Inner spiral multi-condition electromagnetic heating biomass efficient pyrolysis and gasification furnace

A technology of pyrolysis and gasification with multiple conditions, applied in the direction of gasification process, details of gasification device, moving parts of gasifier, etc., can solve problems such as low energy utilization rate, easy aging of resistance wire, low heating efficiency, etc., and achieve Light weight, easy heating rate, high heating efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] For the convenience of description, the following is a detailed description of the internal spiral multi-condition electromagnetic heating biomass high-efficiency pyrolysis gasifier with reference to the accompanying drawings.

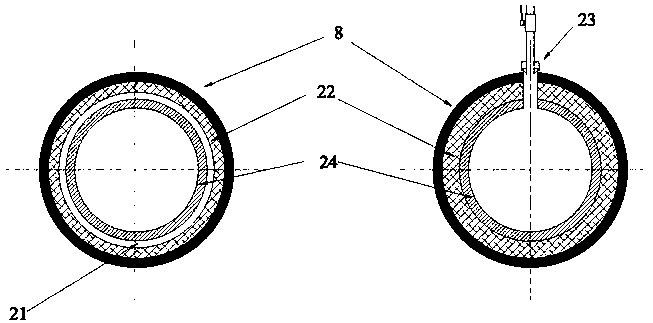

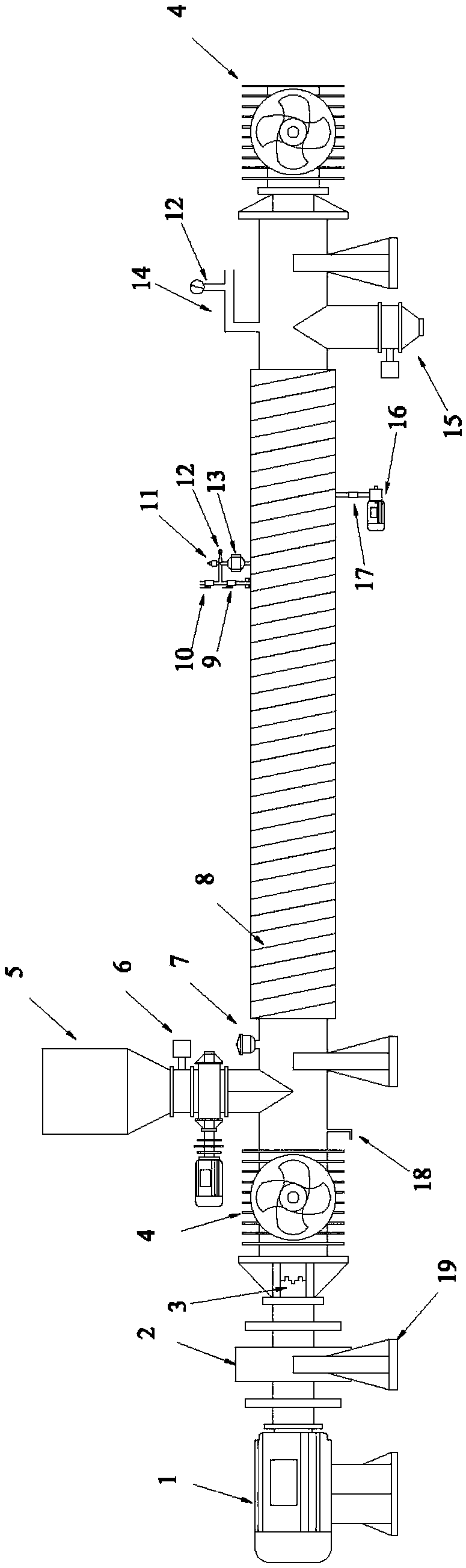

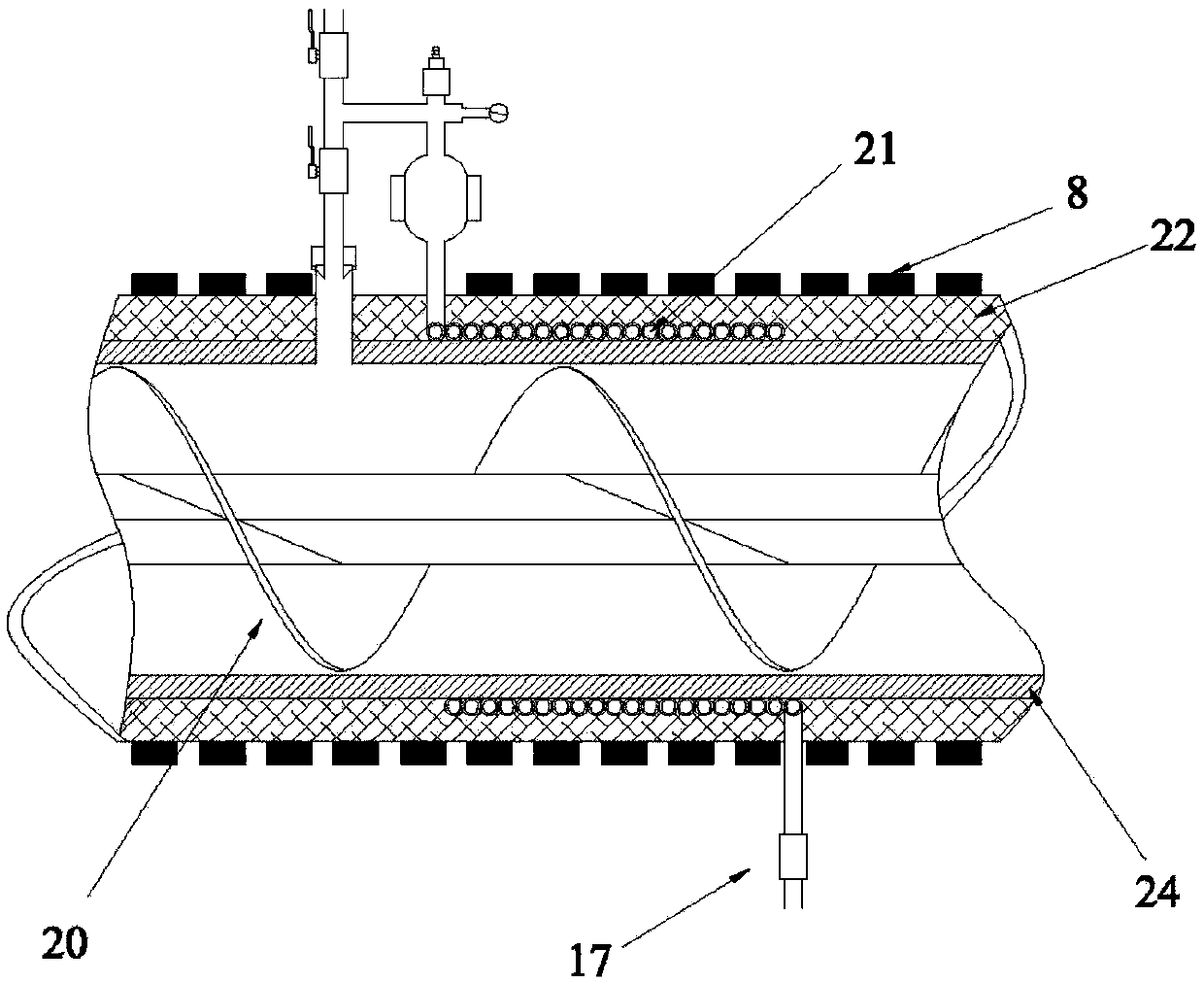

[0022] Such as Figure 1 to Figure 3 As shown in , an internal spiral multi-condition electromagnetic heating biomass high-efficiency pyrolysis gasifier, the furnace body uses a national standard seamless steel pipe as the cylinder 24, and flanges are installed at both ends of the cylinder. The feeding screw 20 inside the cylinder body is fixed between the flanges at both ends of the cylinder body through the sealed bearings at both ends. The front end of the furnace body is a transmission device, the frequency conversion speed regulating motor 1 is directly connected with the reducer 2, and a coupling 3 is connected between the reducer 2 and the feeding screw 20. The structure of the furnace heating chamber is as follows: figure 2 , 3 As sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com