Patents

Literature

35results about How to "Shorten pressurization time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

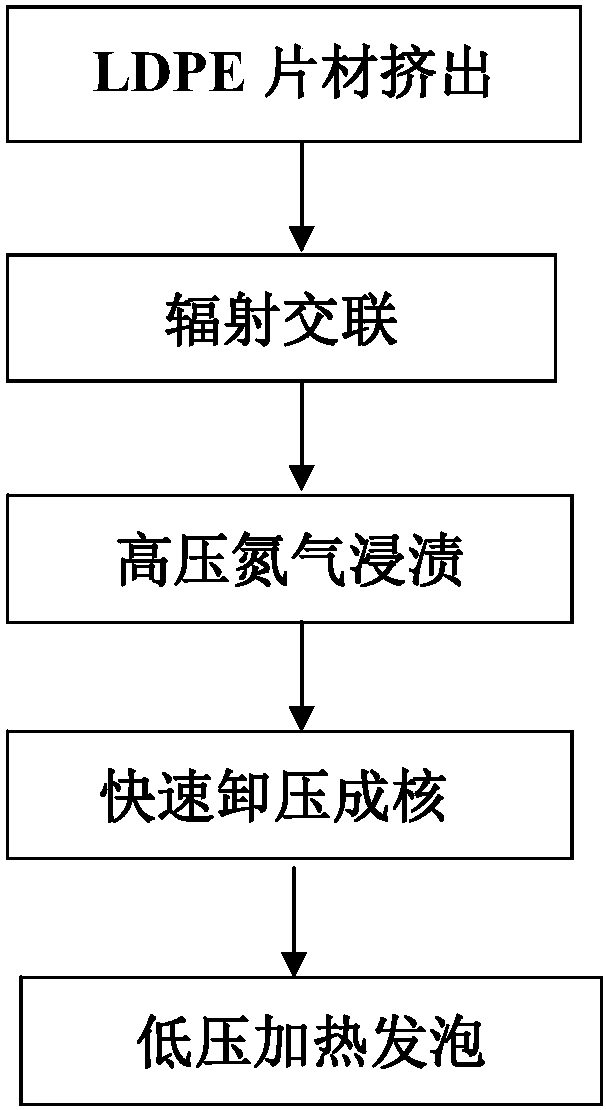

Supercritical fluid foaming polyolefin material and preparing method thereof

ActiveCN106146874AEasy to control the nucleation densityEasy to adjust the degree of expansionPolyolefinPolymer science

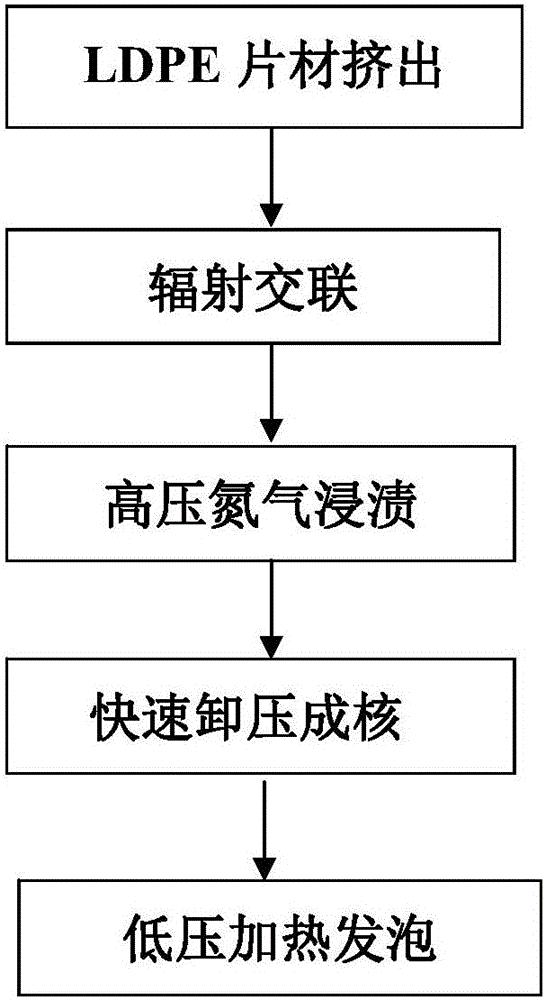

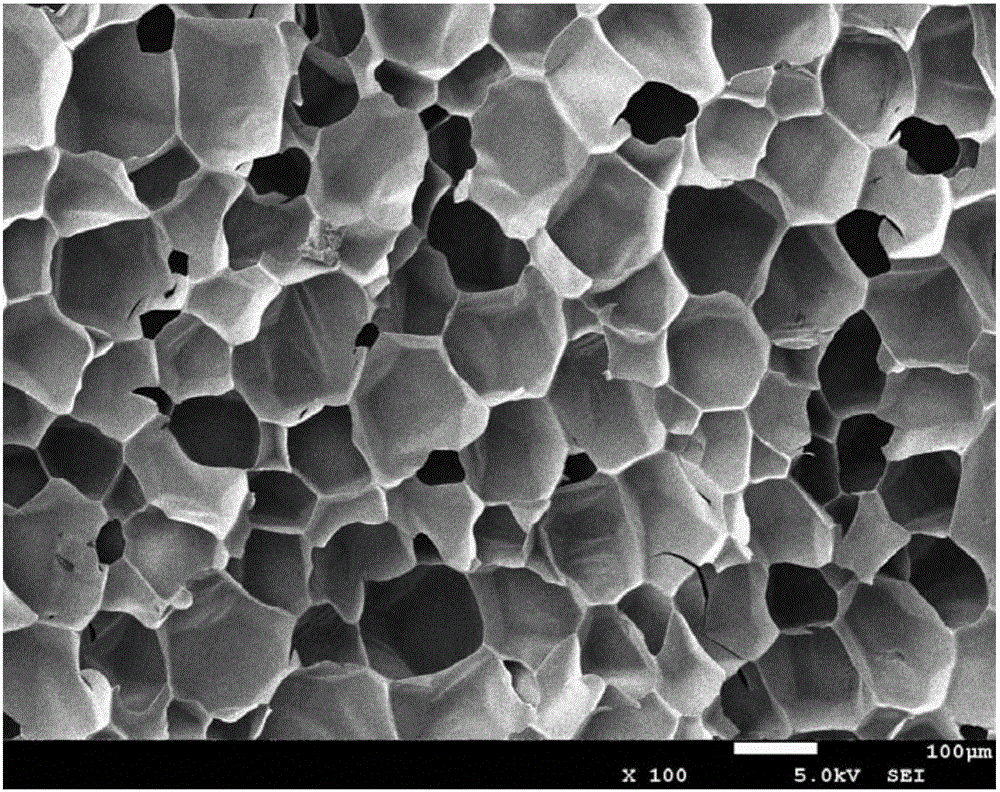

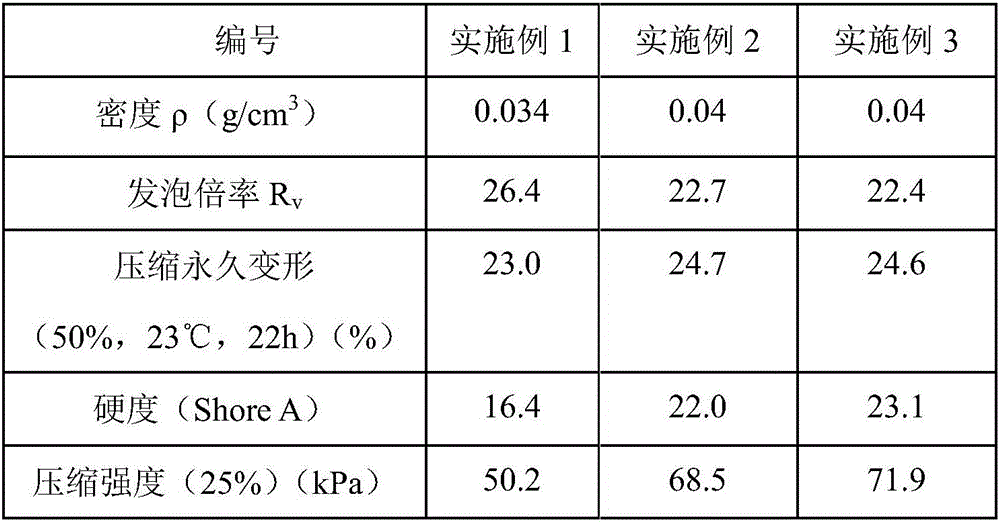

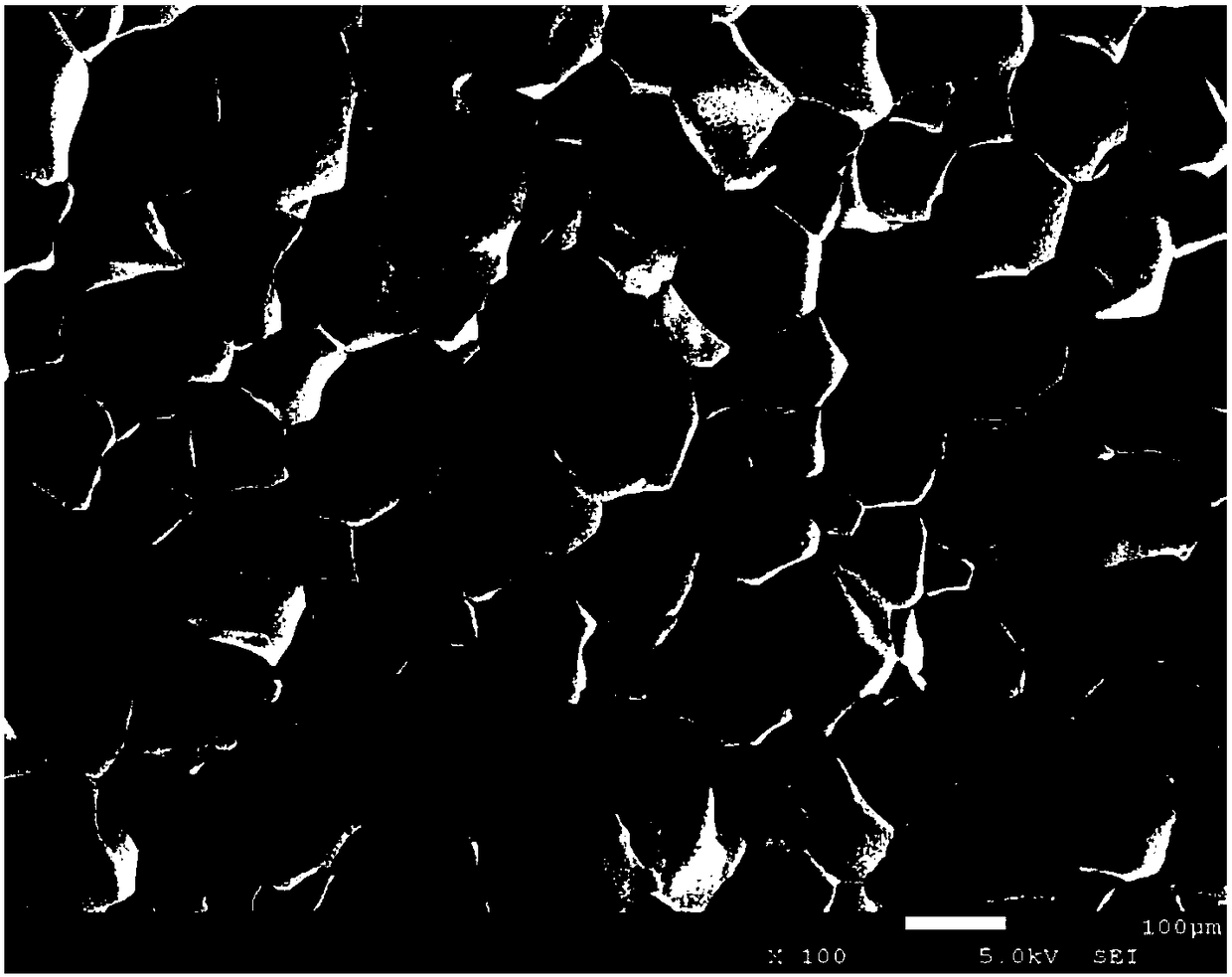

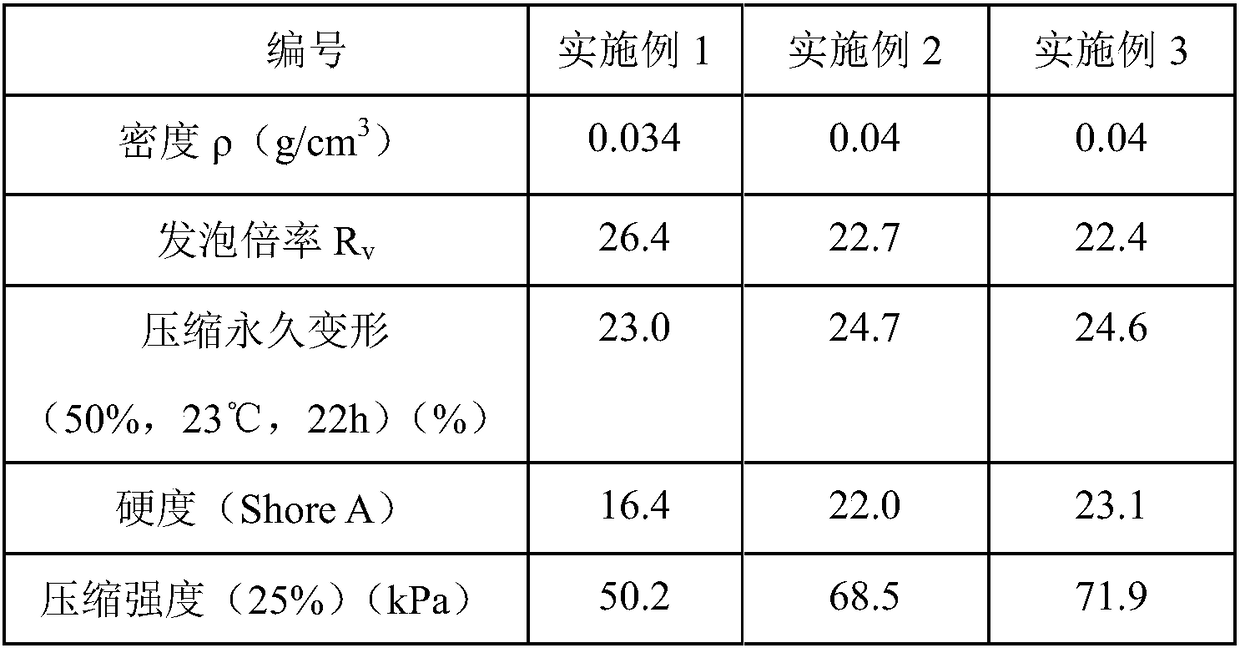

The invention provides a supercritical fluid foaming polyolefin material and a preparing method thereof. The supercritical fluid foaming polyolefin material is prepared through the following steps that a polyolefin sheet is prepared, and the melting point of the polyolefin sheet is Tm; radiation crosslinking is carried out on the polyolefin sheet; the crosslinked polyolefin sheet is put into a pressure container for high-pressure nitrogen impregnation, and the impregnation temperature T1 is equal to Tm+(30-120) DEG C; low-temperature heating foaming is carried out, and the foaming temperature T3 is equal to Tm+(20-50) DEG C, and is smaller than T1. By the adoption of the technical scheme, the requirement for material crystallinity is avoided, the time of reaching a dissolution saturation state of gas is greatly shortened, efficiency is improved, and the foaming material which is fine and uniform in bubble, low in density, high in mechanical strength and regular in shape can be obtained.

Owner:湖州长园特发科技有限公司

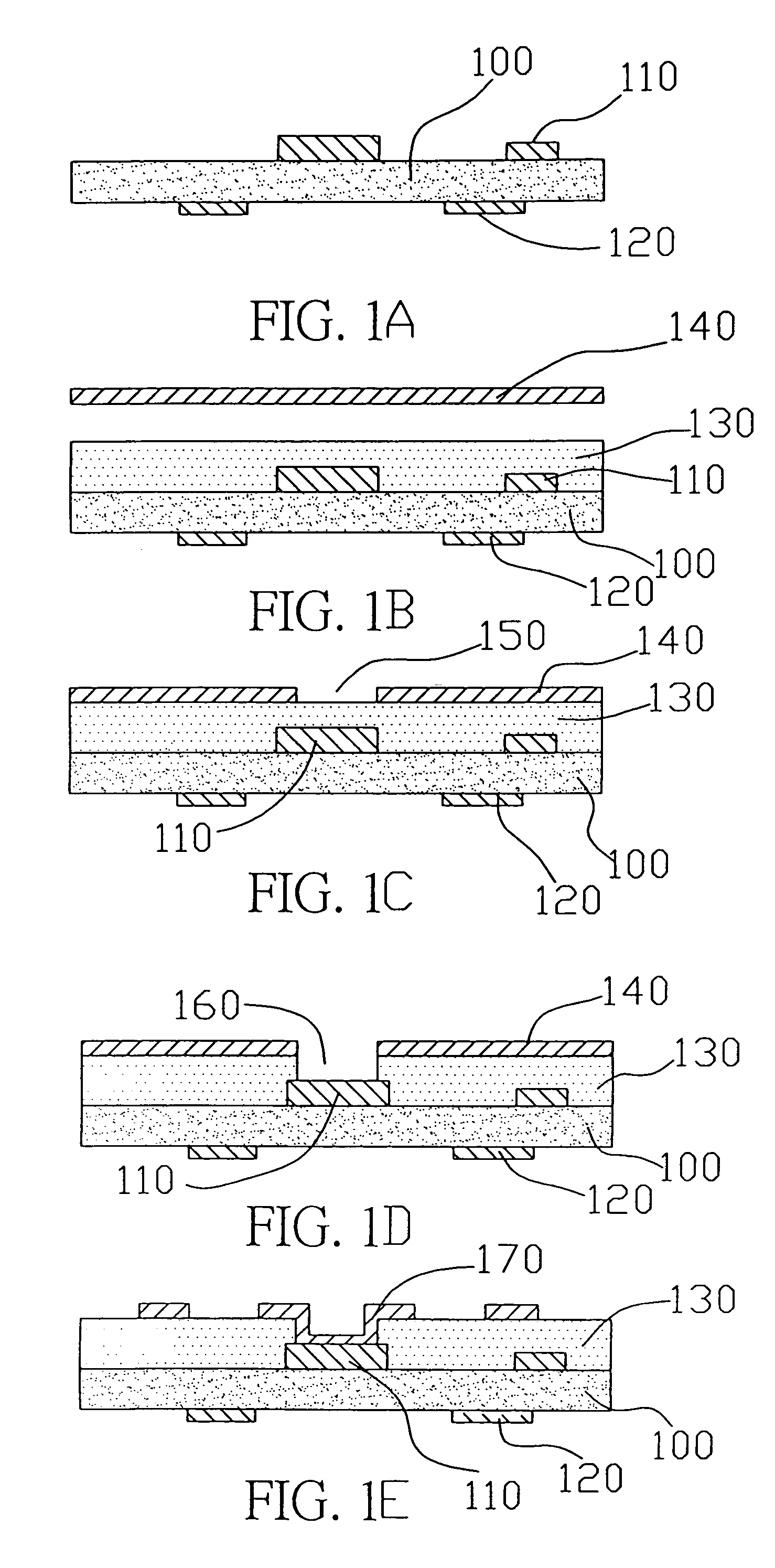

Modular method for manufacturing circuit board

ActiveUS6976306B1Shorten heating timeShorten pressurization timePrinted circuit assemblingLine/current collector detailsDielectricConductive materials

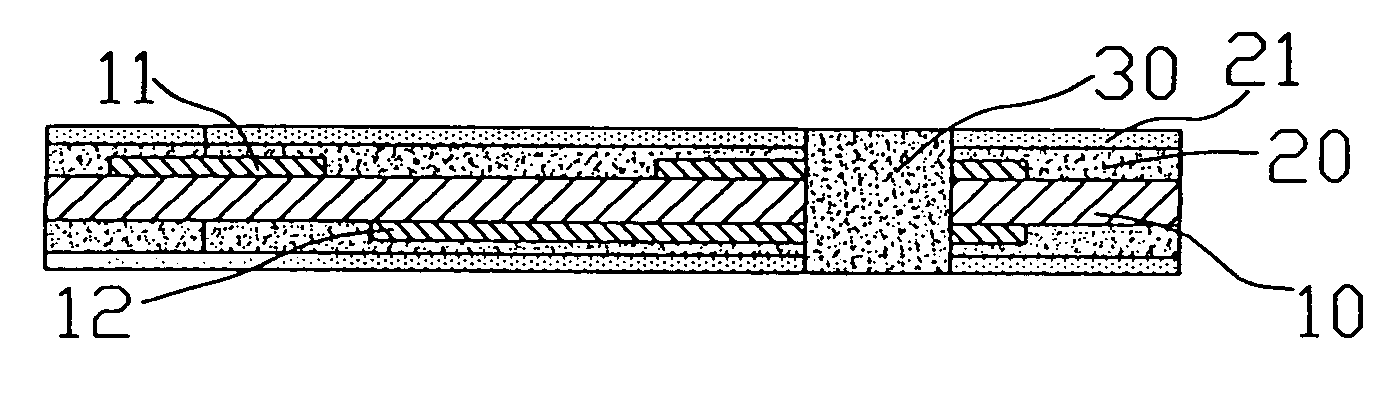

The present invention discloses a modular method for manufacturing circuit boards, which is a method of manufacturing multilayer printed circuit boards with blind and buried vias structure by using basic components as the assembly units. The method comprises the steps of producing electric circuits on the surface of a copper clad laminate by photolithographic and etching methods, pressing a dry film dielectric onto the surface of the laminate by the dry film lamination method after the electric circuit layer is formed, drilling a via and plugging a plastic conductive material into the via to obtain a basic component. When a multilayer printed circuit board having the blind and buried via structure is manufactured, the basic component serves as an assembling unit to stack with other circuit board having blind via and single-sided or double-sided electric circuits according to the multilayer circuit board mode to perform a heating and pressurization procedure and form a multilayer circuit board with blind and buried via structure. Such arrangement not only saves the time for aligning layers, pressing and blind via filled plating of the prior-art technology, but also enhances the yield rate and reduces the failure cost.

Owner:UNITECH PRINTED CIRCUIT BOARD CORP

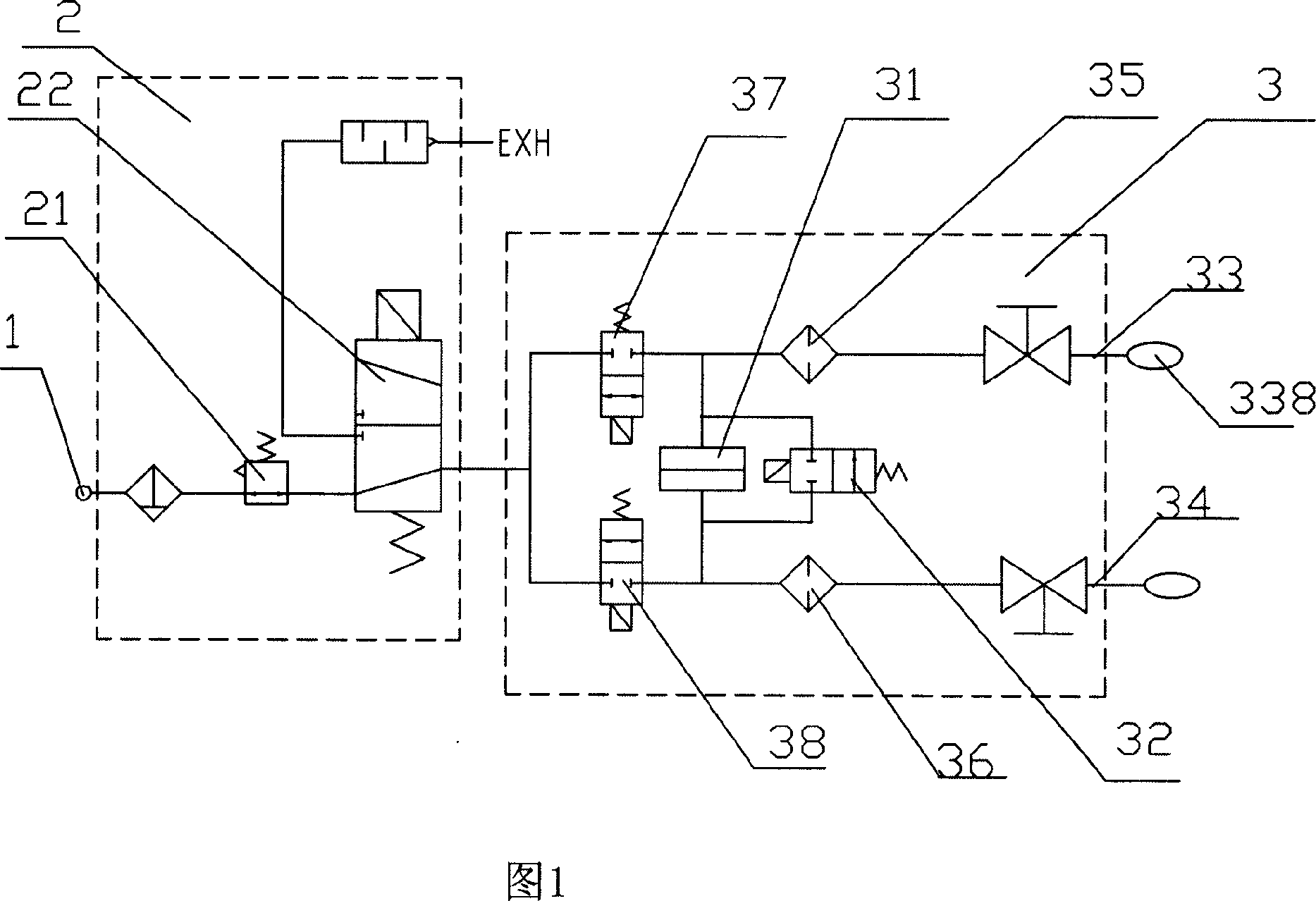

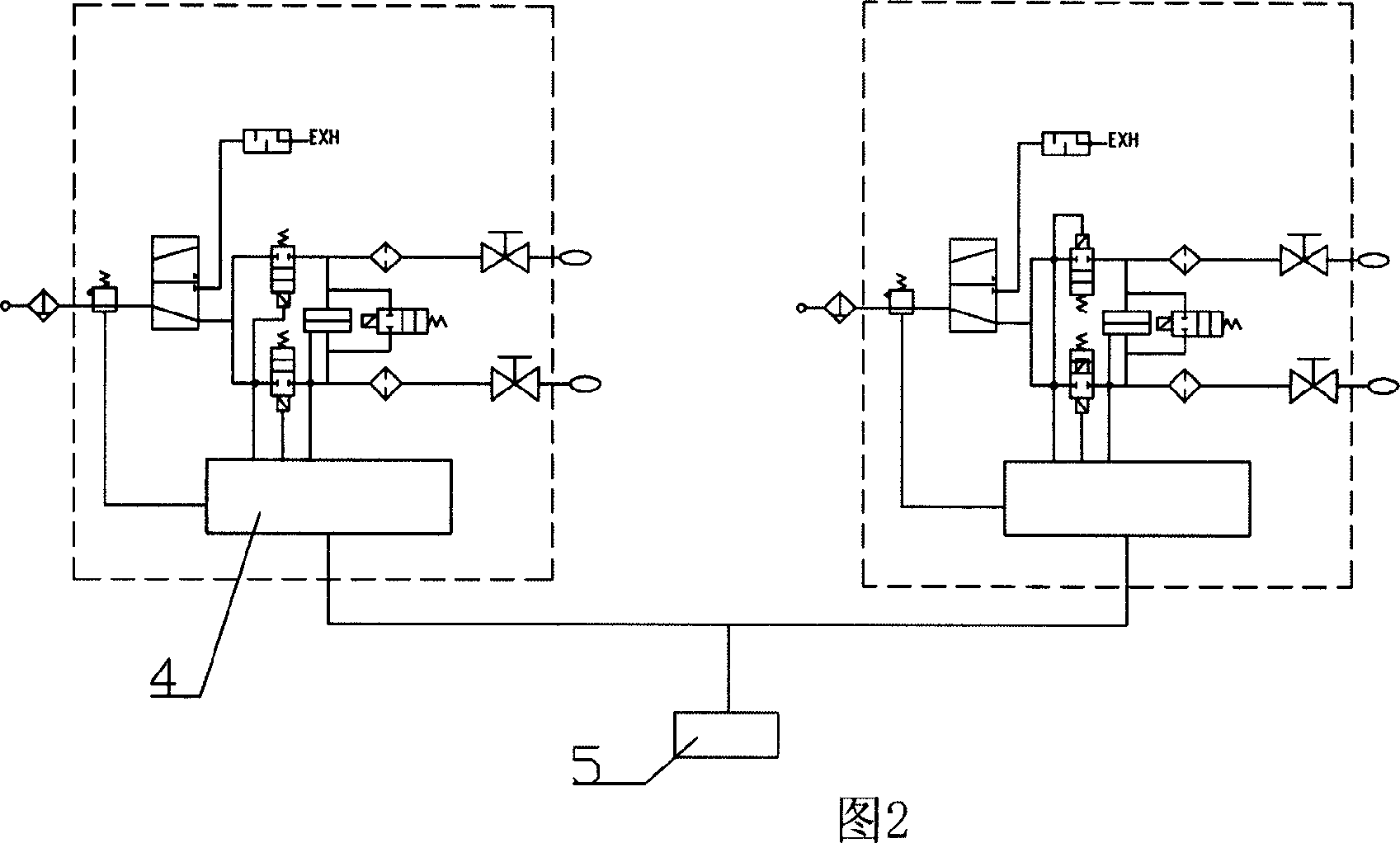

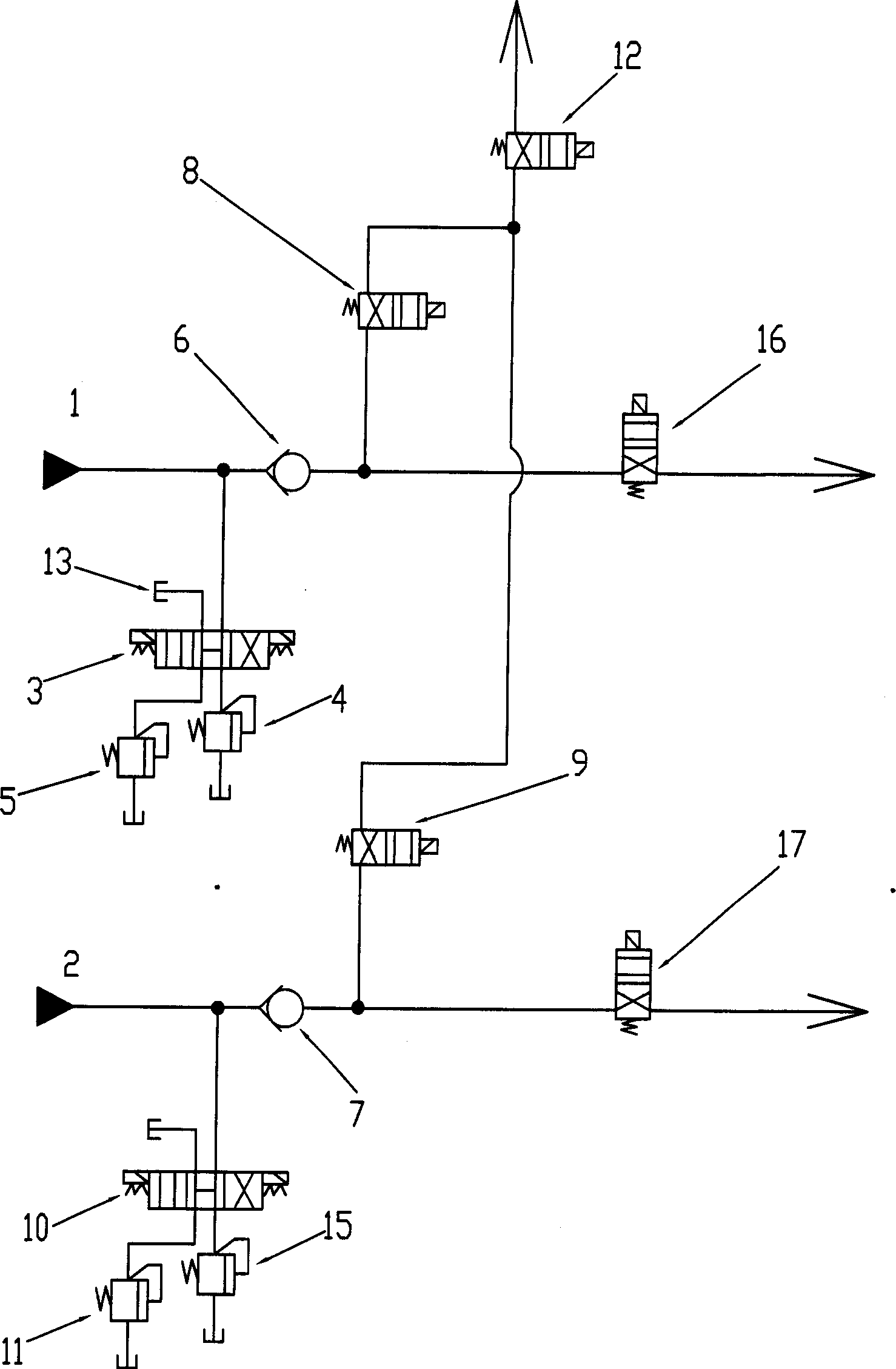

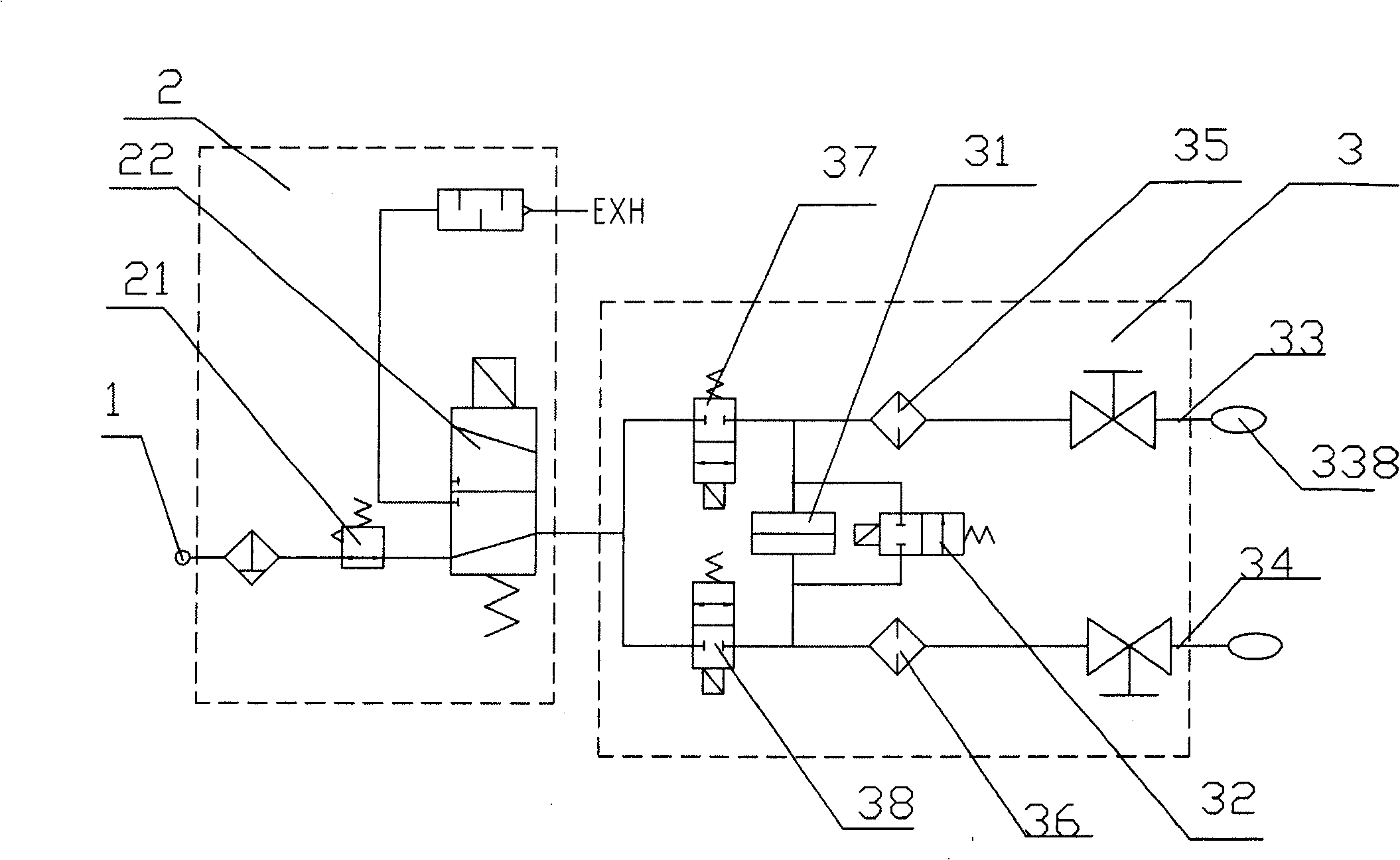

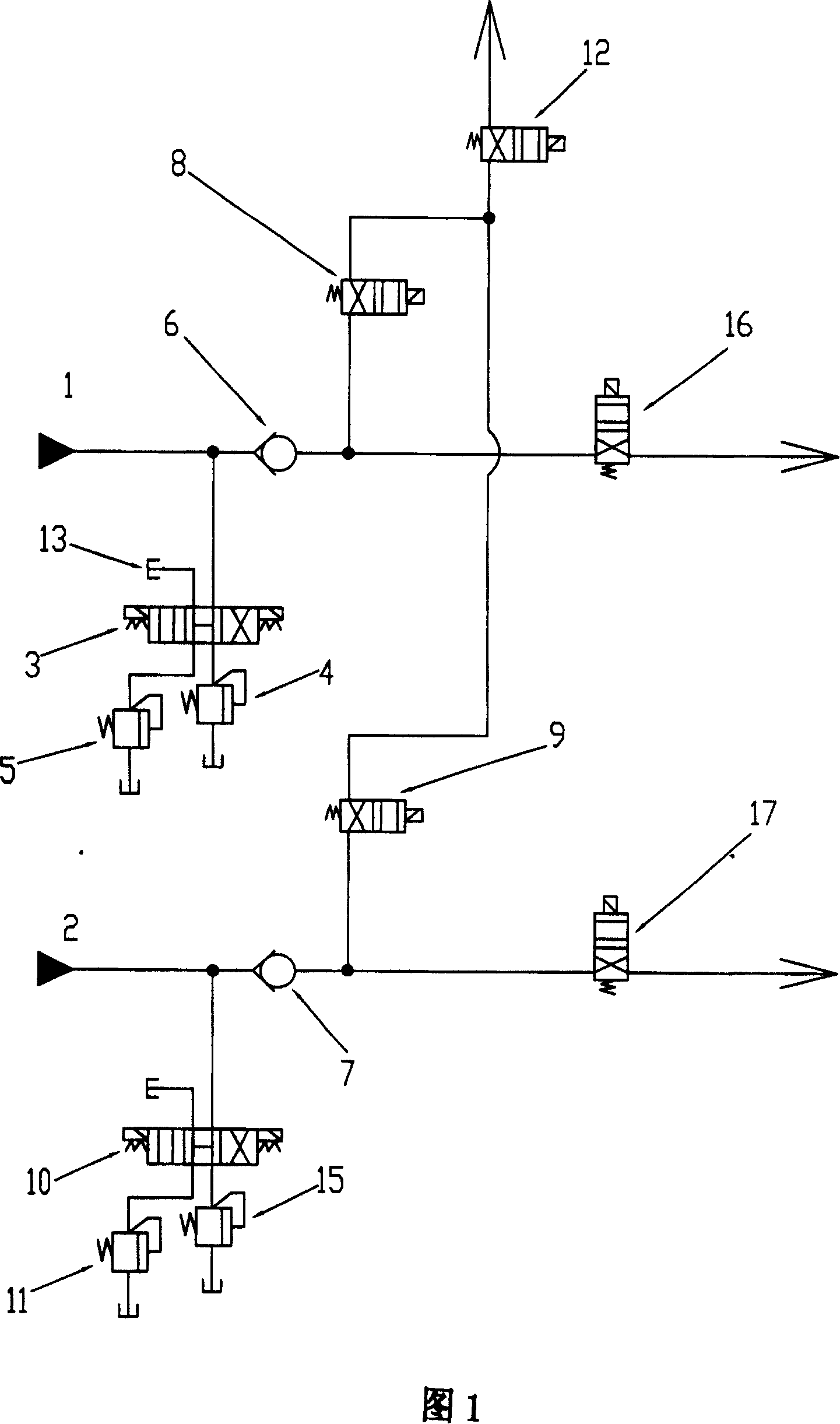

Auto-controlled gas liquid two purpose leakage detector

InactiveCN1948934ASolve the problem that cannot be used twiceSolve cleaning problemsMeasurement of fluid loss/gain rateAutomatic controlDifferential pressure

The invention relates to discloses self control gas liquid dual purpose leak-detector. It includes air source, pressure adjusting unit, differential pressure test unit, control unit connected with the pressure adjusting unit set adjusting valve and differential pressure test unit includes differential pressure transducer, filter, pressure protective valve, prove, and standard parts. The probe is gas liquid dual purpose detecting device. The leak detector of the invention can be used to detect gas or liquid leakage to realize one machine has dual purpose.

Owner:宁波赛盟科技发展有限公司

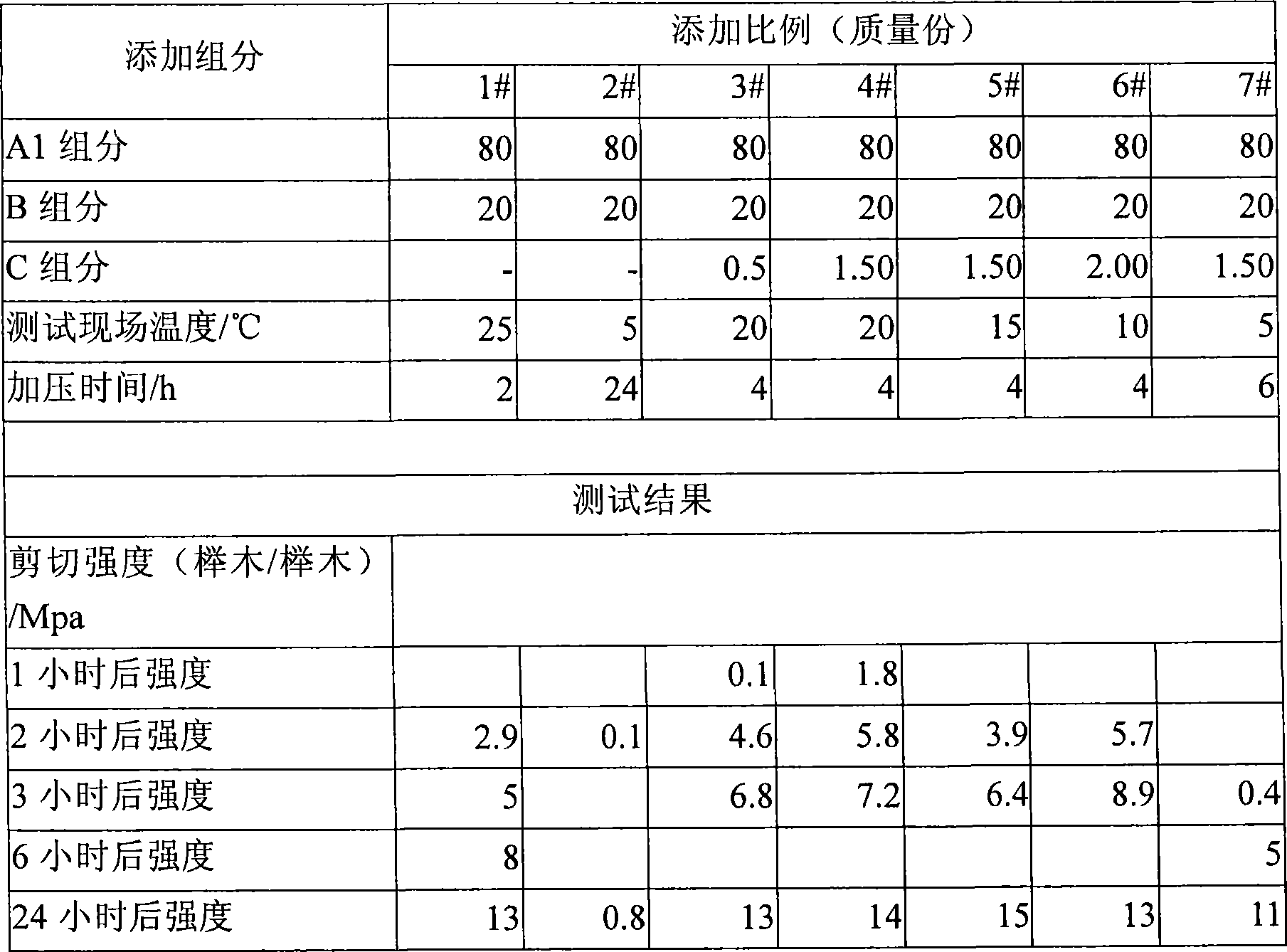

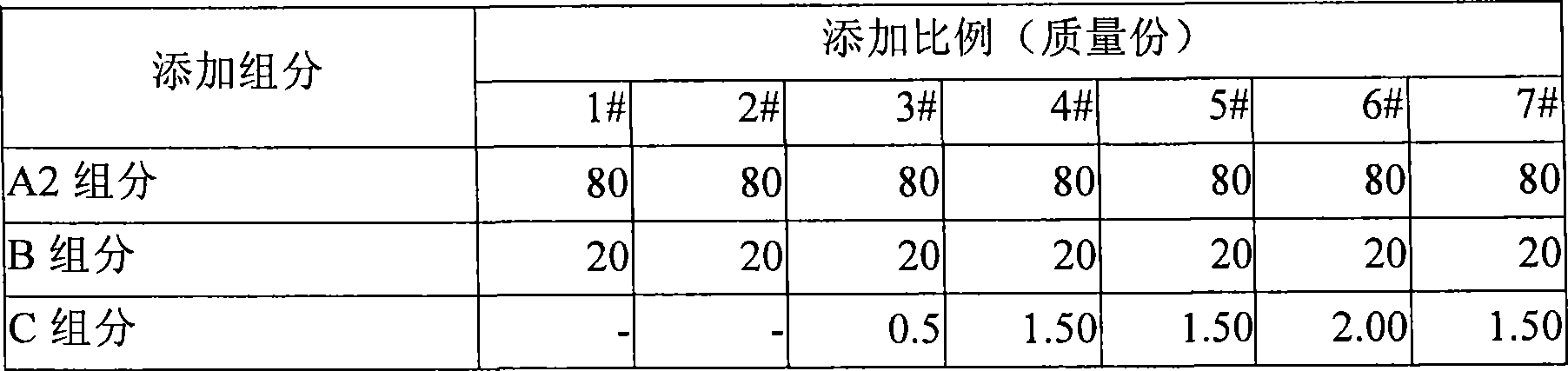

Adhesive and use thereof

InactiveCN101497776AGood storage stabilityImprove curing speedPolyureas/polyurethane adhesivesThin material handlingPolymer sciencePolyol

The invention provides a three component adhesive composite which comprises a first component containing one or a plurality of polylols, a second component containing one or a plurality of isocyanates, and a third component containing one or a plurality of common polyurethane catalysts or modified catalysts thereof. The invention realizes the expected adhesive curing speed and the expected adhering strength at the temperature with wide range by adjusting the adding proportion of the third component according to different applications.

Owner:NAT STARCH & CHEM INVESTMENT HLDG CORP

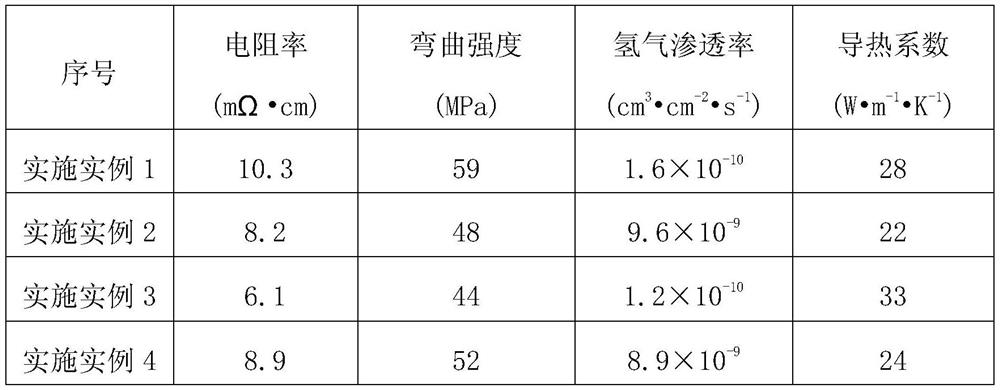

Preparation method of cold-pressed composite bipolar plate

ActiveCN113270605AIncrease profitShorten pressurization timeFuel cellsPolymer sciencePolyvinyl alcohol

The invention discloses a preparation method of a cold-pressed composite bipolar plate, and the method is characterized in that the method comprises the steps: taking raw materials of natural crystalline flake graphite, artificial graphite or / and expanded graphite, a conductive additive, a bonding resin composition, toughening resin and a solvent, wherein the bonding resin composition is formed by mixing novolac epoxy resin, a curing agent and an accelerant, and the toughening resin is polyvinyl butyral resin; dispersing, kneading, internally mixing and drying the raw materials to prepare powder, molding the powder by a mold at normal temperature and high pressure and then performing curing to prepare the cold-pressed composite bipolar plate. The cold-pressed composite bipolar plate prepared by the invention has the characteristics of low gas permeability, small thickness, high strength, excellent corrosion resistance, low resistivity, low production energy consumption, high efficiency and the like, and is suitable for being used as a bipolar plate of a proton exchange membrane fuel cell.

Owner:SICHUAN DONGFANG INSULATING MATERIAL

Method for extracting chestnut flower volatile substances by using supercritical CO2 fluid

InactiveCN102755358AAvoid lossAvoid attenuationAntibacterial agentsRespiratory disorderFunctional foodExtraction methods

The invention discloses a method for extracting chestnut flower volatile substances by using a supercritical CO2 fluid. The method comprises the following steps of: picking fresh chestnut flowers at a full-bloom stage; drying at a low temperature; smashing; storing at a low temperature; adding into an extraction kettle; connecting a CO2 supercritical extracting instrument; adjusting the pressure and temperature of the extraction kettle; extracting in a static state; turning static extraction into dynamic extraction; simultaneously, raising the pressure and the temperature of the extraction kettle; and collecting an extract in a dynamic extracting process, wherein an extract product is a yellow-green oily substance. In the method, volatile substances in chestnut flowers are extracted by using a supercritical CO2 fluid extracting technology, and extracting conditions are changed alternatively through a programmed temperature raising and programmed pressure raising method for extracting and collecting chestnut flower volatile substances. In the method, chestnut flowers are taken as a raw material; the extraction method has the characteristics of rapidness, easiness, convenience, environment friendliness, high efficiency and the like; and the extracted chestnut flower volatile substances can be applied to plant protection, medical and functional foods.

Owner:HEBEI NORMAL UNIVERSITY OF SCIENCE AND TECHNOLOGY

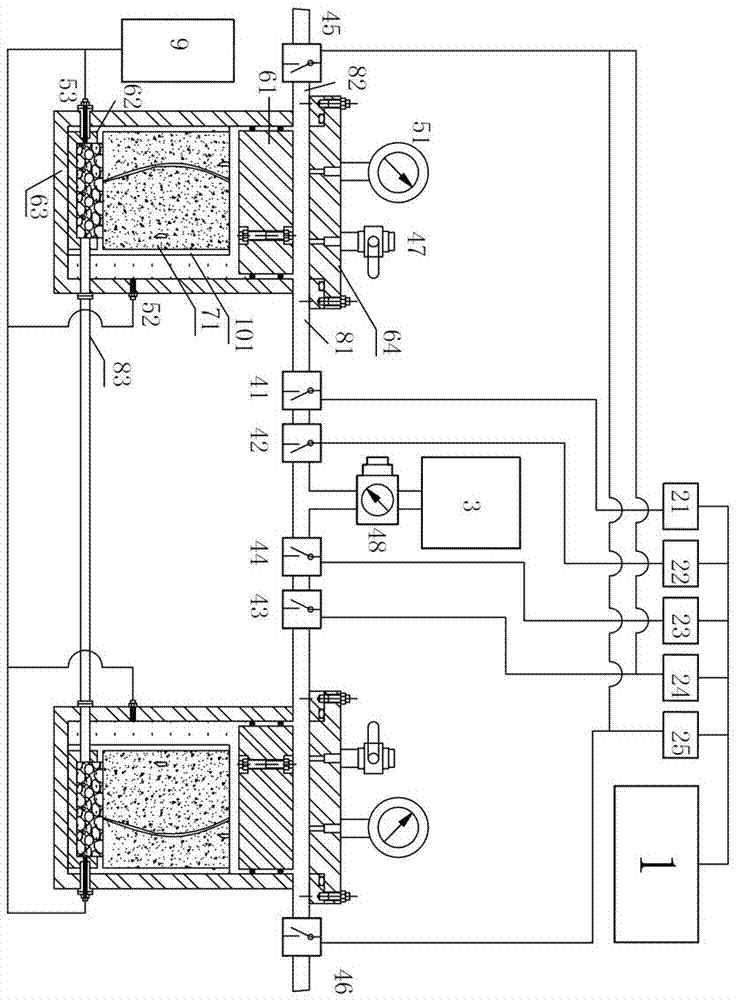

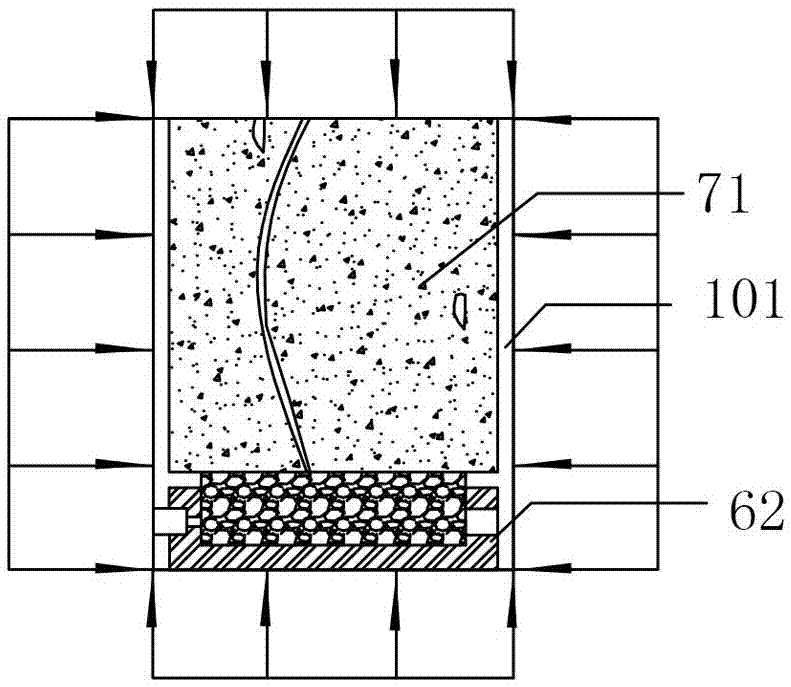

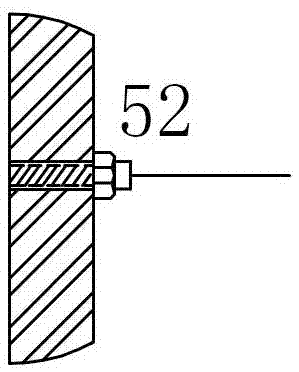

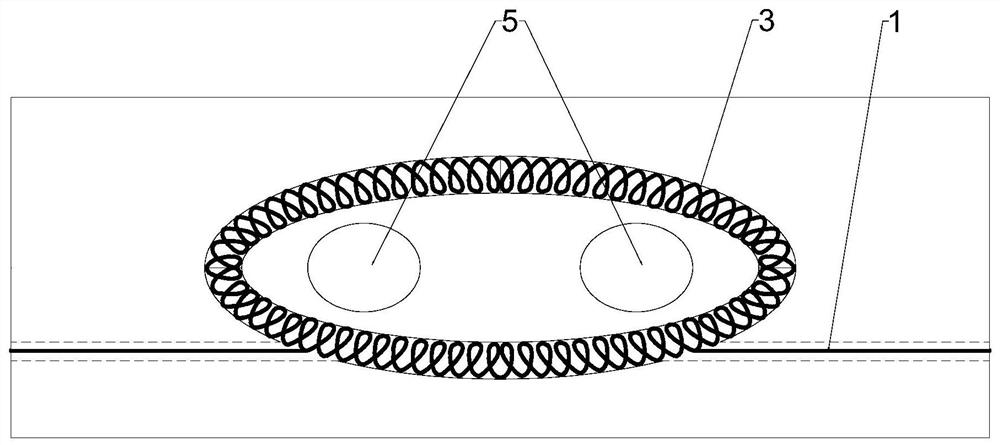

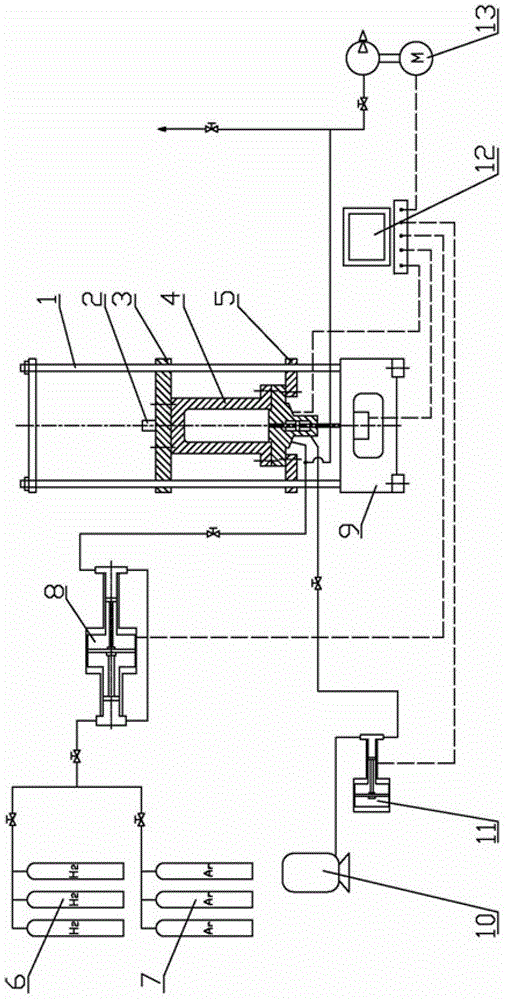

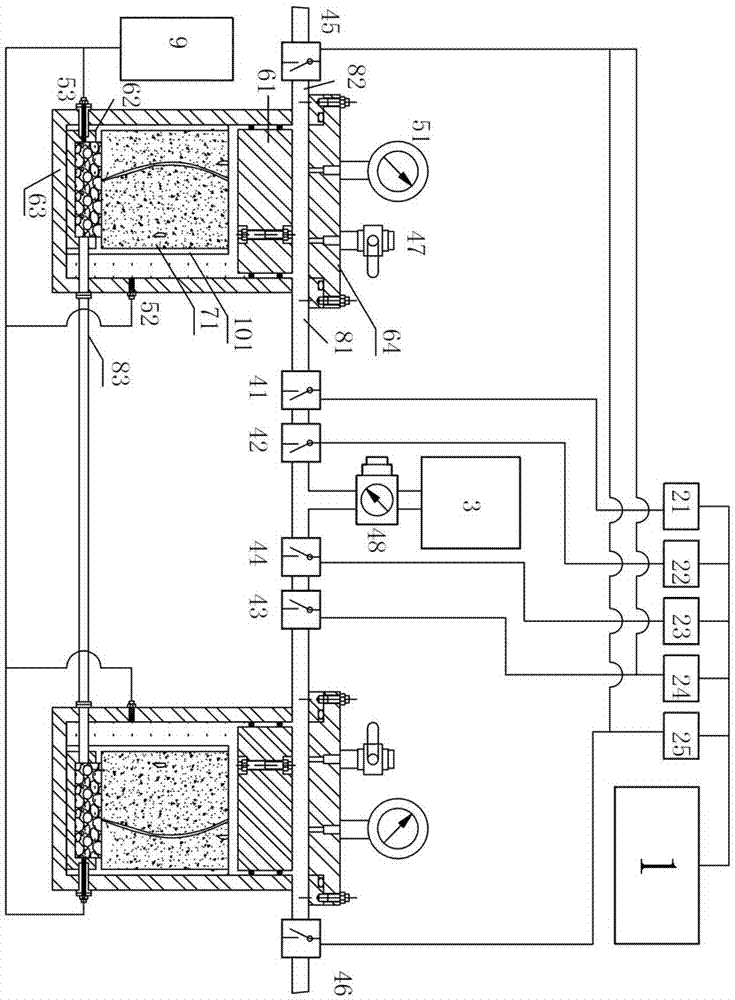

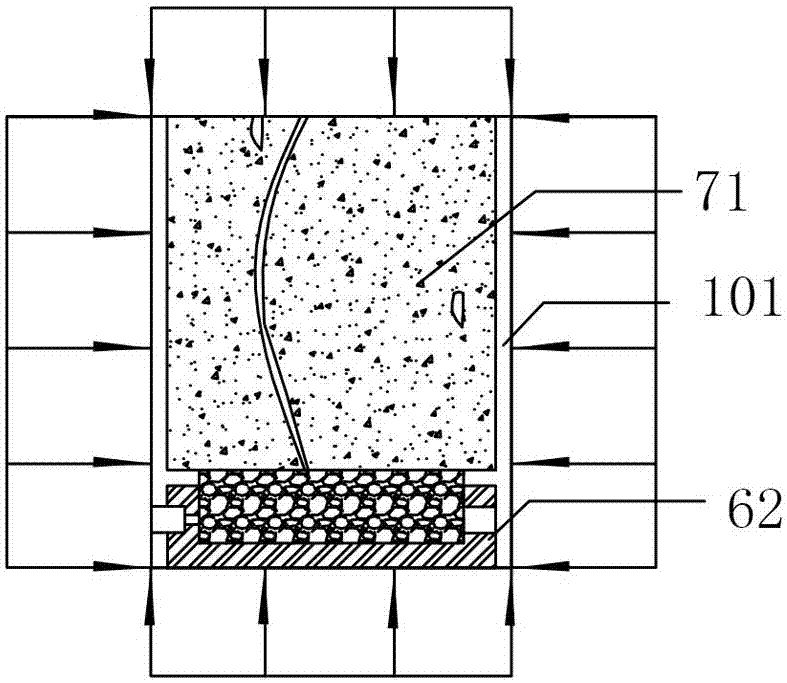

Device and method for simulating test of pore water pressure of asphalt pavement

InactiveCN105445168ANo gapAvoid direct connectionPermeability/surface area analysisPore water pressureForce sensor

The invention discloses a device and a method for simulating a test of pore water pressure of an asphalt pavement. The device comprises at least two pressure containers, wherein a binder is filled between the bottom part of an asphalt concrete specimen in each pressure container and an opening annular part of an opening container; the side wall of each specimen is coated with a sealing part; a first pressure sensor is arranged at the side wall of each pressure container and is used for testing the external water pressure of the corresponding specimen; a second pressure sensor is arranged at the side wall of each opening container and is used for testing the bottom water pressure of the corresponding specimen; the opening containers are communicated by a pipeline which penetrates through the side walls of the pressure containers. The method has the advantages that by adopting a control process meeting different wheel load functions and characteristics, the specimens in the pressure containers are successively and respectively loaded, the internal and external water pressures of each specimen are effectively sealed and isolated, and the external water pressure and pore water pressure during loading are monitored in real time. The device has the advantages that the directional flowing of pore water is realized, and a dynamic response rule of the pore water pressure of asphalt concrete under the action of dynamically-changed external water pressure can be tested.

Owner:广州市和富市政工程有限公司

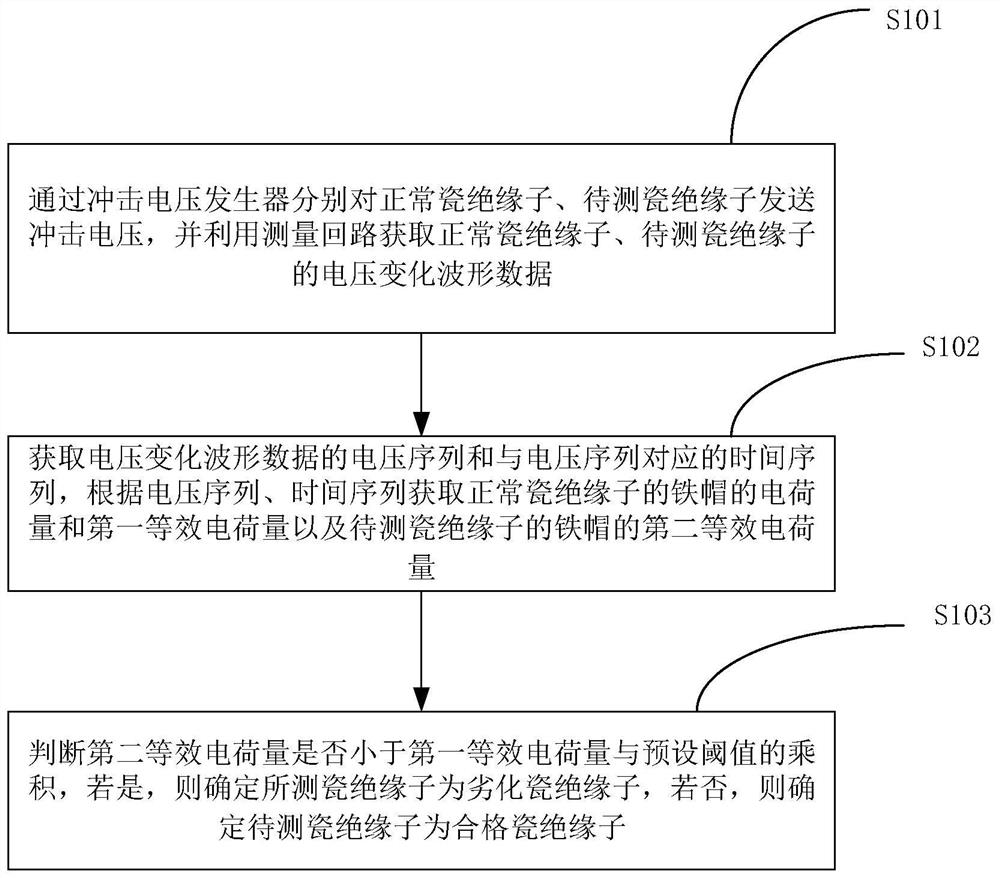

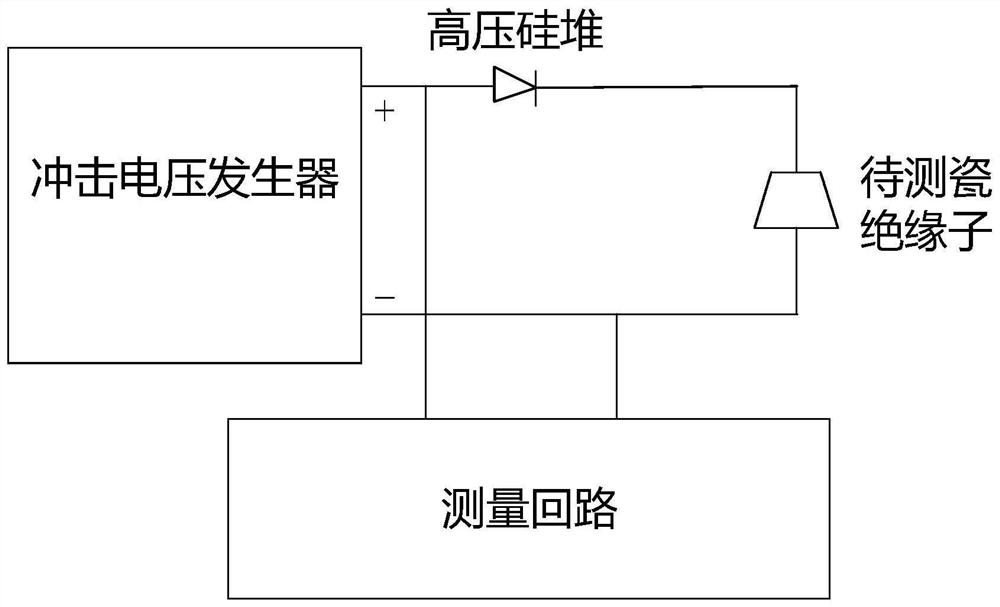

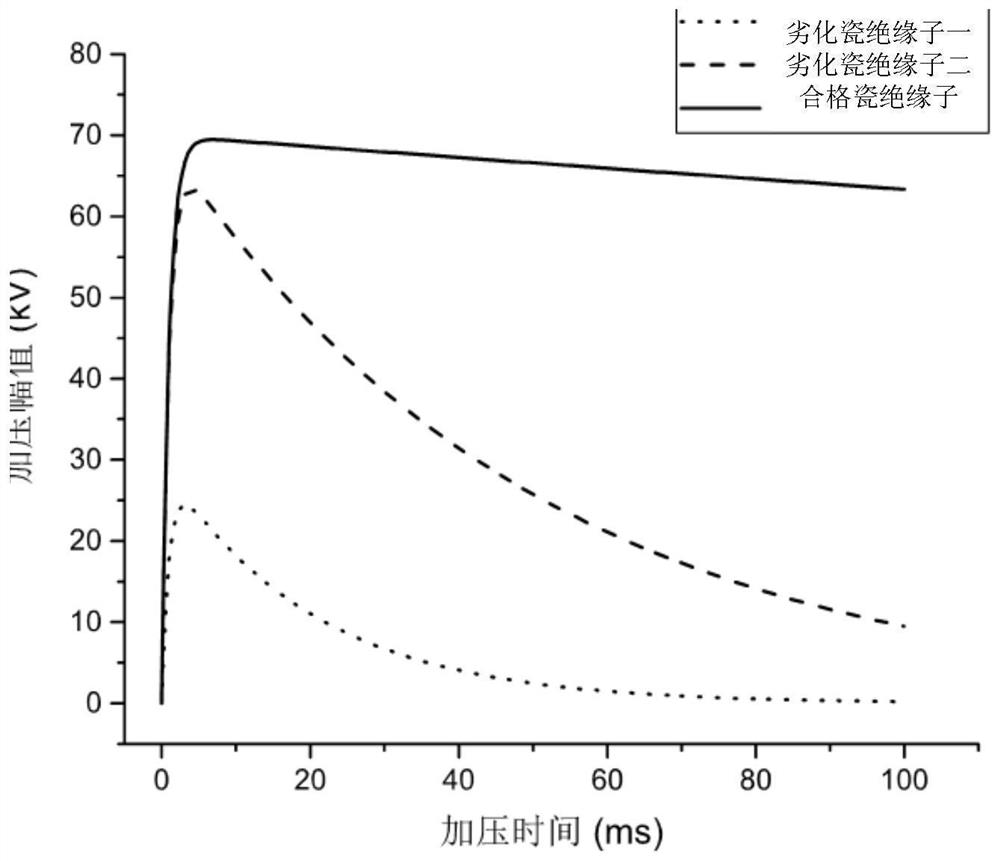

Porcelain insulator detection method and porcelain insulator detection circuit

PendingCN111707909AAvoid missing testShort pressurization timeTesting dielectric strengthVoltage generatorMiniaturization

The invention provides a porcelain insulator detection method and a porcelain insulator detection circuit, and the porcelain insulator detection method comprises the steps: S101, respectively transmitting an impact voltage to a normal porcelain insulator and a to-be-detected porcelain insulator through an impact voltage generator, and obtaining voltage change waveform data through a measurement loop; S102: according to the obtained voltage sequence and time sequence, obtaining the charge quantity of the normal porcelain insulator, the first equivalent charge quantity and the second equivalentcharge quantity of the to-be-detected porcelain insulator; and S103, judging whether the to-be-detected porcelain insulator is a deteriorated porcelain insulator or not according to whether the secondequivalent charge quantity is smaller than the product of the first equivalent charge quantity and a preset threshold value or not. The impulse voltage generator sends impulse voltage to the porcelain insulator, the short-time high voltage of the impulse voltage is used for breaking through internal defects of a porcelain part of the porcelain insulator and exposing internal insulation, the problem of missing detection of a deteriorated porcelain insulator is avoided, the pressurization time is short, the power is low, the energy consumption is low, and miniaturization and large-batch detection of detection equipment are facilitated.

Owner:广州广华智电科技有限公司

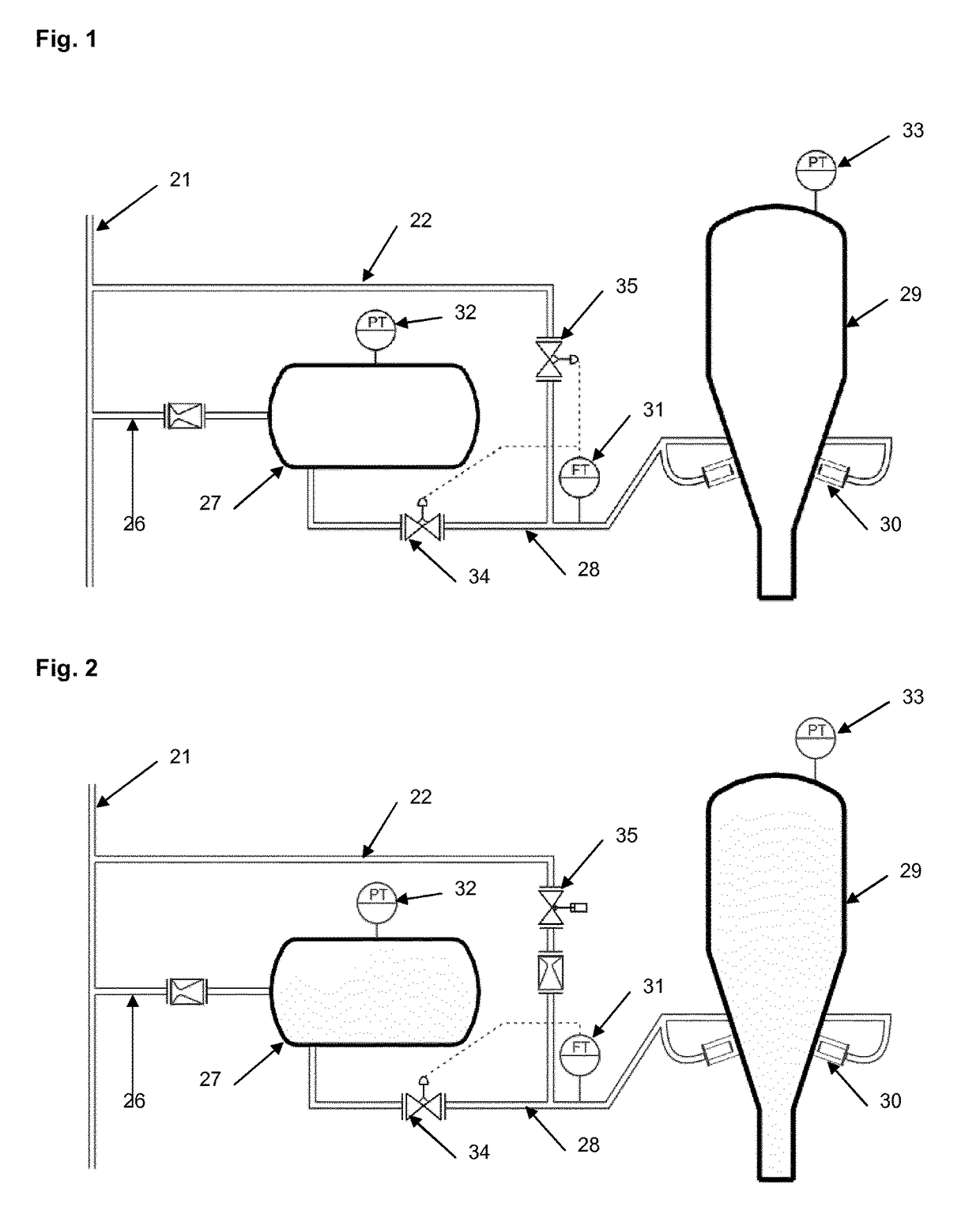

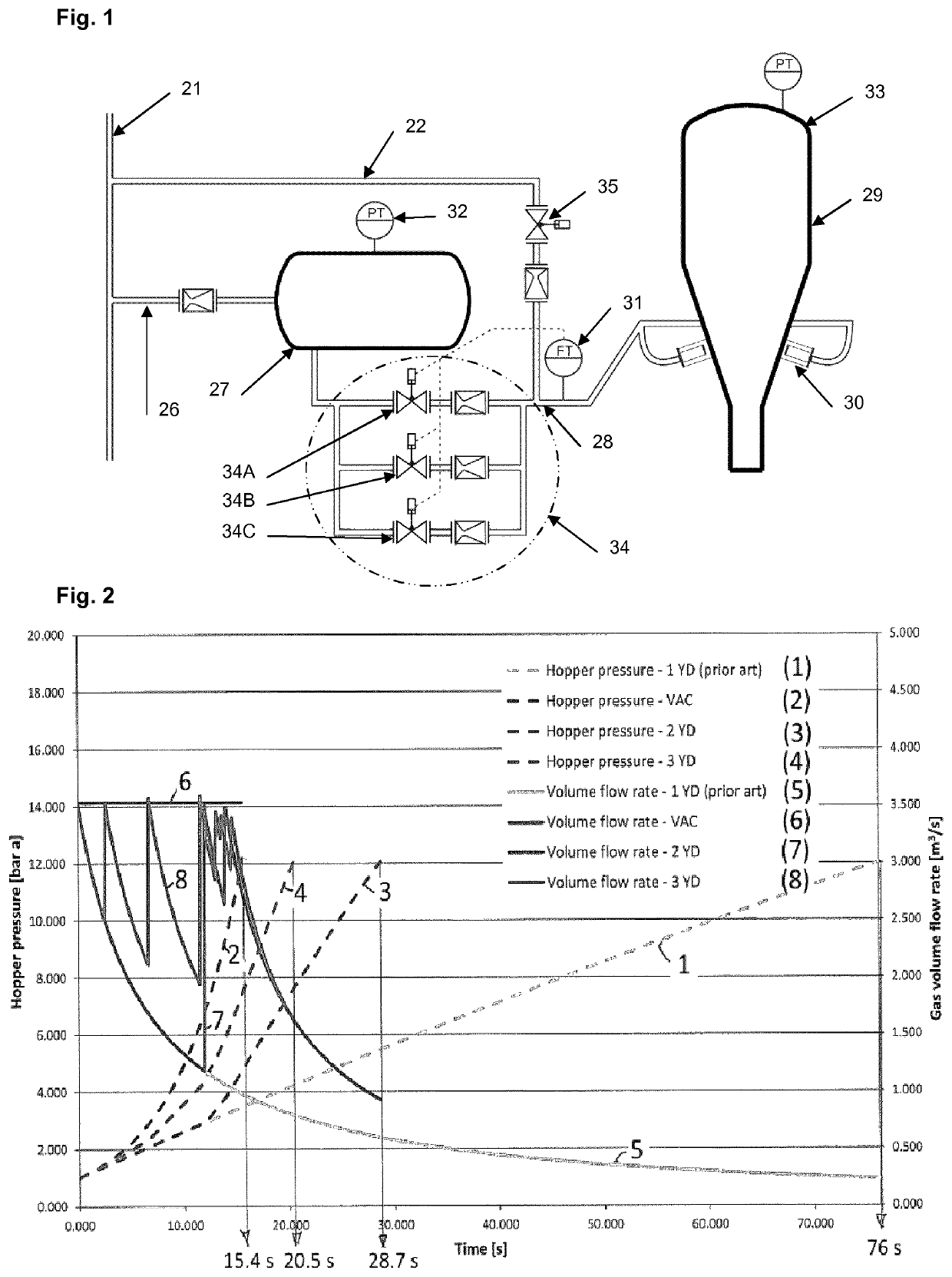

Pressurising of bulk material in lock hoppers

ActiveUS10150925B2Shorten pressurization timeReduce noise nuisanceGasifier moving partsBulk conveyorsProduct gasEngineering

Owner:PAUL WURTH SA

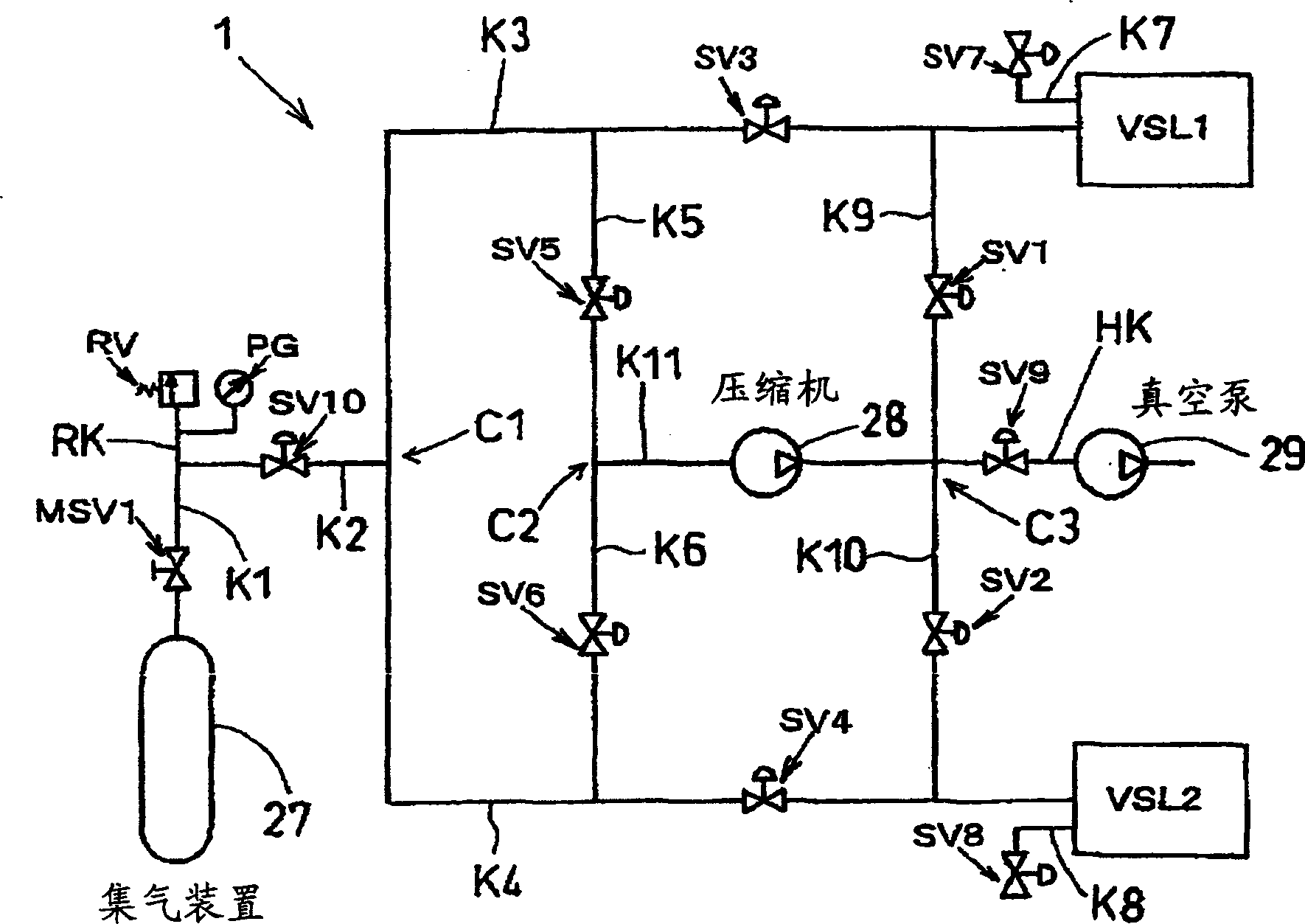

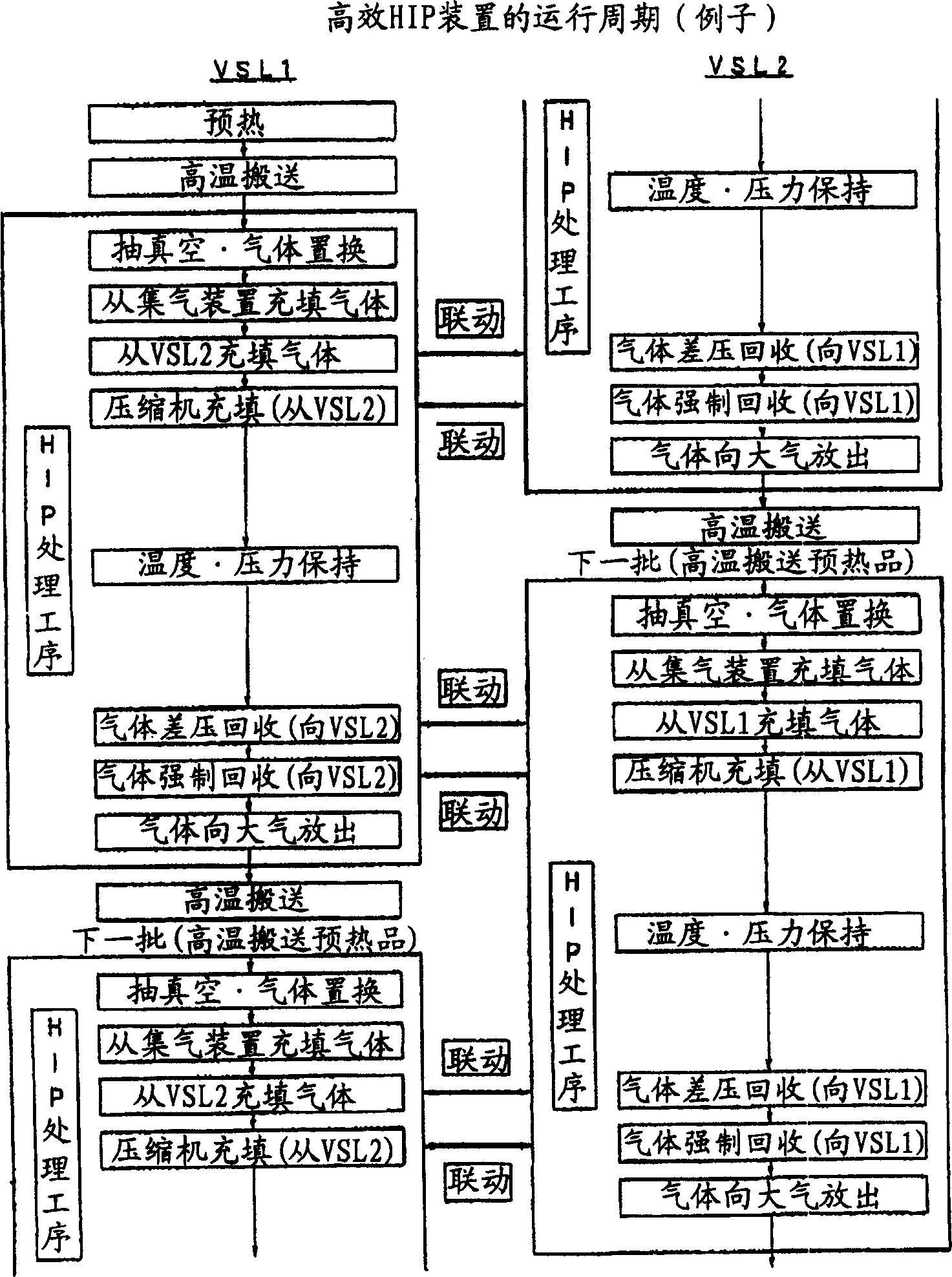

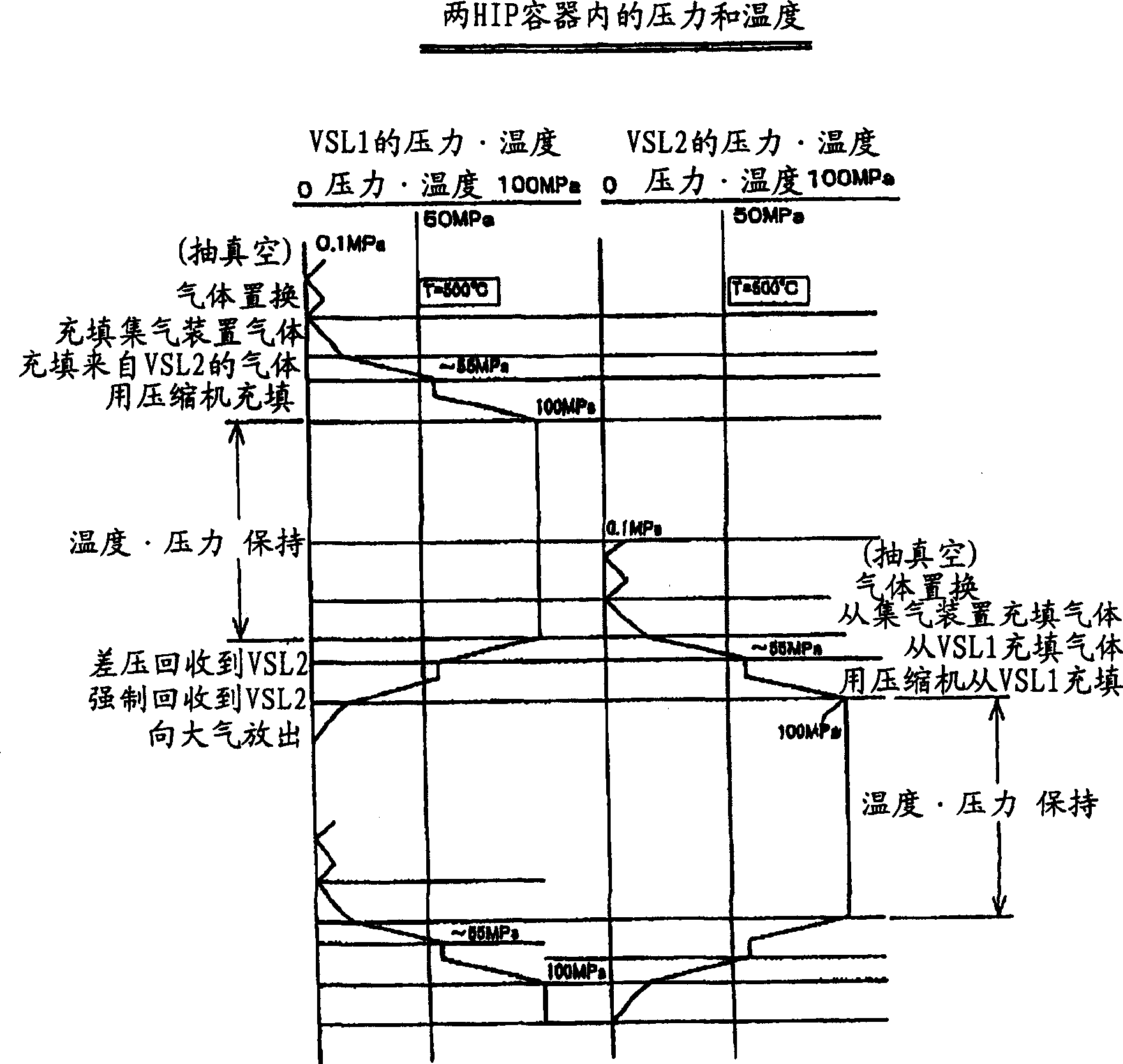

Soaking pressing method and apparatus

InactiveCN1468676AAvoid Substantial Pressure Reduction IssuesLow costFurnace typesPipeline systemsProduct gasEngineering

Owner:KOBE STEEL LTD

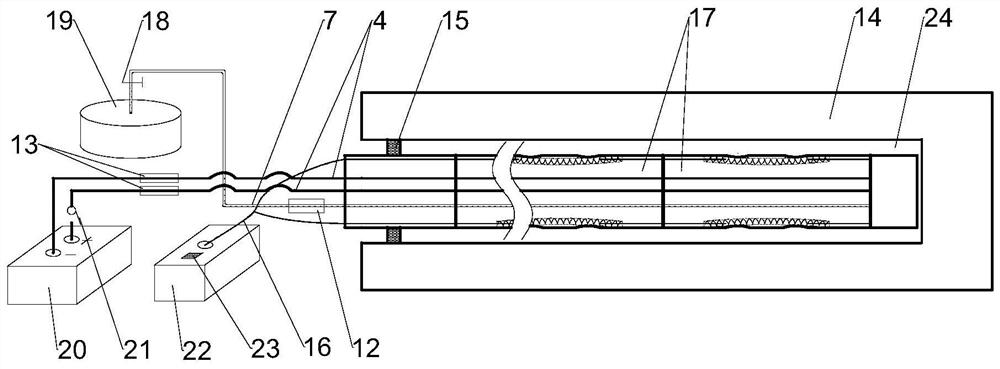

Punching device and method based on cooperation of nanofluid electro-hydraulic breakdown and infrared thermal radiation

ActiveCN112459722AImprove thermal conductivityIncrease transfer speedThermal drillingFluid removalEngineeringCoal

The invention relates to a nanofluid-based electro-hydraulic breakdown and infrared thermal radiation coordinated punching device and method, the device comprises a drill rod, a movable hole packer, an electro-hydraulic breakdown assembly and an infrared radiation heating assembly, the punching device is installed at a planned punching position, the hole packer is used for sealing a hole, and theelectro-hydraulic breakdown assembly and the infrared radiation heating assembly are installed at the same time. Then a liquid injection pump station is used for injecting nanofluid into the liquid injection cavity, then a high-voltage electric pulse generator supplies power to the positive and negative electrode plates to trigger the electro-hydraulic effect to conduct punching, and finally an infrared heater is started to crack the coal body through thermal stress. The high-pressure electro-hydraulic punching technology and the infrared thermal radiation heating technology are combined by adopting the nanofluid which is an energy transport working medium with high heat transfer performance, the advantages that electro-hydraulic breakdown is convenient and easy to precisely control can beexerted, the coal body can be rapidly heated and cracked by utilizing infrared radiation heating, and the purposes of coal seam permeability improvement and crack development are efficiently achieved. The method is simple, reliable in performance and convenient to maintain, and has a wide engineering application prospect.

Owner:CHINA UNIV OF MINING & TECH

Method of reducing hydraulic system power of multi layer hot press and practical appts

InactiveCN1833842AShorten closing timeShorten pressurization timeWood working apparatusFlat articlesProduction lineEnergy consumption

A method for decreasing the power of hydraulic system for multi-layer hydraulic press used to produce raw boards features that the hydraulic oil source for board loading and unloading machines is introduced to the closing and pressing procedures of hot press, resulting in high closing and pressing speed, low capacity of hydraulic system, and low energy consumption.

Owner:ZHENJIANG ZHONGFOMA MACHINERY

Rapid board-splicing water-based adhesive

InactiveCN107057609AFast usable timeFast dryingNon-macromolecular adhesive additivesStarch adhesivesWater basedAdhesive

The invention discloses a rapid board-splicing water-based adhesive. The rapid board-splicing water-based adhesive comprises the following materials in parts by weight: 35 to 40 percent of a macromolecular acrylic acid polymer, 5 to 10 percent of industrial corn starch, 30 to 35 percent of calcium powder, 10 to 15 percent of 15 percent polyvinyl alcohol solution, 0.05 to 0.1 percent of a wetting agent, 0.1 to 0.5 percent of a dispersing agent, 0.1 to 0.5 percent of a mildewproof agent, and 10 to 15 percent of water. Through the proportion of the materials, the rapid board-splicing water-based adhesive has the advantages of long useable time, high drying speed and high adhesion strength when being used cooperatively with 10 to 15 percent of a curing agent, can meet the pressure relief requirement 15 minutes after board splicing, greatly shortens the pressurizing time and improves labor efficiency and economic benefit for customers.

Owner:东莞市三宏胶粘材料有限公司

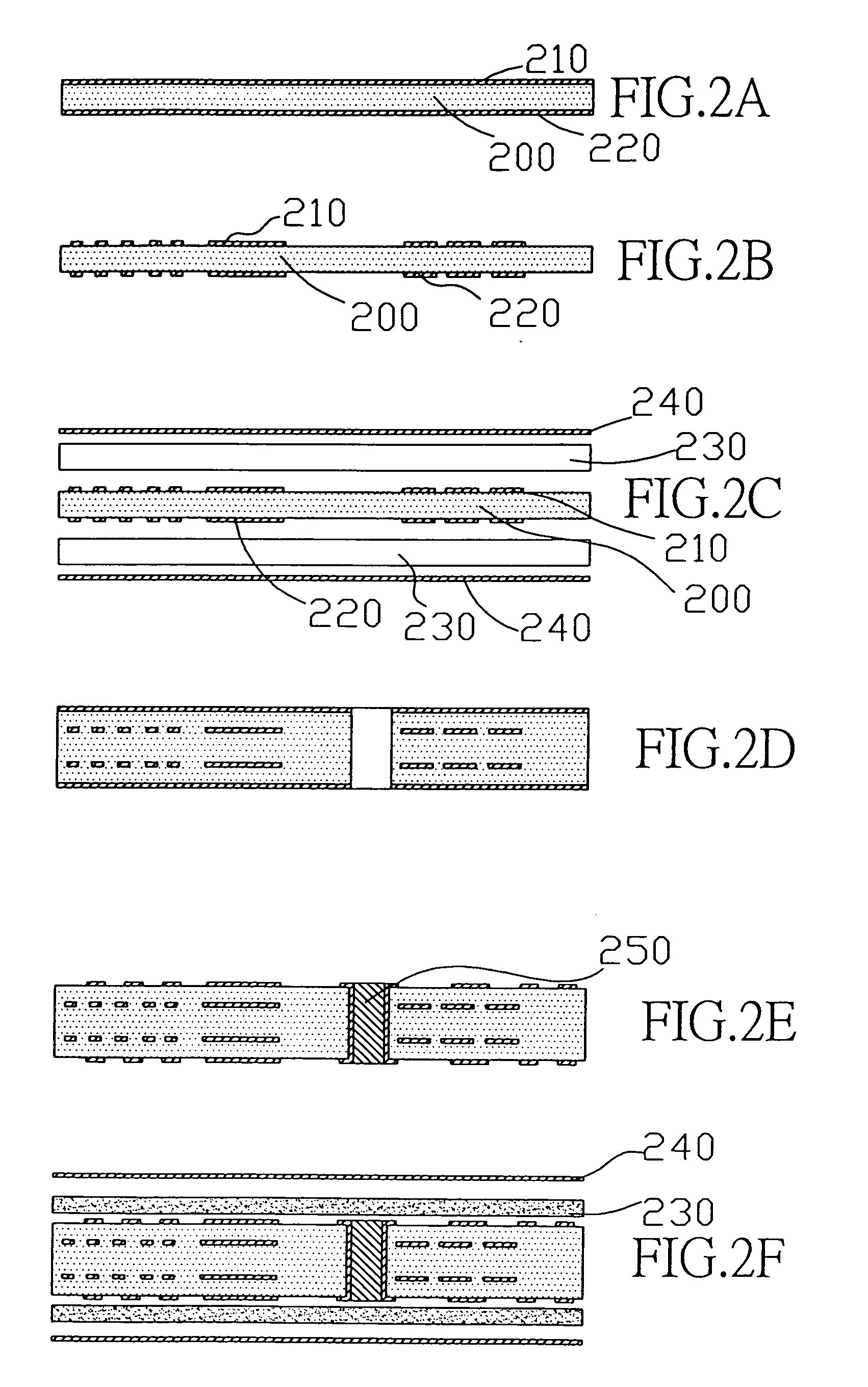

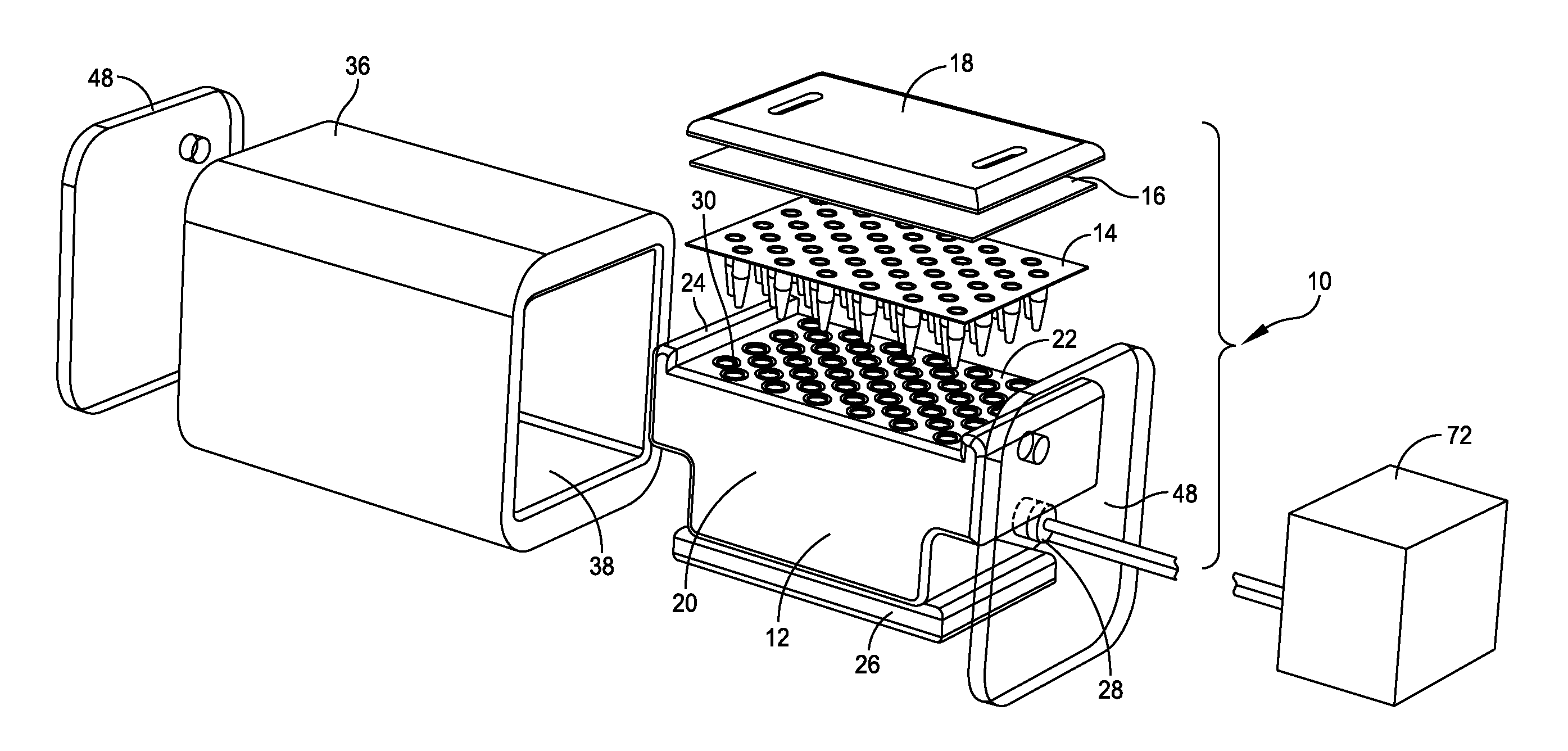

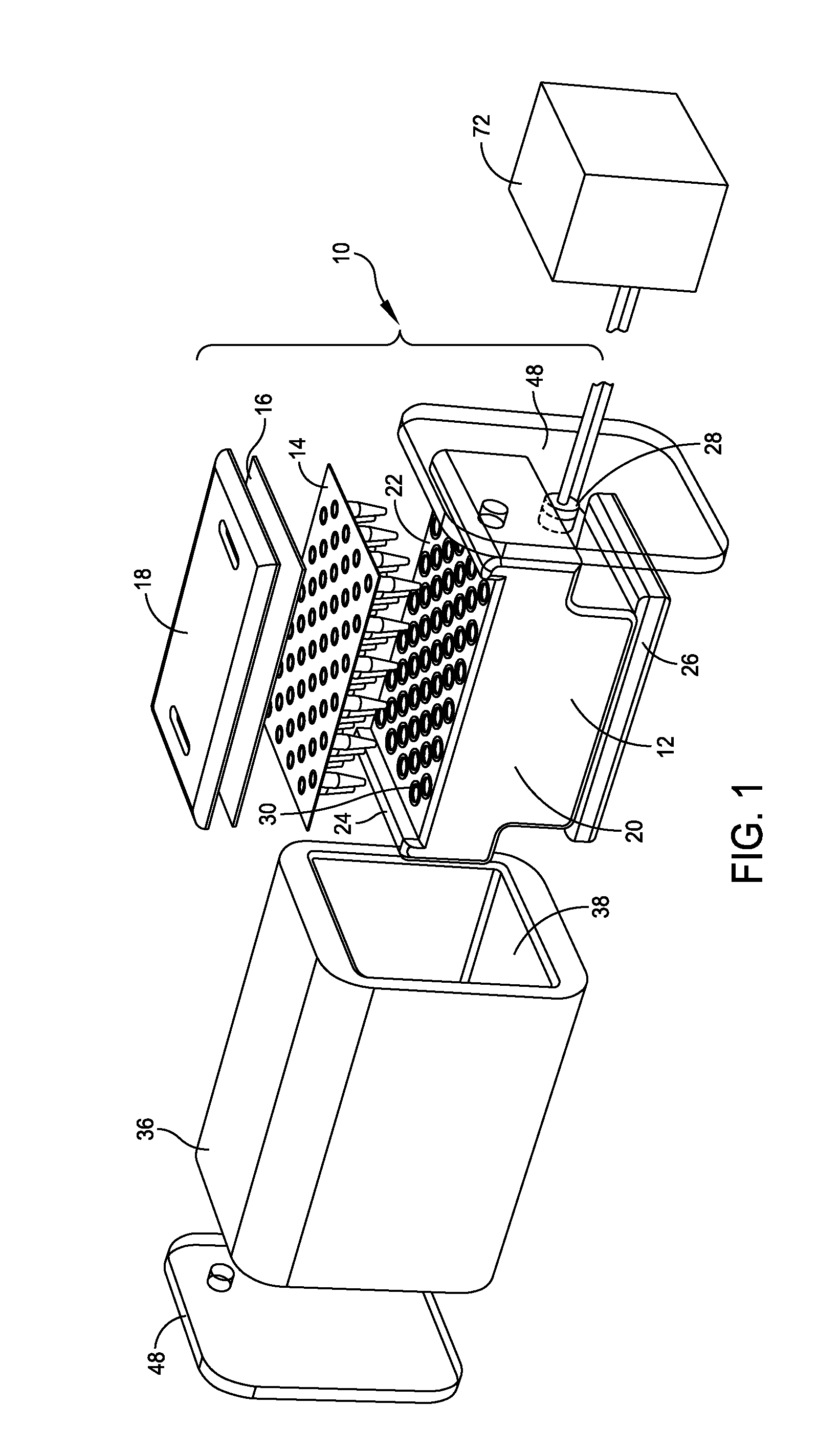

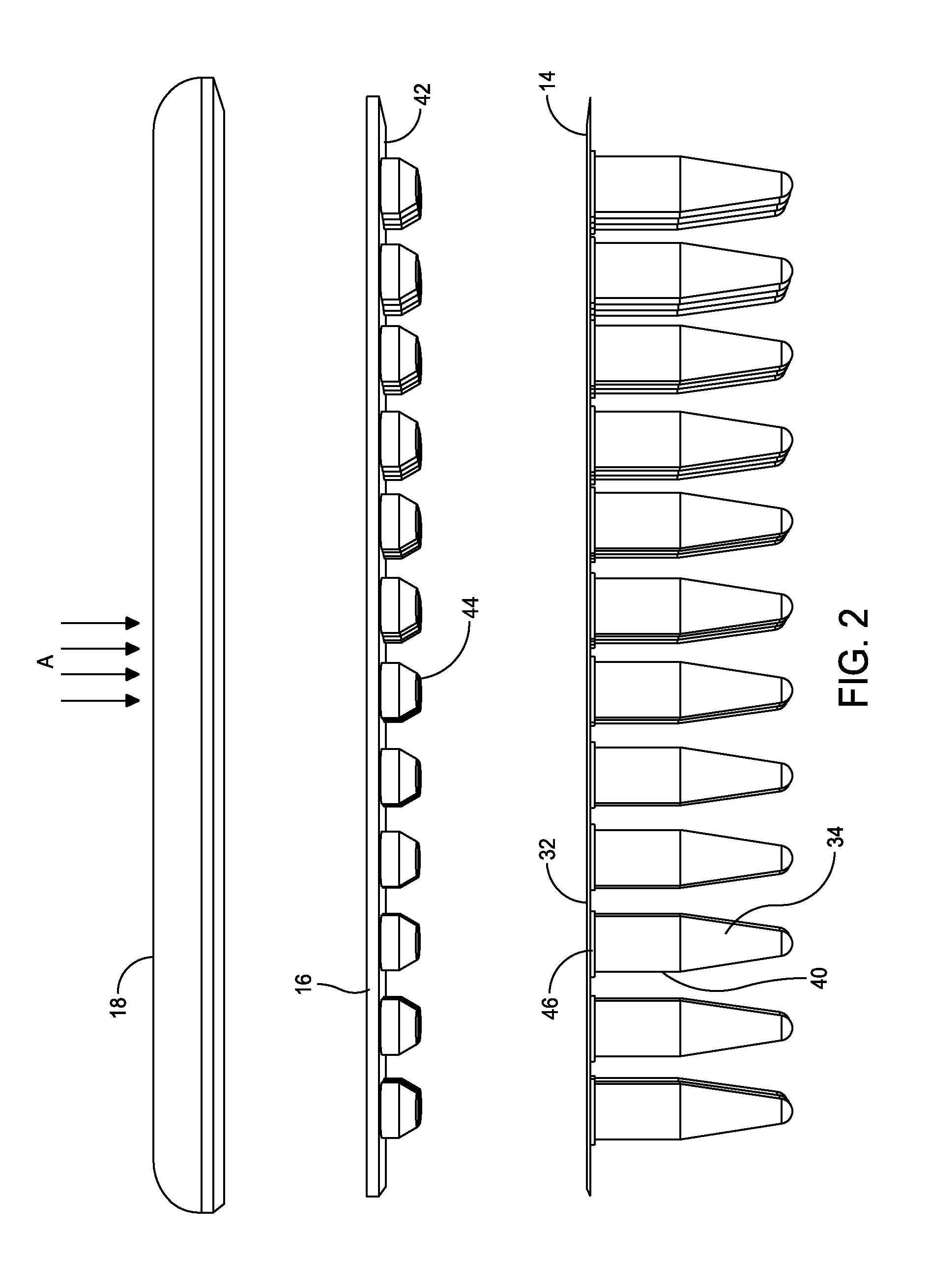

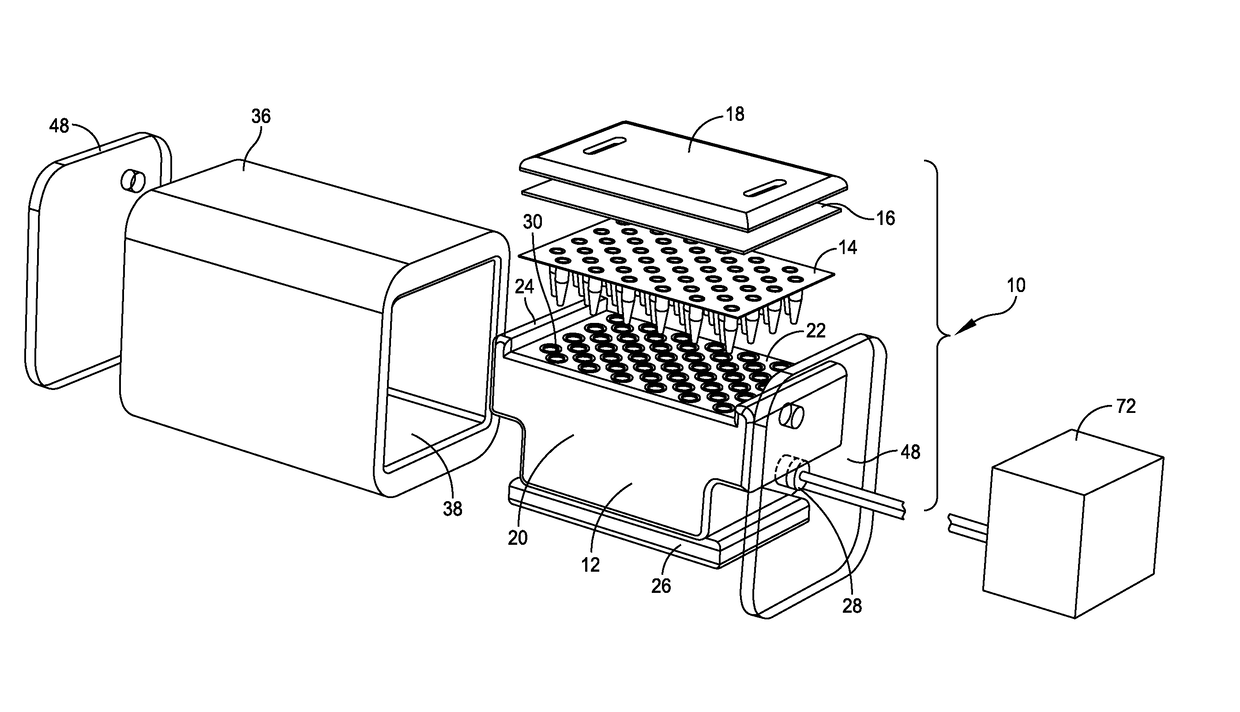

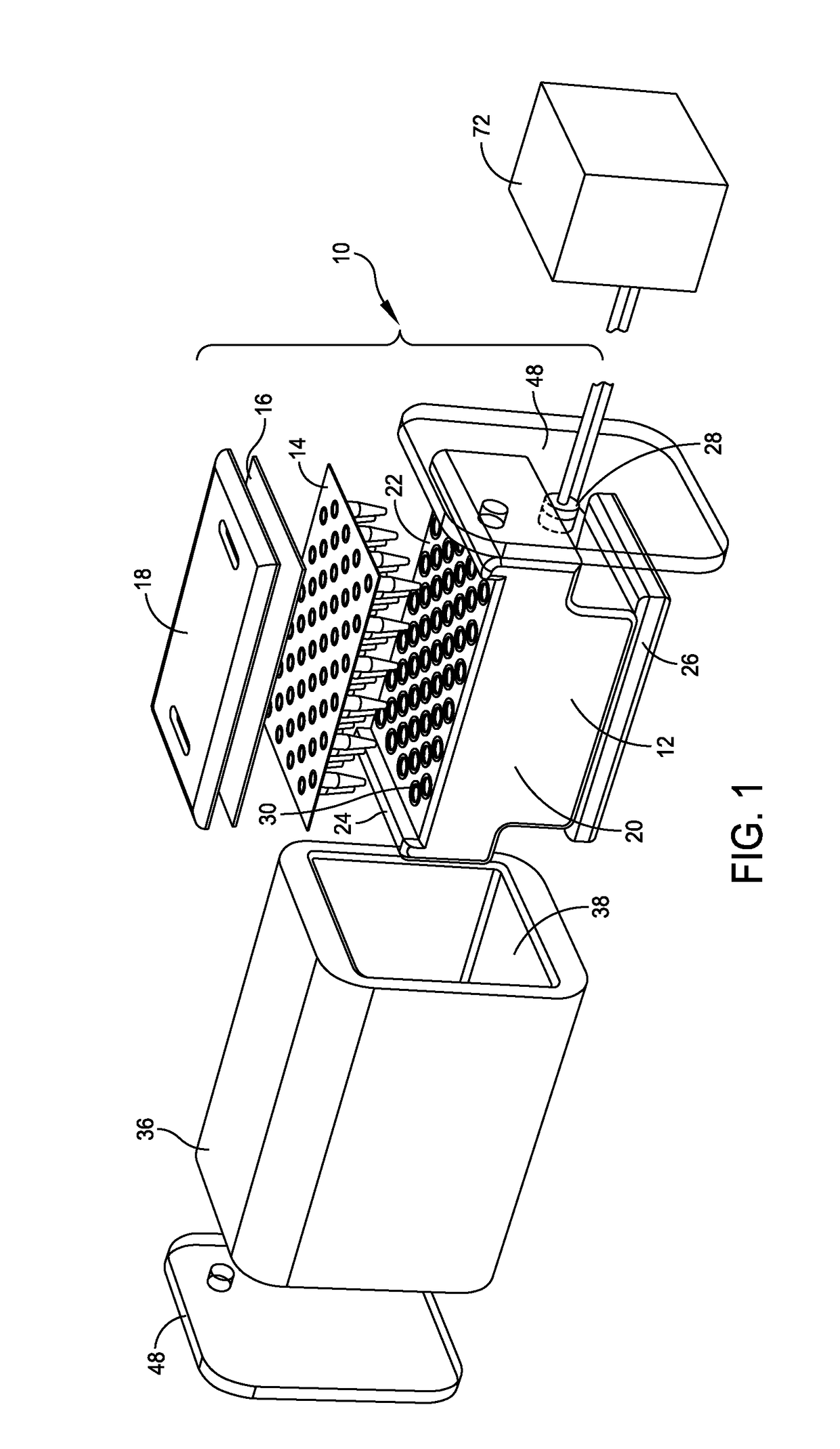

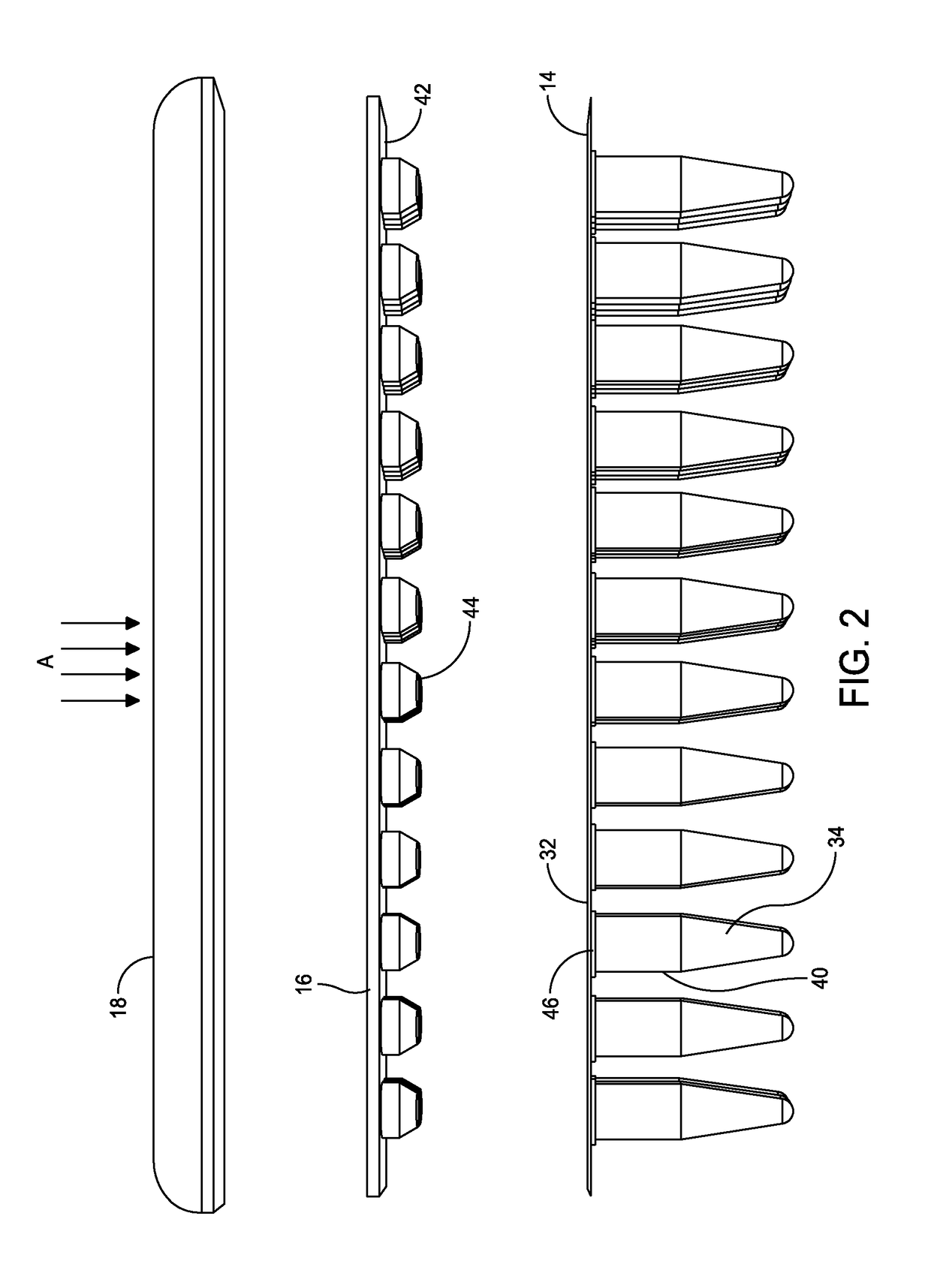

System and method for microplate pressurization

ActiveUS20120103113A1Small sizeShorten pressurization timeChemical analysis using titrationPreparing sample for investigationMicrowell PlateEngineering

A pressurizable sample system includes a microplate having a planar plate surface and several sample wells. Each sample well has a flange positioned circumferentially around an outer surface of the sample well and against the planar plate surface. The sample system further includes a capping plate with a planar cap surface and several caps projecting from the planar cap surface. Each cap has a geometrical configuration in complementary correspondence with the configuration of the sample well.

Owner:PRESSURE BIOSCI

A kind of supercritical fluid foamed polyolefin material and preparation method thereof

The invention provides a supercritical fluid foaming polyolefin material and a preparing method thereof. The supercritical fluid foaming polyolefin material is prepared through the following steps that a polyolefin sheet is prepared, and the melting point of the polyolefin sheet is Tm; radiation crosslinking is carried out on the polyolefin sheet; the crosslinked polyolefin sheet is put into a pressure container for high-pressure nitrogen impregnation, and the impregnation temperature T1 is equal to Tm+(30-120) DEG C; low-temperature heating foaming is carried out, and the foaming temperature T3 is equal to Tm+(20-50) DEG C, and is smaller than T1. By the adoption of the technical scheme, the requirement for material crystallinity is avoided, the time of reaching a dissolution saturation state of gas is greatly shortened, efficiency is improved, and the foaming material which is fine and uniform in bubble, low in density, high in mechanical strength and regular in shape can be obtained.

Owner:湖州长园特发科技有限公司

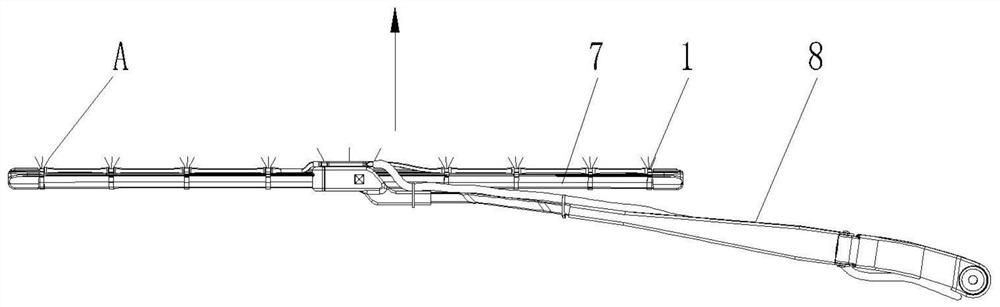

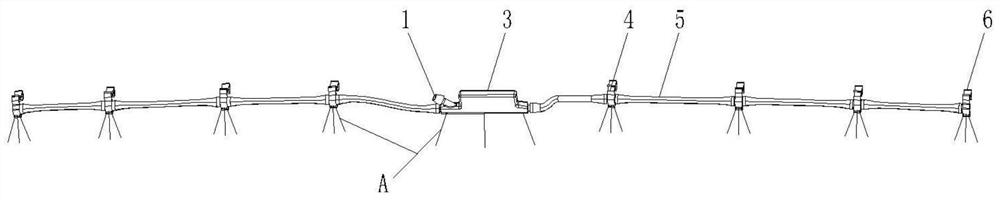

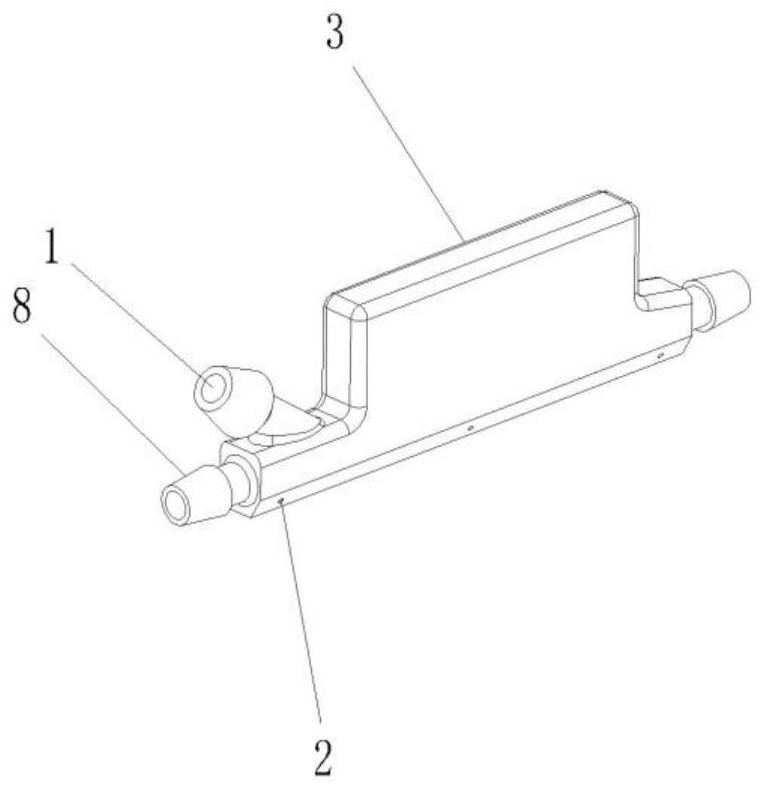

Wiper blade nozzle holder

PendingCN114228664AShorten pressurization timeEasy to cleanVehicle cleaningAutomotive engineeringManufacturing engineering

The wiper blade nozzle support comprises a wiper support body used for installing a wiper blade, a liquid inlet hole and a plurality of liquid spraying holes are formed in the wiper support body, the liquid inlet hole is used for guiding washing liquid into the wiper support body and spraying the washing liquid out of the liquid spraying holes, and the liquid spraying holes are located in the side, in the wiping direction of a windshield, of the wiper support body; according to the wiper blade nozzle support, the pressurizing time of a washing pump each time can be shortened, the washing liquid spraying area is always dynamically kept in front of the wiping direction of the wiper blade, washing liquid is sprayed in the wiping stage of the wiper blade, the washing liquid is effectively used for cleaning a windshield, consumption of the washing liquid is reduced, meanwhile, the cleaning effect is improved, and energy conservation and consumption reduction are facilitated.

Owner:重庆金康赛力斯新能源汽车设计院有限公司

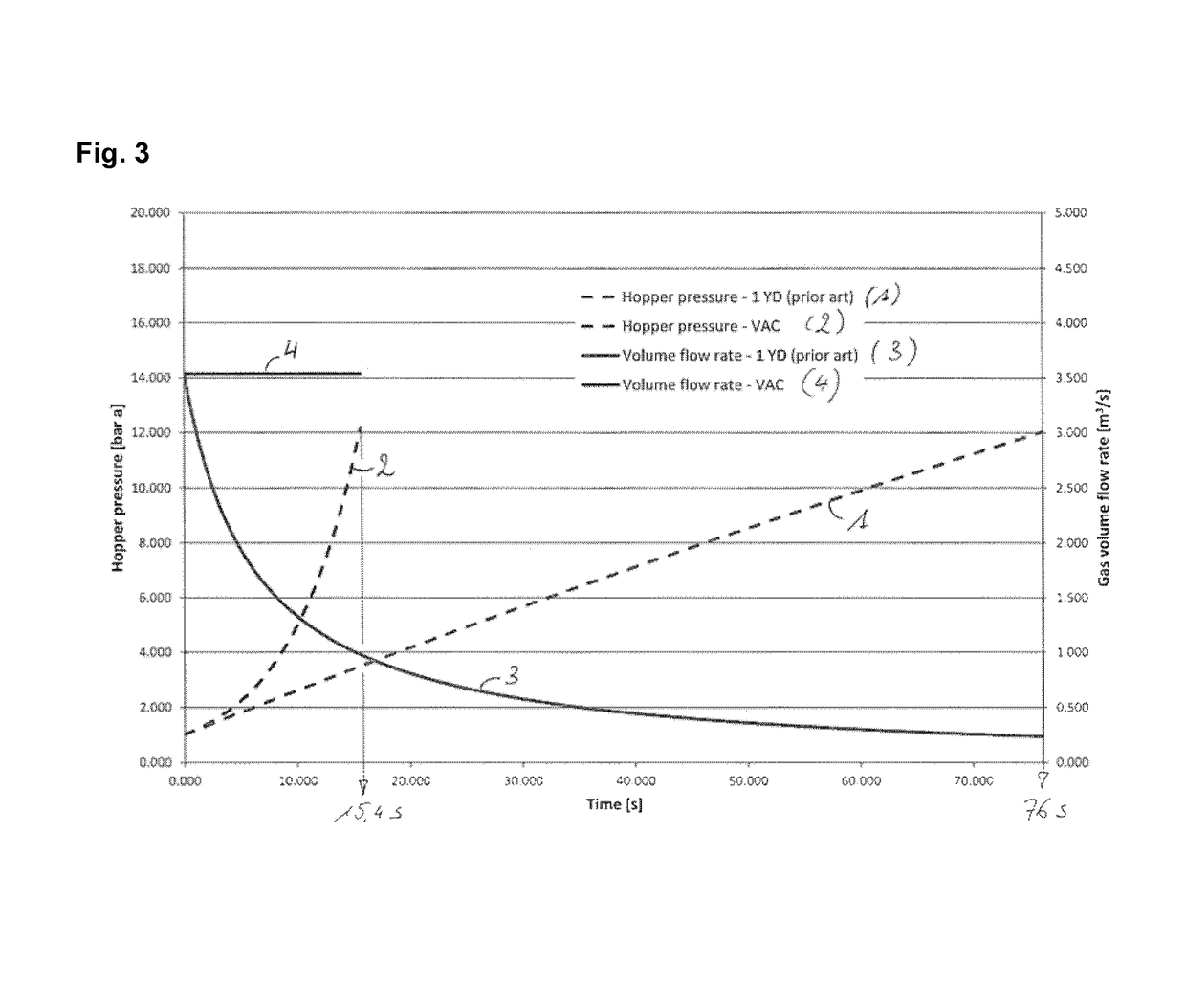

Enhanced pressurising of bulk material in lock hoppers

ActiveUS10633199B2Shorten pressurization timeReduce noise nuisanceBulk conveyorsLine tubingEngineering

A process for pressurizing bulk material in an apparatus for pressurizing bulk material in a hopper; wherein the hopper is configured as a lock hopper containing a bulk material, wherein the apparatus comprises a source of pressurized gas, lines to convey the pressurized gas from the source of pressurized gas to one or more inlets of the lock hopper, a valve arrangement arranged in the lines, wherein the process is characterized in that said valve arrangement comprises at least two valves arranged in parallel, each valve being connected to a downstream Laval tuyere, and in that said valves are controlled to open in an operating sequence to provide pressurizing gas with an adjusted gas flow rate to the lock hopper.

Owner:PAUL WURTH SA

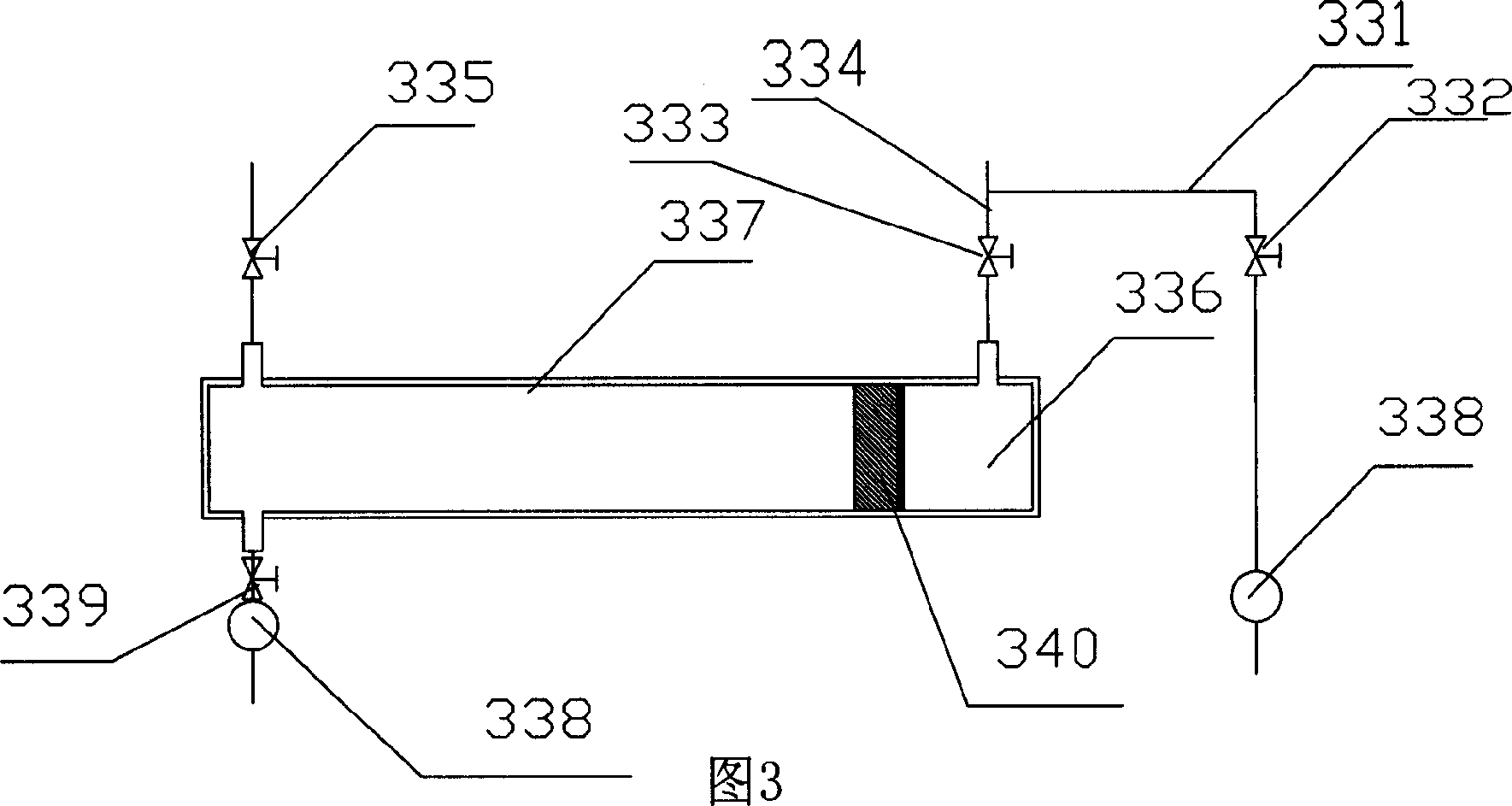

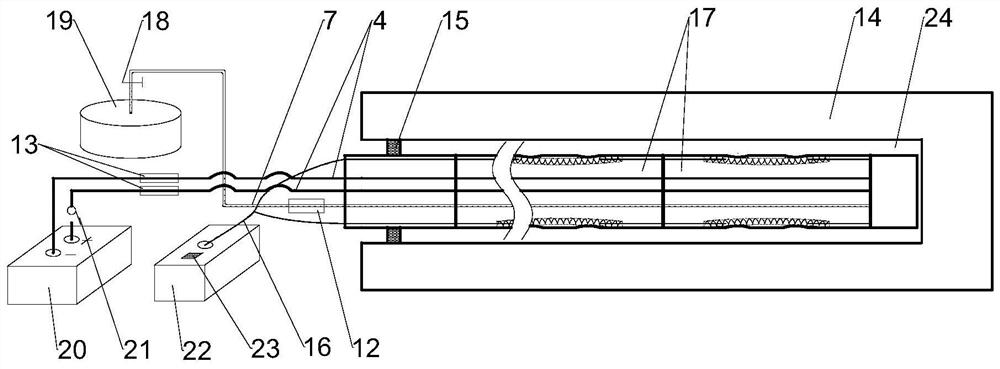

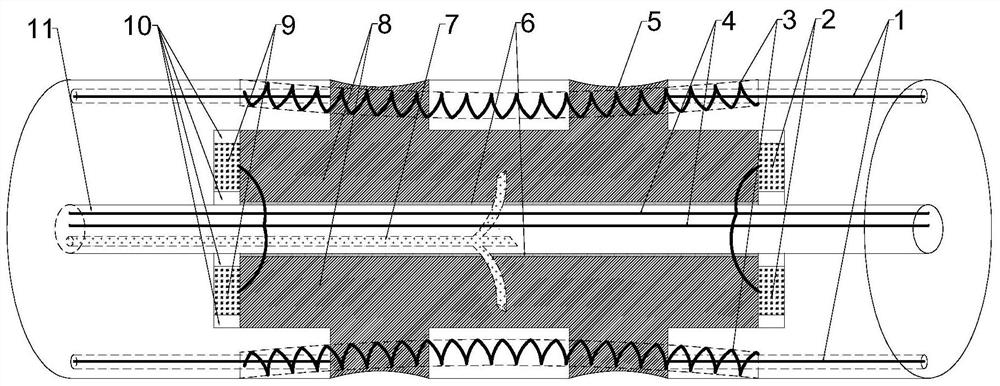

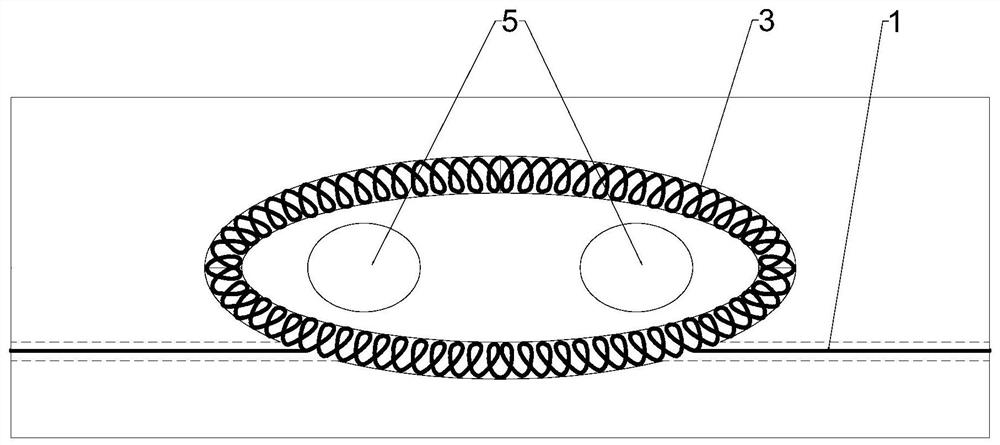

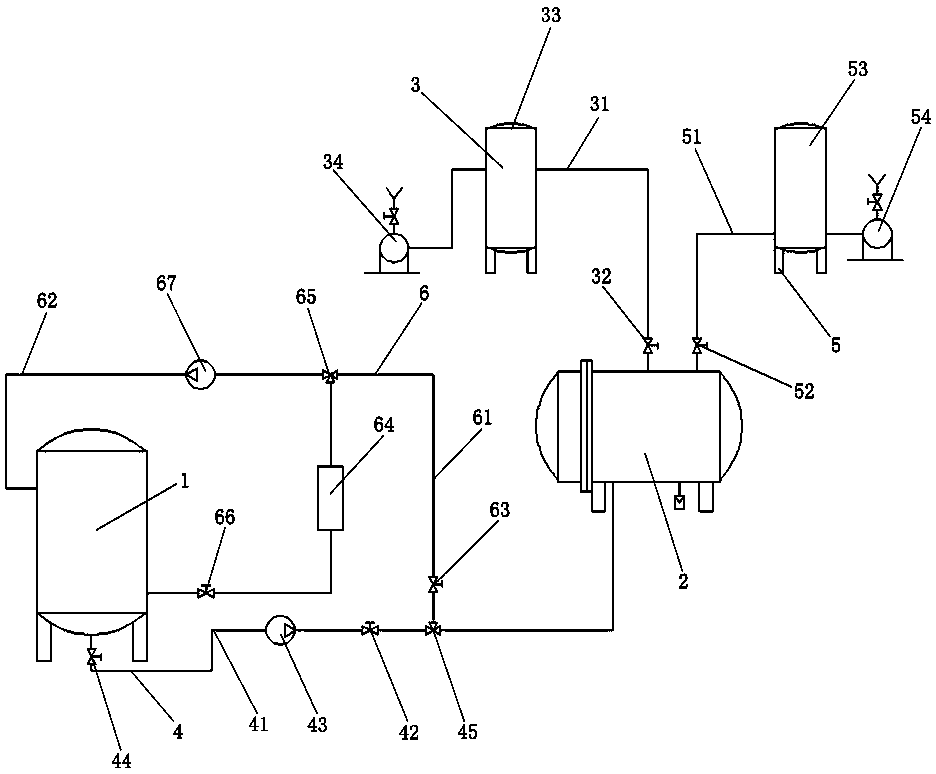

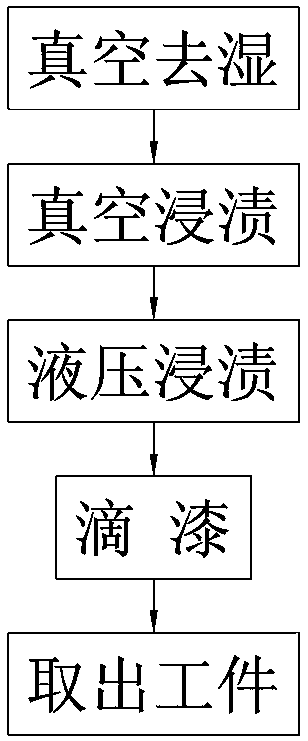

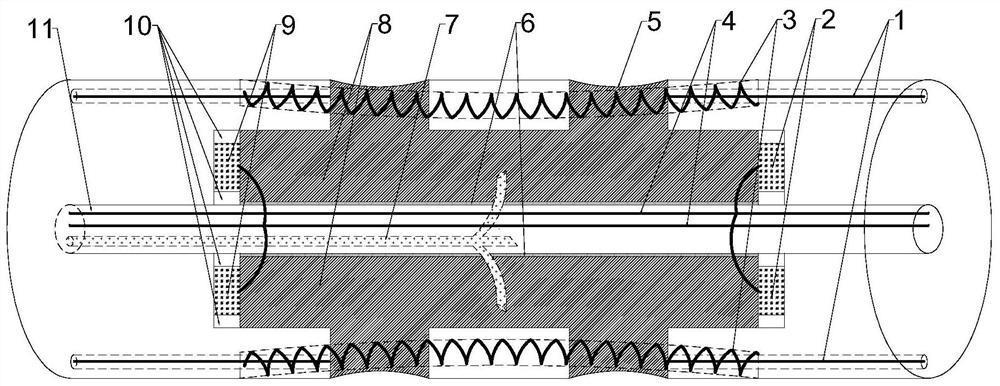

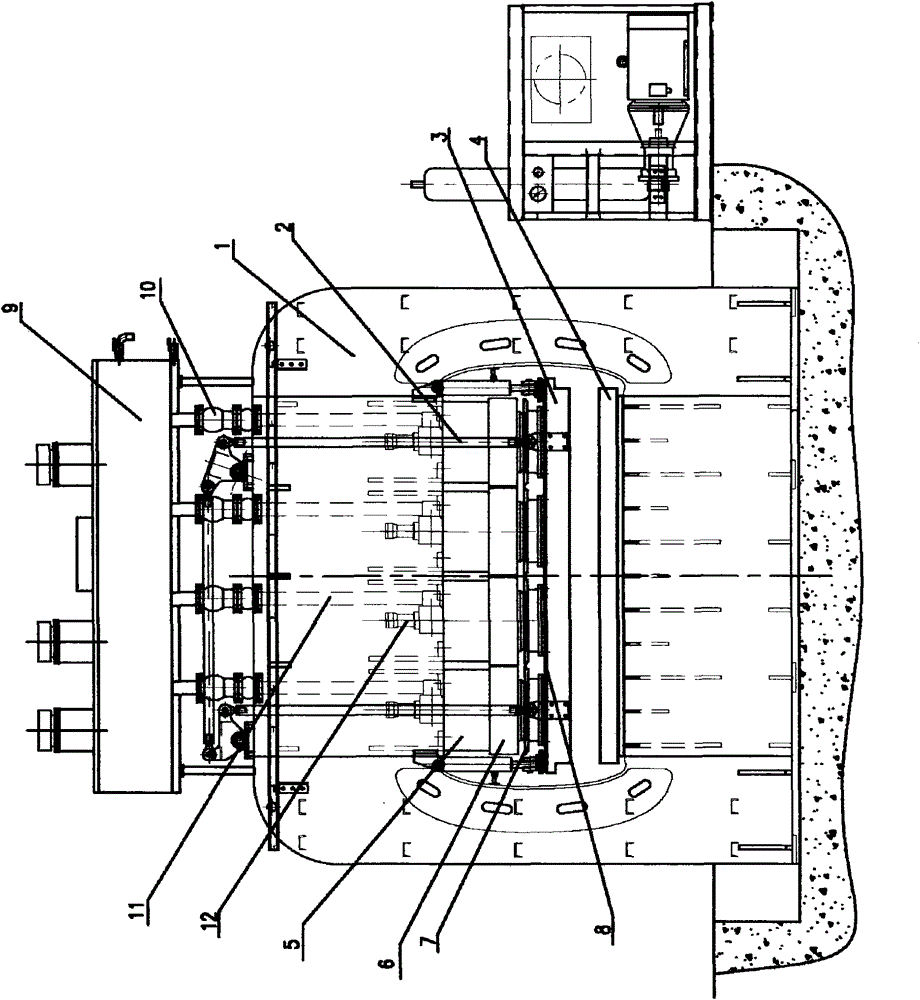

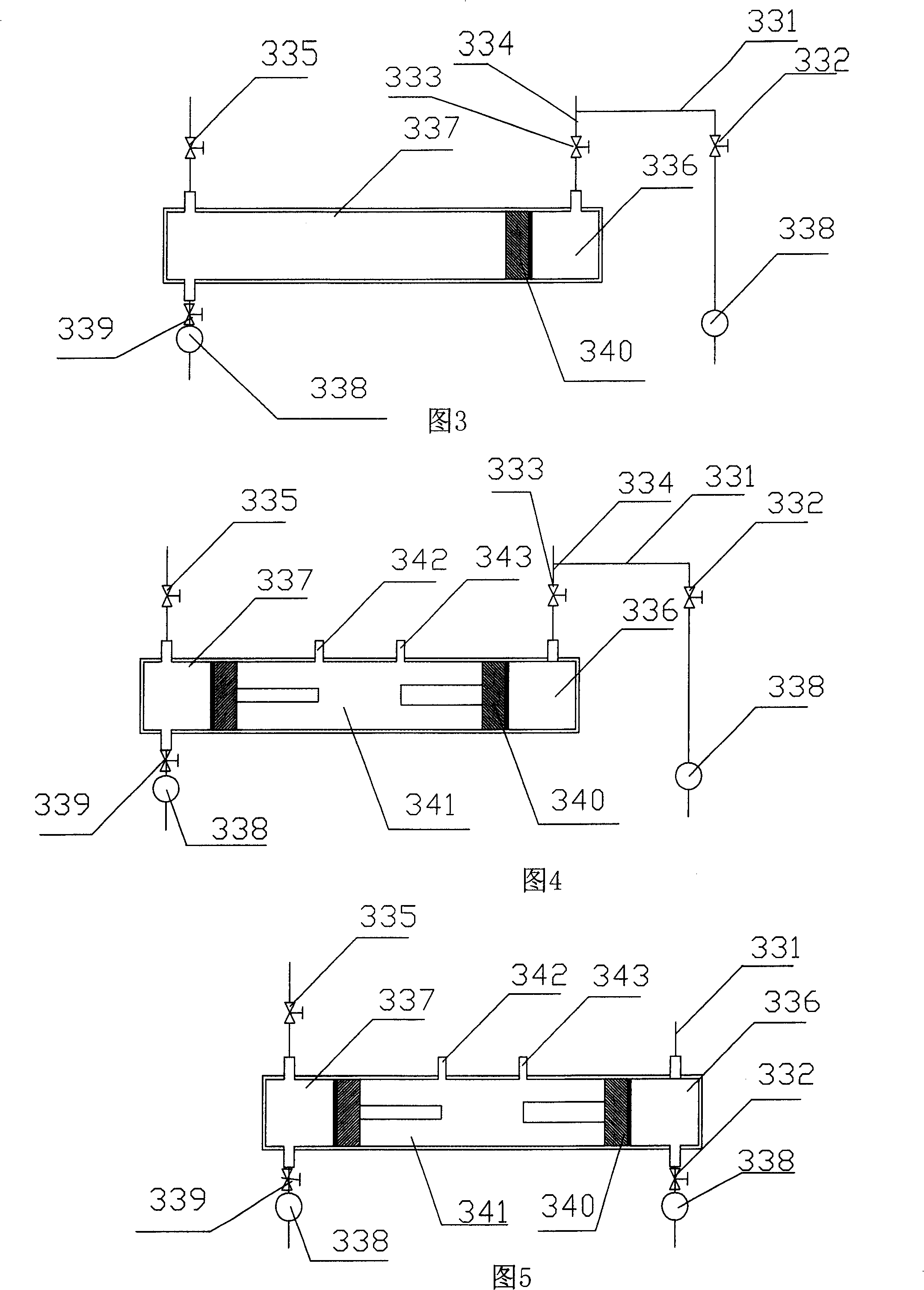

Vacuum hydraulic impregnation device and impregnation method

ActiveCN106881237BSupercharged quicklyHigh rated pressureLiquid surface applicatorsCoatingsLacquerEngineering

The invention discloses a vacuum liquid pressure impregnation (VLPI) device and an impregnation method. The device comprises a paint storage tank, a paint soaking tank, a vacuum set, an external pressurizing assembly, an evacuating assembly, and an internal circulation assembly. The vacuum set and the evacuating assembly are both connected to the paint soaking tank. The paint storage tank is connected to the paint soaking tank through the external pressurizing assembly. One end of the internal circulation assembly is connected to the paint storage tank, and the other end is connected to the external pressurizing assembly. The method comprises the following steps: step one, carrying out vacuum dehumidifying; step two, performing vacuum paint soaking; step three, carrying out liquid pressure impregnation; step four, dripping paint; and step five, taking out workpiece. The provided device and method have the advantages that the pressure increasing is rapid and stable, the impregnation effect and product quality are high, and the paint filtering frequency is reduced.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

A punching device and method based on nanofluid-based liquid-electric breakdown and infrared thermal radiation

ActiveCN112459722BImprove thermal conductivityIncrease transfer speedThermal drillingFluid removalEngineeringMaterials science

The invention relates to a punching device and method based on nanofluid-based electrohydraulic breakdown and infrared thermal radiation. First install the punching device at the planned punching position, and seal the hole with a hole sealer, then inject nanofluid into the injection chamber with a liquid injection pump station, and then a high-voltage electric pulse generator supplies power to the positive and negative electrode plates to trigger The hydraulic effect is used for punching, and finally the infrared heater is turned on to cause thermal stress to crack the coal body; the present invention uses nanofluid, an energy transport medium with high heat transfer performance, to combine high-pressure hydraulic punching technology with infrared heat radiation heating technology Combined, it can not only take advantage of the convenience and precision control of hydraulic and electric breakdown, but also use infrared radiation heating to rapidly raise the temperature to crack the coal body, effectively achieve the purpose of coal seam permeability enhancement and fracture development, and the method is simple, reliable, and easy to maintain , has broad engineering application prospects.

Owner:CHINA UNIV OF MINING & TECH

System and method for microplate pressurization

ActiveUS10105704B2Small sizeShorten pressurization timeChemical analysis using titrationPreparing sample for investigationMicrowell PlateEngineering

Owner:PRESSURE BIOSCI

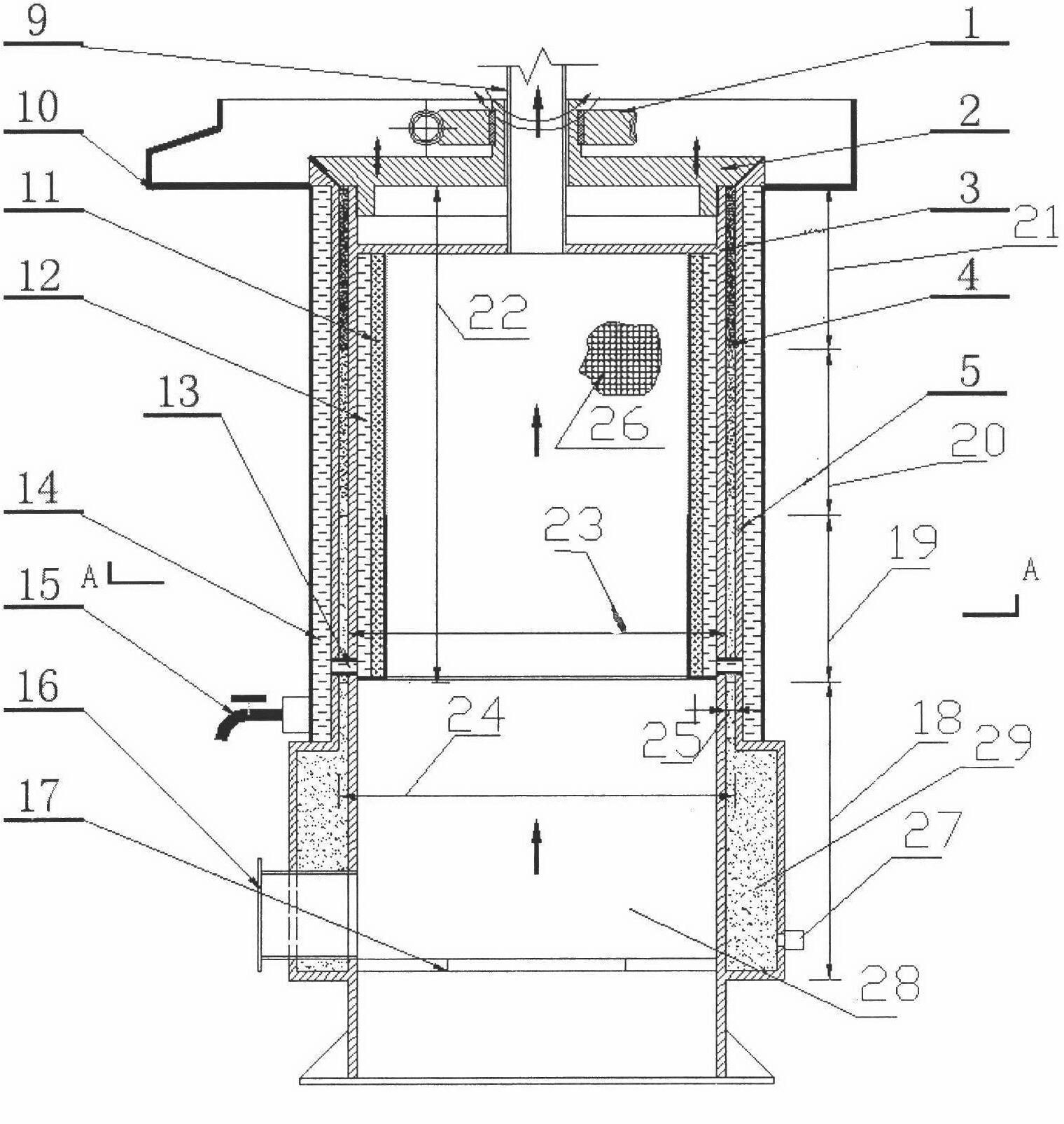

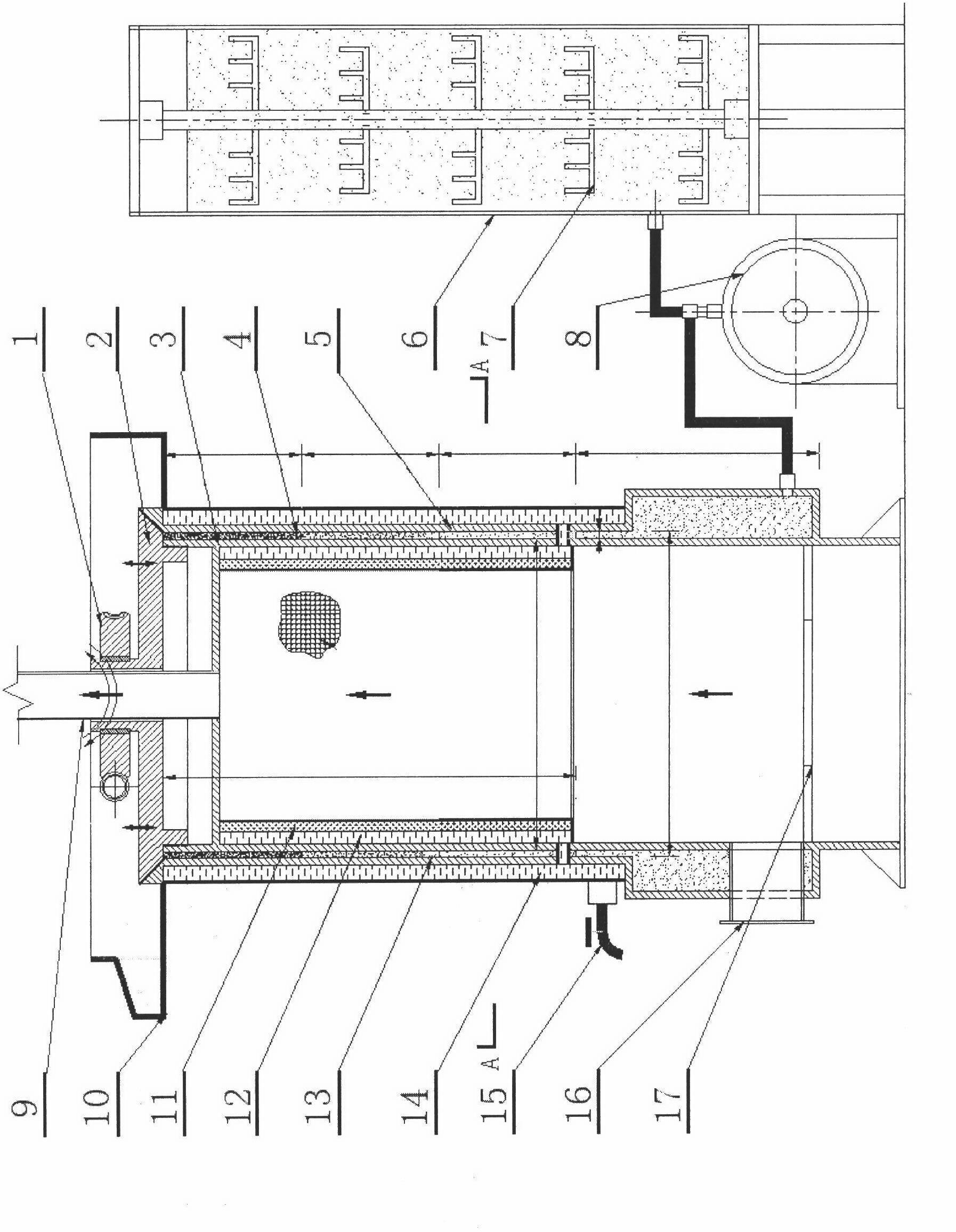

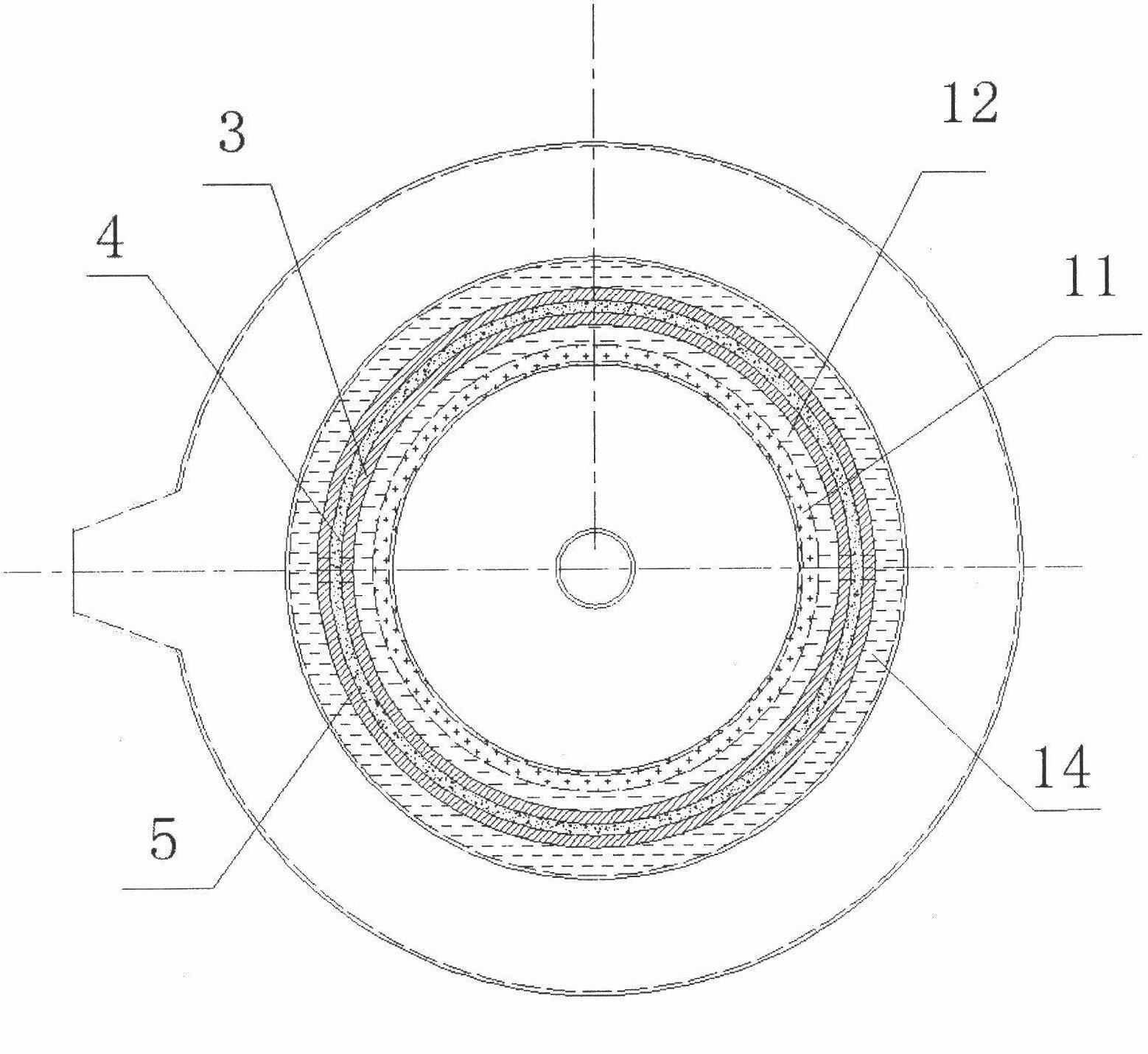

Cylindrical gap type continuous filter press

InactiveCN102657967AEasy to dehydrateWide applicabilityGravity filtersStationary filtering element filtersAutomatic controlEngineering

The invention discloses a cylindrical gap type continuous filter press. A slurry homogeneous stirrer is arranged in a slurry homogenizing tower, and a slurry outlet pipe of the slurry homogenizing tower is fixedly communicated with a high-pressure slurry inlet through a high-pressure slurry pump. The filter press consisting of a dewatering part and a heating part also comprises a worm drive pair, a discharging circular seam regulator, a cylindrical inner steel cylinder, a cylindrical outer steel cylinder, a thermal-protective coating, an inner water jacket, an outer water jacket and a heating furnace, wherein the inner steel cylinder and the outer steel cylinder of the dewatering part at the upper part are uniformly provided with a plurality of filtering holes along the circumference, and the inner steel cylinder and the outer steel cylinder of the dewatering part at the lower part are internally provided with the heating furnace; and the inner water jacket is fixedly communicated with the outer water jacket through an inner water jacket communicating pipe and an outer water jacket communicating pipe which are symmetrically arranged front and back, and the inner water jacket communicating pipe and the outer water jacket communicating pipe are arranged between the inner steel cylinder and the outer steel cylinder. The cylindrical gap type continuous filter press has the advantages of good dewatering property, wide application range, capability of realizing continuous and automatic control, and low operation cost.

Owner:何宁川

Hot-pressing laminator with uniform-type oil cylinder oil supply device

InactiveCN104552501ALower working temperatureExtended service lifePlywood pressesVeneer pressesHeat pressBall valve

A hot-pressing laminator with a uniform-type oil cylinder oil supply device comprises a rack, connecting rod synchronizing mechanisms, an oil cylinder body, an upper hot-pressing plate, a lower hot-pressing plate and the uniform-type oil cylinder oil supply device. The hot-pressing laminator is characterized in that the connecting rod synchronizing mechanisms are mounted on two sides of the rack, one ends of the connecting rod synchronizing mechanisms are connected onto the upper hot-pressing plate while the other ends of the same are connected on the rack, a driving head of the oil cylinder body is connected with the upper hot-pressing plate, a heat-insulating pad seat is arranged between the driving head and the upper hot-pressing plate, an oil collecting disc is mounted at the lower end, below the heat-insulating pad seat, of the oil cylinder body, the lower hot-pressing plate is positioned below the upper hot-pressing plate and fixed on the rack, the oil cylinder oil supply device is mounted at the top of the rack and connected with the oil cylinder body through oil ways, a cock valve is arranged on each oil way, and a liquid flushing ball valve is vertically connected on each oil way. The hot-pressing laminator has the advantages of uniformity in oil cylinder liquid flushing time, short pressurizing time, small oil way flow loss, high liquid flushing speed and convenience in maintenance.

Owner:无锡市陆通机械有限公司

Bonding technology used between metal and metal

InactiveCN105268821AConsistent joint strengthEliminates uneven joint strengthMetal working apparatusMetal sheetFlanging

The invention relates to the technical field of metal plates, in particular to a bonding technology used between metal and metal. The bonding technology comprises the following steps that (1) a metal component to be connected is provided, a protrusion is machined on the end face of the metal component to be connected, a groove is machined in the portion below the head of the protrusion, and the head of the protrusion forms an annular protrusion; (2) a metal sheet is provided, a through hole conforming to the size of the outer diameter of the annular protrusion is punched in the metal sheet, and the edge of the through hole is machined into a flanging; and (3) the annular protrusion is put into the flanging hole of the metal sheet and subjected to extrusion machining, and the flanging of the metal sheet is pressed into the groove of the metal component to be connected, so that the metal sheet is tightly bonded with the metal component to be connected. Compared with the prior art, the bonding technology makes the strength between the metal sheet and the metal component to be connected be consistent and free of the limitation of texture.

Owner:赵敏

Auto-controlled gas liquid two purpose leakage detector

InactiveCN100453994CSolve the problem that cannot be used twiceSolve cleaning problemsMeasurement of fluid loss/gain rateAutomatic controlDifferential pressure

The invention relates to discloses self control gas liquid dual purpose leak-detector. It includes air source, pressure adjusting unit, differential pressure test unit, control unit connected with the pressure adjusting unit set adjusting valve and differential pressure test unit includes differential pressure transducer, filter, pressure protective valve, prove, and standard parts. The probe is gas liquid dual purpose detecting device. The leak detector of the invention can be used to detect gas or liquid leakage to realize one machine has dual purpose.

Owner:宁波赛盟科技发展有限公司

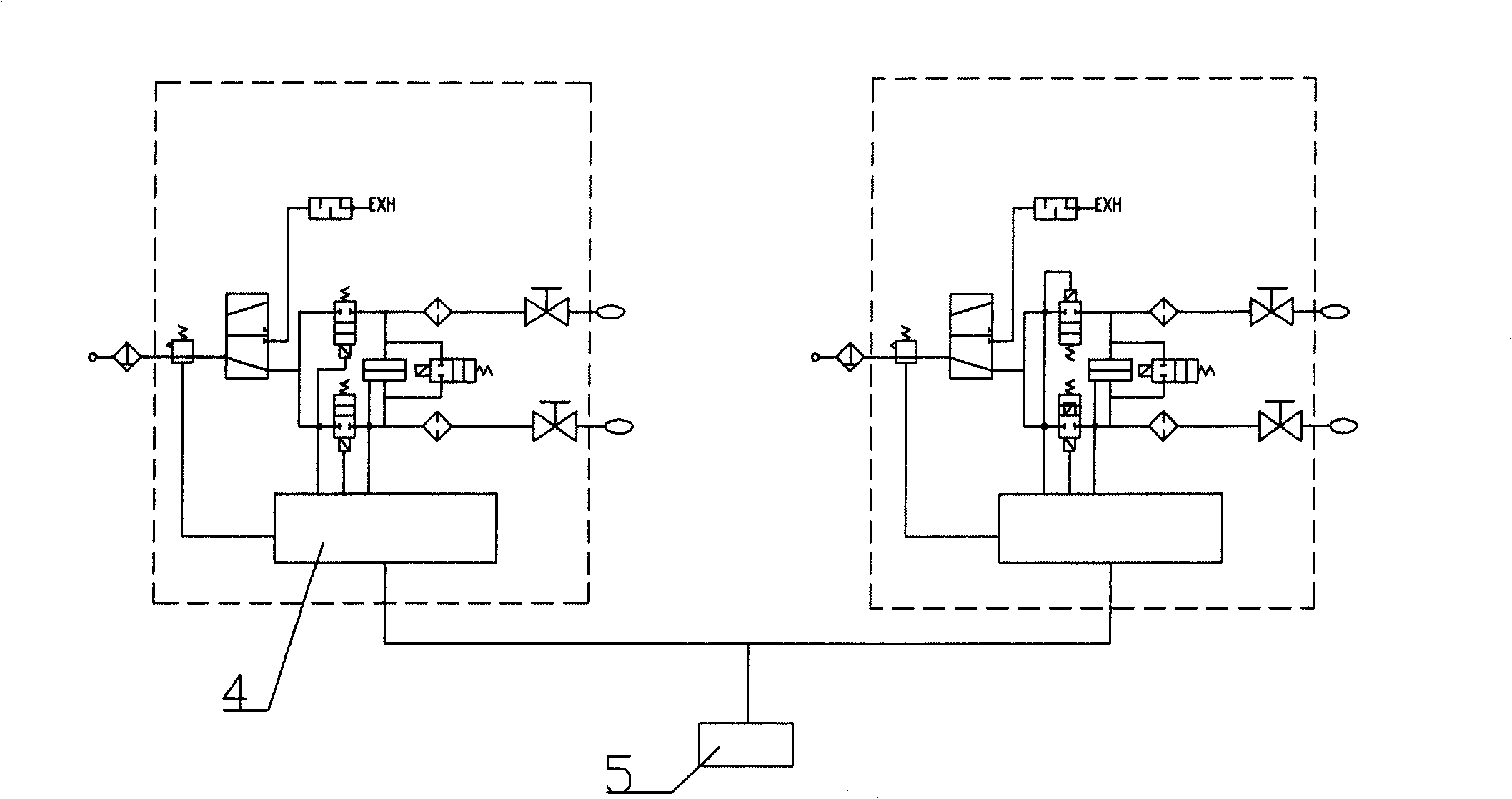

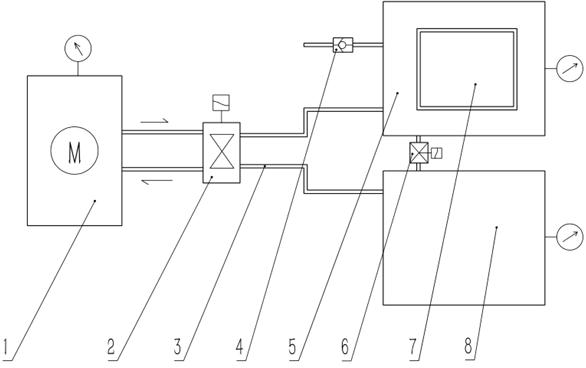

3D printing high-pressure rapid pressurizing device and energy-saving method

InactiveCN112192844AReduce wasteShorten pressurization timeAdditive manufacturing apparatusManufacturing environment conditioningProcess engineeringStress sensors

The invention provides a 3D printing high-pressure rapid pressurizing device which comprises an air compressor, a printing bin and an air storage tank. The air compressor is connected with the printing bin and the air storage tank through a reversing valve and a high-pressure air pipe, the printing bin and the air storage tank are connected through a pipeline, a bin tank communicating control valve is arranged on the connecting pipeline, and a bin door and a ventilation pipe are arranged on the printing bin. A one-way valve is arranged on the ventilation pipe, pressure sensors are arranged onthe printing bin and the air storage tank, a control unit is connected with the pressure sensors, the bin tank communicating control valve and the reversing valve, and the air compressor, the printingbin and the air storage tank form a circulation body through pipelines, the bin tank communicating control valve and the reversing valve, wherein the bin tank communicating control valve and the reversing valve are installed on the pipelines. Through a simple circulating device, the pressurizing time can be greatly shortened by adopting the method, energy waste is reduced, and the printing cost is low.

Owner:SUZHOU ANHUI SAIERWODE INTERNET OF THINGS TECH CO LTD

Method of reducing hydraulic system power of multi layer hot press and practical appts

InactiveCN100374266CShorten closing timeShorten pressurization timeWood working apparatusDomestic articlesProduction lineEngineering

Owner:ZHENJIANG ZHONGFOMA MACHINERY

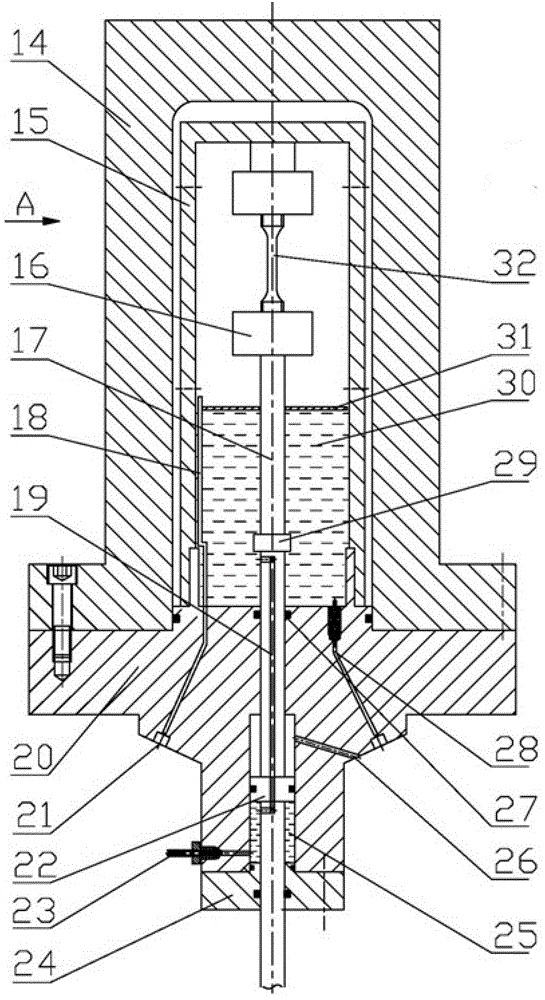

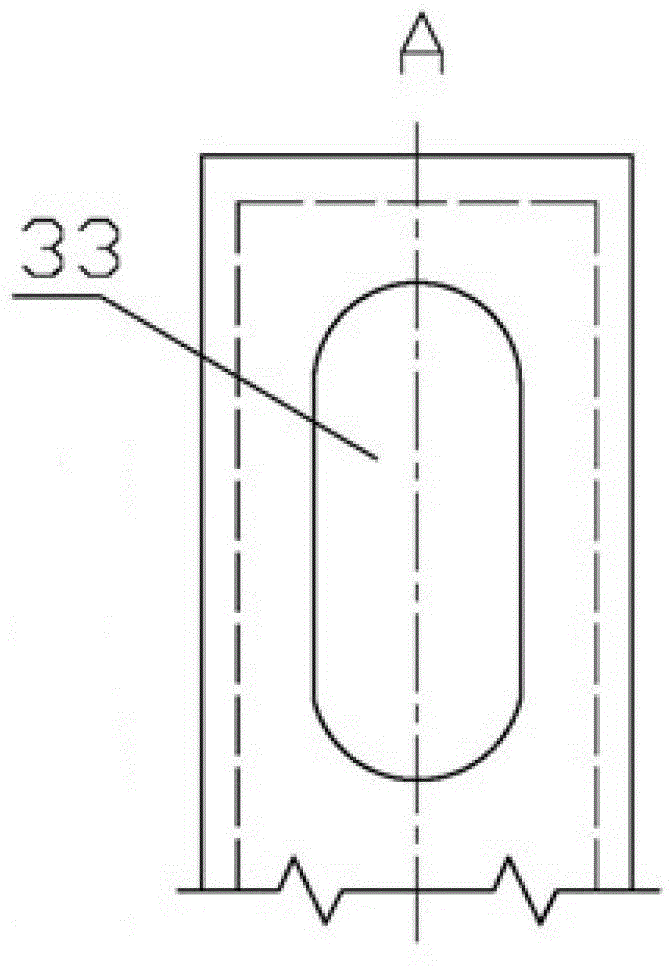

Material testing device under high-pressure hydrogen environment based on ionic liquids and operation method

ActiveCN103278390BRequirements for reduced rated maximum outlet pressureIncrease pressureMaterial strength using tensile/compressive forcesPressure transmissionEngineering

The invention relates to a testing technique of mechanical properties of materials, in order to provide a material testing device under a high-pressure-hydrogen environment based on ionic liquids and an operation method. A high-pressure hydrogen environment box of the device is internally provided with a cylindrical sample support; the lower end of a loading rod is connected with a power output device of a host machine, and the upper end of the loading rod penetrates through an end cover, and extends into the sample support to be connected with a sample fixture; the ionic liquids are filled in an internal space below an open pore in the top of the sample support; a balance cavity is arranged at the bottom of the end cover, and is composed of an extending section of the tail end of the end cover, a piston connected with the loading rod and a seal bottom cover of the balance cavity; and the loading rod is provided with a load sensor. According to the invention, the balancing cavity and the high-pressure hydrogen environment box transfer pressure by utilizing the ionic liquids, and the hydrogen leakage hazard generated when the pressure is transferred by using hydrogen is prevented; and high-pressure dynamic seal elements, rather than high-pressure hydrogen, in the device, are all in contact with the ionic liquids, thus hydrogen leakage is prevented, and the device safety is improved.

Owner:ZHEJIANG UNIV

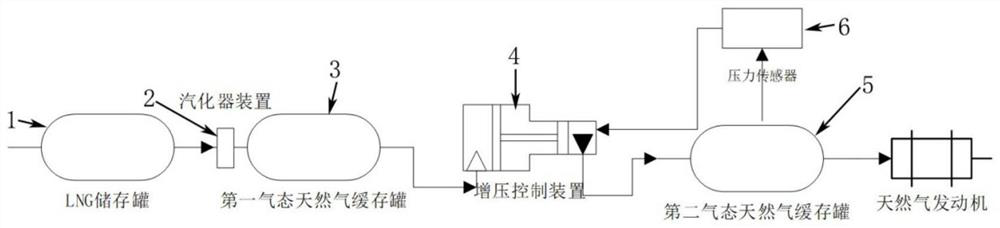

LNG (Liquefied Natural Gas) pressurization control system

PendingCN113124315AAchieve normal startupImprove driving convenienceGas handling/storage effectsPipeline systemsStress sensorsBuffer tank

The invention discloses an LNG (Liquefied Natural Gas) pressurization control system. Liquefied natural gas is stored in an LNG storage tank, and the liquefied natural gas is converted into gaseous natural gas through a vaporizer device and stored in a first gaseous natural gas buffer tank; a pressure sensor detects the air pressure of a second gaseous natural gas buffer tank and sends the air pressure to a pressurization control device; when the pressurization control device detects that the received air pressure is smaller than a preset minimum value, the gaseous natural gas in the first gaseous natural gas buffer tank is pumped into the second gaseous natural gas buffer tank, and when the air pressure of the second gaseous natural gas buffer tank reaches the air pressure for starting the natural gas engine, a natural gas engine is started; and when the pressurization control device detects that the received air pressure is larger than a preset maximum value, the pressurization control device stops working. The pressurization control device is arranged for air exhaust and pressurizing, rapid pressurizing can be achieved in a short time, engine starting is achieved in a short time, and driving convenience is improved.

Owner:常州易控汽车电子股份有限公司

An asphalt pavement pore water pressure simulation test device and method

InactiveCN105445168BNo gapAvoid direct connectionPermeability/surface area analysisAdhesivePore water pressure

An asphalt pavement pore water pressure simulation test device comprises at least two pressure vessels (63), each of which is provided with an asphalt concrete test piece (71); and an open container (62). Adhesive (101) is filled in between the bottom of the asphalt concrete test piece (71) and an open annular portion of the open container (62), and the side wall of the asphalt concrete test piece (71) is coated with the adhesive (101). The side wall of the pressure vessel (63) is provided with a first pressure sensor (52) for measuring the external water pressure of the asphalt concrete piece (71). The side wall of the open container (62) is provided with a second pressure sensor (53) for measuring the water pressure at the bottom of the asphalt concrete piece (71). Each open container (62) communicates through a pipe (83) which passes through the side wall of each pressure vessel (63). In the test method of the device, the test pieces (71) in each pressure vessel (63) are sequentially loaded by using a control flow which meets different wheel load characteristics, which can achieve the directional movement of the pore water, and the dynamic response of water pressure in asphalt concrete pores can be tested under the effect of the dynamically changing external water pressure.

Owner:广州市和富市政工程有限公司

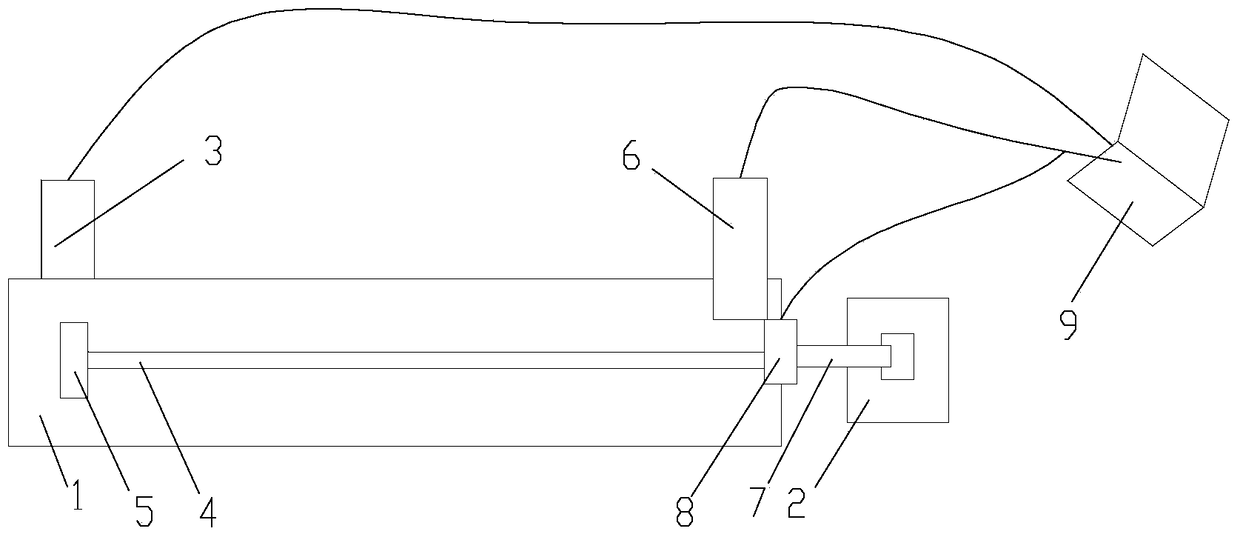

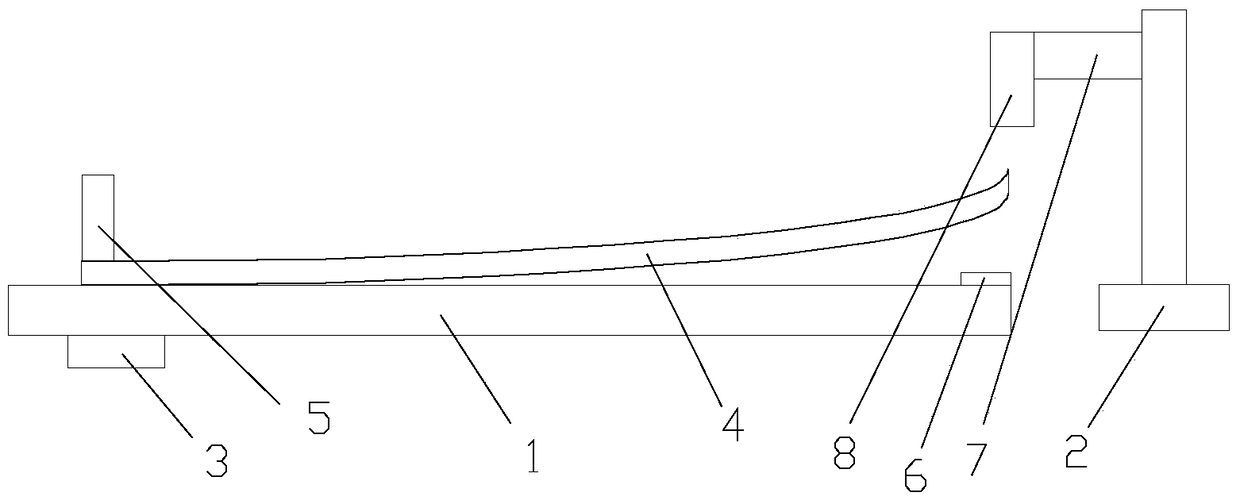

A device and method for testing the bending strength of bamboo slices by ultrasonic motor

ActiveCN105403470BLow heating temperatureShorten pressurization timeMaterial strength using steady bending forcesElectric machineryFlexural strength

The invention discloses an apparatus and method for testing the bending strength of a bamboo chip by using an ultrasonic motor. The apparatus comprises a test platform and the ultrasonic motor, wherein one end of the test platform is provided with an in-place sensor and a press block used for fixing one end of the bamboo chip, the other end of the test platform is provided with a horizon sensor, a mover of the ultrasonic motor is provided with a measuring head, a force transducer is mounted on the measuring head, and the in-place sensor, the horizon sensor and the measuring head are connected with intelligent control equipment. The apparatus and method can rapidly and accurately detect the aligning strength of bamboo chips, are beneficial for combination of bamboo chips with small and similar aligning strength into a bamboo plate, and enable the amount of needed glue to be decreased, heating temperature and pressurization time to be reduced, energy to be saved, cost to be lowered and process refinement to be realized.

Owner:FUJIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com