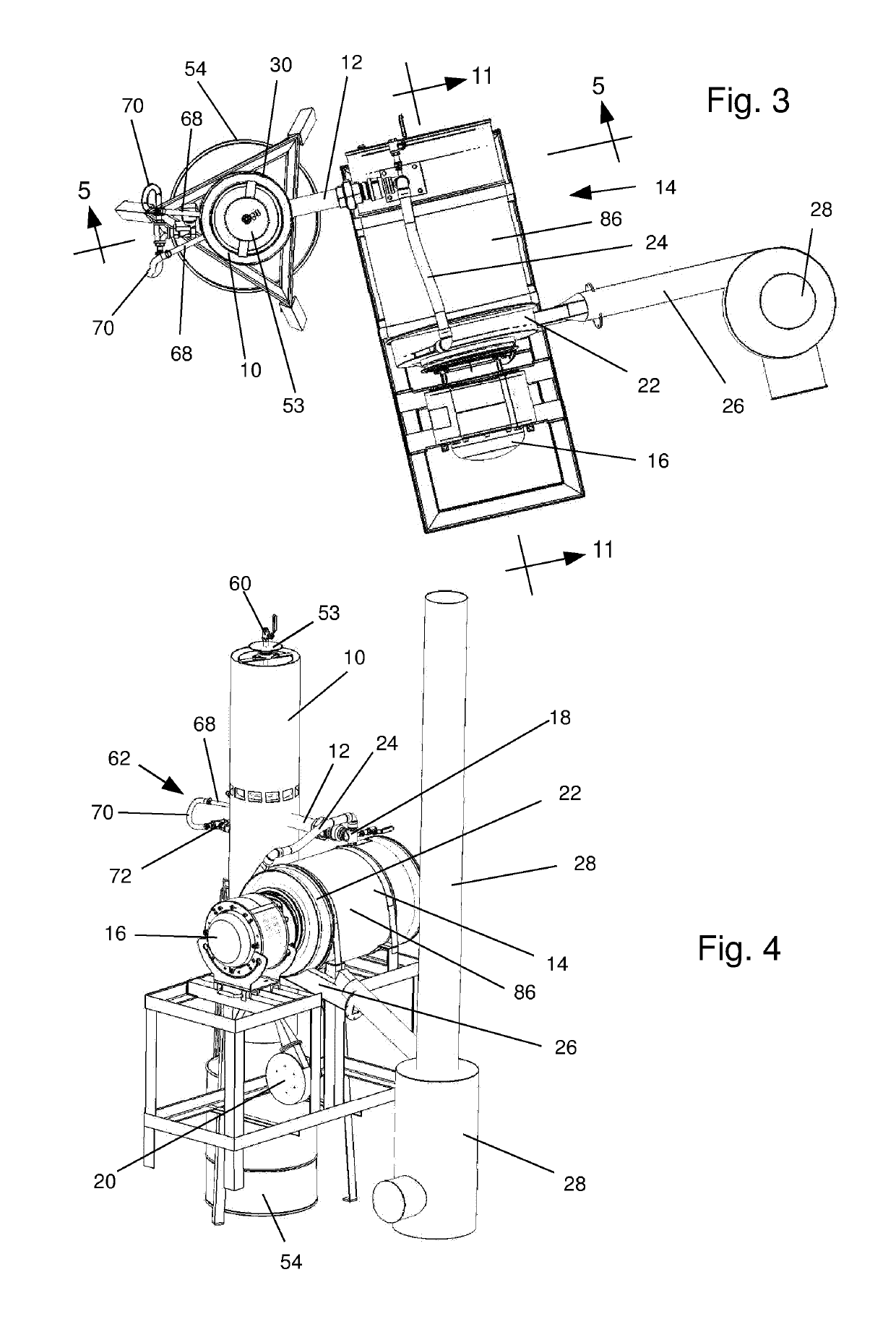

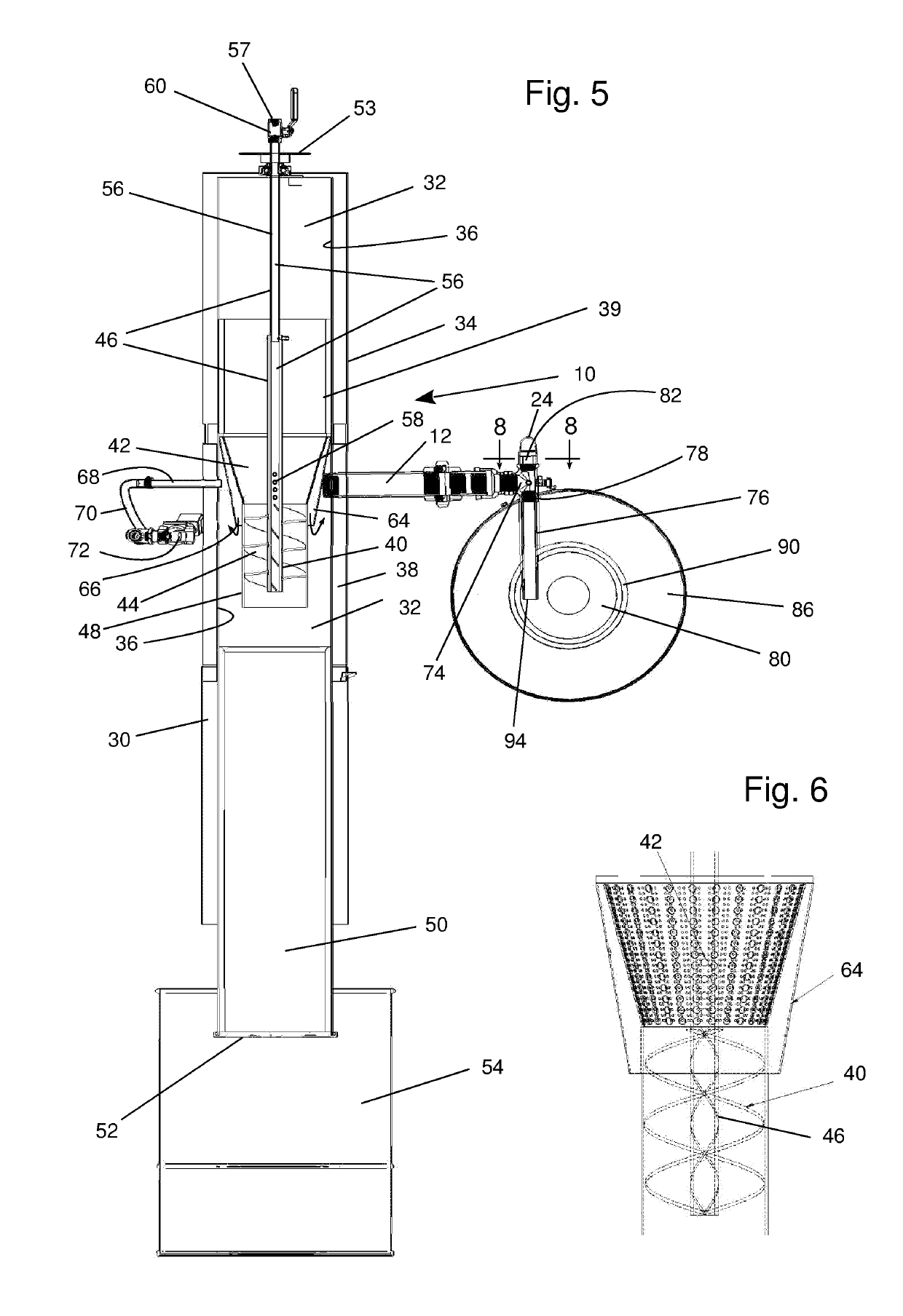

Parallel path, downdraft gasifier apparatus and method

ActiveUS20150052813A1Rapid and precise control of environmentFor fast and precise controlBioreactor/fermenter combinationsBiological substance pretreatmentsOxidation zoneOxygen

A method for using a downdraft gasifier comprising a housing and a refractory stack contained within the housing. The refractory stack may comprise various sections. Apertures in the sections may be aligned to form multiple columnar cavities. Each columnar cavity may comprise an individual oxidation zone. The method of use may include the steps of placing a feedstock into an upper portion of the refractory stack, measuring the temperature of each columnar cavity, and adjusting the flow of oxygen to a particular columnar cavity to maintain the temperature of the particular columnar cavity within a particular range.

Owner:STRATEAN

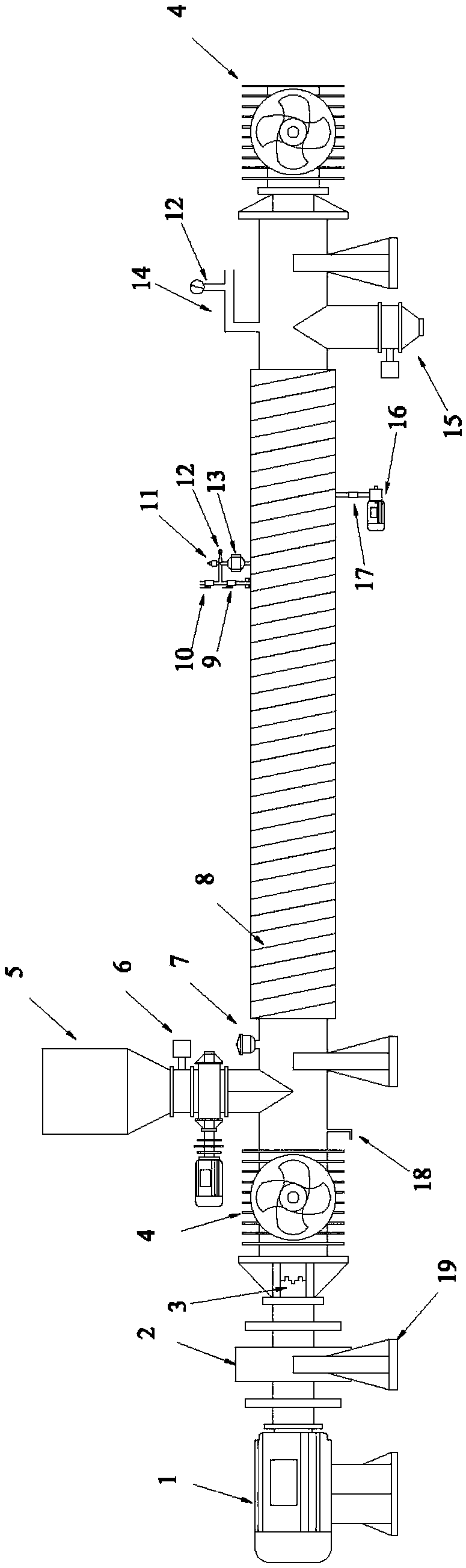

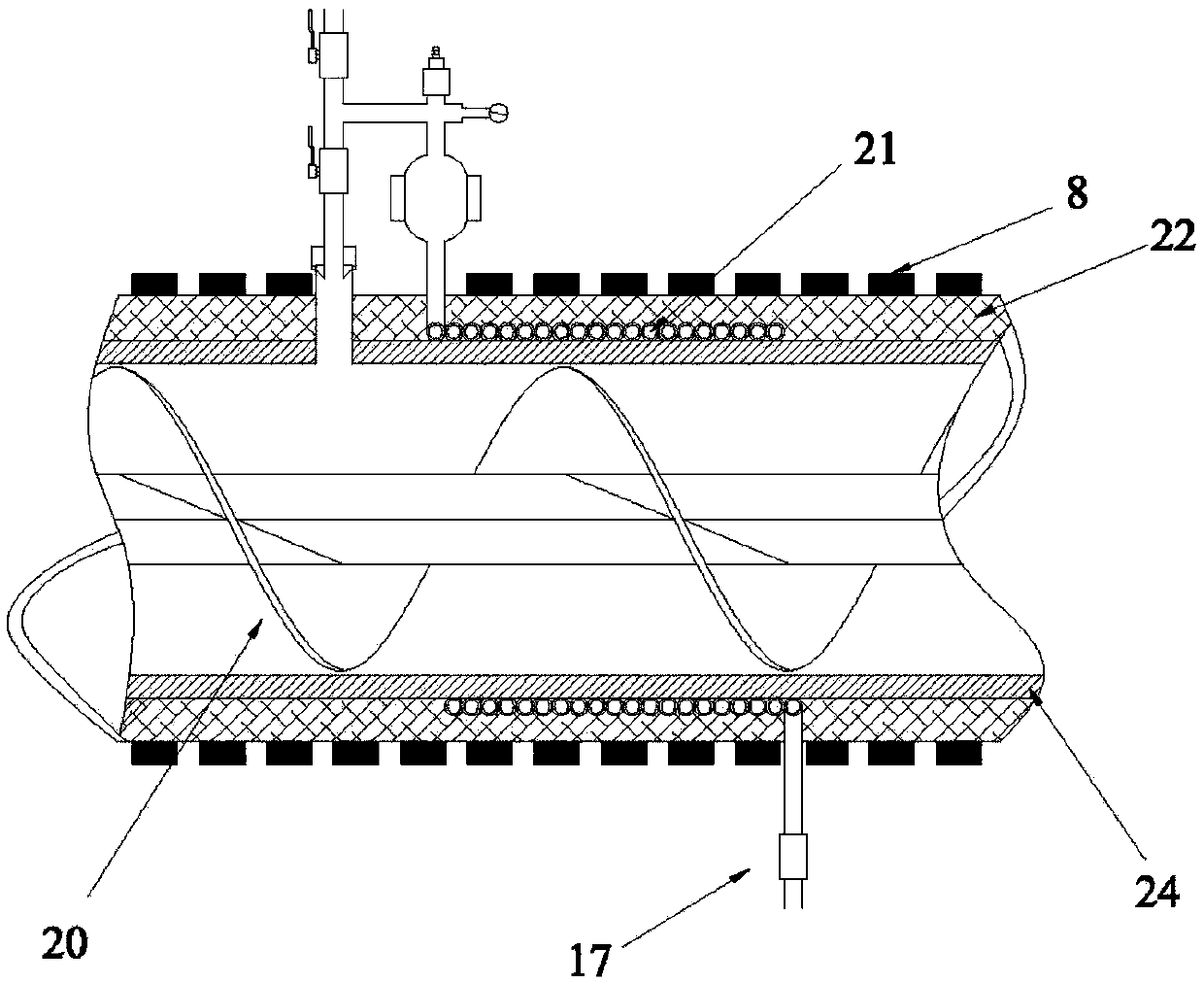

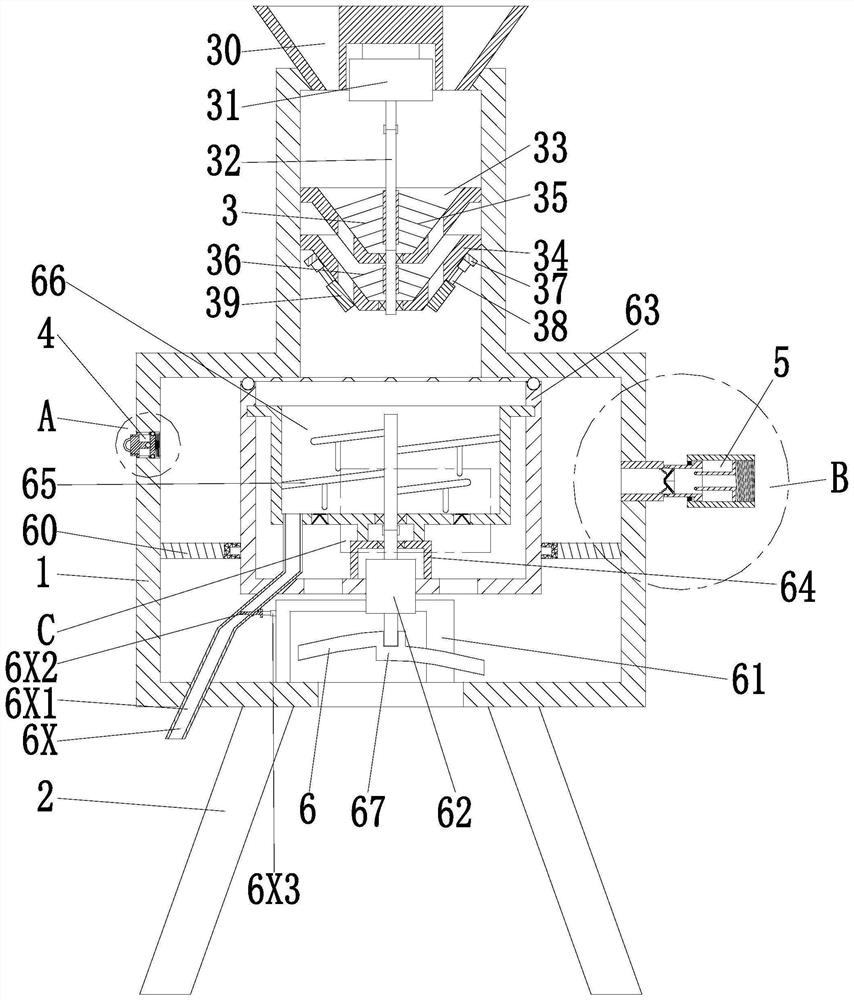

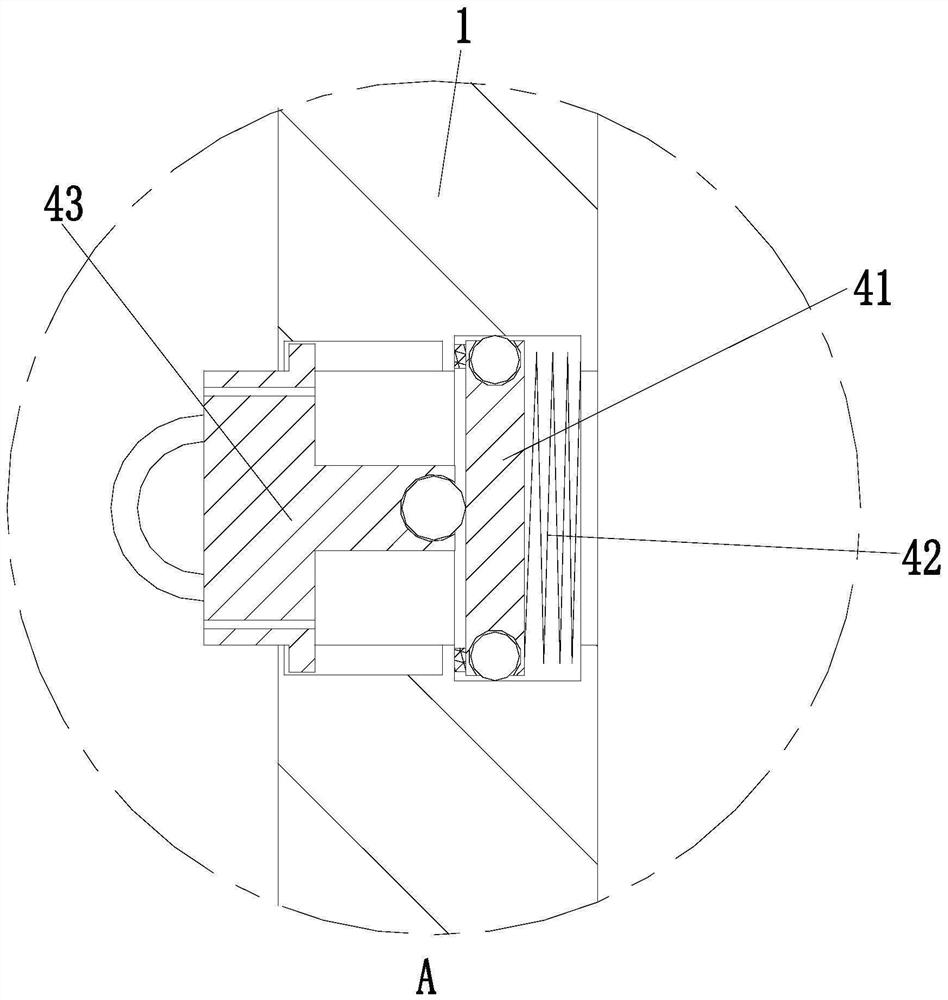

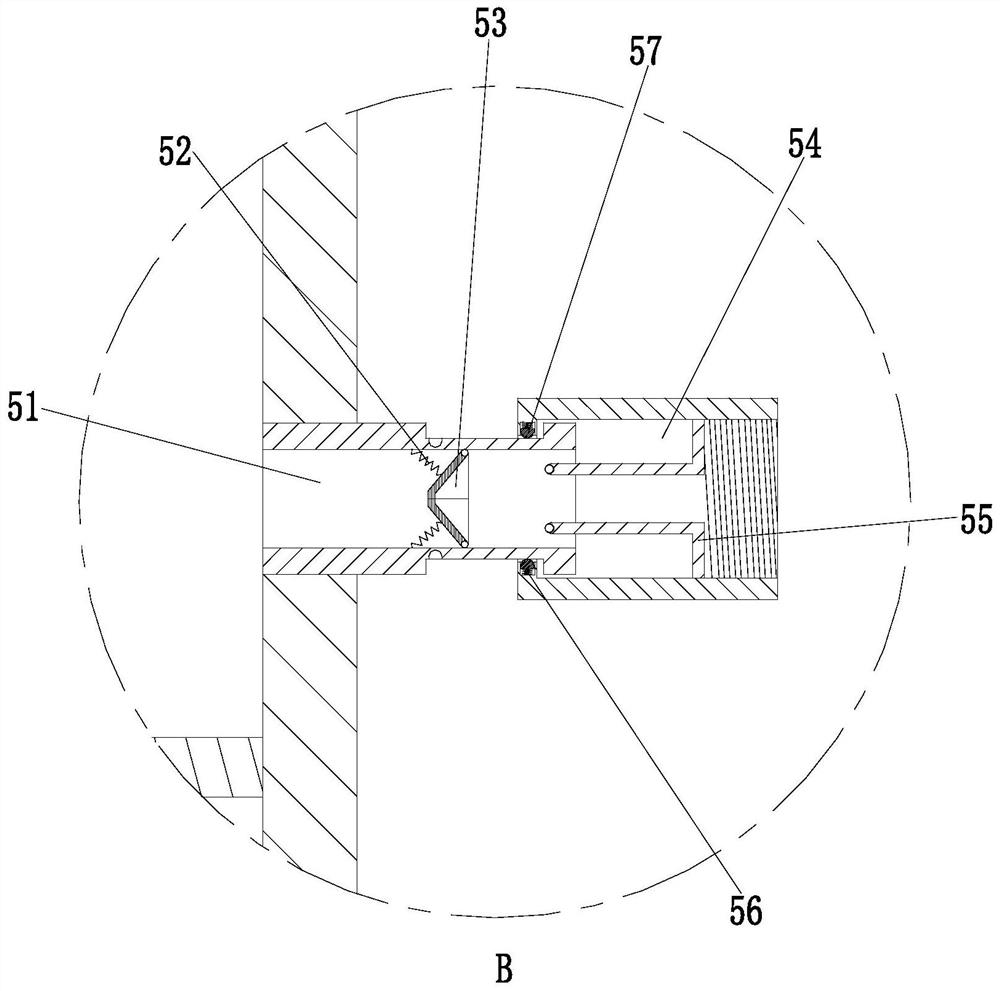

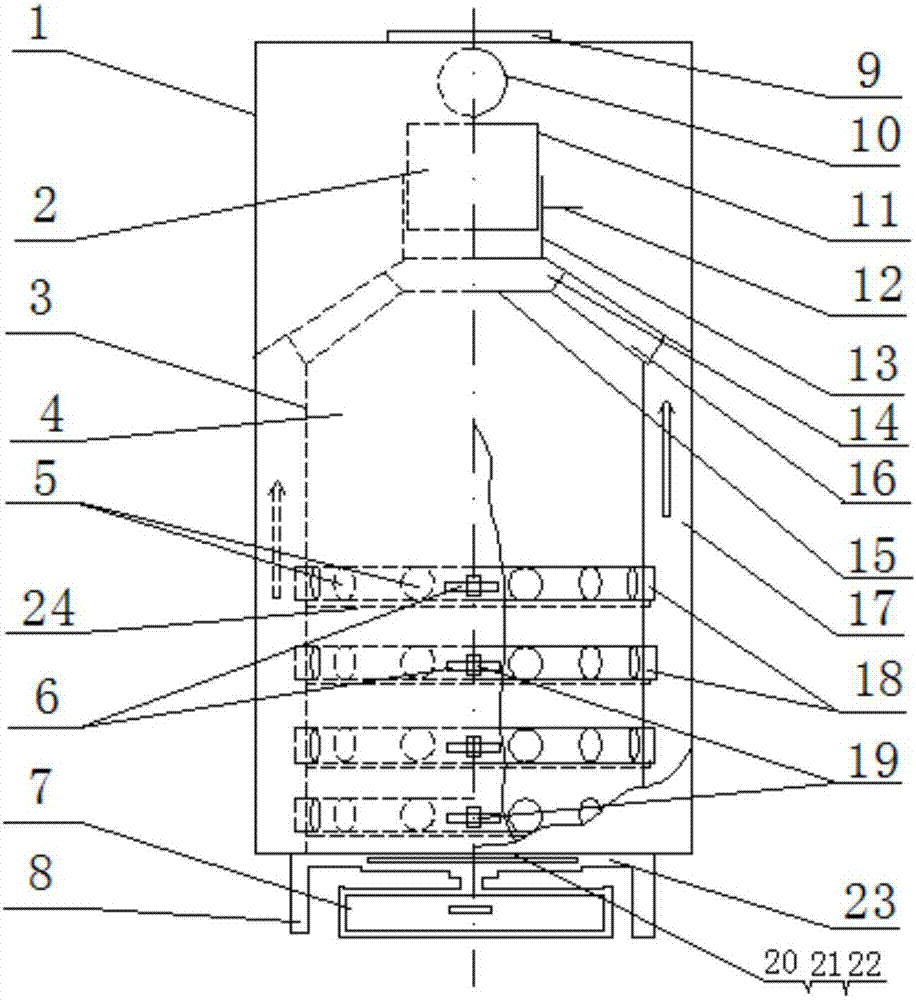

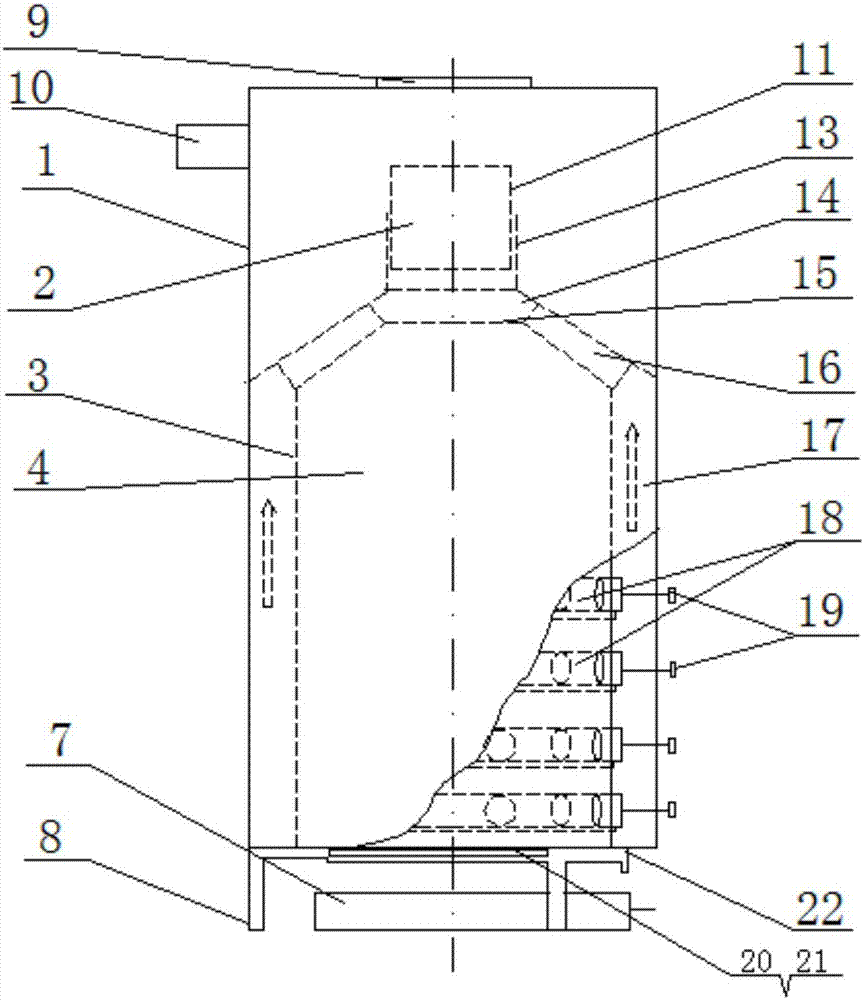

Inner spiral multi-condition electromagnetic heating biomass efficient pyrolysis and gasification furnace

PendingCN107699289AImprove heating efficiencyImprove securityGasifier mechanical detailsGasifier moving partsProcess engineeringElectromagnetic heating

The invention relates to an inner spiral multi-condition electromagnetic heating biomass efficient pyrolysis and gasification furnace. The inner spiral multi-condition electromagnetic heating biomassefficient pyrolysis and gasification furnace comprises a heating system, a steam self-producing spraying system and a bearing temperature dissipating system; the heating system comprises a cylinder body, a material conveying helix, an asbestos heat-insulating layer and an electromagnetic coil; the steam self-producing spraying system comprises a miniature make-up pump, a heated copper pipe, a steam generator, a steam nozzle and the like; steam generated by the steam generator enters the cylinder body through the nozzle to be subjected to reaction; and the bearing temperature dissipating systemcomprises a sealing bearing, a flange disk and a radiator. The inner spiral multi-condition electromagnetic heating biomass efficient pyrolysis and gasification furnace is specifically provided withan efficient electromagnetic heating system and a gas and steam self-producing spraying system, the device heats the cylinder body and the material conveying helix by an electromagnetic heating mode,materials are heated uniformly through conveying and stirring, pyrolysis and gasification of the materials are accelerated, different atmosphere conditions are provided for pyrolysis of biomass by introducing different gases and steam, the yield of pyrolysis gas and oil products is increased, and the quality of charcoal is improved to a certain degree.

Owner:ACADEMY OF PLANNING & DESIGNING OF THE MINIST OF AGRI

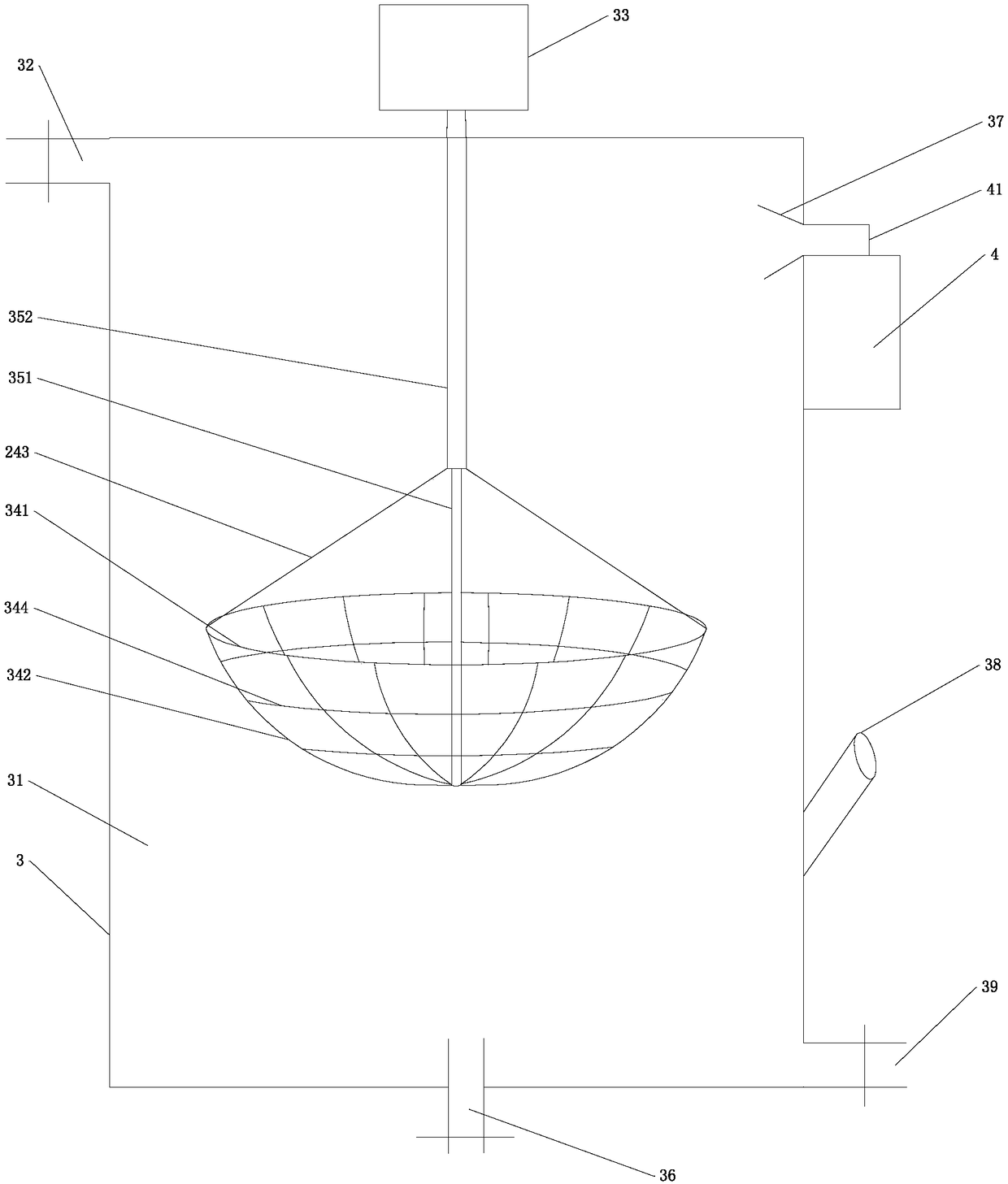

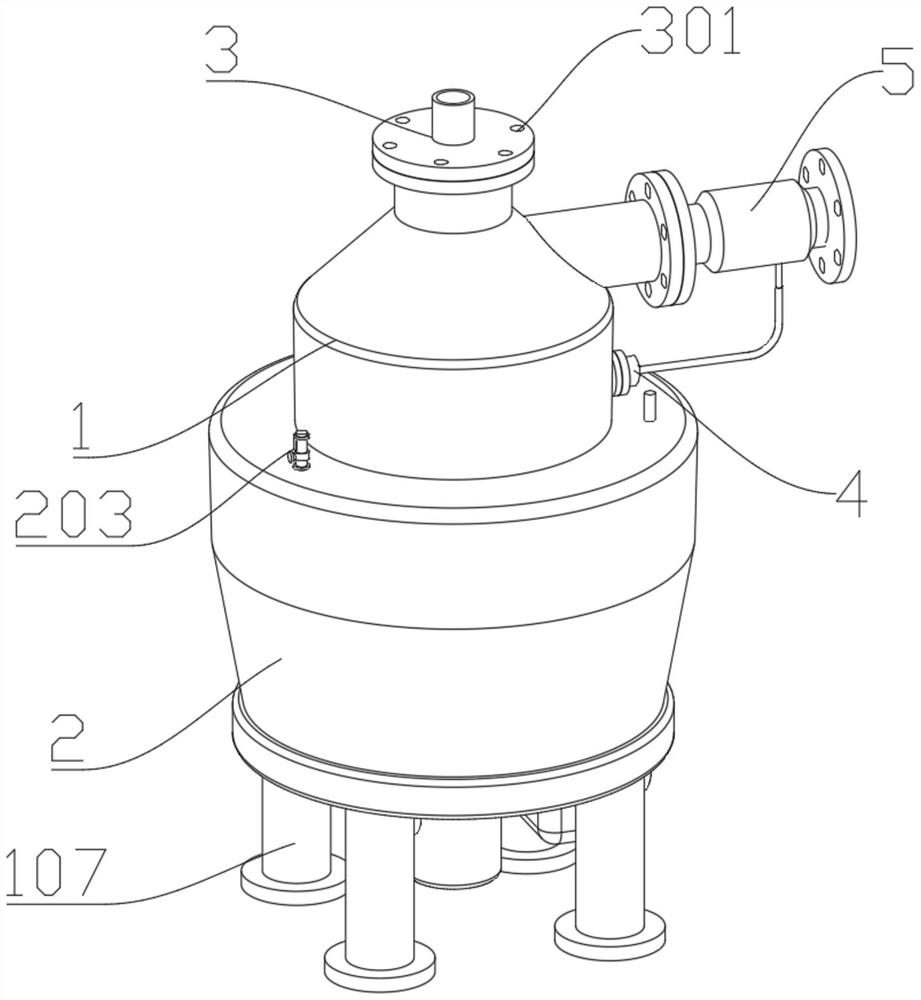

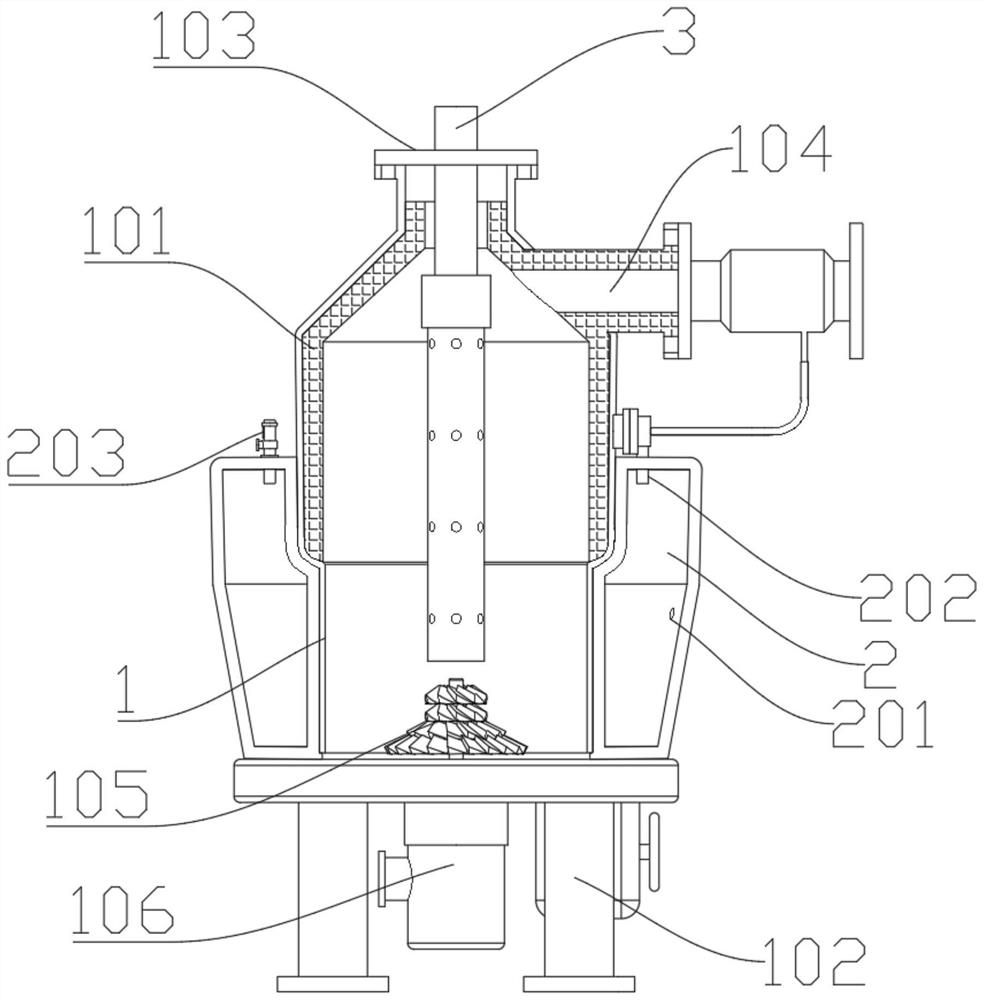

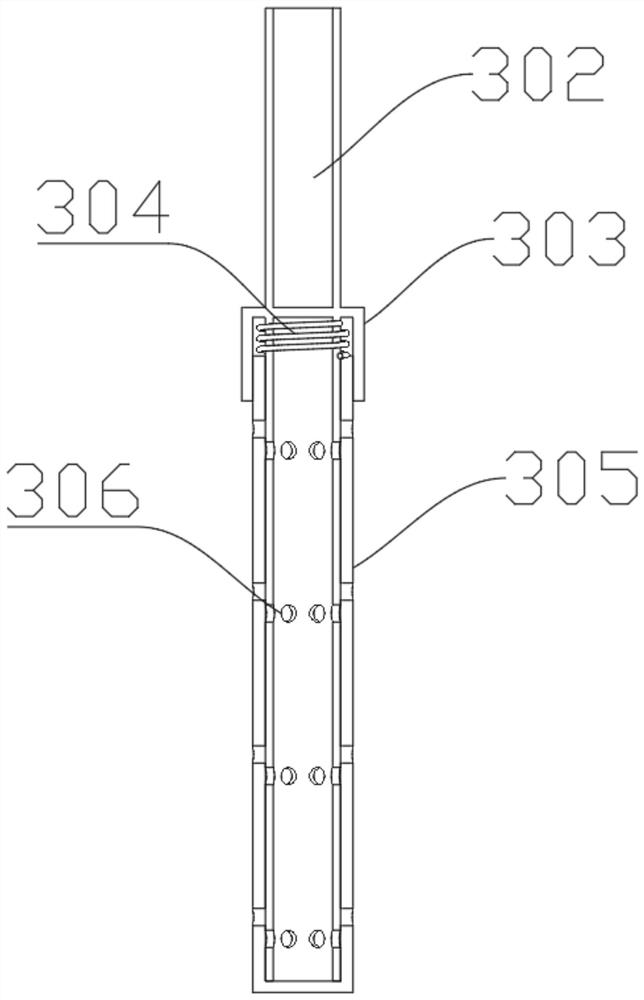

Biomass gasifier

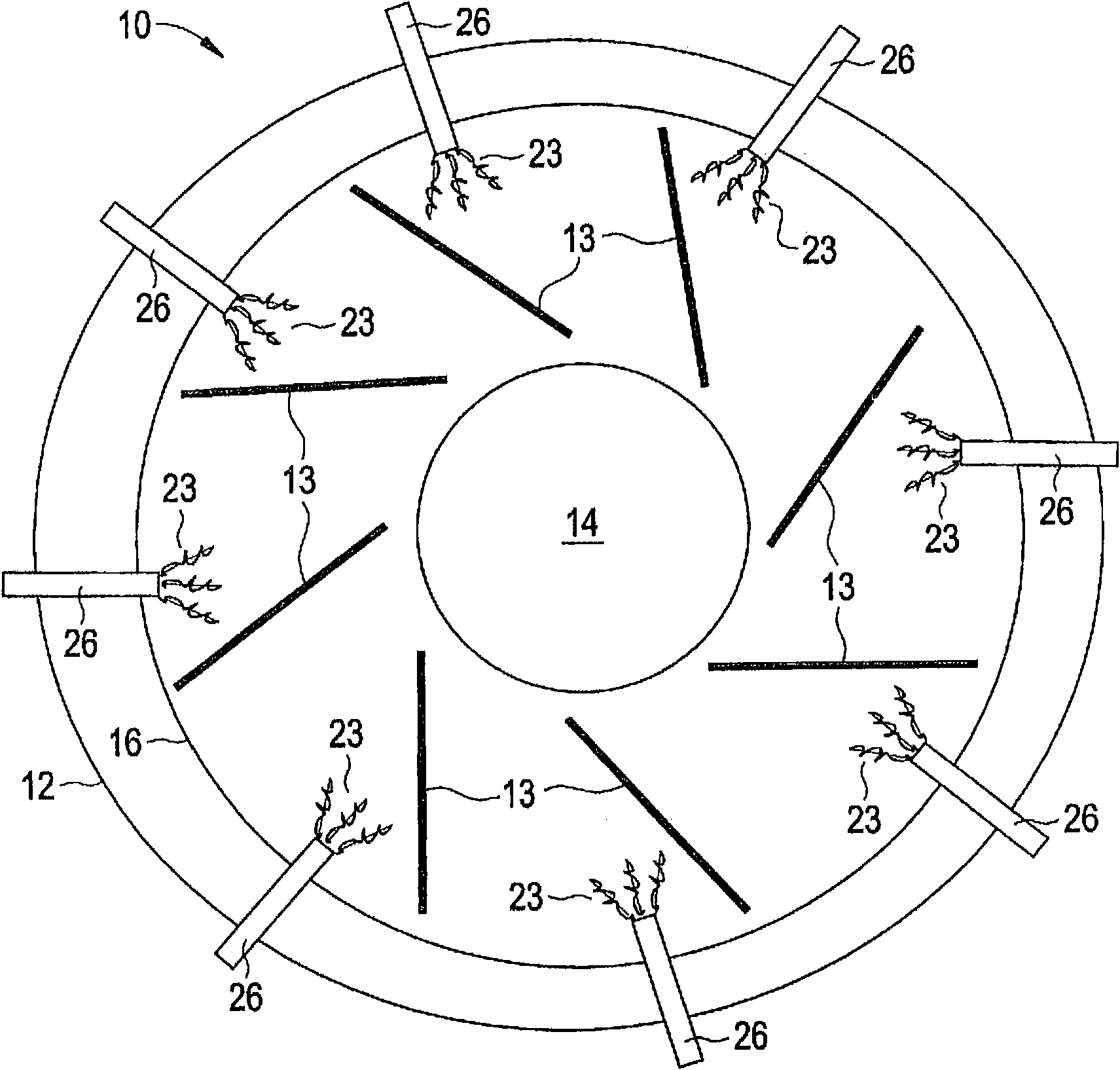

The present application thus provides a gasifier for use in converting a feedstock material into a syngas. The gasifier may include an outer chamber, a reaction zone positioned within the outer chamber, and a disruption device maneuverable within the outer chamber to ensure a steady flow of the feedstock material into the reaction zone without bridging.

Owner:AIR PROD & CHEM INC

Grading pyrolysis and gasification and high-temperature tar removal and dust removal integrated process for biomass circulating fluidized bed

ActiveCN109609198AIncrease gas calorific valueImprove thermal efficiencyCombustible gas chemical modificationProductsCatalytic pyrolysisHeat carrier

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Pressurising of bulk material in lock hoppers

ActiveUS10150925B2Shorten pressurization timeReduce noise nuisanceGasifier moving partsBulk conveyorsProduct gasEngineering

Owner:PAUL WURTH SA

Biomass fuel gasification furnace

InactiveCN112094670AEnsure gas pressure balanceEnsure safetyGasifier feeding meansGasifier moving partsThermodynamicsFuel gasification

The invention provides a biomass fuel gasification furnace. The biomass fuel gasification furnace comprises a reaction box, supporting legs, a feeding unit, an air valve unit, an air guide unit and amaterial containing unit. Supporting feet are evenly arranged at the lower end of the reaction box, a feeding unit is arranged in the upper end of the reaction box, an air valve unit is arranged on the side wall of the left end of the reaction box, an air guide unit is arranged on the side wall of the right end of the reaction box, and a container is arranged in the lower end of the reaction box.The invention solves the problems as follows: according to an existing biomass fuel gasification furnace, fuel in the gasification furnace cannot be fully combusted, so that internal gas emission is affected by insufficient combustion of internal fuel particles, waste of the fuel particles combusted in an internal fuel cylinder cannot be completely discharged, and the environment is polluted are solved, the waste is accumulated in the inner fuel cylinder, and the internal capacity of the inner fuel cylinder and the combustion of the waste are influenced; besides, the internal air pressure of the existing gasification furnace cannot be balanced, so that the use safety of the gasification furnace is influenced, and the like.

Owner:汤先忠

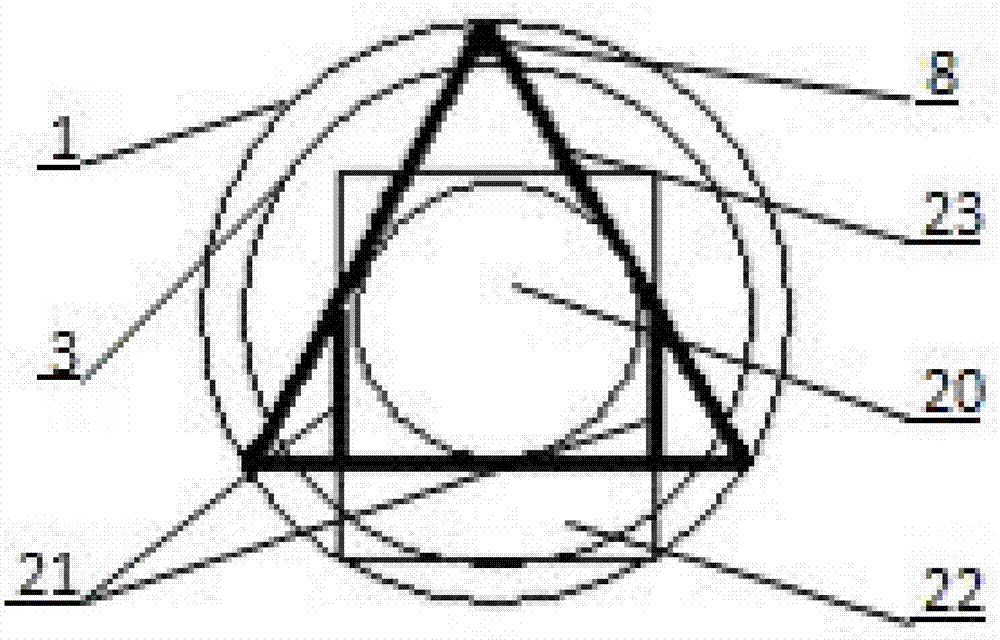

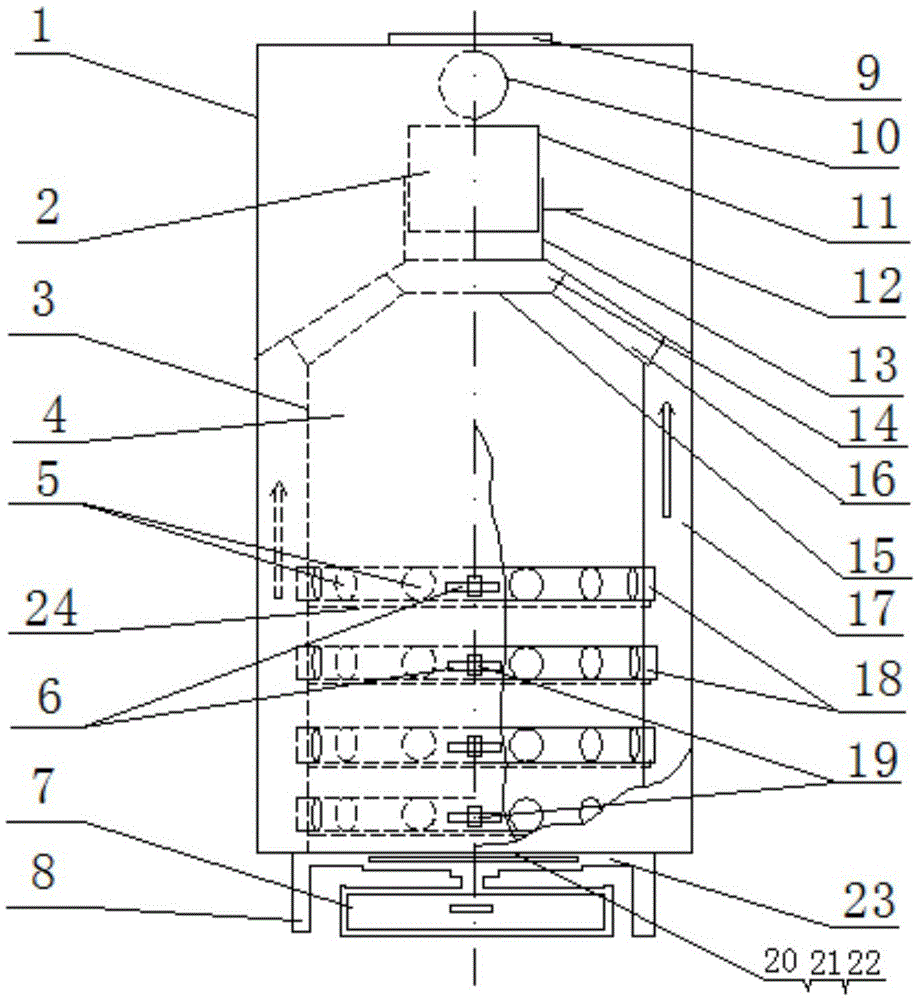

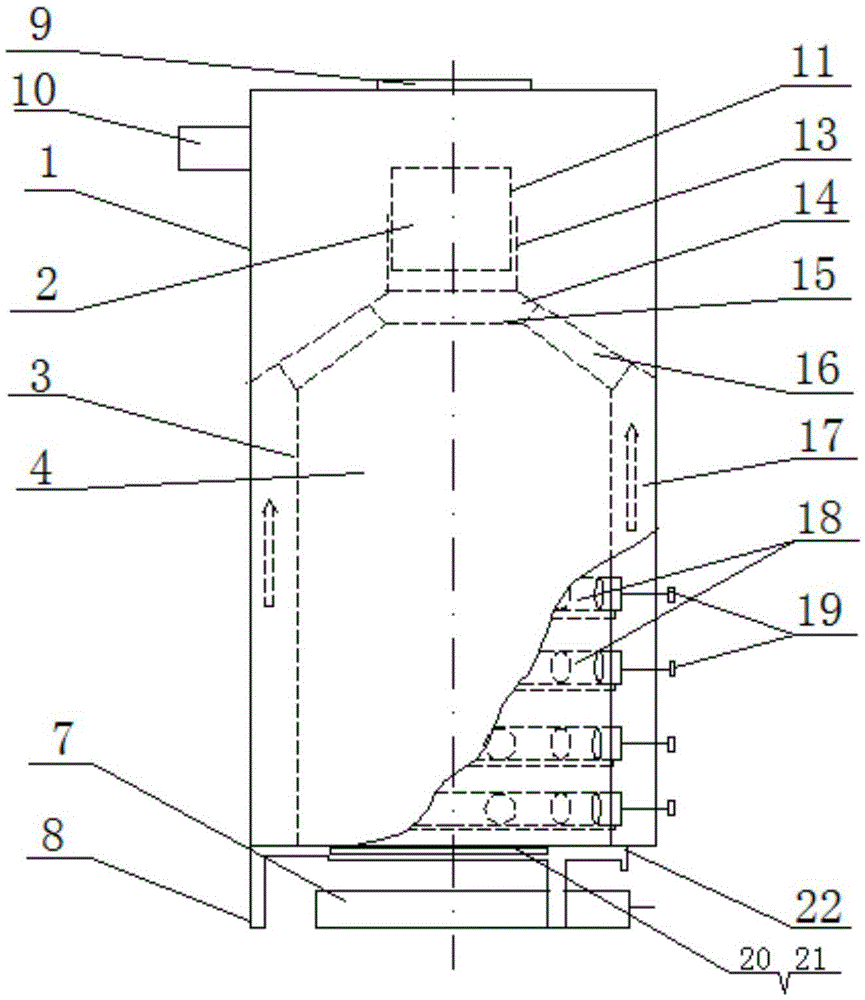

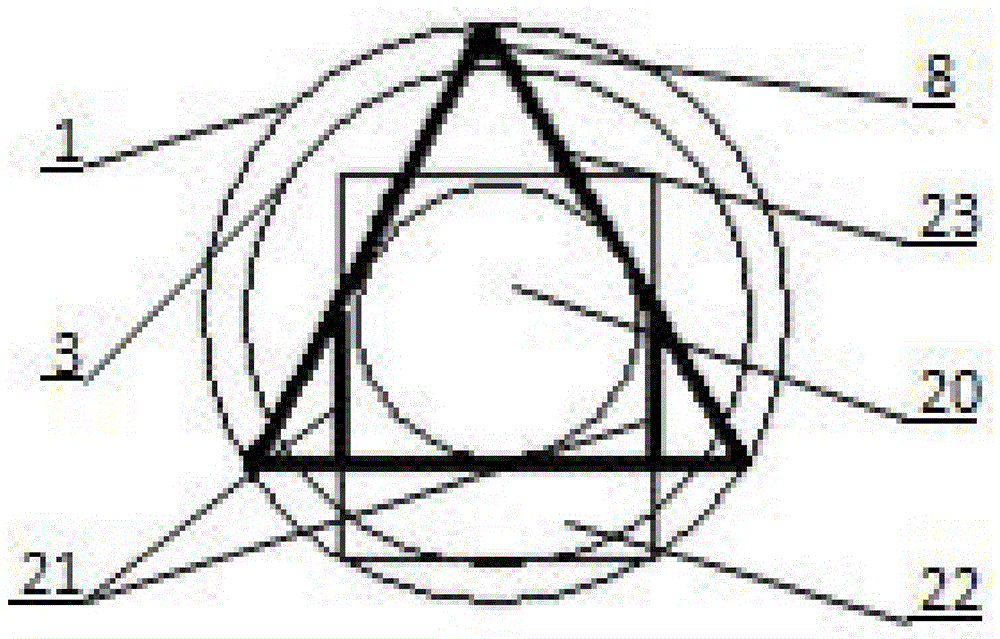

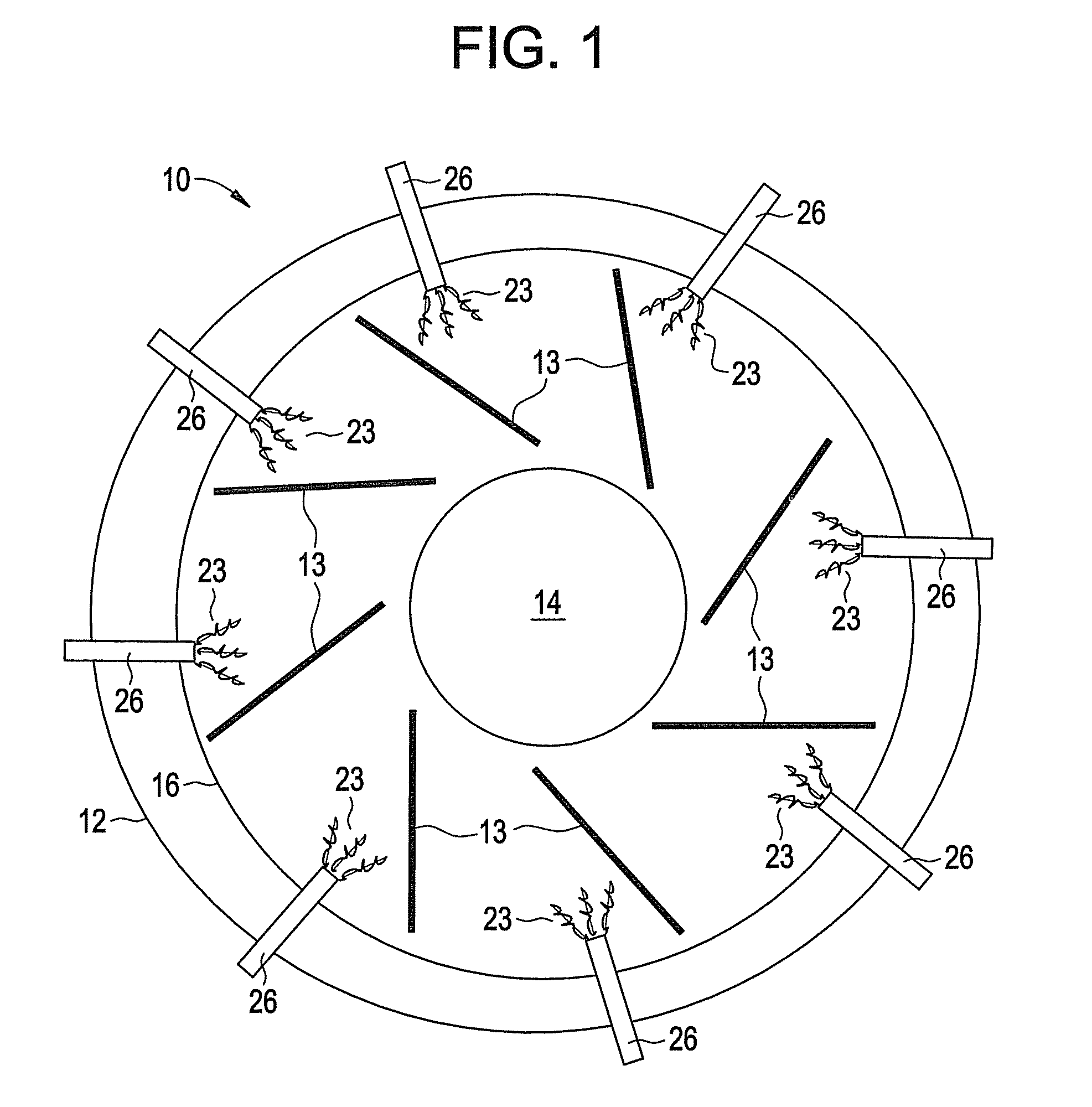

Integrated biomass self-powered cyclone gasification combustion furnace

ActiveCN105570874BWell mixedReduce pollutionDomestic stoves or rangesGasifier moving partsCycloneCombustion chamber

The invention relates to an integrated type biomass self-operated cyclone gasification combustion furnace, and belongs to biomass gasification furnaces. The technical problems that an existing biomass combustion furnace is severe in environmental pollution and incapable of outputting biomass char are mainly solved. According to the technical scheme adopted for solving the technical problems, the integrated type biomass self-operated cyclone gasification combustion furnace comprises a shell, a furnace foot, a furnace ring cover, a flue, a furnace door, a plug board groove, a plug board and a furnace base frame; the combustion furnace further comprises an inner barrel, a multiple rows of primary air inlet holes, a plurality of primary air adjusting grooves, a char discharging hopper, a combustion chamber inner barrel, a combustion chamber outer barrel, a secondary air inlet, eight to ten guide vanes and a plurality of primary air adjusting rings, primary air adjusting knobs and barrier strips; the shell is a bottomless cylinder; the inner barrel is arranged in an inner cavity of the shell and located on the middle-lower portion of the inner cavity of the shell; the shell and the inner barrel are together installed on a bracket composed of the furnace foot and the furnace base frame; the furnace door is arranged on the bottom surface of the inner barrel.

Owner:COTTON RES INST SHANXI ACAD OF AGRI SCI

Integrated type biomass self-operated cyclone gasification combustion furnace

ActiveCN105570874AWell mixedReduce pollutionDomestic stoves or rangesGasifier moving partsCombustion chamberEngineering

The invention relates to an integrated type biomass self-operated cyclone gasification combustion furnace, and belongs to biomass gasification furnaces. The technical problems that an existing biomass combustion furnace is severe in environmental pollution and incapable of outputting biomass char are mainly solved. According to the technical scheme adopted for solving the technical problems, the integrated type biomass self-operated cyclone gasification combustion furnace comprises a shell, a furnace foot, a furnace ring cover, a flue, a furnace door, a plug board groove, a plug board and a furnace base frame; the combustion furnace further comprises an inner barrel, a multiple rows of primary air inlet holes, a plurality of primary air adjusting grooves, a char discharging hopper, a combustion chamber inner barrel, a combustion chamber outer barrel, a secondary air inlet, eight to ten guide vanes and a plurality of primary air adjusting rings, primary air adjusting knobs and barrier strips; the shell is a bottomless cylinder; the inner barrel is arranged in an inner cavity of the shell and located on the middle-lower portion of the inner cavity of the shell; the shell and the inner barrel are together installed on a bracket composed of the furnace foot and the furnace base frame; the furnace door is arranged on the bottom surface of the inner barrel.

Owner:COTTON RES INST SHANXI ACAD OF AGRI SCI

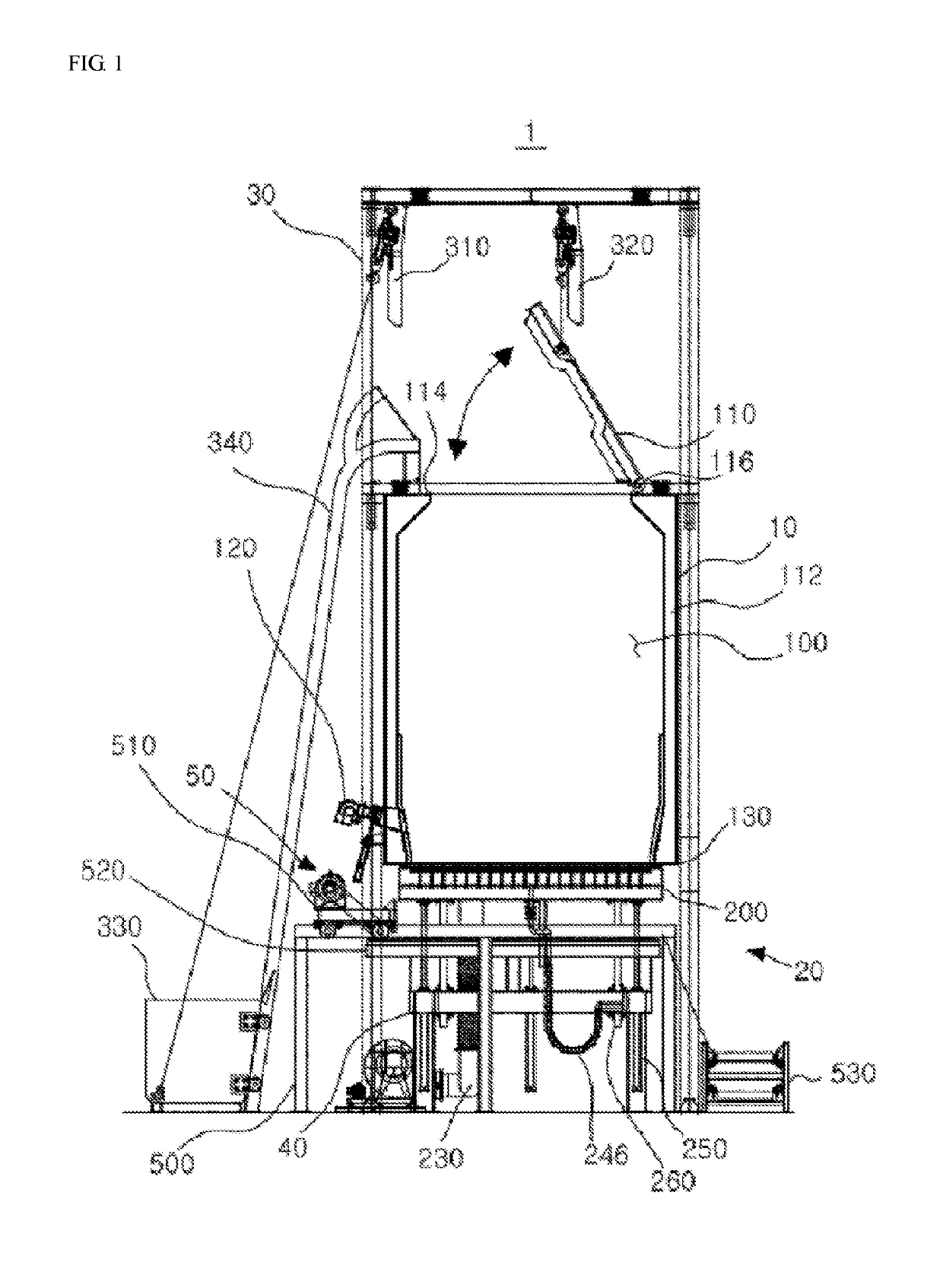

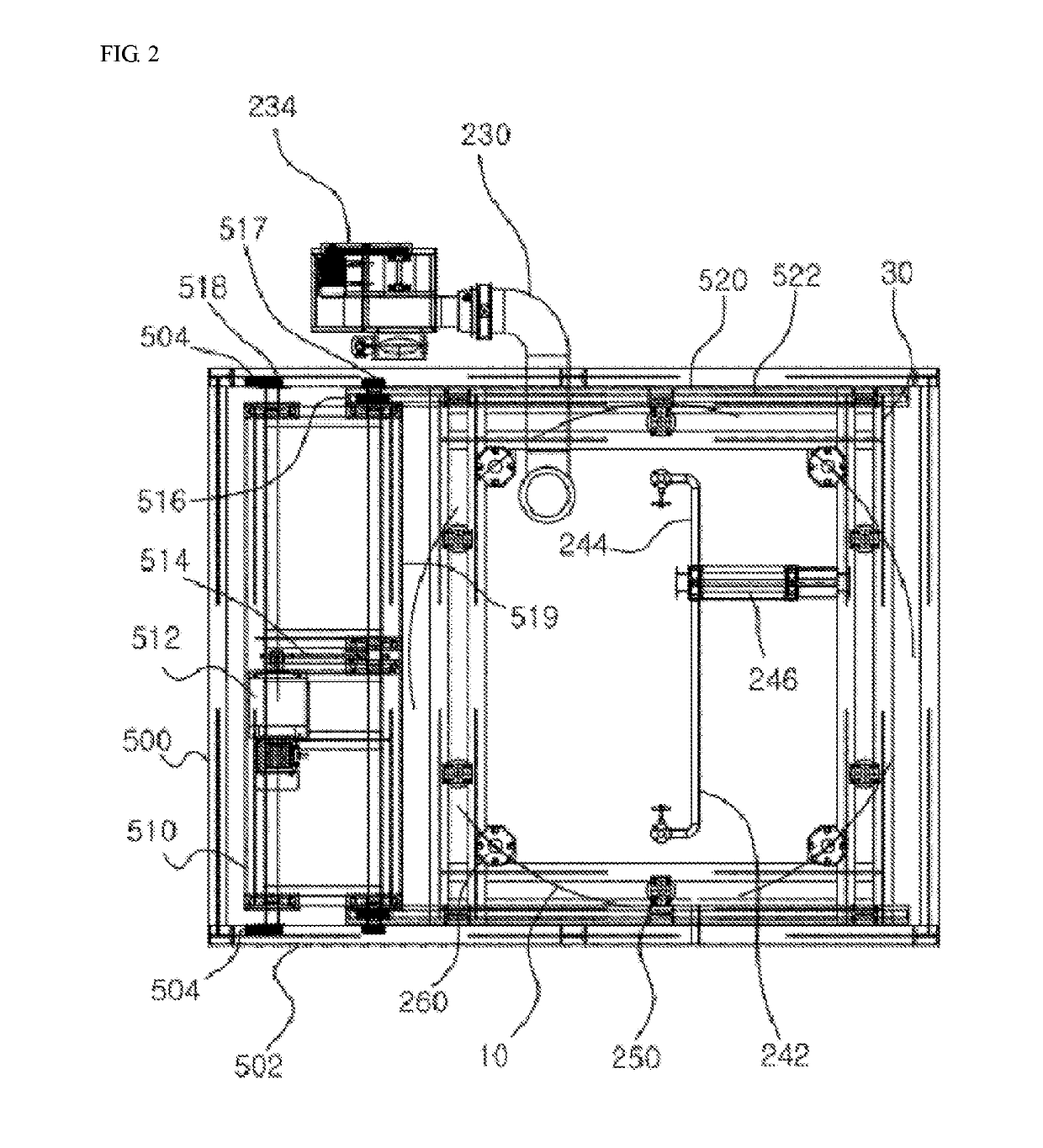

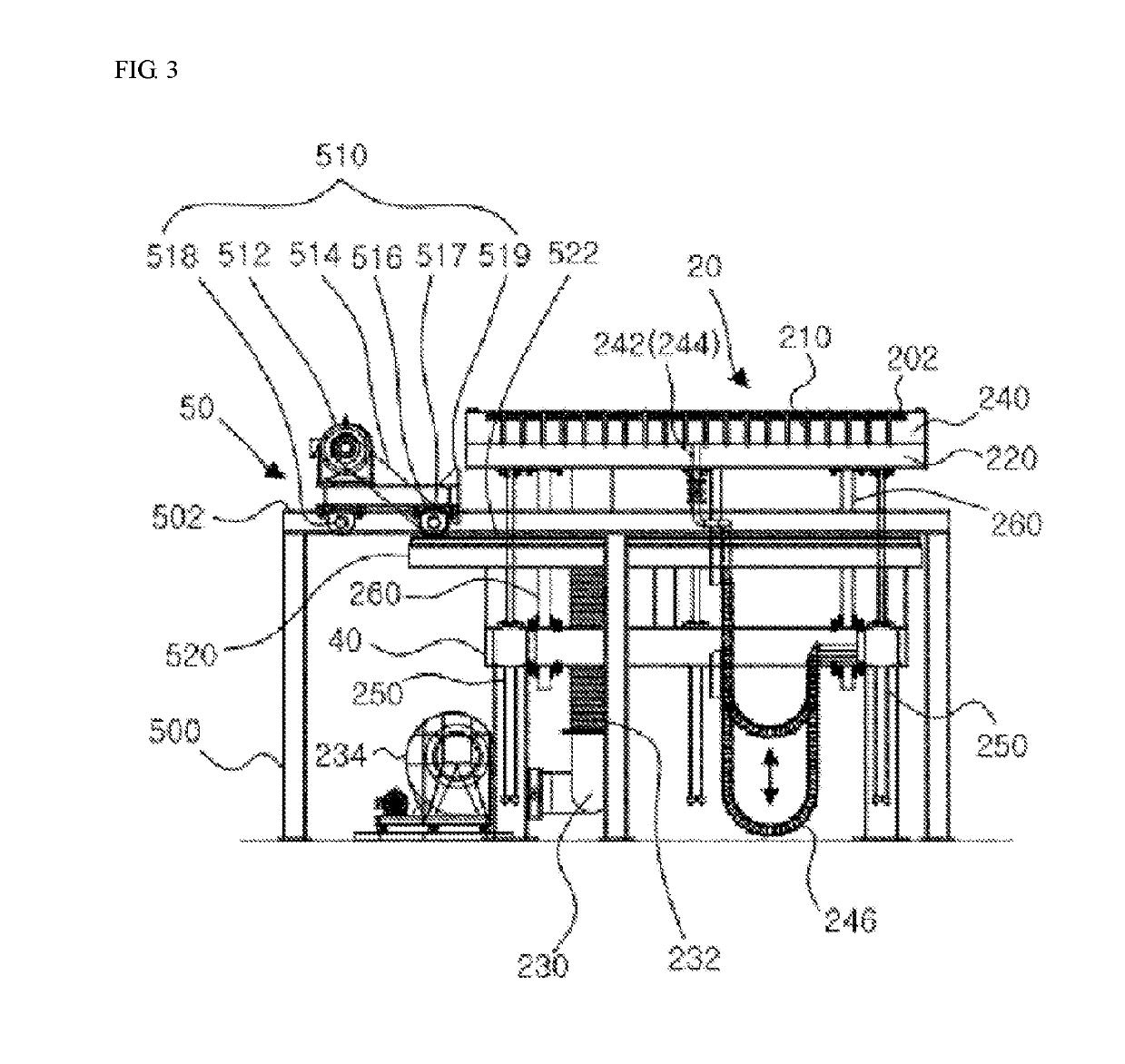

Pyrolysis gasifier comprising automatic ash processor

ActiveUS20190292472A1Shorten the timeImprove processing efficiencyGasifier mechanical detailsGasifier moving partsMechanical engineeringPyrolysis

A pyrolysis gasifier includes a tubular body configured to receive and pyrolyze a combustible waste, a bottom door disposed below the tubular body to selectively seal the tubular body, a main frame supporting the tubular body, a base frame supporting the bottom door, an automatic ash processor configured to, while traveling in one direction, push and remove ash remaining on the bottom door after pyrolysis of the combustible waste, and a guide frame supporting the automatic ash processor and configured to guide the travel of the automatic ash processor.

Owner:LIM YUNG TAEK +1

Gasification furnace built-in tar gasification circulating system

ActiveCN105482836AEmission reductionReduce pollutionGasifier mechanical detailsGasifier moving partsTarEngineering

The invention relates to a gasification furnace built-in tar gasification circulating system which comprises a feeder, a gasifier and a separation cooler which are sequentially connected, wherein the gasifier comprises a furnace body; the top of furnace body is provided with an automatic cover opening / closing mechanism; the outside of the furnace body is connected with an air intake mechanism and a cooling mechanism; the bottom of the furnace body is provided with an ash discharge mechanism; a tar gasifier is arranged above the ash discharge mechanism; the tar gasification mechanism comprises an inner liner and an outer liner; the top and bottom of the region between the inner liner and outer liner are respectively provided with a seal-structure upper cover and a bottom plate which is uniformly distributed with small holes; a gasifying agent is arranged on the bottom plate; wood charcoal generated by gasified biomass falls on the ash discharge mechanism and is accumulated in the inner liner; and the outer side of the outer liner is provided with a gas outlet pipe and the separation cooler. The gasification furnace built-in tar gasification circulating system is reasonable in design, simple to operate and convenient for maintenance, and has the advantages of high safety linkage coefficient, high automation degree, high continuous gas production capacity and high gas purity. The gasification furnace built-in tar gasification circulating system performs circulating gasification on the tar generated by the reaction, so the fume and tar emissions are low, thereby greatly lowering the environment pollution and especially air pollution.

Owner:ZHEJIANG JIUFAN NEW ENERGY TECH CO LTD

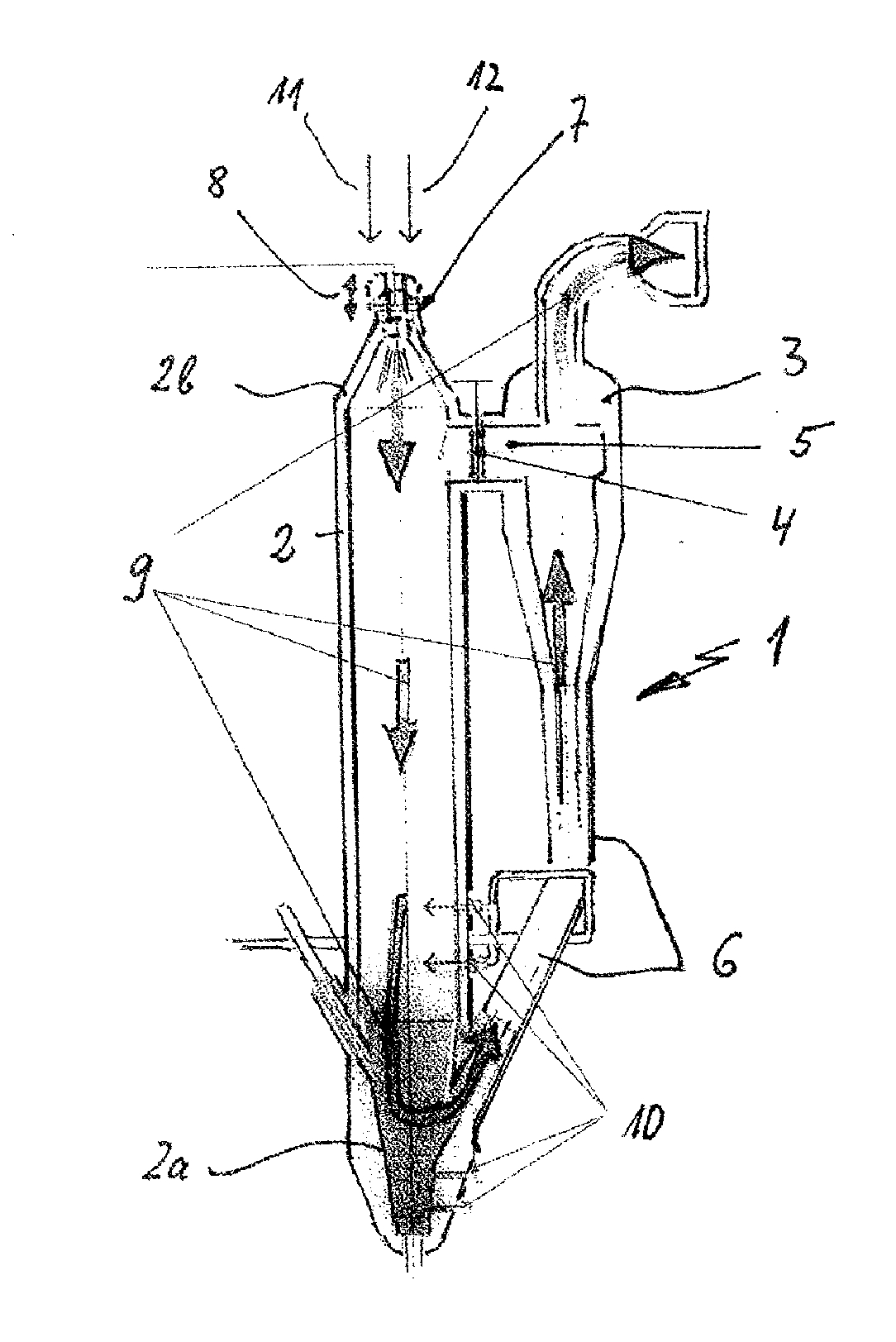

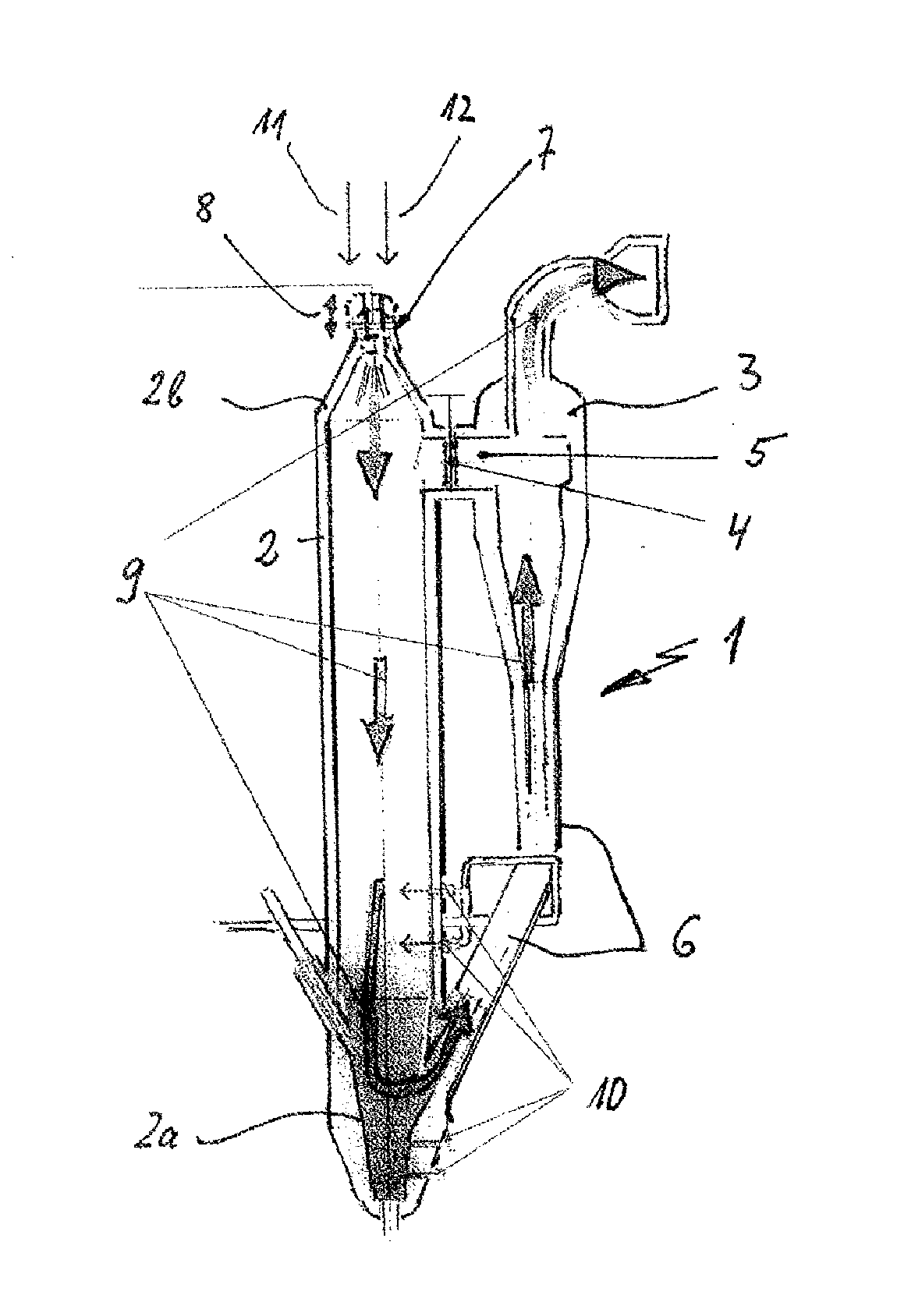

Method for heating a high temperature winkler gasifier

A method for heating a high-temperature Winkler gasifier during the start-up of the gasifier includes the use of at least one burner for heating purposes. A gasifier head of the Winkler gasifier is assigned a cyclone with a return conduit for returning the particles separated off in the cyclone into the fluidized bed in the lower region of the gasifier, by means of which method the heating of a high-temperature Winkler gasifier is simplified and made substantially independent of the structural size of the gasifier. The at least one burner, which is installed in the head region of the gasifier and which acts downward into the interior of the gasifier, allows gas flow to be generated in the reverse direction through the return conduit of the cyclone.

Owner:THYSSENKRUPP IND SOLUTIONS AG

Gasifier Having a Slag Breaker and Method of Operating the Same

InactiveUS20140352214A1Excessive removalEasy to disassembleHydrogenGasifier moving partsCombustionSlag

A gasifier comprises an internal chamber, a slag collection region, a slag passageway, a slag breaker, and an actuator. The internal chamber comprises a main combustion region that is configured and adapted to gasify fuel. The slag collection region is located beneath the main combustion region. The slag passageway operatively connects the main combustion region to the slag collection region. The slag breaker comprises a face that is movable relative to the internal chamber. The face is configured and adapted to move within the slag passageway in a manner such that the face contacts and mechanically breaks solidified slag into chunks of solidified slag that then fall into the slag collection region. The actuator is connected to the slag breaker and is configured and adapted to move the face of the slag breaker.

Owner:TRUSTEES OF THE ALICE ANHEUSER BEIMS MOORE IRREVOCABLE TRUST 1 & THE ALICE ANHEUSER BEIMS MOORE IRREVOCALBE TRUST 2 FBO GRANDCHILDREN

Gasification furnace baking device capable of automatically adjusting temperature

ActiveCN114752419AEven contactAvoid breakingGasifier moving partsCombustible gas productionTemperature controlAutomatic control

The invention discloses a gasifier baking device capable of automatically adjusting temperature, and belongs to the technical field of coal gasifiers. The gasification furnace baking device capable of automatically adjusting the temperature comprises a gasification furnace and a baking furnace assembly, the gasification furnace comprises a furnace wall, a coal inlet is formed in the top end of the furnace wall, a coal gas outlet is formed in the side face of the top of the furnace wall, and a cooling layer is arranged on the outer side of the bottom of the furnace wall. The oven assembly comprises an oven feeding device, a temperature detection device and an automatic control valve, the oven feeding device is detachably installed in the coal inlet, the automatic control valve is detachably installed at the end, away from the oven wall, of the coal gas outlet, and the temperature detection device is installed on the outer side of the middle of the oven wall; and the temperature detection device is connected with the automatic control valve through a heat-resistant hose. According to the invention, the problems that the internal temperature of the gasification furnace is difficult to keep equivalent and the temperature control precision of the baking furnace is not enough in the baking furnace device on the market at present are effectively solved.

Owner:ANHUI UNIV OF SCI & TECH

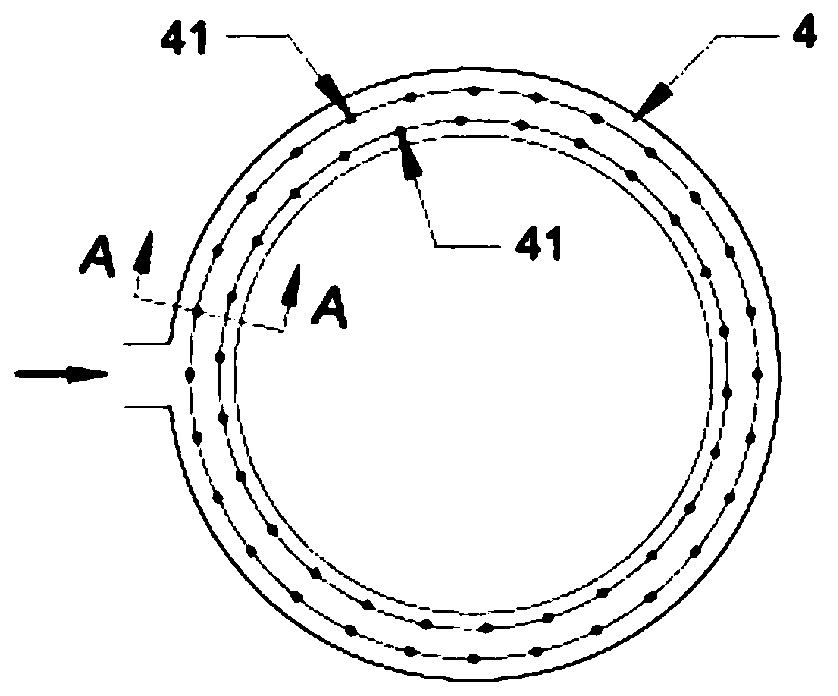

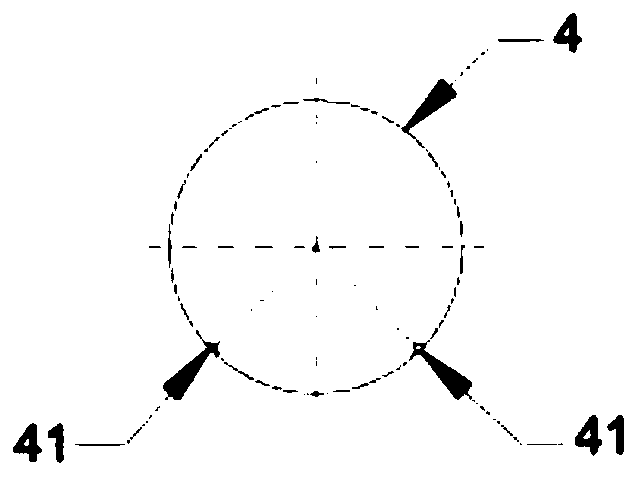

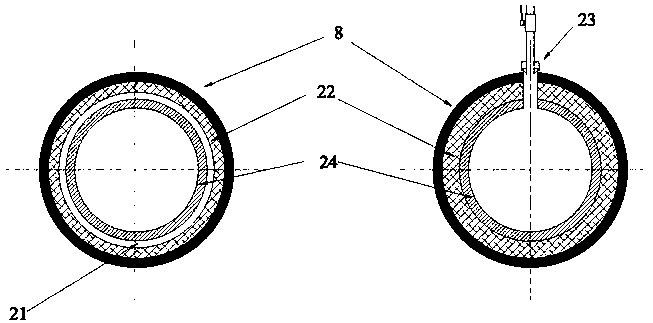

Vertical vibration superconducting pyrogasification furnace for garbage

InactiveCN109423340ALarge capacity reductionHigh pyrolysis gasification efficiencyGasifier moving partsGasification processes detailsVertical vibrationRadiant heat

The invention relates to a vertical vibration superconducting pyrogasification furnace for garbage. The vertical vibration superconducting pyrogasification furnace is composed of three parts, i.e., adouble-layered tube furnace body, a furnace body vibrator and a burner. The vertical vibration superconducting pyrogasification furnace is characterized in that the double-layered tube furnace body iscomposed of two layers of a circular tube and a double-layer circular head, and the two layers of the circular tube communicate with the double-layer circular head to form a cup-shaped superconductor; the inner tube wall of the cup-shaped superconductor is provided with heat-dissipating fins, and the outer tube wall of the cup-shaped superconductor is wrapped by a high-temperature-resistant heat-insulating layer; the double-layer circular head is filled with a high-temperature superconductive working medium; the burner is placed in the part, located at the lower part of the double-layer circular head, of a furnace base; the furnace body vibrator is arranged at the lower part of the furnace base; and a furnace cover is provided with a feeding tube equipped with a valve and a water injection nozzle. The burner uses gas produced by the garbage pyrogasification furnace for heating at the lower part of the exterior of the furnace body, and generated radiant heat can be rapidly and uniformly transmitted to garbage in the furnace body via the cup-shaped superconductor and a chimney, thereby completing high-efficiency pyrogasification of the garbage. The garbage reaction zone of the pyrogasification furnace has high temperature and good homoiothermic properties, so the dangers of bonding, bulging, block-forming and coking of garbage caused by local overheating in conventional single-layer cracking furnaces are avoided, the release of harmful cracked substances is shielded, the generation of dioxin is suppressed, and gas production efficiency is high; and solid residues produced after cracking can be used as a chemical raw material for manufacturing of active carbon, and comprehensive economic benefits are significantly improved.

Owner:西安美润环保工程技术有限公司 +1

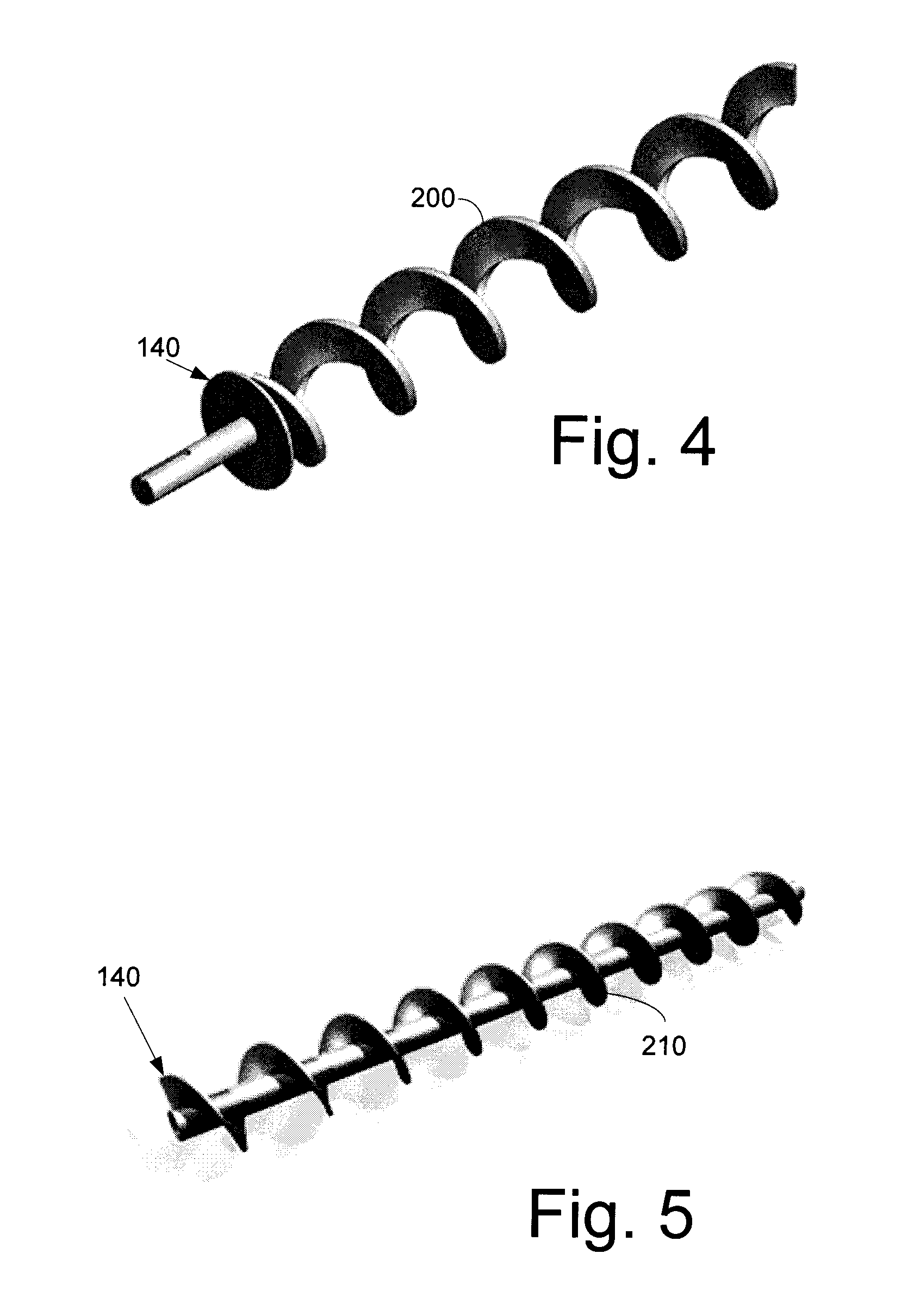

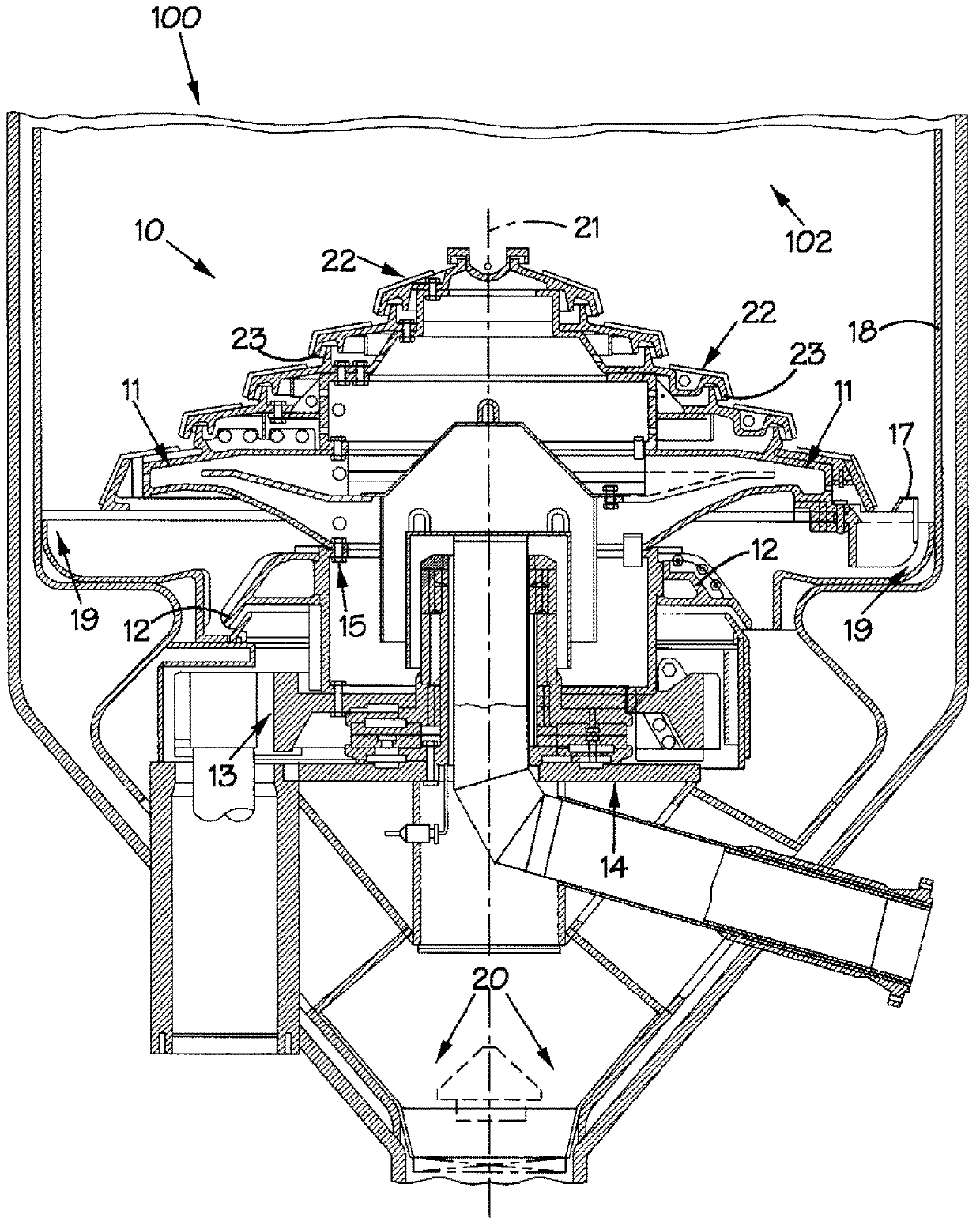

Gasifier

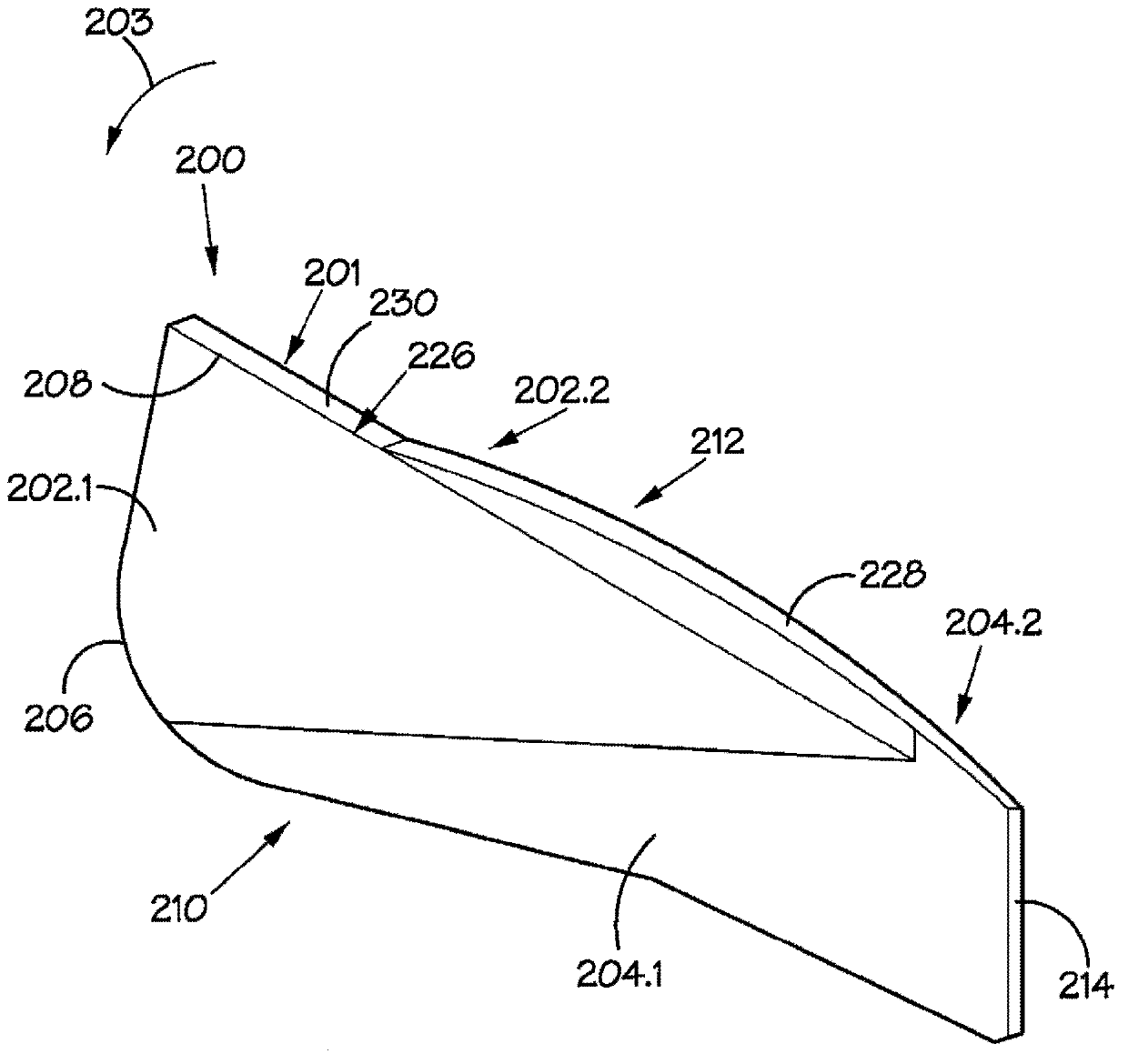

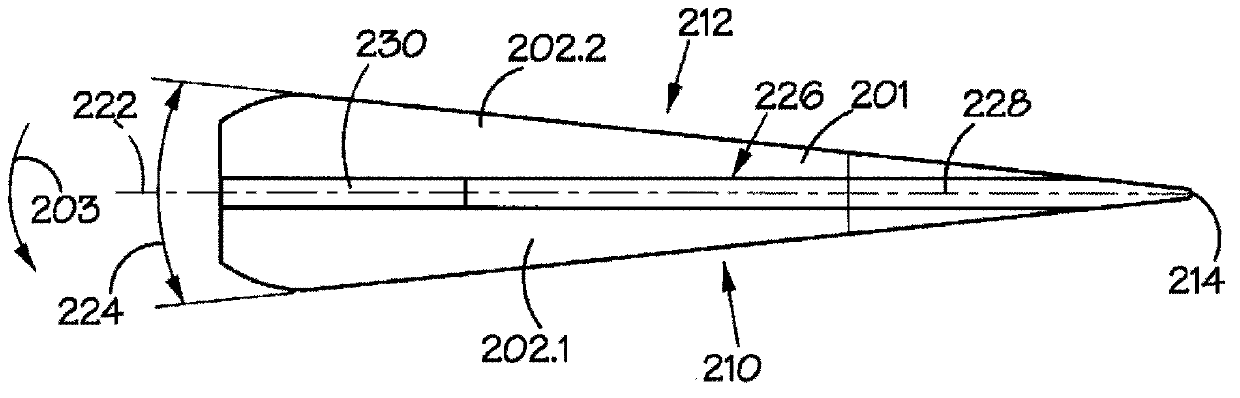

Agasifier.A solids handling equipment rotary plough (200) includes an elongate metal body (201) with a leading face (210) and a trailing face (212). The body (201) is configured to be mounted to a rotary component for rotation about an axis of rotation at least in one direction which is an operative forward direction such that the leading face (210) leads the trailing face (212). At least the leading face (210) has at least two major operatively upwardly and outwardly extending surfaces (202.1, 204.1) which are not coplanar. A first major surface (202.1) is angled operatively rearwardly and upwardly relative to the forward direction of rotation at an angle of at least 1 DEG to the vertical. A second major surface (204.1) is angled operatively forwardly and outwardly at an angle of at least 1 DEG relative to a radius of a circle described in use by the rotary plough (200) when rotating in the operative forward direction.

Owner:SASOL TEKHNOLODZHI PROPRIEHJTEHRI LTD

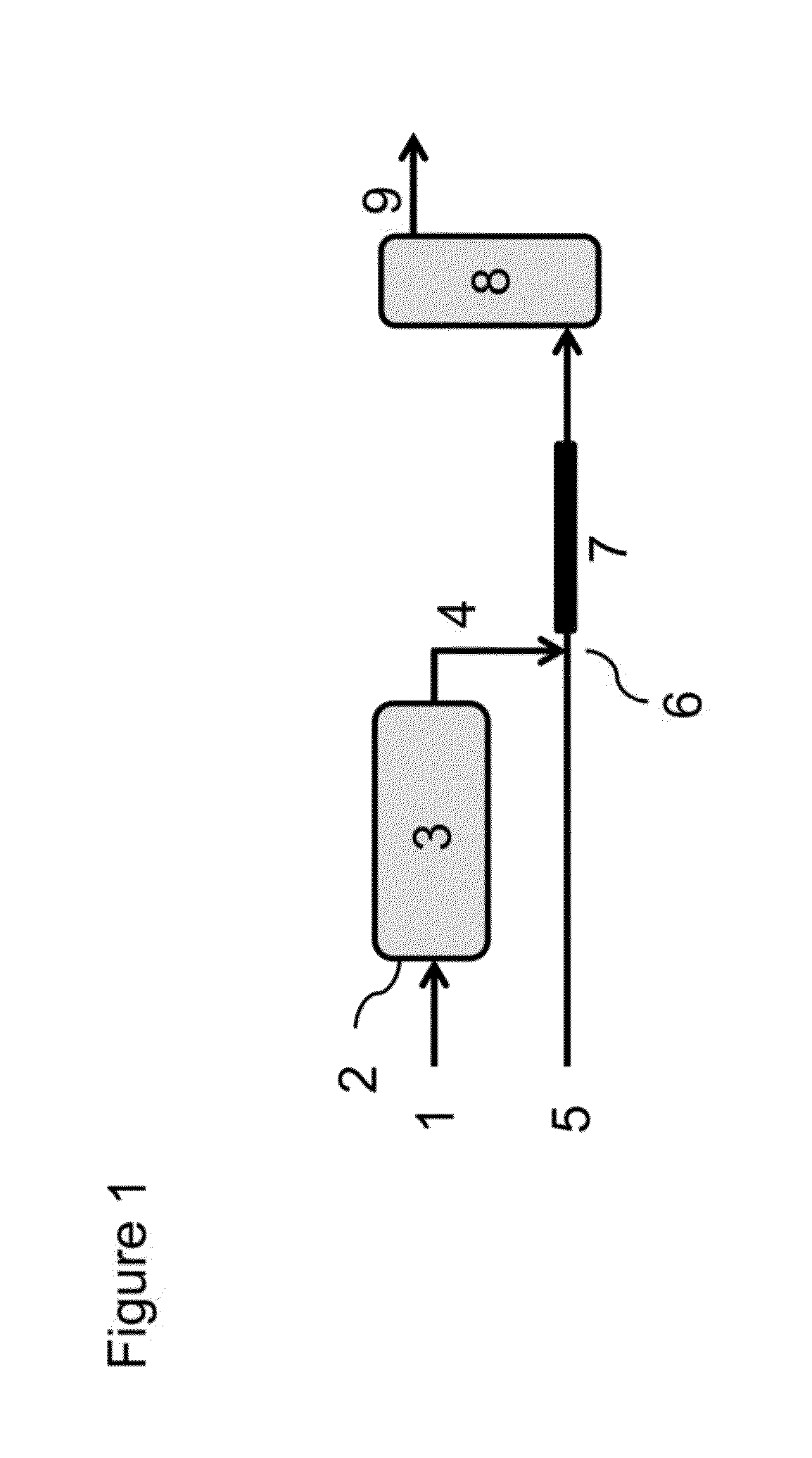

Systems for pyrolysis vapor upgrading

InactiveUS20150071836A1Improve responseGasification catalystsGasifier moving partsOrganic matterAmount of substance

This disclosure relates to systems for the fast pyrolysis of organic matter. More specifically, it relates to systems for the catalytic modification of vapors created during the fast pyrolysis of organic matter to create transportation fuel or a transportation fuel component. The inventive systems either catalytically stabilize or convert at least a first portion of pyrolysis vapors, then combine them with a portion of raw, unconverted bio-derived pyrolysis vapors at a temperature and pressure sufficient for molecules of the combined vapors to react and produce hydrocarbons of increased molecular weight that are suitable for use as a hydrocarbon transportation fuel or component thereof.

Owner:PHILLIPS 66 CO

Biomass gasifier with disruption device

Owner:AIR PROD & CHEM INC

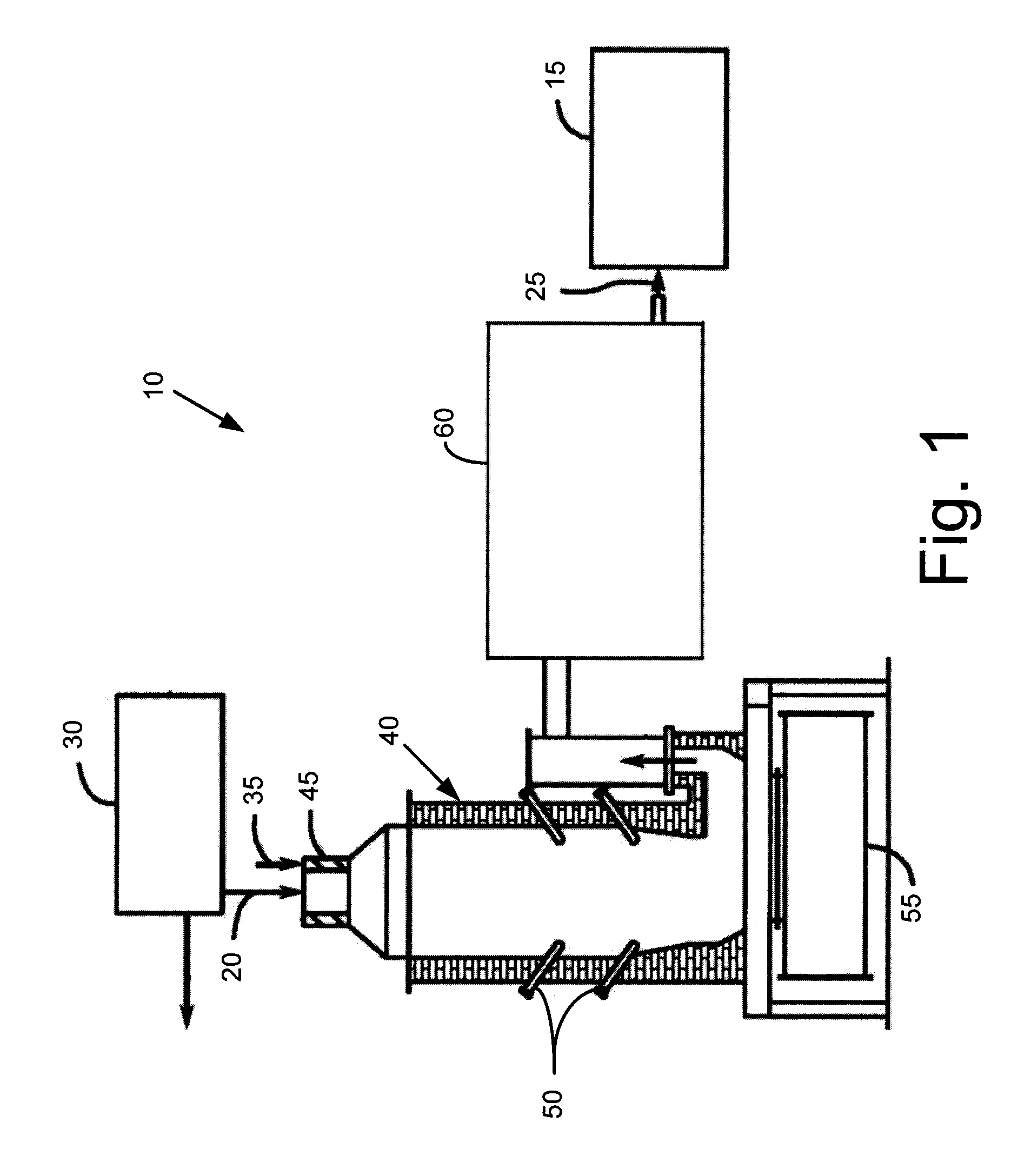

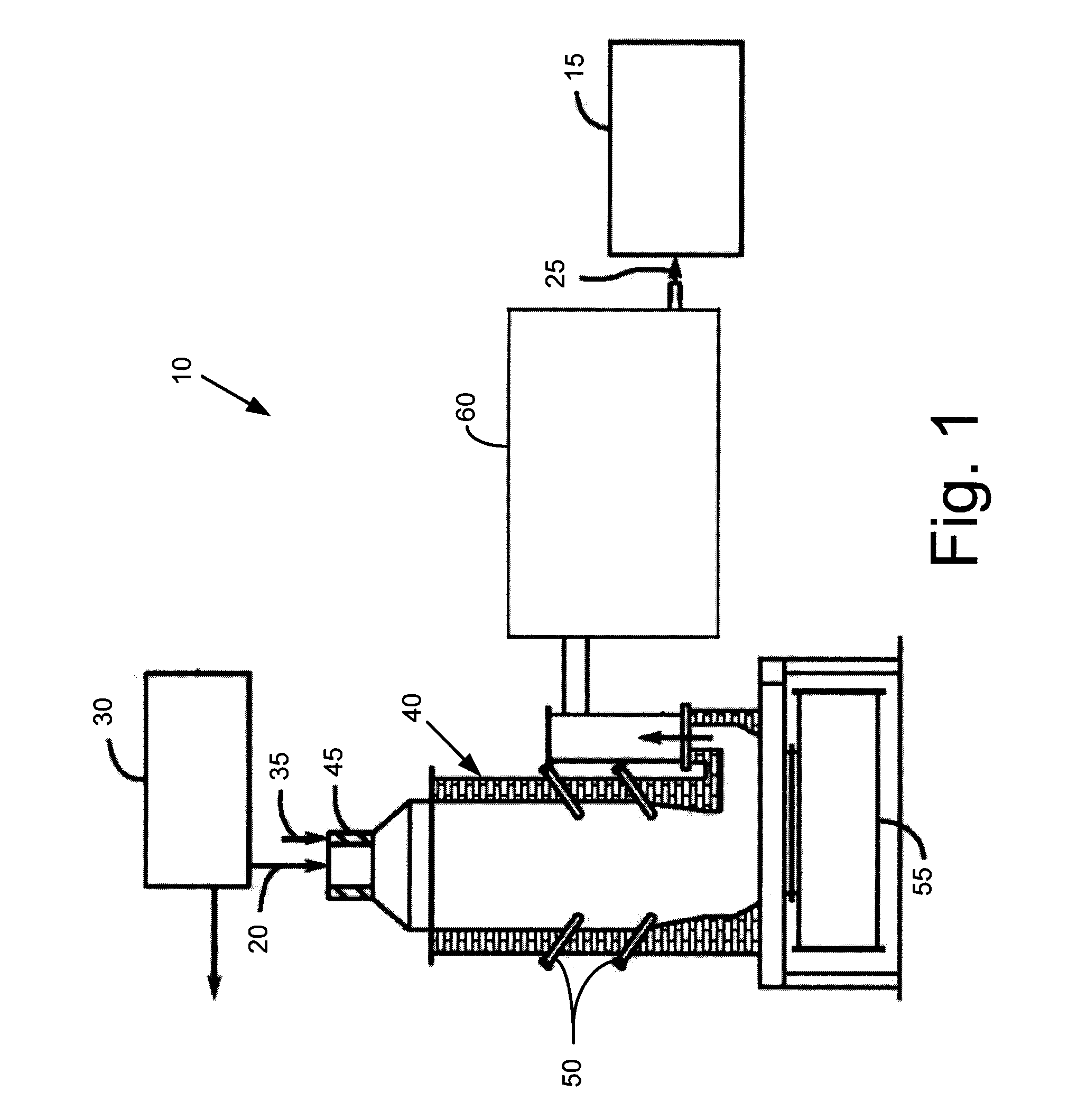

Continuously operable mechanical or electrical power source fueled by gas or solid fuel including gas from improved biomass downdraft gasifier

Owner:CHAGNOT CATHERINE J

Continuously operable mechanical or electrical power source fueled by gas or solid fuel including gas from improved biomass downdraft gasifier

The invention includes a downdraft gasifier having a rotatable auger / grate extending through its reduction zone. The auger at times moves biofuel through the gasifier and at times supports it in the gasifier. A frusto-conical biomass grate funnels biomass onto the auger and is perforate for permitting the passage of gases while retaining the biomass. A guide tube surrounds the auger below the frusto-conical biomass grate. The invention also includes mixing gas or solid particulate fuel in a conduit segment that houses a mixing chamber. Fuel is fed through a fuel inlet port into the mixing chamber. High velocity combustion air from a blower is forced into the mixing chamber through a restricted orifice that generates a suction pressure for drawing gas or solid particulate fuel into the mixing chamber. A combustion chamber supply conduit delivers fuel from the mixing chamber into a burner.

Owner:CHAGNOT CATHERINE J

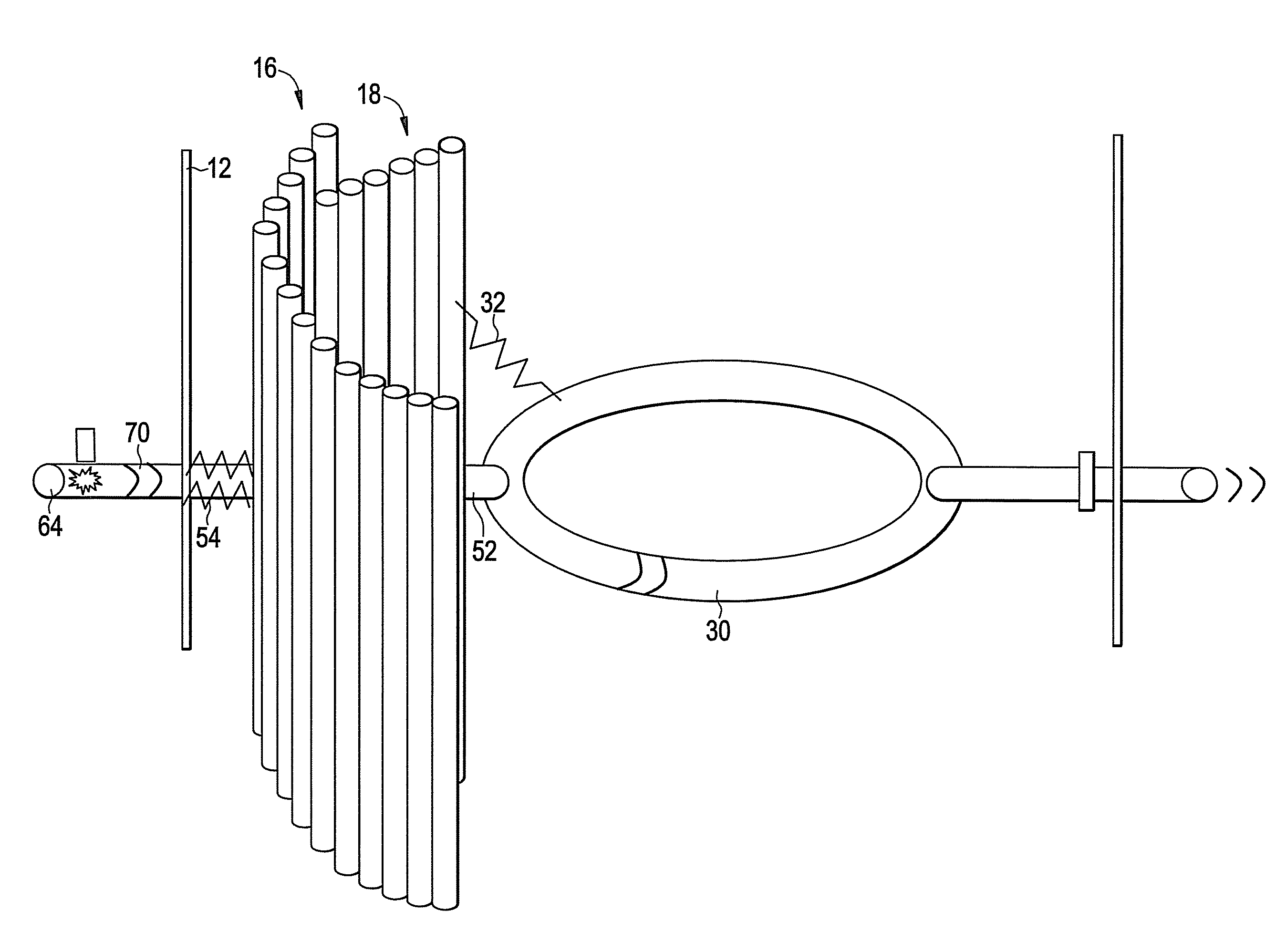

Method and apparatus of particulate removal from gasifier components

Disclosed is a method of removing a particulate layer from a gasification system component including locating a shedding apparatus in operable communication with the gasification system component. A force is transmitted from the shedding apparatus into the gasification system component and the particulate layer is shed from the gasification system component as a result of the force. Further disclosed is a syngas cooler for a gasification system including a vessel and a plurality of thermal energy transfer platens located in the vessel. A shedding apparatus is in operable communication with the plurality of platens and is capable of shedding a particulate layer from the plurality of platens by transmitting a force to the plurality of platens. The apparatus includes a manifold disposed between the shedding apparatus and the plurality of platens and connected to the plurality of platens via one or more struts capable of distributing the force to the plurality of platens.

Owner:AIR PROD & CHEM INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com