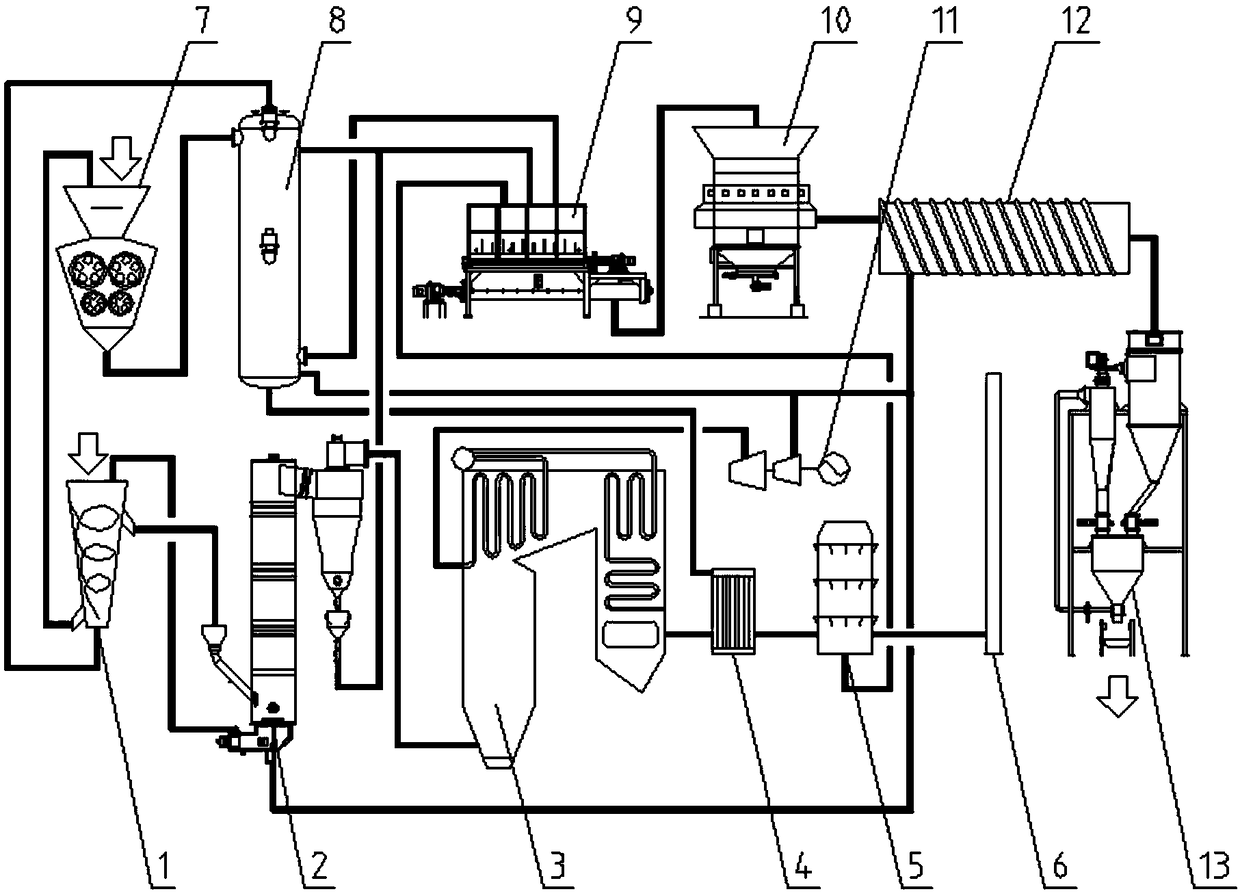

Cyclic utilization device and method for preparing carbon-based organic fertilizer by carbonizing fluidized bed biomass

A technology of biomass charcoal and carbonization equipment, which is applied to the treatment of biological organic parts, fertilizers made of biological waste, steam generation methods using pressure combustion, etc., and can solve high power consumption, fuel consumption, large material and energy waste, etc. problems, to achieve good thermal insulation, efficient utilization, and improve fermentation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] After sorting the biomass straw, the biomass with a moisture content of ~18% is sent to the fluidized bed carbonization device. The straw and organic matter with a moisture content of ~42% mainly include 10% chicken manure, 12% pig manure, 17% cow manure, 5% sewage Mud, 27% rotten fruits and vegetables, 15% cassava residue, 2% sugar residue are mixed together, crushed and added with microorganisms, pretreated and sent to a fermentation device for fermentation.

[0043] The working temperature in the fluidized bed carbonization device is controlled at 400°C to carbonize the straw, and the fermentation gas CH is fed into the fluidized bed carbonization device. 4 Content ~ 60%, H 2 The content is ~2%, and the ratio (volume ratio) of low-parameter steam to fermentation gas is 1:6. The carbon content of straw charcoal produced by the reaction is ~63%, and the calorific value of straw gas is ~1620Kcal / Nm 3 (air vaporization calorific value 3 ).

[0044] The straw gas is se...

Embodiment 2

[0047] Biomass bamboo chips are sorted and the biomass with a moisture content of 12-30% is sent to the fluidized bed carbonization device. The bamboo chips and organic matter with a moisture content of 30-56% mainly include 20% pig manure, 12% rabbit manure, and 35% human manure , 6% edible fungus residue, 15% distiller's grains, and 2% furfural residue are mixed together, crushed and added with microorganisms, and sent to a fermentation device for fermentation after pretreatment.

[0048] The working temperature in the fluidized bed carbonization device is controlled at 610°C to carbonize the bamboo chips, and the fermentation gas CH is passed into the fluidized bed carbonization device. 4 Content ~ 35%, H 2 The content is ~1%, and at the same time, the ratio (volume ratio) of low-parameter steam to fermentation gas is 1:15. The carbon content of bamboo chip charcoal produced by the reaction is ~81%, and the calorific value of bamboo chip gas is ~1520Kcal / Nm 3 (air vaporiz...

Embodiment 3

[0052] The biomass sawdust is sorted and the biomass with a moisture content of 21-30% is sent to the fluidized bed carbonization device. The wood chips and organic matter with a moisture content of 30-37% mainly include 3% sheep manure, 7% horse manure, 27% swill, 10% Moldy feed, 7% medicine dregs, and 8% soy sauce dregs are mixed together, crushed and added with microorganisms, and sent to a fermentation device for fermentation after pretreatment.

[0053] The working temperature in the fluidized bed carbonization device is controlled at 700°C to carbonize the sawdust, and the fermentation gas CH is passed into the fluidized bed carbonization device. 4 Content ~ 1%, H 2 The content is ~0.6%, and the ratio (volume ratio) of low-parameter steam to fermentation gas is 1:10. The carbon content of sawdust charcoal produced by the reaction is ~83%, and the calorific value of wood chip gas is ~1220Kcal / Nm 3 (air vaporization calorific value 3 ).

[0054] Sawdust gas is sent to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com