Grading pyrolysis and gasification and high-temperature tar removal and dust removal integrated process for biomass circulating fluidized bed

一种循环流化床、热解气化的技术,应用在气化工艺、可燃气体化学改性、化学工业等方向,能够解决催化剂积碳失活、规模小、增加运行成本和投资等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

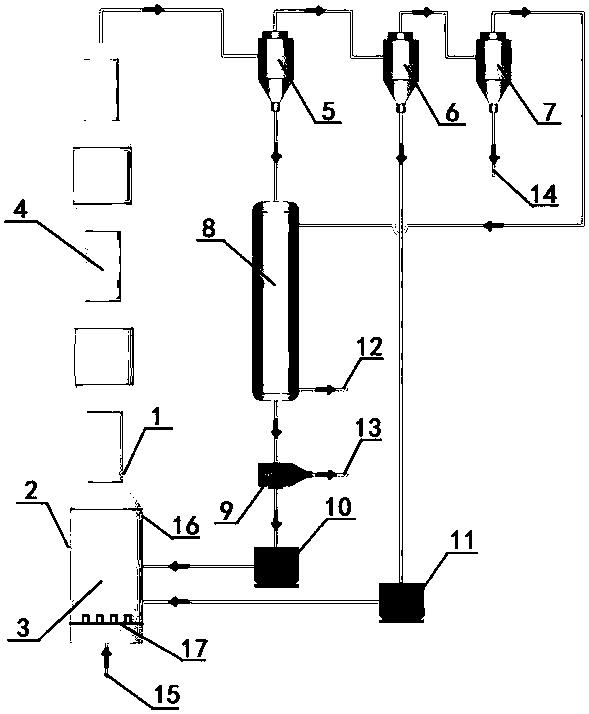

[0014] Embodiment, the biomass particle that is less than 5mm is sent into the middle and lower part of the carrying fluidized bed (4) in the upper part of the circulating fluidized bed (16) through the biomass particle inlet (1), and a small amount of supplementary heat carrier less than 5mm is added from Heat carrier inlet (2) to the lower part of the turbulent fluidized bed (3) of the circulating fluidized bed (16); Mixing, heating, high-temperature rapid hydrogen pyrolysis reaction, and high-speed carrying up; cracked oil and gas in the middle and upper part of the fluidized bed (4) at 700-900 ° C, the gas-phase hydrogen carrier and semi-coke synergistic catalytic cracking reaction, tar Cracking into low-molecular gaseous hydrocarbons such as methane and ethane; after the reaction, the heat carrier, semi-coke and high-temperature gas undergo four-stage gas-solid separation, and the large particle carrier and semi-coke separated by the first-stage gas-solid separator (5) are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com