Method and apparatus of particulate removal from gasifier components

A technology of particulate matter and components, applied in the field of gasification systems and processes, can solve problems such as blockage of downstream components and dangers of syngas coolers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

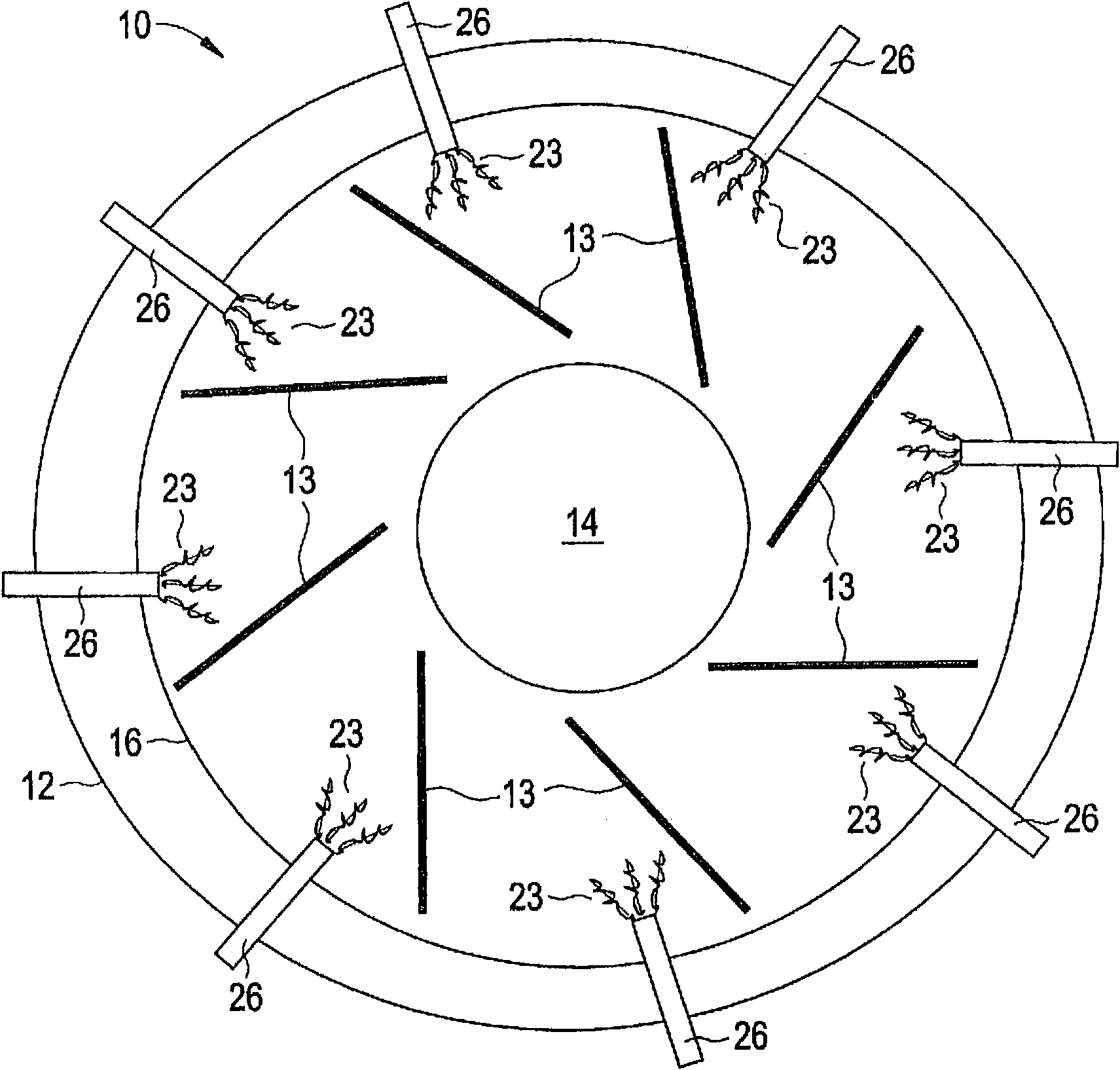

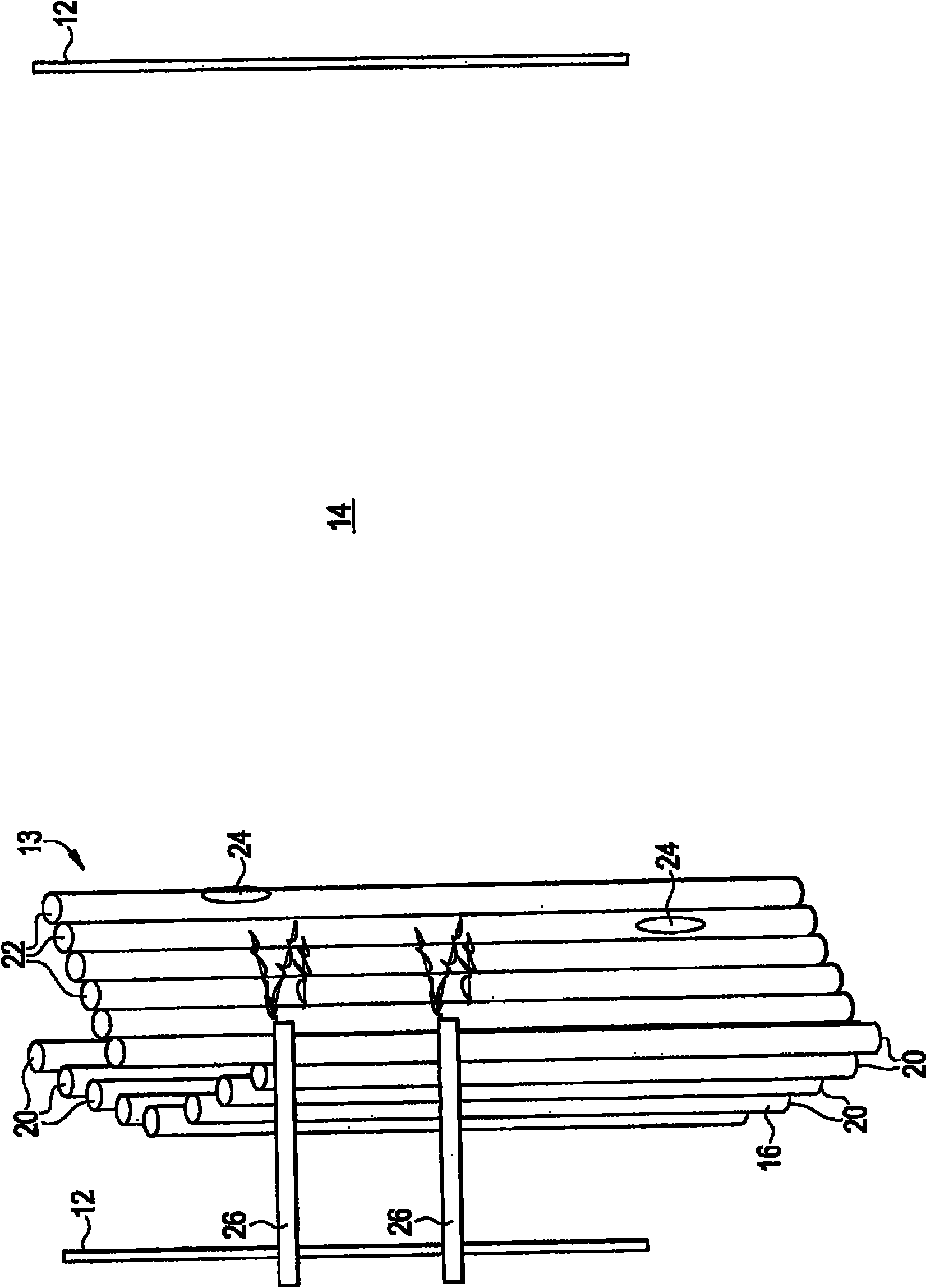

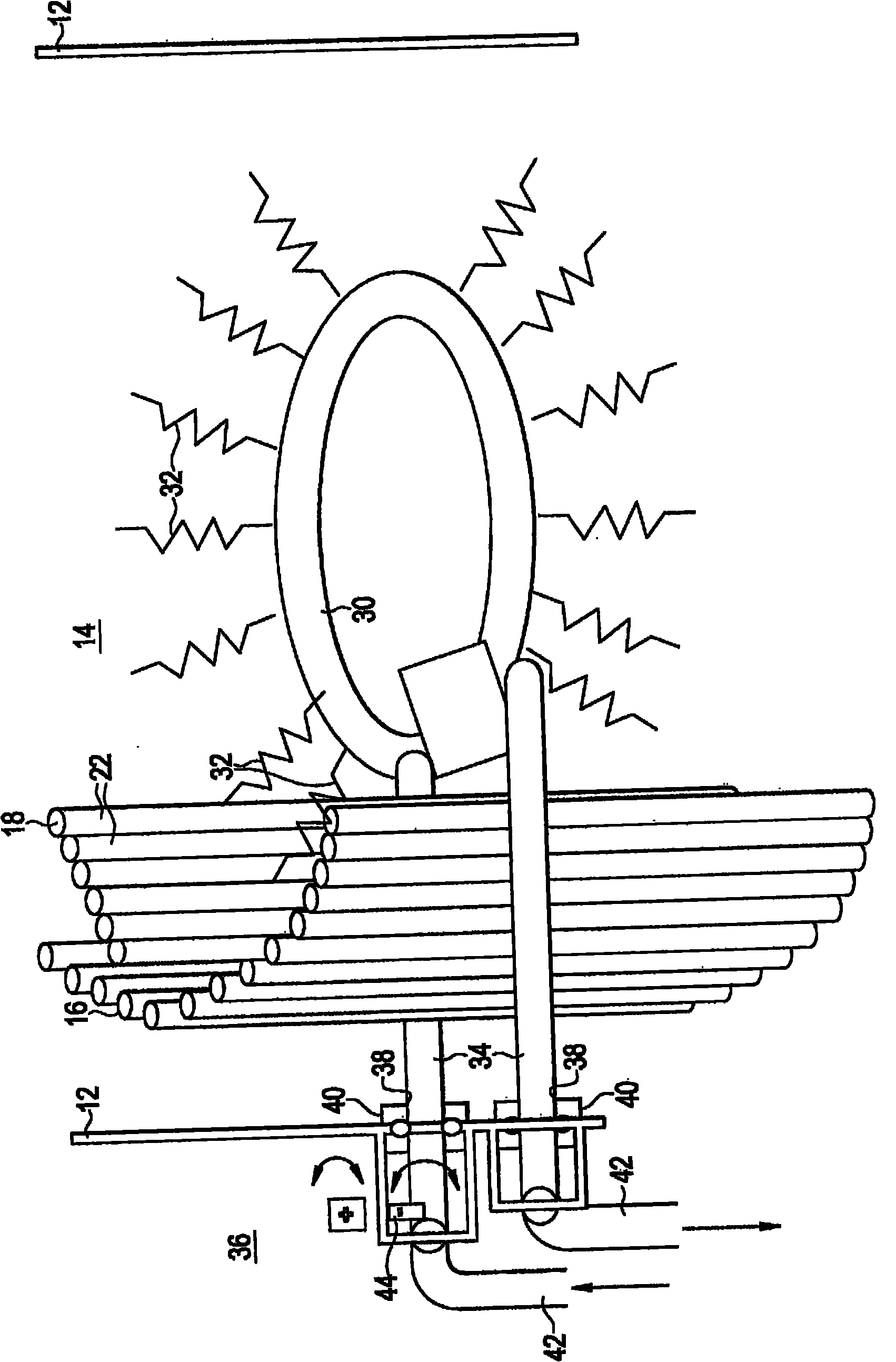

[0025] figure 1 Shown is one embodiment of a gasification system component, in this example a syngas cooler 10 . The syngas cooler 10 includes a vessel shell 12 that defines an outer surface of the syngas cooler 10 . A number of internal components may be disposed inside the vessel shell 12 within the interior 14 of the syngas cooler 10 . Some of these components, including the tube cage 16 and one or more sets of screens 18 , are constructed and arranged to facilitate the transfer of thermal energy from the syngas in the syngas cooler 10 to the tube cage 16 and / or the screens 18 . Although figure 1 Eight sets of screens 18 are shown in , but it should be understood that other numbers of sets of screens 18 may be provided in the interior 14 of the syngas cooler 10 , such as 10 or 12 sets of screens 18 . Such as figure 2 As shown in , the tube cage 16 includes a plurality of individual cage tubes 20 and each set of screens 18 includes a plurality of screen tubes 22 . Duri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com