Multi-Zone Carbon Conversion System with Plasma Melting

a carbon conversion and multi-zone technology, applied in the direction of gasification process details, combustion process, combustible gas production, etc., can solve the problem of becoming less desirable to dispose of waste materials by incineration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

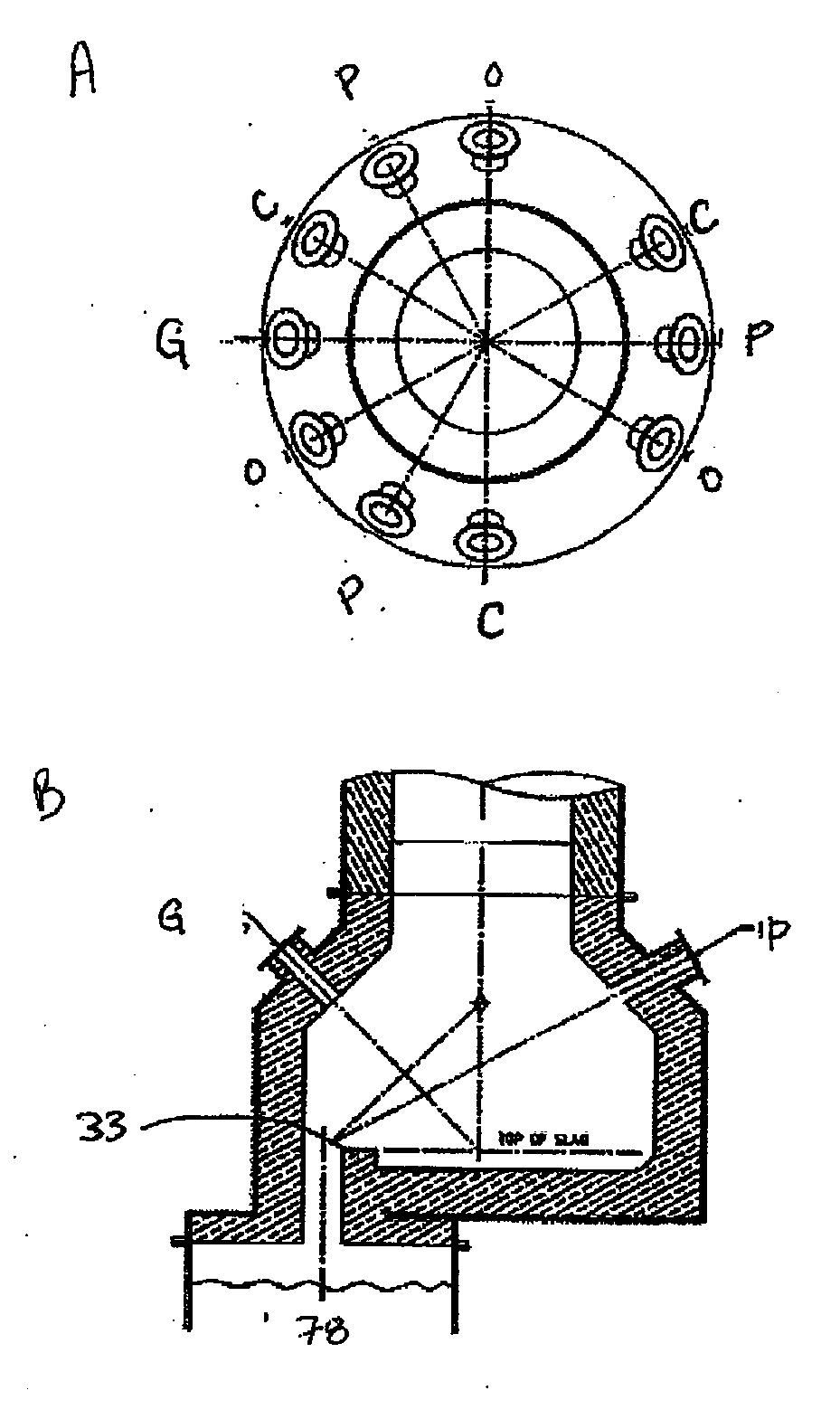

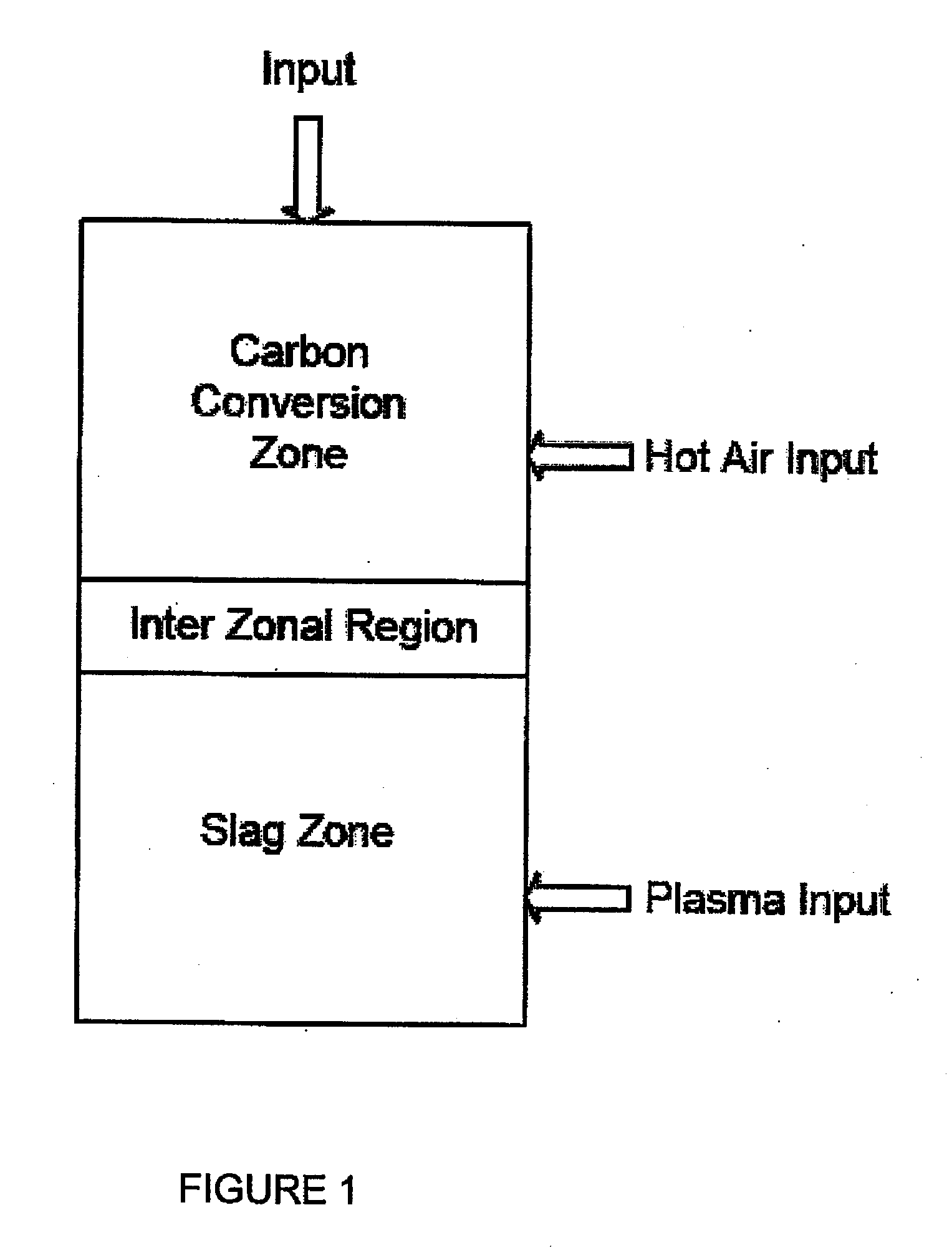

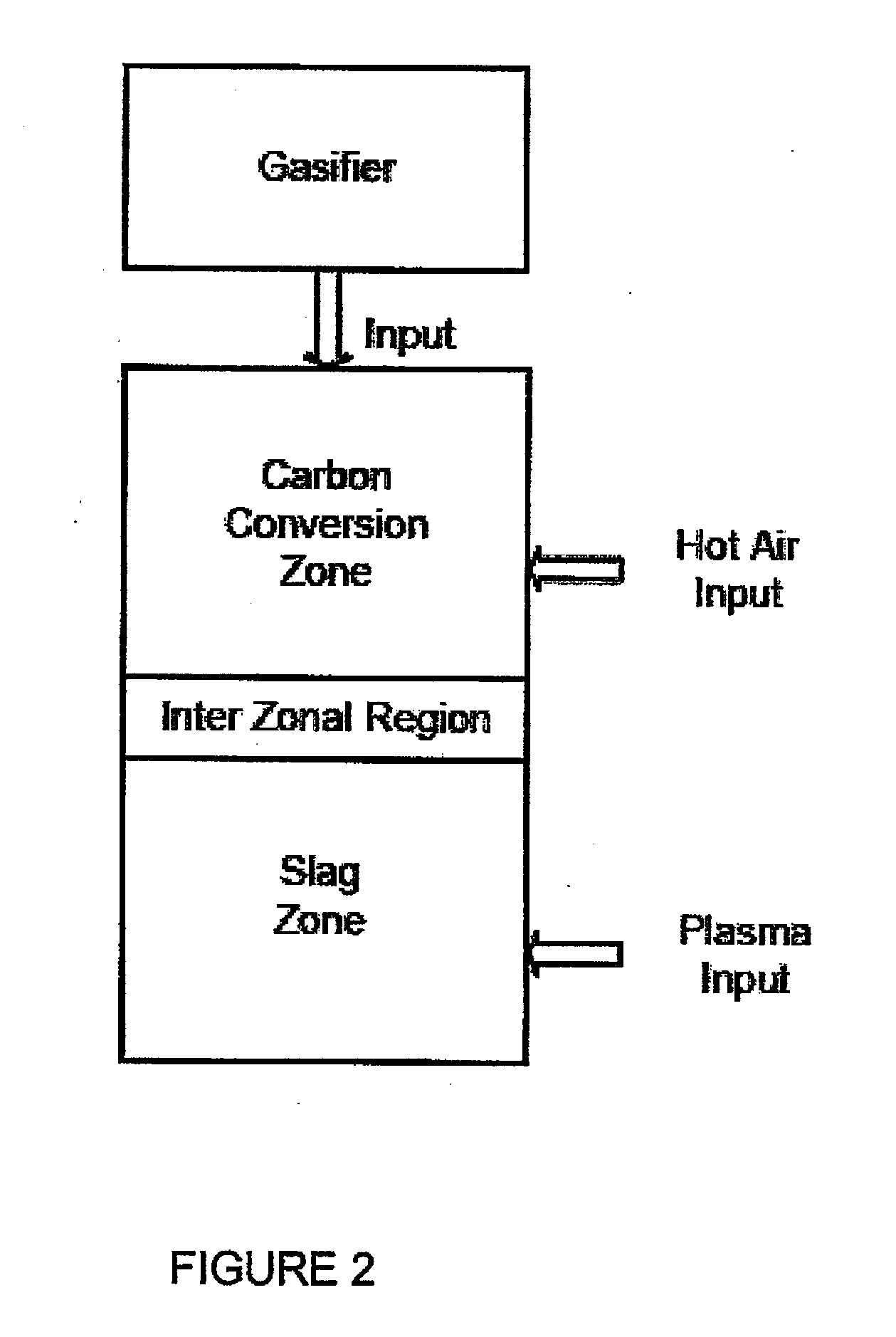

Referring to FIGS. 8, 11, 18 to 25, the multi-zone carbon converter (110) is zonally segregated by an interzonal region (112) into a upper carbon conversion zone (111) and lower slag melting zone (113). The carbon conversion zone (111) is maintained at a temperature of about 950° C. to about 1100° C. and the slag melting zone is maintained at a temperature of about 1350° C. to about 1600° C.

Referring to FIGS. 8, 11, 18 to 25, in the illustrated embodiment the multi-zone carbon converter (110) comprises a refractory-lined vertically-oriented chamber (115) having a processed feedstock input (120), gas outlet (125), a slag outlet (130), and zone-specific heating system (i.e. a system that can establish two temperature zones) comprising an air box (135) and plasma torch (140). If necessary, the processed feedstock input is optionally equipped with a grinder (not shown) to homogenize the size of the inputted material.

The chamber (115) is a refractory-lined steel weldment having a substan...

example 2

The general structure and design of the multi-zone carbon converter is as described above, in that the carbon conversion zone and slag zone are substantially the same as that described in Example 1. Referring to FIGS. 10 and 26, in the illustrated embodiment the multi-zone carbon converter (310) comprises a refractory-lined vertically-oriented chamber (315) having a processed feedstock input (not shown), syngas outlet (325), a slag outlet (330), and zone-specific heating system (i.e. a system that can establish two temperature zones) comprising an air inlets (not shown) and plasma torch (340).

Referring to FIGS. 10 and 26, the inter-zonal region comprises a physical impediment to regulate the flow of material from the carbon conversion zone to the slag zone. In the instant embodiment, the physical impediment comprises a series of substantially parallel refractory line tubes (345) mounted within a mounted with a mounting ring (350). The tubes are mounted such that there is a gap (355)...

example 3

The general structure and design of the multi-zone carbon converter is as described above, in that the carbon conversion zone and slag zone are substantially the same as that described in Example 1. Referring to FIG. 27, in the illustrated embodiment the multi-zone carbon converter (210) comprises a refractory-lined vertically-oriented chamber (315) having a processed feedstock input (not shown), syngas outlet (not shown), a slag outlet (230), and zone-specific heating system (i.e. a system that can establish two temperature zones) comprising an air inlets (not shown) and plasma torch (240).

Referring to FIG. 27, the inter-zonal region comprises a physical impediment to regulate the flow of material from the carbon conversion zone to the slag zone. In the instant embodiment, the physical impediment comprises a series of interconnected refractory bricks (245). The bricks are mounted on a mounting element (250) such that there are gaps (255) between adjacent bricks.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com