Gasification furnace baking device capable of automatically adjusting temperature

A technology of automatic adjustment and temperature detection device, which is applied in the field of coal gasification furnace, can solve the problems of equal internal temperature of gasification furnace and insufficient accuracy of oven temperature control, etc., and achieve the effect of quick installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

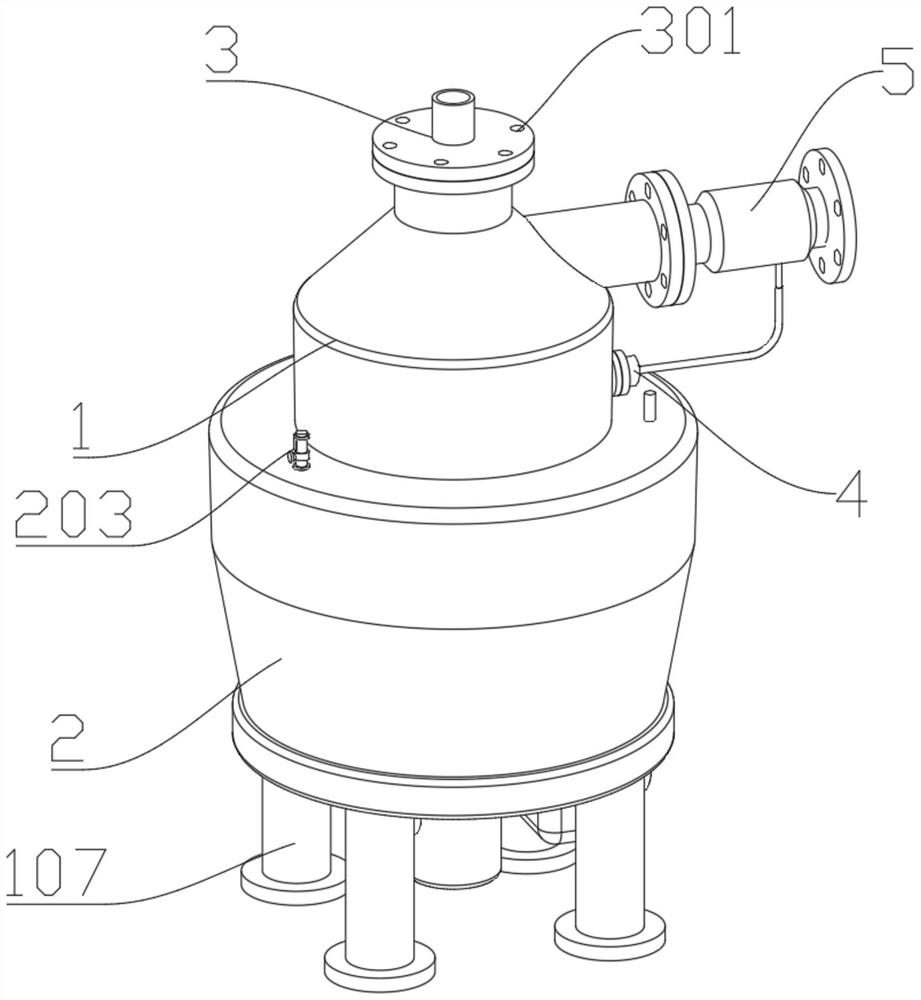

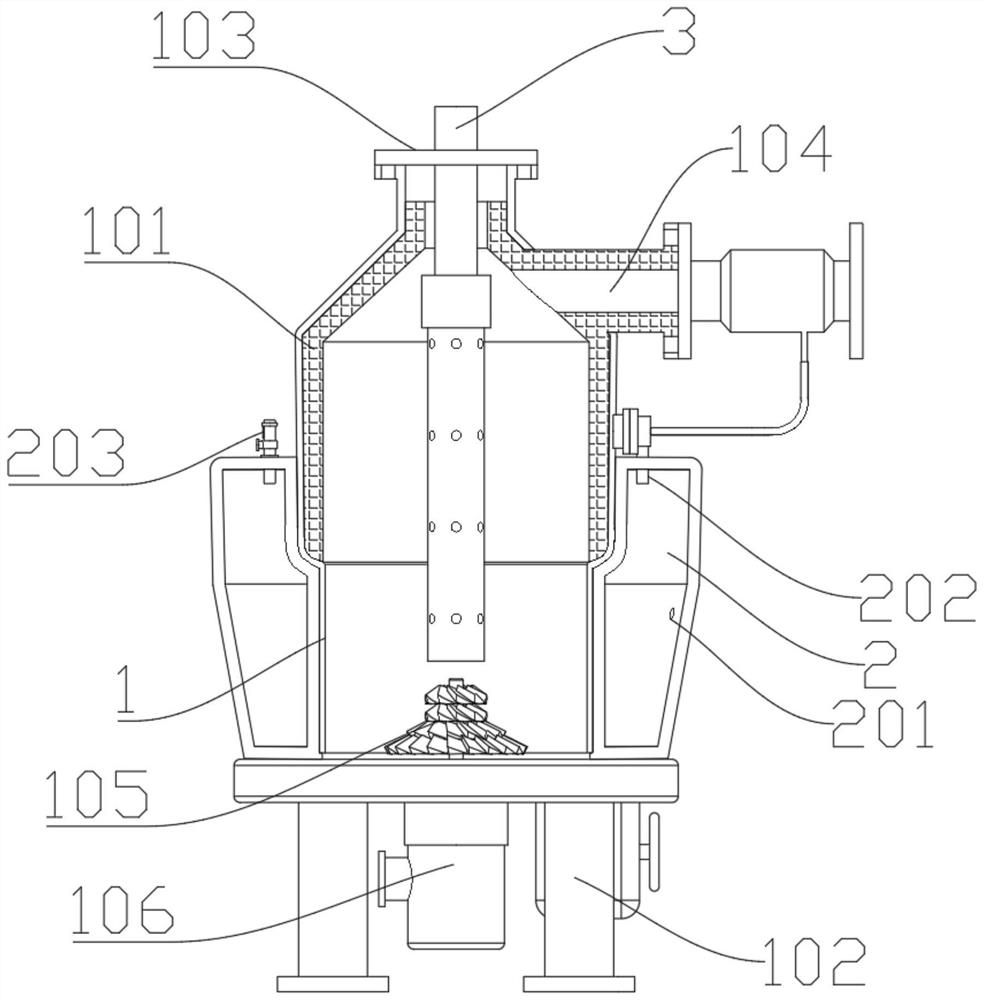

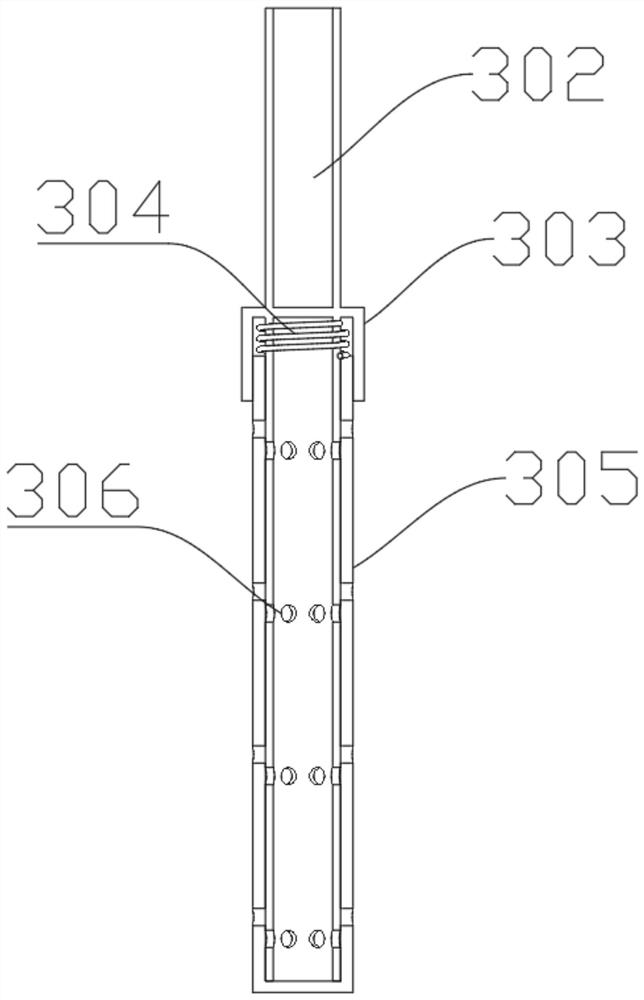

[0035] Please refer to Figures 1-3, a gasifier oven device for automatic temperature adjustment, including a gasifier 1 and oven components, the gasifier 1 includes a furnace wall 101, and the top of the furnace wall 101 is provided with a coal inlet 103 , the top side of the furnace wall 101 is provided with a gas outlet 104, the bottom outer side of the furnace wall 101 is provided with a cooling layer 2, and the oven assembly includes an oven feeding device 3, a temperature detection device 4 and an automatic control valve 5, and the oven feeding device 3 It is detachably installed inside the coal inlet 103, the automatic control valve 5 is detachably installed at the end of the gas outlet 104 away from the furnace wall 101, the temperature detection device 4 is installed on the outside of the middle of the furnace wall 101, and the temperature detection device 4 is connected to the automatic control valve. 5 Connected by a heat-resistant hose 405, the interior of the heat-r...

Embodiment 2

[0043] The difference from Embodiment 1 is that, referring to FIG. 4 , the temperature detection device 4 includes a fixing member 401 and a moving member 403 , the fixing member 401 is fixedly installed on the outside of the furnace wall 101 , and a heat-conducting metal rod is fixed inside the fixing member 401 . A402, the moving piece 403 can be movably connected with the fixing piece 401, and a heat-conducting metal rod B404 is inserted at one end of the moving piece 403 close to the fixing piece 401. When the fixing piece 401 is connected with the moving piece 403, the heat-conducting metal rod A402 and the heat-conducting metal rod B404 In close contact, a heat-resistant hose 405 is provided at the end of the moving piece 403 away from the fixing piece 401 , and a regulating valve 406 is provided on the top of the moving piece 403 .

[0044] The temperature detection device 4 can transmit the temperature inside the gasifier 1 to the mercury inside the heat-resistant hose ...

Embodiment 3

[0047] The difference from Embodiment 2 is that, please refer to Figures 5-7, the automatic control valve 5 includes a valve body 501, the radius of the middle of the valve body 501 is larger than the radius of both ends, and the inner walls of both ends of the valve body 501 are fixed with fixed rods. 502, the middle part of the valve body 501 is two chambers, the end close to the gas outlet 104 is a sealing chamber, and the end far from the gas outlet 104 is a gas delivery chamber, and the radius of the gas delivery chamber is larger than the sealing chamber.

[0048] A moving piston 505 is fitted inside the sealing chamber. The middle of the moving piston 505 has a hole and a central shaft 503 is inserted in the hole. A spring B504 is provided, and two ends of the spring B504 are respectively fixedly connected with the fixed rod 502 and the moving piston 505 near the gas outlet 104 .

[0049] The inside of the gas delivery chamber is in frictional contact with a swivel ring...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com